With spraycans they put down so little material that you can't really sand between coats. 10 coats with cans will be many many cans worth.

With gloss white I would not bother with lacquer as it will be difficult to see and is just extra work and cost for negligible effect.

Your main problem using primer from spraycans is that you are going to struggle to hide all the imperfections, and the MDF will soak up spraycan primer like a sponge. You can get clear MDF sealer from Blackfriar or Rustins which can be brushed or rollered on and carefully flatted back. Then put on your spraycan primer. The primer needs the most coats as you are trying to hide imperfections. You will probably need at least 5 coats with spraycan primer before you can even gently flat back. 10 coats could well be realistic. Try to get your wood as good as possible first, but be careful not to rub back too much as the faces of MDF are basically just paper coating a core.

The colour only needs to get coverage and a bit extra for some flatting back and polishing. 4 coats may be enough if you lay it down nicely. Not easy to do for a novice working outside though.

Basically, if you want a real top finish spraycans is a massive amount of work. If you are thinking to go from a bare speaker to a polished finished one this weekend, well you might have problems. The paint (especially from spraycans) will shrink over time so it's best to leave it to do it's thing before flatting back.

Don't rush the coats (at least 10 mins, more like 15+ in this cold weather) or you will get a solvent reaction and it will all need stripping off.

What wet and dry papers have you got? I'd suggest something like the following.

P120 for the MDF

P240 for first pass on primer

P400 for second pass on primer

P600 for third pass on primer

P1200 for first pass on colour

P2000 for second pass on colour

With gloss white I would not bother with lacquer as it will be difficult to see and is just extra work and cost for negligible effect.

Your main problem using primer from spraycans is that you are going to struggle to hide all the imperfections, and the MDF will soak up spraycan primer like a sponge. You can get clear MDF sealer from Blackfriar or Rustins which can be brushed or rollered on and carefully flatted back. Then put on your spraycan primer. The primer needs the most coats as you are trying to hide imperfections. You will probably need at least 5 coats with spraycan primer before you can even gently flat back. 10 coats could well be realistic. Try to get your wood as good as possible first, but be careful not to rub back too much as the faces of MDF are basically just paper coating a core.

The colour only needs to get coverage and a bit extra for some flatting back and polishing. 4 coats may be enough if you lay it down nicely. Not easy to do for a novice working outside though.

Basically, if you want a real top finish spraycans is a massive amount of work. If you are thinking to go from a bare speaker to a polished finished one this weekend, well you might have problems. The paint (especially from spraycans) will shrink over time so it's best to leave it to do it's thing before flatting back.

Don't rush the coats (at least 10 mins, more like 15+ in this cold weather) or you will get a solvent reaction and it will all need stripping off.

What wet and dry papers have you got? I'd suggest something like the following.

P120 for the MDF

P240 for first pass on primer

P400 for second pass on primer

P600 for third pass on primer

P1200 for first pass on colour

P2000 for second pass on colour

Last edited:

Thanks for the info.

I'm actually working with oak.

I have so far done about 15 coats of primer over the last few weeks, but my surface is still not flat. I should have been more careful flattening the surface before starting my primer. However after putting £75 of primer on, I'm not too sure what to do with it.

I have patches that wont sand flat (with 400).

My intention was to lay the base coat and all the clear coats within a few hours, then leave for a month before doing the finishing.

How would you suggest getting the surface flatter in it's current state?

It is a large surface area, but I cannot afford to strip back again. I just need an idea to flatten the surface on top of the primer.

I'm actually working with oak.

I have so far done about 15 coats of primer over the last few weeks, but my surface is still not flat. I should have been more careful flattening the surface before starting my primer. However after putting £75 of primer on, I'm not too sure what to do with it.

I have patches that wont sand flat (with 400).

My intention was to lay the base coat and all the clear coats within a few hours, then leave for a month before doing the finishing.

How would you suggest getting the surface flatter in it's current state?

It is a large surface area, but I cannot afford to strip back again. I just need an idea to flatten the surface on top of the primer.

Get a cheap black spraycan and dust it over the area. Leave it 30 minutes then start flatting. Black will be left in the low spots. You need a long and solid bottomed block with your abrasive tightly fixed to get your surface flat and I'd go coarser than P400 as it sounds like you have a long way to go yet.

