Preface

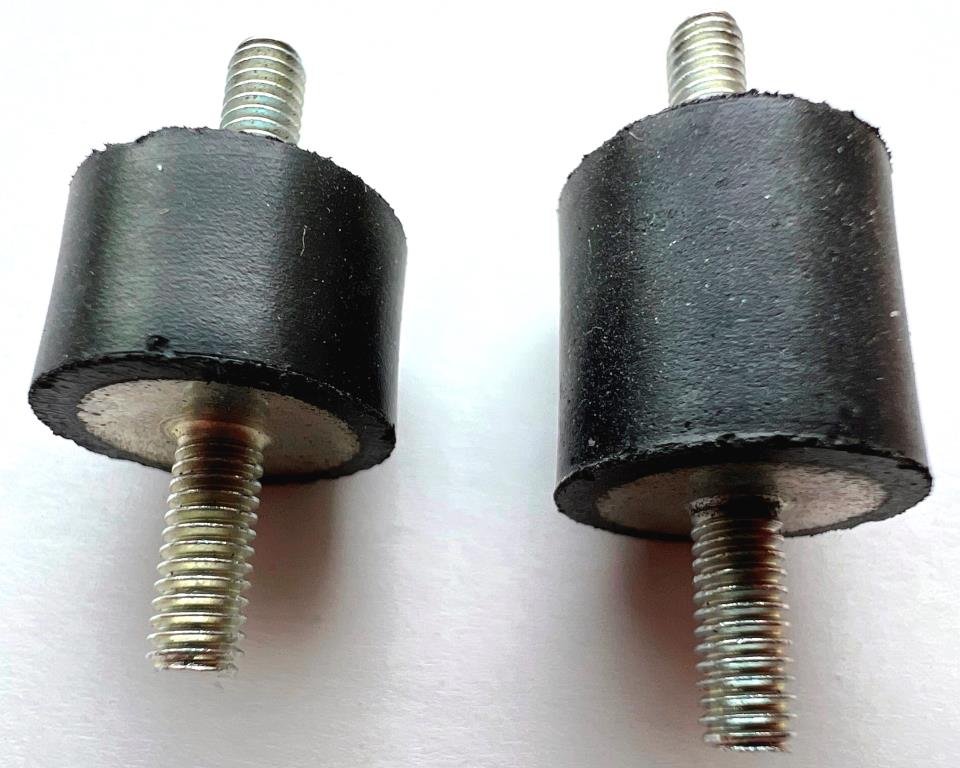

* Initially I experimented with grommets to modify the bias transformer mounting, but the most effective result came from using rubber anti-vibration studs to isolate the vibrations (Fig. 1).

Figure 1. Elesa VD1-1510M4 (left) not used, and Elesa VD1-1515M4 (right) used in this installation.

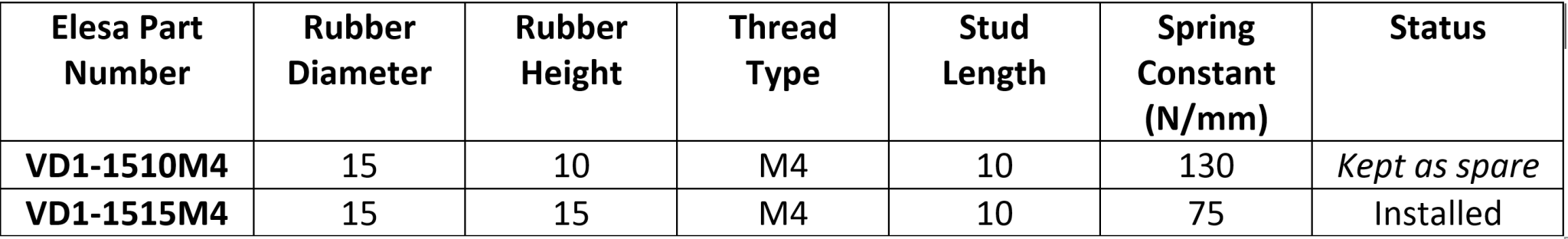

Table 1. Specifications of Elesa Type VD1 Rubber Vibration Dampers - dimensions in mm.

