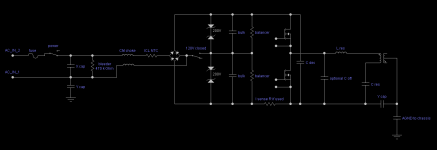

This is as much as the primary power stage can be simplified without safety issues or malfunction.

There are a few equivalent variants ("isomers") obtainable by exchanging parts that are in series, or by moving one part from one mains wire to another (as long as there are no EMI issues by doing so, another standard rule: "the square wave goes first to the inductor").

Recommended distance between mains leads before/at CM filter and across fuse: >=4mm.

Recommended distance between HV/switching/GND nodes at/after diode bridge: >=1mm.

Distance between nodes of primary and secondary sides (including mounting holes): >=6mm.

There are a few equivalent variants ("isomers") obtainable by exchanging parts that are in series, or by moving one part from one mains wire to another (as long as there are no EMI issues by doing so, another standard rule: "the square wave goes first to the inductor").

Recommended distance between mains leads before/at CM filter and across fuse: >=4mm.

Recommended distance between HV/switching/GND nodes at/after diode bridge: >=1mm.

Distance between nodes of primary and secondary sides (including mounting holes): >=6mm.

Attachments

Last edited:

Off-line power supply discussion used to be regulated by forum rules. Off-line power supply production and commercialization used to be regulated by safety agencies. You can argue that South America is SMPS Bronx, but these discussions are being archived and read from many locations around the world.

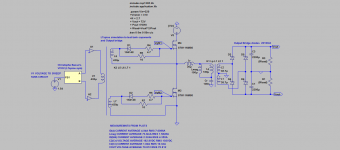

I am checking with Christophe Basso now to see if the LTspice models are valid for this controller.

Would be nice to provide a LTSpice Model for the NCP1396 as well, the one I use for years.

Check FAN7688 and associated app. note AN6104. However "scientific poking"/"carbon copy" method does not work neither in audio world nor in PSU one.

Try to replicate reference design to begin with.

Simulations usually create false impression of simplicity.

Tweaking off the shelf PSU for a different output voltage is not straightforward.

P.S. LLC, having rather low EMI and high efficacy does have quite a few disadvantages, starting with poor transient response to load and/or primary voltage variations. That's said it's mainly used in server power supplies being powered from stable DC bus and operate at near constant load.

Magnetics design alone has to satisfy mutually exclusive requirements of proper coupling, proximity losses, fringe flux etc. etc.

Good luck.

Try to replicate reference design to begin with.

Simulations usually create false impression of simplicity.

Tweaking off the shelf PSU for a different output voltage is not straightforward.

P.S. LLC, having rather low EMI and high efficacy does have quite a few disadvantages, starting with poor transient response to load and/or primary voltage variations. That's said it's mainly used in server power supplies being powered from stable DC bus and operate at near constant load.

Magnetics design alone has to satisfy mutually exclusive requirements of proper coupling, proximity losses, fringe flux etc. etc.

Good luck.

FAN7688 is very good controller with many usefull features but that comes with some complexities in design and by my opinion it is not goot choice for "my first LLC", it is for very experienced designers.

Regarding LLC based on MCU, forget any 8bit MCU and Arduino in general, use dsPIC33, TI Picollo or some ARM based MCU with powerfull PWM features.

Designing MCU based offline SMPS is more challenging tnan analog ones becase you need to completly understand LLC operation and produce that behaviors trough higly optimesed and bugs-free code and in addition you need to understand completely undelaing MCU modules (A/D, timers, PWM etc).

In addition you need to take care about issolation of digital part, how you will interface yor PC and programner/debugger ...

My advice for everyone trying to build first offline LLC is to start with some low voltage input converter, for example 12V or 24V input and covert that to +/-30V, no more than 100W.

Good choice for controller IC can be UCC25600, try, experiment, observe U/I waveforms, learm from that and later start with High Voltage input converters.

Regarding LLC based on MCU, forget any 8bit MCU and Arduino in general, use dsPIC33, TI Picollo or some ARM based MCU with powerfull PWM features.

Designing MCU based offline SMPS is more challenging tnan analog ones becase you need to completly understand LLC operation and produce that behaviors trough higly optimesed and bugs-free code and in addition you need to understand completely undelaing MCU modules (A/D, timers, PWM etc).

In addition you need to take care about issolation of digital part, how you will interface yor PC and programner/debugger ...

My advice for everyone trying to build first offline LLC is to start with some low voltage input converter, for example 12V or 24V input and covert that to +/-30V, no more than 100W.

Good choice for controller IC can be UCC25600, try, experiment, observe U/I waveforms, learm from that and later start with High Voltage input converters.

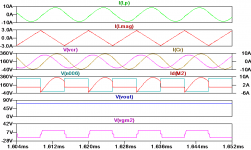

I recommend starting with an unregulated LLC-design operating at a fixed frequency tuned to series resonant frequency of LLC tank. So it does not matter which LLC-controller is at hand. This is the switched mode replacement for toroidal transformer supplies, i.e. output voltage follows main voltage directly with some 100Hz ripple, at quite a low output impedance. I built several of these with output up to 500W. Most heat was produced by secondary rectifiers, so the next step was introducing synchronous rectifiers to reduce heat sink dimensions.

Then you have the choice between a transformer with "integrated magnetics", i.e. loose coupling for sufficient stray inductance, or a separate series choke - making compact transformer design easier.

Then you have the choice between a transformer with "integrated magnetics", i.e. loose coupling for sufficient stray inductance, or a separate series choke - making compact transformer design easier.

Last edited:

If short circuited/overloaded the no protection/feedback series resonant circuit will blow-up. The same will happen in case of improper timing like trying to operate below resonance due to capacitive impedance at the inverter. Moreover resonant frequency does change, depending on load. Self-oscillating thingy which follows the frequency intrinsically is not that easier to play with.I recommend starting with an unregulated LLC-design operating at a fixed frequency tuned to series resonant frequency of LLC tank. ...

@alexberg

Exactly.

That is the reason I recommend to play with low voltage input on "primary" side and power the converter with curren limited source, for example from laptop (brick) adapter or similar.

Use cheap IRFZ44N transistors, IR2110 driver and any LLC controller like IR2153 or UCC25600 and even if that blows up it's not soo bad, at least learn from such mistakes.

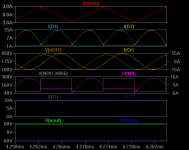

Start with open-loop, change frequency, change L/C tank, observe U/I waveforms and later close the regulation loop.

When that is finished, at least they will get one useful peace of hardware for some other project and that is the base knowledge for "real" HV off-line LLC converter.

Exactly.

That is the reason I recommend to play with low voltage input on "primary" side and power the converter with curren limited source, for example from laptop (brick) adapter or similar.

Use cheap IRFZ44N transistors, IR2110 driver and any LLC controller like IR2153 or UCC25600 and even if that blows up it's not soo bad, at least learn from such mistakes.

Start with open-loop, change frequency, change L/C tank, observe U/I waveforms and later close the regulation loop.

When that is finished, at least they will get one useful peace of hardware for some other project and that is the base knowledge for "real" HV off-line LLC converter.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- 700 - 800W LLC Converter