You may well end up taking off most of the primer and even rub through whilst knocking the high spots down, sorry to say, but that's the price you pay for not getting the levelling right in the first place. At least you learnt for next time

To be honest, the less primer thickness you have on the less problems you will have with cracking, shrinking and solvent reactions anyway.

A note on terminology. Basecoat is actually a specific paint that is meant to be clearcoated. What you get in Halfords spraycans is not basecoat and doesn't need to be clearcoated unless its metallic.

You may well end up taking off most of the primer and even rub through whilst knocking the high spots down, sorry to say, but that's the price you pay for not getting the levelling right in the first place. At least you learnt for next time

To be honest, the less primer thickness you have on the less problems you will have with cracking, shrinking and solvent reactions anyway.

A note on terminology. Basecoat is actually a specific paint that is meant to be clearcoated. What you get in Halfords spraycans is not basecoat and doesn't need to be clearcoated unless its metallic.

Last edited:

Thanks again.

I can see the dark patches of primer where it's not going flat.

I guess it's time to bite the bullet and start it again

When it comes to the base and clear coats...do I let the base fully dry before moving on to the clears?

And I'm still not sure if the clears coats should be done in the same session?

When you say 15 mins between coats is that for all 10 of my clear?

Cheers

I can see the dark patches of primer where it's not going flat.

I guess it's time to bite the bullet and start it again

When it comes to the base and clear coats...do I let the base fully dry before moving on to the clears?

And I'm still not sure if the clears coats should be done in the same session?

When you say 15 mins between coats is that for all 10 of my clear?

Cheers

Glad you are accepting that you can't bodge it for a piano finish

Because the gloss white is not intended to be clearcoated, it should be left to dry at least overnight. Then before putting the clear on, the white should be flatted with P600 or P800 to key it for the clear. Don't worry that the keying makes it look dull, the clear will transform it into a gloss.

Every coat from an aerosol regardless of whether it's primer, colour or clear will need 15 minutes. A problem with aerosols is they have such high solvent content that if you rush it the solvent gets trapped and without warning on coat number 9 out of 10 the finish wrinkles up and you are back to square 1.

Because the gloss white is not intended to be clearcoated, it should be left to dry at least overnight. Then before putting the clear on, the white should be flatted with P600 or P800 to key it for the clear. Don't worry that the keying makes it look dull, the clear will transform it into a gloss.

Every coat from an aerosol regardless of whether it's primer, colour or clear will need 15 minutes. A problem with aerosols is they have such high solvent content that if you rush it the solvent gets trapped and without warning on coat number 9 out of 10 the finish wrinkles up and you are back to square 1.

Last edited:

Hi,

I've just joined the forum, this thread is really fantastic, its a shame the original pictures are not available for reference.

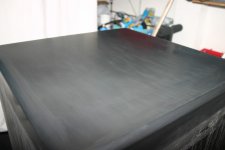

I've tried to follow the process as best as I could being an amateur diyer. I've build a sub box, sealed, primed, wet sanded with 1000, colour coated, wet sanded with 1500. The next stage is to clear coat, I will be using lacquer but I really wanted to validate that what I have so far is kind of expected. I used black gloss spray paint for the colour coat. So after wet sanding it feels very smooth, I've attached some pictures, I'd just like to know if they kind of look as expected, I know its very hard to tell on a computer screen. I just wasn't expecting it to looks so rough

I've just joined the forum, this thread is really fantastic, its a shame the original pictures are not available for reference.

I've tried to follow the process as best as I could being an amateur diyer. I've build a sub box, sealed, primed, wet sanded with 1000, colour coated, wet sanded with 1500. The next stage is to clear coat, I will be using lacquer but I really wanted to validate that what I have so far is kind of expected. I used black gloss spray paint for the colour coat. So after wet sanding it feels very smooth, I've attached some pictures, I'd just like to know if they kind of look as expected, I know its very hard to tell on a computer screen. I just wasn't expecting it to looks so rough

Attachments

As jplesset said you have to be sure your base coat and clear coat are compatible. You are ready to polish when your sanded finish is totally even. It looks to me like your base still shows seams and some orange peel. If your clear builds up thick enough this might not matter but if the clear is thin you will sand through when you try to flatten the clear before polishing it. Don't be discouraged, getting a perfectly flat and glossy black finish is very difficult and time consuming but can be done.