* A full set of specifications for the VD1 series can be obtained from the attached specification sheet. An optional stainless-steel version VD1-SUS is available for wet or corrosive applications but isn't needed here.

Preparation

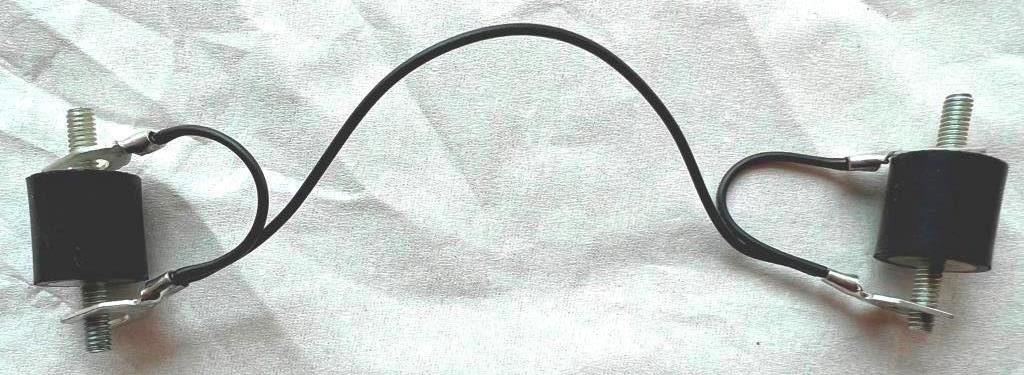

Figure 2. Pre-assembly showing wiring harness for connecting both ends of each VD1-1515M4.

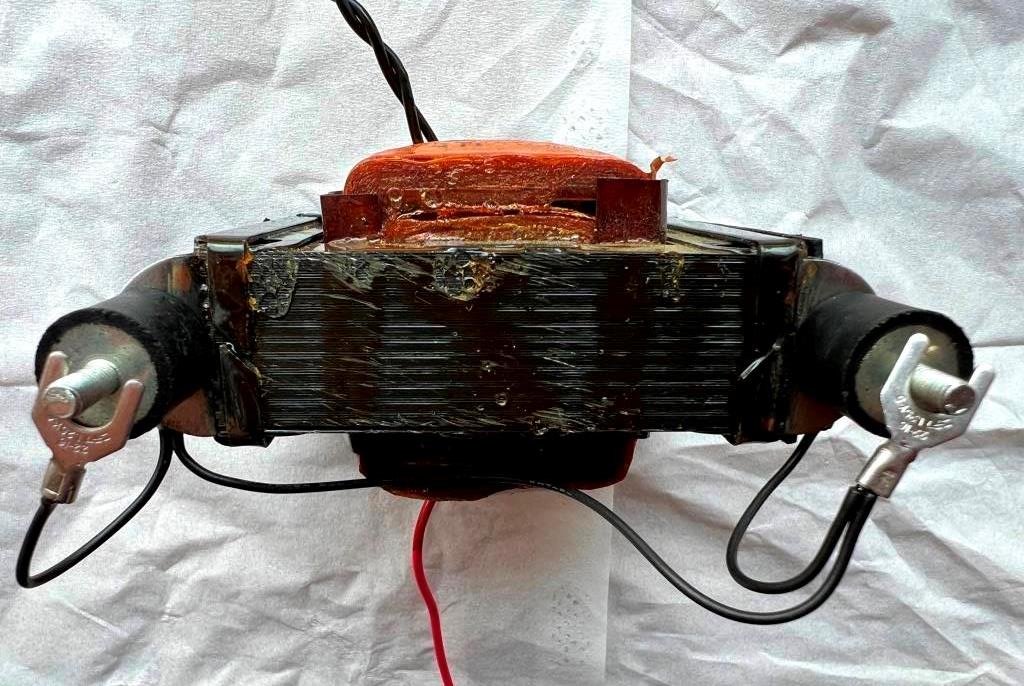

Figure 3. Partial assembly, VD1-1515M4 pair and wiring harness attached to transformer base.

