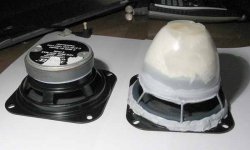

Here are some picks of some experimental mods I talked about over on full range driver forum to some cheap 4 inch PA drivers, the mods include:

1) Tissue paper to outside cone to improve joint to surround

2) PVA g;ue to front and rear of cone

3) Whizzer heavily PVAed

4) Dustcap cutout so as a small section in the centre only radiates

5) Serrating the whizzer

6) 5 felt pads to cone behind whizzer

7) Legs cut out except the one with the contact wires and replaced with wire which is araldited in

8) Lower part of frame surround also cut down to add extra breathing space

9) Edge on lower frame surround has rubber tubing glued to it to direct the air smoothly over the edge

10) Bluetac around edge to smooth flow further

11) Plastic desert cone inverted over magnet to smooth flow behind cone and in reverse direction

12) Plastic cone filled with rubber matt, but will be filled with expanding foam on final drivers

13) Junction between plastic cone and frame filled with bluetac

14) Spider and surround treated to a good dose of virgin olive oil, which seems to free them up nicely and no downsided on previous drivers I tried this on

15) Small rubber half dome applied to centre cap as a type of dome tweeter.

I will include a socond post with the std driver to compare

These things are about 94db efficient and they sound amazing on an open baffle when used with a sub and an active filter to stop frequencies below 50Hz.

Oh and they sound absolutely nothing like the original at all

They extend to about 16khz no worries and I have used a rear firing super tweet fro additional ambience.

Have yet to try them in a double bass box, but should be good as I am using a far less modded version in some at present with very nice results.

1) Tissue paper to outside cone to improve joint to surround

2) PVA g;ue to front and rear of cone

3) Whizzer heavily PVAed

4) Dustcap cutout so as a small section in the centre only radiates

5) Serrating the whizzer

6) 5 felt pads to cone behind whizzer

7) Legs cut out except the one with the contact wires and replaced with wire which is araldited in

8) Lower part of frame surround also cut down to add extra breathing space

9) Edge on lower frame surround has rubber tubing glued to it to direct the air smoothly over the edge

10) Bluetac around edge to smooth flow further

11) Plastic desert cone inverted over magnet to smooth flow behind cone and in reverse direction

12) Plastic cone filled with rubber matt, but will be filled with expanding foam on final drivers

13) Junction between plastic cone and frame filled with bluetac

14) Spider and surround treated to a good dose of virgin olive oil, which seems to free them up nicely and no downsided on previous drivers I tried this on

15) Small rubber half dome applied to centre cap as a type of dome tweeter.

I will include a socond post with the std driver to compare

These things are about 94db efficient and they sound amazing on an open baffle when used with a sub and an active filter to stop frequencies below 50Hz.

Oh and they sound absolutely nothing like the original at all

They extend to about 16khz no worries and I have used a rear firing super tweet fro additional ambience.

Have yet to try them in a double bass box, but should be good as I am using a far less modded version in some at present with very nice results.

Attachments

Hi Poynton

Oh there pretty cheap, $12.50 each in OZ or about $9.50US.

They are on special at the moment for $25.00 a pair but normally they are about $17.00

There from altronics

Heres a link

http://www.altronics.com.au/index.asp?area=item&id=C0626

Oh there pretty cheap, $12.50 each in OZ or about $9.50US.

They are on special at the moment for $25.00 a pair but normally they are about $17.00

There from altronics

Heres a link

http://www.altronics.com.au/index.asp?area=item&id=C0626

Hiya zero one, that's a pretty impressive set of mods. After poking around here I'm starting to become interested in driver mods, but haven't yet stumbled across a good collection of information about it. Searches I do on 'speaker driver mods' seem to cast too wide a net. Is there a good collection of information about this topic out there on the net? If not, perhaps people would be interested in pouring info into this thread?

I've got questions like:

What problems does each of these mods address? What are the sonic charecteristics of the problem and of it's resolution? Some of these I can motivate just by looking, others (tissue paper? dustcap cutout?) not so much. What considerations should lead me to perform a given mod or rule it out? Do these mods change the design parameters of the driver?

could you dish out some specifics of the execution on #7 and #14?

