Hello Nannok

I have bad experience with the graphite pipe. When I drill in to easily crack.

So I must buy carbon fibre tube and aluminium (arrow shaft), titanium I have.

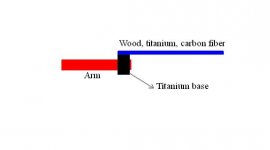

I imagine to do my head shell these way

I will get 6.1mm x 20mm titanium strip, I use that as a base, I can drill that (the arm hole) and screw holes.

For the top where I mount the cartridge I can test wood, carbon fibre, titanium, aluminium etc.

I made a sketch so you can see it.

These how look the Linn head shell on these graphite tube.

Thank you

Greetings Gabor

I have bad experience with the graphite pipe. When I drill in to easily crack.

So I must buy carbon fibre tube and aluminium (arrow shaft), titanium I have.

I imagine to do my head shell these way

I will get 6.1mm x 20mm titanium strip, I use that as a base, I can drill that (the arm hole) and screw holes.

For the top where I mount the cartridge I can test wood, carbon fibre, titanium, aluminium etc.

I made a sketch so you can see it.

These how look the Linn head shell on these graphite tube.

Thank you

Greetings Gabor

Attachments

Hello

Today I got a aluminium arrow shaft. Easton brand 34" long.

Probably will be enough for two arm a longer and a shorter arm.

I have to find out how I can remove that 3 plastic from the end with out scratching or damaging the tube.

I want to insert a brass tube from the suspension until the counter weight end.

Can you let me know how long yours that part of the arm please.

If I build a suspension like yours I want that "needle" which hold the arm to go into the brass tube. Also the counter weight not to damage the aluminium pipe.

The brass is heavy but I have to use something. For that reason I need to know how long brass I cut and that will be glued in to the end of the tube.

I'll buy carbon fibre tube, I do not suffer with the graphite golf club shaft.

To heavy and to make it lighter I drill into. That crack sometimes the tube. Also that dust es itchy, toxic.

I would like to get a light arm, what I get from the golf club still to heavy I think compare to the aluminium tube or the titanium tube.

The titanium must be very well damped

I have to find a piece of plywood to start testing the parts .

These is a interesting suspension but I do not understand how the pivot works with that wire.

That over $1300 DIY tonearm on the Epay..

Greetings Gabor

Today I got a aluminium arrow shaft. Easton brand 34" long.

Probably will be enough for two arm a longer and a shorter arm.

I have to find out how I can remove that 3 plastic from the end with out scratching or damaging the tube.

I want to insert a brass tube from the suspension until the counter weight end.

Can you let me know how long yours that part of the arm please.

If I build a suspension like yours I want that "needle" which hold the arm to go into the brass tube. Also the counter weight not to damage the aluminium pipe.

The brass is heavy but I have to use something. For that reason I need to know how long brass I cut and that will be glued in to the end of the tube.

I'll buy carbon fibre tube, I do not suffer with the graphite golf club shaft.

To heavy and to make it lighter I drill into. That crack sometimes the tube. Also that dust es itchy, toxic.

I would like to get a light arm, what I get from the golf club still to heavy I think compare to the aluminium tube or the titanium tube.

The titanium must be very well damped

I have to find a piece of plywood to start testing the parts .

These is a interesting suspension but I do not understand how the pivot works with that wire.

That over $1300 DIY tonearm on the Epay..

Greetings Gabor

Attachments

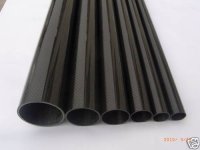

Carbon tube

Hello Nannok

These is the Carbon tube I want to test it also.

UV protected, used for aviation, modeling etc.

I will try two suspension, similar like yours and the ball type. All do the second can have problem shy in bass..

Greetings Gabor

Hello Nannok

These is the Carbon tube I want to test it also.

UV protected, used for aviation, modeling etc.

I will try two suspension, similar like yours and the ball type. All do the second can have problem shy in bass..

Greetings Gabor

Attachments

Hello James and welcome

Glass is very heavy, fragile, damping and mounting not so easy.

These carbon fiber tube graphite loaded.

9X7X1000mm weight 35Gr the 1M

12x13x1000mm weight 31Gr the 1M.

These tubes are way to light. May be need some extra weight because even half is to long and to light.

Glass fibre way heavy easy to crack that is no good.

Real glass is to heavy, probably ring...

I would not waste time to try it out. I didn't saw commercial tonearm made out of glass.

Please lead to the glass tube what you are thinking about.

Greetings Gabor

Glass is very heavy, fragile, damping and mounting not so easy.

These carbon fiber tube graphite loaded.

9X7X1000mm weight 35Gr the 1M

12x13x1000mm weight 31Gr the 1M.