Figure 4. Bias transformer reinstalled with new VD1-1515M4 pair and ground wiring.

* Fortunately, this installation using the VD1-1515M4 pair allowed just enough clearance between the bias transformer housing and the large 50 K ohm resistor (Fig. 4).

Results

- This report is a follow-up to, "Acoustat Magne-Kinetic Interface MK-121-2 - A Successful Restoration" https://www.diyaudio.com/community/...ace-mk-121-2-a-successful-restoration.404764/

- As stated in this restoration report, "Initial Symptoms. When powered up, annoying hum noise coming from both interfaces." This noise issue was addressed in section "Minimization of 50 Hz induced hum noise" accompanied by Figures 19 and 20 in the report, whereby applying synthetic rubber sheeting to the chassis was effective in reducing the hum noise.

- However, I was intrigued by the comment from Mr. AAM from his review of my report where he kindly replied with, "And speaking of the bias transformer, later units had the transformer mounted on rubber grommets, alleviating the "chassis hum" you experienced."

- As these are my only pair of Acoustat electrostatic loudspeakers having purchased them new in 1980, I would never have known about this subsequent change to the transformer mounting. So, thanks to Mr. AAM for sharing this information, it got me thinking!

- While the initial restoration report addressed reducing the hum noise, the purpose of this report is to minimize the noise vibrations at its source.

- Without having information about how the transformer mounting was changed in subsequent production or the parts involved, another purpose of this report is to share with our members an inexpensive solution using commercially available parts.

* Initially I experimented with grommets to modify the bias transformer mounting, but the most effective result came from using rubber anti-vibration studs to isolate the vibrations (Fig. 1).

Figure 1. Elesa VD1-1510M4 (left) not used, and Elesa VD1-1515M4 (right) used in this installation.

- Two vibration dampers are required for each bias transformer, or total 4 for the pair of speakers.

- Of the two series of vibration dampers purchased, VD1-1510M4 of rubber height 10mm and VD1-1515M4 of rubber height 15mm, I decided to first try the VD1-1515M4 as it had the softer spring constant (Table 1). In the event of insufficient clearance between the bias transformer housing and the high-voltage board with the VD1-1515M4, then I would change to the lower profile VD1-1510M4.

- An M4 thread type was chosen as the M4 diameter was close to the diameter of the original mounting hardware, whereas the next size up M6 would require enlarging the chassis holes.

Table 1. Specifications of Elesa Type VD1 Rubber Vibration Dampers - dimensions in mm.

* A full set of specifications for the VD1 series can be obtained from the attached specification sheet. An optional stainless-steel version VD1-SUS is available for wet or corrosive applications but isn't needed here.

Preparation

- Safety. Ensure the AC power cord is disconnected, and the high voltage circuit has been fully discharged.

- A consequence of the rubber damping material is it isolates the earth connection between transformer housing and chassis. Proper grounding is very important, both for safety and to complete the connection to the bias high voltage.

- To re-establish the ground connection a small wiring harness was constructed (Fig. 2).

Figure 2. Pre-assembly showing wiring harness for connecting both ends of each VD1-1515M4.

Figure 3. Partial assembly, VD1-1515M4 pair and wiring harness attached to transformer base.

- The inside surface of the interface's chassis was lightly sanded around the mounting holes to ensure a bare metal contact with the grounding wire lugs.

- Finally, the bias transformer with wiring harness and anti-vibration studs was installed back in the interface using M4 fastening hardware (Fig. 4).