I am interested in a first driver modding project along these lines. Hmmm maybe that pioneer 8"? Or perhaps a friend's cheapo towers where the marketing dept kept coming back with "can we get more drivers in there?" If I can talk him into it... Hmmmm ideas, ideas....

Hmmmm ideas, ideas....

thx!

I've got questions like:

What problems does each of these mods address? What are the sonic charecteristics of the problem and of it's resolution? Some of these I can motivate just by looking, others (tissue paper? dustcap cutout?) not so much. What considerations should lead me to perform a given mod or rule it out? Do these mods change the design parameters of the driver?

could you dish out some specifics of the execution on #7 and #14?

I am interested in a first driver modding project along these lines. Hmmm maybe that pioneer 8"? Or perhaps a friend's cheapo towers where the marketing dept kept coming back with "can we get more drivers in there?" If I can talk him into it...

Hmmmm ideas, ideas....

Hmmmm ideas, ideas....thx!

Hi Adam

Your right about sites on speaker mods, not so easy and I have yet to find one definitve source, and of course you find many conflicting ideas

Most mods I have made in my audio gear have been "gut feeling" derived, and many have been failures, I do a lot of tweaking so I guess thats to be expected. I go only on what my ears tell me.

With these drivers most of the mods are driven from past experiments.

All mods will change the parameters of the driver, but I don't get hung up on that all I'm interested in is the final sound which I derive from lots of fiddling, but for those who want to use speaker box design programs it would be a bit messy I guess.

Here are a few of my thoughts, but don't take it as gospel.

The tissue paper is used to strenghten the link between the cone and the surround in a sort of staggered fashion, there are three layers with the each having a different width, I feel this spreads the stresses at the interface better and improves bass reproduction. In my first experiment this was very pronounced so well worth while.

Of course the tissue paper does add a little weight along with the glue, but as these are PA drivers that tend to be quite forward in the mids this actually helps for a smoother result in my case anyway.

The removal of the legs does two things, cuts down HF relfection through the back of the cone and allows I feel for better and more balanced rearward airflow that I feel substantially improves the lower bass. The lack of HF relfection seems to clean up the mid/highs a bit

The use of round legs I feel gives a much smoother less disturbed air flow in both directions which should allow the cone to respond more accurately to any input, ideally I guess the legs should be sort of egg shaped in cross section but I won't go there.

The rubber tubing over the cutdown edge does much the same thing, when I looked at the frame above the rear of the surround area I felt it must cause some problems with smooth airflow as the frame lips on pressed frame drivers curve inwards with a sharp internal lip and airflow I feel gets directed into the dead area under the lip and would cause interactions with the air moving directly above the surround itself, which on 4 inch drivers is a pretty substantial proportion of the whole amount of air being moved in total by the rearward movement of the cone. Once again a gut feeling but the sound is good.

The treatment of the spider and surround with virgin olive oil is intended to add a little more flexibility, probably a does the same thing as breaking the driver in. only pretty much instantly. Anyway the fisrt time I tried this I did a back to back test (with ears) one speaker virgined and one not, the difference was pronounced, basically the sound was smoother all round.

I brush on three very light coats with an artist brush, on the faom surrounds they soak right in no problems, the spider needs to be treated lightly.

Now the dustcaps mods....

First up in std form these drivers are pretty squaky, so I tried phase plugs, this smoothed the sound massively but I also found the highs were now pretty reserved. The thing with these drivers is the coil former is actually a cardboard tube, and the dust cap adds a lot of strength to the top end of that tube, unfortunately I feel the hard dust cap also interacts with the whizzer to produce phase problems and harsh treble in some cases.

My feeling was if I could maintein the stength and remove the interaction I would get a better result, hence the cutout design, it works really well and comprared to the phase plugged drivers the difference is huge, the phase plugged ones really need a super tweeter for best results, this version sounds pretty much as good HF wise as the tweeter augmented version but with better upper mids.

I think the serrations on the edge of the whizzer also help a bit but I didn't get to do any tests with just this mod alone in place.