These tubes are way to light. May be need some extra weight because even half is to long and to light.

Glass fibre way heavy easy to crack that is no good.

Real glass is to heavy, probably ring...

I would not waste time to try it out. I didn't saw commercial tonearm made out of glass.

Please lead to the glass tube what you are thinking about.

Greetings Gabor

Hello Nannok

I just ordered the material today from Vancouver for the Schroeder tonearm suspension I will test yours to.

Sometimes the simple can (usually) sound better. I think about the extra weight where I ad the magnet can influence the arm in a negative way.

You already mentioned these when I wanted to ad something to the arm for the pivot.

I agree with you.

I will test both, which one will sound better I try to perfect that.

Also if I have the titanium tubes and golf balls I think I test that to with out lubrication container.

That will give some idea to know if is worth to spend time with that.

Tomorrow I remove the arm, I'll buy some carbon fibre vinyl to cover the holes etc.

These is nice material and cheap solution and look professional on the deck. Of course first I cover the arm hole with a thin metal sheet.

http://www.ebay.ca/itm/320814510437?ssPageName=STRK:MEWAX:IT&_trksid=p3984.m1438.l2649

I ordered 2" brass 1/2" thick for counter weight I don't know if that will be enough for a 12" or longer arm.

Greetings Gabor

I just ordered the material today from Vancouver for the Schroeder tonearm suspension I will test yours to.

Sometimes the simple can (usually) sound better. I think about the extra weight where I ad the magnet can influence the arm in a negative way.

You already mentioned these when I wanted to ad something to the arm for the pivot.

I agree with you.

I will test both, which one will sound better I try to perfect that.

Also if I have the titanium tubes and golf balls I think I test that to with out lubrication container.

That will give some idea to know if is worth to spend time with that.

Tomorrow I remove the arm, I'll buy some carbon fibre vinyl to cover the holes etc.

These is nice material and cheap solution and look professional on the deck. Of course first I cover the arm hole with a thin metal sheet.

http://www.ebay.ca/itm/320814510437?ssPageName=STRK:MEWAX:IT&_trksid=p3984.m1438.l2649

I ordered 2" brass 1/2" thick for counter weight I don't know if that will be enough for a 12" or longer arm.

Greetings Gabor

Hello Nannok

Today I took most of the part of from the Dual 1229, I started to prepare to do some tests with the arms.

I got socked when I realised it has only 10w motor.

My Elac has 15W. Now I got confused.

Even do the Dual has 3.1Kg platter over all the Elac much better turntable.

I taught if it has heavy platter it must have strong motor.

I was wrong.

The Elac has 2.3Kg platter and stronger motor. It has better platter bearing and over all better deck.

I had a big plan to build a strong plinth a great arm or two.

Now I don't know really what to do.

The Elac need speed adjustment very often (probably the motor need some lubrication), the Dual keep the speed but with my little finger I can stop the platter.

I'm really confused.

With a 10W motor worth to build and invest a couple hundred Dollar or better to wait until I get a Elac or Lenco which has also 15W motor?

What would you do?

I do not want to use my Elac as a donor. It is really nice deck great condition, just need a better arm or just rewired that old arm.

I hope you didn't got tired to answer me..

I can put the Dual together in case and sell it..

I have a Denon DP-30L II and that has 15W motor or a old belt drive Pioneer and that has 19W.

How important the motor how strong??

Please let me know your opinion.

Thank you

Greetings Gabor

Today I took most of the part of from the Dual 1229, I started to prepare to do some tests with the arms.

I got socked when I realised it has only 10w motor.

My Elac has 15W. Now I got confused.

Even do the Dual has 3.1Kg platter over all the Elac much better turntable.

I taught if it has heavy platter it must have strong motor.

I was wrong.

The Elac has 2.3Kg platter and stronger motor. It has better platter bearing and over all better deck.

I had a big plan to build a strong plinth a great arm or two.

Now I don't know really what to do.

The Elac need speed adjustment very often (probably the motor need some lubrication), the Dual keep the speed but with my little finger I can stop the platter.

I'm really confused.

With a 10W motor worth to build and invest a couple hundred Dollar or better to wait until I get a Elac or Lenco which has also 15W motor?

What would you do?

I do not want to use my Elac as a donor. It is really nice deck great condition, just need a better arm or just rewired that old arm.

I hope you didn't got tired to answer me..

I can put the Dual together in case and sell it..

I have a Denon DP-30L II and that has 15W motor or a old belt drive Pioneer and that has 19W.

How important the motor how strong??

Please let me know your opinion.

Thank you

Greetings Gabor

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- a thread for "resto-mod" turntables...(administrators/moderators please read)