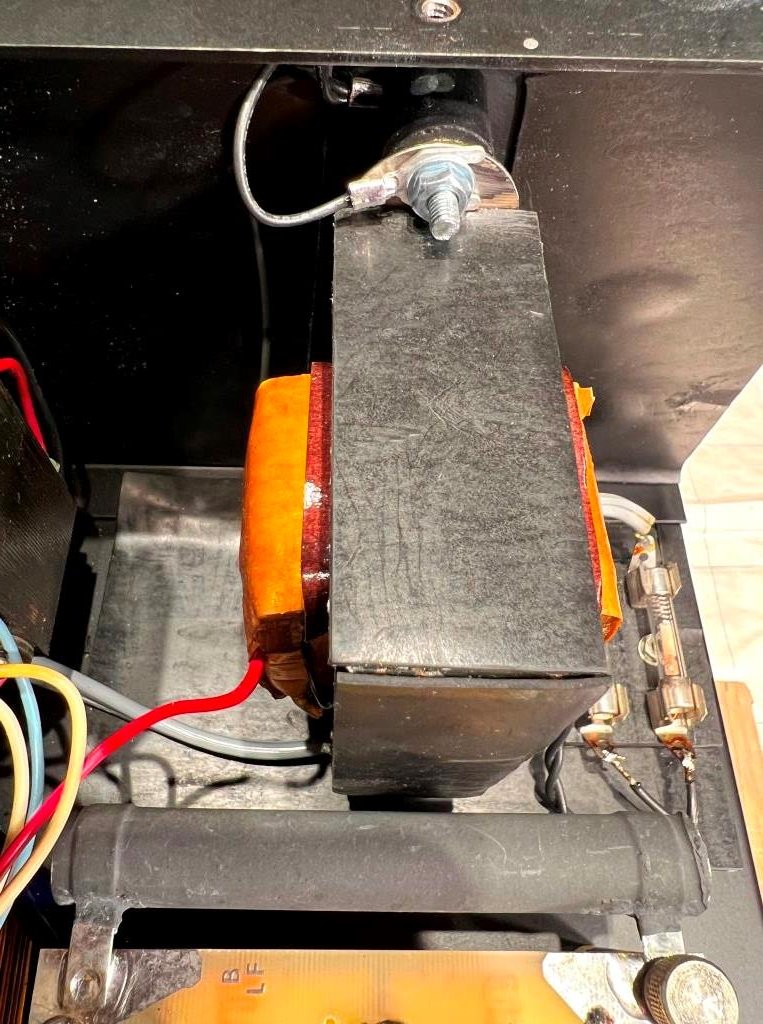

Figure 4. Bias transformer reinstalled with new VD1-1515M4 pair and ground wiring.

* Fortunately, this installation using the VD1-1515M4 pair allowed just enough clearance between the bias transformer housing and the large 50 K ohm resistor (Fig. 4).

Results

- After installing these parts and upon powering up I was pleasantly relieved all transformer hum noise is gone, both interfaces are now dead quiet. Considering the parts cost less than $5 per interface this was a worthwhile modification.

- Previously when placing your hand on the interface chassis you could feel the vibrations, but this is greatly diminished now.

- Regarding the initial approach of attaching synthetic rubber isolation sheets to the chassis, this was left in place as it does no harm.

- Side note, while the reduction in hum noise was clearly apparent, I was not expecting any changes in the audio sound quality. But there is a very subtle improvement with a clearer, more open sound. I don't think I'm imagining things as I have owned these speakers for 44 years and am accustomed to their amazing sound quality, on the other hand I cannot quantify in measurements what I have heard. While it's difficult to say, one theory might be the previous mechanical vibrations throughout the chassis impacted the performance of different components, whereas these chassis vibrations are now considerably diminished.

- Why it took me so long to act on Mr. AAM's comment regarding transformer isolation? To be honest the biggest priority after restoring the interfaces was repairing the multiple broken stator wire joints, documented in "Acoustat Stator Wire Repair: Hints and Lessons Learned" and this effort took over a year to complete before I could address the transformer hum. https://www.diyaudio.com/community/...wire-repair-hints-and-lessons-learned.404881/

- As mentioned, I purchased two series of vibration dampers, VD1-1510M4 of rubber height 10mm which I kept as spare, and VD1-1515M4 of rubber height 15mm which I installed and documented in this report. Should one day the VD1-1515M4 rubber become soft and the bias transformer begins to sag, my plan is to change to the lower profile VD1-1510M4 having a higher spring constant (Table 1).

- While not documented in this report, other makes of similar anti-vibration hardware could give similar results.

- VD1 series, Japanese. https://www.imao.co.jp/files/ja/pdf/vd1.pdf

- VD1 series, English. https://www.imao.com/files/en/pdf/vd1-e.pdf