I think cutting out the contre cap this way also removes a little issue in that with these drivers the centre cap pretty much seals the area inside the former, this means there is air that has to be compressed with every stroke of the cone, I guess it adds damping but I also think it reduces the abiltiy of the driver to respond to electrical inputs as quickly as possible and possiblly also reduces bass response.

Overall I think modding drivers can be very beneficial, but I think using cheap drivers is the way to go at first anyway, less to loose.

If you have 3 drivers you can mod one as a sacrificial unit and compare it at each step along the way to an unmodded driver, when you get the result you want then mod the other 2 for final use.

Well I hope this helps and happy modding.

Your right about sites on speaker mods, not so easy and I have yet to find one definitve source, and of course you find many conflicting ideas

Most mods I have made in my audio gear have been "gut feeling" derived, and many have been failures, I do a lot of tweaking so I guess thats to be expected. I go only on what my ears tell me.

With these drivers most of the mods are driven from past experiments.

All mods will change the parameters of the driver, but I don't get hung up on that all I'm interested in is the final sound which I derive from lots of fiddling, but for those who want to use speaker box design programs it would be a bit messy I guess.

Here are a few of my thoughts, but don't take it as gospel.

The tissue paper is used to strenghten the link between the cone and the surround in a sort of staggered fashion, there are three layers with the each having a different width, I feel this spreads the stresses at the interface better and improves bass reproduction. In my first experiment this was very pronounced so well worth while.

Of course the tissue paper does add a little weight along with the glue, but as these are PA drivers that tend to be quite forward in the mids this actually helps for a smoother result in my case anyway.

The removal of the legs does two things, cuts down HF relfection through the back of the cone and allows I feel for better and more balanced rearward airflow that I feel substantially improves the lower bass. The lack of HF relfection seems to clean up the mid/highs a bit

The use of round legs I feel gives a much smoother less disturbed air flow in both directions which should allow the cone to respond more accurately to any input, ideally I guess the legs should be sort of egg shaped in cross section but I won't go there.

The rubber tubing over the cutdown edge does much the same thing, when I looked at the frame above the rear of the surround area I felt it must cause some problems with smooth airflow as the frame lips on pressed frame drivers curve inwards with a sharp internal lip and airflow I feel gets directed into the dead area under the lip and would cause interactions with the air moving directly above the surround itself, which on 4 inch drivers is a pretty substantial proportion of the whole amount of air being moved in total by the rearward movement of the cone. Once again a gut feeling but the sound is good.

The treatment of the spider and surround with virgin olive oil is intended to add a little more flexibility, probably a does the same thing as breaking the driver in. only pretty much instantly. Anyway the fisrt time I tried this I did a back to back test (with ears) one speaker virgined and one not, the difference was pronounced, basically the sound was smoother all round.

I brush on three very light coats with an artist brush, on the faom surrounds they soak right in no problems, the spider needs to be treated lightly.

Now the dustcaps mods....

First up in std form these drivers are pretty squaky, so I tried phase plugs, this smoothed the sound massively but I also found the highs were now pretty reserved. The thing with these drivers is the coil former is actually a cardboard tube, and the dust cap adds a lot of strength to the top end of that tube, unfortunately I feel the hard dust cap also interacts with the whizzer to produce phase problems and harsh treble in some cases.

My feeling was if I could maintein the stength and remove the interaction I would get a better result, hence the cutout design, it works really well and comprared to the phase plugged drivers the difference is huge, the phase plugged ones really need a super tweeter for best results, this version sounds pretty much as good HF wise as the tweeter augmented version but with better upper mids.

I think the serrations on the edge of the whizzer also help a bit but I didn't get to do any tests with just this mod alone in place.

I think cutting out the contre cap this way also removes a little issue in that with these drivers the centre cap pretty much seals the area inside the former, this means there is air that has to be compressed with every stroke of the cone, I guess it adds damping but I also think it reduces the abiltiy of the driver to respond to electrical inputs as quickly as possible and possiblly also reduces bass response.

Overall I think modding drivers can be very beneficial, but I think using cheap drivers is the way to go at first anyway, less to loose.

If you have 3 drivers you can mod one as a sacrificial unit and compare it at each step along the way to an unmodded driver, when you get the result you want then mod the other 2 for final use.

Well I hope this helps and happy modding.