Evan

Evan

Attachments

10 or more coats total. catalyzed. 2 weeks drying before polishing. I use primer tinted to the finish color to get everything flat. Yes, veneered doors and solid drawer fronts.

I made that piece about 7 years ago. I got to see it recently when installing a new bit of cabinets for the customer. Black is still perfect and the door/drawer color came together over time.

Evan

I made that piece about 7 years ago. I got to see it recently when installing a new bit of cabinets for the customer. Black is still perfect and the door/drawer color came together over time.

Evan

Hi Anyone who's reading this...

I'm in the final stages if building a plinth for my turntable - its a simple thing, two layers of plywood stuck together with all the relevant holes and channels.

So, I'm thinking about how to finish it, and I'm leaning towards a nice gloss finish - Probably black, maybe white.

While Im trying to digest this thread i need to think about how to prime it, and presumably how to fill in those little imperfections in the wood.

With regard to the imperfections, would a simple wood filler be okay?. I've noticed in a couple of spots on the edge of the plywood layers an occasional small hole - these are very small, and if I was going to venner it I wouldn't worry about it. But gloss paint will show them up I think.

And primer - I have a lot of BIN Zinsser hanging around. I love this stuff and have worked with it before. Can anyone think of a reason not to use it?

I'm in the final stages if building a plinth for my turntable - its a simple thing, two layers of plywood stuck together with all the relevant holes and channels.

So, I'm thinking about how to finish it, and I'm leaning towards a nice gloss finish - Probably black, maybe white.

While Im trying to digest this thread i need to think about how to prime it, and presumably how to fill in those little imperfections in the wood.

With regard to the imperfections, would a simple wood filler be okay?. I've noticed in a couple of spots on the edge of the plywood layers an occasional small hole - these are very small, and if I was going to venner it I wouldn't worry about it. But gloss paint will show them up I think.

And primer - I have a lot of BIN Zinsser hanging around. I love this stuff and have worked with it before. Can anyone think of a reason not to use it?

Plywood will need a lot of work to get gloss smooth, it has a grain. Zinsser BIN is fine as a primer but has zero build (it's not intended to build).

You are best taking it to a car bodyshop and getting them to lay down some polyester high build primer then sand to smooth and spray colour. If you insist on DIY then you may get away with applying this primer with a roller and a lot of block sanding.

You are best taking it to a car bodyshop and getting them to lay down some polyester high build primer then sand to smooth and spray colour. If you insist on DIY then you may get away with applying this primer with a roller and a lot of block sanding.

Plywood will need a lot of work to get gloss smooth, it has a grain. Zinsser BIN is fine as a primer but has zero build (it's not intended to build).

You are best taking it to a car bodyshop and getting them to lay down some polyester high build primer then sand to smooth and spray colour. If you insist on DIY then you may get away with applying this primer with a roller and a lot of block sanding.

Cool!

I dont know much about polyester high build primer - Is it something that comes in a spray can?

And will it adhere to wood okay?

Last edited:

This is 2015, and I am delighted with Shinobiwan's excellent piece "A 'how to' for High Gloss Finishing".

It is however a bit frustrating - now that I am going professional by releasing my own brand of speakers (konfortiaudio.com) that all images are missing in the original post from 2006; the links to 'village photos' are there, but they are all broken.

I am currently paying some guy to paint my cabinets piano black, and it is a PITA to have consistency from him (too much work on the side), let alone convince him that any orange peel is unacceptable. That is why I want to "do it myself" - ain't that what all of us do?

I am not internet-savvy enough to know why the images were hosted out of diyaudio.com back then, but I am mature and respectful enough to forever thank the people who have kept diyaudio.com up for so long.

It is however a bit frustrating - now that I am going professional by releasing my own brand of speakers (konfortiaudio.com) that all images are missing in the original post from 2006; the links to 'village photos' are there, but they are all broken.

I am currently paying some guy to paint my cabinets piano black, and it is a PITA to have consistency from him (too much work on the side), let alone convince him that any orange peel is unacceptable. That is why I want to "do it myself" - ain't that what all of us do?

I am not internet-savvy enough to know why the images were hosted out of diyaudio.com back then, but I am mature and respectful enough to forever thank the people who have kept diyaudio.com up for so long.

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- A 'how to' for High Gloss Finishing