As far as I know food oil hardens as time goes by - on surround at least use silicone oil

Looks like a nice driver - I would like to try a very thin coating with polyurethane glue (foam), much easier and very effective

Chassis, I would just strengthen it with small pieces of wood and pack some felt around it

But ofcourse you could go radical, and build a new chassis of wood - thats what I am doing, with another selfmade driver

Looks like a nice driver - I would like to try a very thin coating with polyurethane glue (foam), much easier and very effective

Chassis, I would just strengthen it with small pieces of wood and pack some felt around it

But ofcourse you could go radical, and build a new chassis of wood - thats what I am doing, with another selfmade driver

I have a page on 2 of the mods i continue to use over 7 over again....

http://t-linespeakers.org/design/tweeks.html

dave

http://t-linespeakers.org/design/tweeks.html

dave

Air drying oils..

olive oil is organic and will over time polymerize (when exposed to oxygen) so while it works it will not last as a softening agent. Using a silicon fluid would be better. Reinforcement of the former to cone joint is a good idea and will most likely be more effective than soft damping which while effective will add a lot of extra mass to drive. The more efficiency you can preserve the better I think. You might try a shorted turn around the outside edge of the magnet disk. I have used both solid copper wraps as well as copper foil soldered together for this. While this is a long way from the voice coil it is better than a kick in the pants and costs next to nothing. Any help to squeezr a little extra bandwidth is ok by me even if it is only a db or two.

olive oil is organic and will over time polymerize (when exposed to oxygen) so while it works it will not last as a softening agent. Using a silicon fluid would be better. Reinforcement of the former to cone joint is a good idea and will most likely be more effective than soft damping which while effective will add a lot of extra mass to drive. The more efficiency you can preserve the better I think. You might try a shorted turn around the outside edge of the magnet disk. I have used both solid copper wraps as well as copper foil soldered together for this. While this is a long way from the voice coil it is better than a kick in the pants and costs next to nothing. Any help to squeezr a little extra bandwidth is ok by me even if it is only a db or two.

PS....

try shorting the basket to the negative speaker terminal. You need to check to see if the basket makes electrical connection to the top plate so if it does not then make a physical connection to the top plate that you can solder a wire to then connect the other end of the wire to the negative speaker terminal. This is a nice little mod all on its own. Please don't ask me to explain how/why it works it just does. Give it a listen for yourself.

try shorting the basket to the negative speaker terminal. You need to check to see if the basket makes electrical connection to the top plate so if it does not then make a physical connection to the top plate that you can solder a wire to then connect the other end of the wire to the negative speaker terminal. This is a nice little mod all on its own. Please don't ask me to explain how/why it works it just does. Give it a listen for yourself.

Hi moray james

Thanks for the ideas, I will certainly try them, I have wondered about the olive oil, up till now I have had no problem at all, one pair of drivers trated several months ago but I'm sure the silicon fluid would be better.

The coil to cone junction is an area I have considered and even tried reninforcing on previous drivers with phase plugs, basically i painted PVA around the inside of the junction and it did make an improvement, but you have made me look a little further now and I have found on these drivers that if I push the whizzer in I could get a brush with some PVA or perhaps araldite into the junction on the outside of the former.

The shorted turn sounds interesting, I assume you mean a ring of copper that surrounds the perimeter of the magnet that is earthed to the frame?

On another pair of drivers I tried the wire to the neg terminal and I felt it worked but I must admit I forgot to do it here, thanks for that, I think I might of read of it in one of your posts at some time.

Another Idea I had for stiffening the main cone which I think came out of planet10s posts at some time was to cut say five slits in the cone in a spoke like fashion but all running in the same direction then fill the slit with neat PVA welds.

Overall I guess we need to keep the mass as low as possible but then again the increased stiffness and lowered pumping losses should help redress some of the issues with added weight.

Many Thanks

zero one

Thanks for the ideas, I will certainly try them, I have wondered about the olive oil, up till now I have had no problem at all, one pair of drivers trated several months ago but I'm sure the silicon fluid would be better.

The coil to cone junction is an area I have considered and even tried reninforcing on previous drivers with phase plugs, basically i painted PVA around the inside of the junction and it did make an improvement, but you have made me look a little further now and I have found on these drivers that if I push the whizzer in I could get a brush with some PVA or perhaps araldite into the junction on the outside of the former.

The shorted turn sounds interesting, I assume you mean a ring of copper that surrounds the perimeter of the magnet that is earthed to the frame?

On another pair of drivers I tried the wire to the neg terminal and I felt it worked but I must admit I forgot to do it here, thanks for that, I think I might of read of it in one of your posts at some time.

Another Idea I had for stiffening the main cone which I think came out of planet10s posts at some time was to cut say five slits in the cone in a spoke like fashion but all running in the same direction then fill the slit with neat PVA welds.

Overall I guess we need to keep the mass as low as possible but then again the increased stiffness and lowered pumping losses should help redress some of the issues with added weight.

Many Thanks

zero one

Guys,

A little high resolution documentation of performance changes would be nice. I know that some would rather be lucky than good, but there are positives to being good.

It is easy to change the performance of a transducer. It is not easy to improve the performance. With proper documentation, you would at least know you are heading in the right direction.

Without documentation you get into a well documented area of experimenter bias. Subjective testimony is not considered reliable.

Maybe better to save your money and purchase a better performing transducer in stock condition. Then you could play with optimizing performance in an enclosure or room.

Best,

Mark

A little high resolution documentation of performance changes would be nice. I know that some would rather be lucky than good, but there are positives to being good.

It is easy to change the performance of a transducer. It is not easy to improve the performance. With proper documentation, you would at least know you are heading in the right direction.

Without documentation you get into a well documented area of experimenter bias. Subjective testimony is not considered reliable.

Maybe better to save your money and purchase a better performing transducer in stock condition. Then you could play with optimizing performance in an enclosure or room.

Best,

Mark

planet10 said:

Hi Dave,

Is there a reason you don't add duct seal to the leg of the frame for a small driver like the 40-1197 or FE127E? I applied ductseal to the legs on the Radio Shack 40-1197 but I never made a comparison to the a driver without ductseal.

Another idea would be to use something rigid like epoxy to fill the gap between the motor and frame.

On some stamped frame drivers where the leg is rather wide, like the Radio Shack 40-1271, I found that using ductseal on the inside of the legs helped reduce reflections back through the cone.

Felt on the back of driver with a large magnet seems like a good idea too: http://www.humblehomemadehifi.com/Solo206.html

edit=typo

<<Hi Dave,

Is there a reason you don't add duct seal to the leg of the frame for a small driver like the 40-1197 or FE127E? I applied ductseal to the legs on the Radio Shack 40-1197 but I never made a comparison to the a driver without ductseal.

Another idea would be to use something rigid like epoxy to fill the gap between the motor and frame.

On some stamped frame drivers where the leg is rather wide, like the Radio Shack 40-1271, I found that using ductseal on the inside of the legs helped reduce reflections back through the cone.

Felt on the back of driver with a large magnet seems like a good idea too: http://www.humblehomemadehifi.com/Solo206.html>>

Hi,

I don't presume to speak for Dave, however we've done all of the above to my "HiTweek Black Box Speaker" which uses a Radio Schack 40-1197 blue box driver. I've mentioned it so many times that I'm afraid that most here are getting a little tired of hearing about it.

To wit: Felt was glued to the inside of the legs with Aleene's Tacky Glue. Then the junction between the magnet and frame was epoxied to add strength followed (originally) with oil-based modelling clay to the legs and up to the magnet. This was replaced later with Dave's Duct Seal. The entire Magnet structure was then covered with a "Felt Hat" that was carefully cut to completely wrap around the sides of the magnet. Glued with a fair amount of Aleene's, the sides were held in place with an Audiophile approved rubber band, which has been left in place all these years. I don't know when TonyG first tried the felt, and there may have been others in the past, but at the time I hadn't seen anyone else doing this. Dave subsequently tried it out on a 103/1197 driver and measured a slight improvement, so at least we know it's an improvement. That was the state of the driver when I entered it in "The Puget Sound! DIY Speaker Contest" about 2 1/2 years ago. In the Bass Reflex box I designed for myself, it was one of the top 3 in the contest for flat FR, as measured by Dan Wiggins of Adire Audio using Praxis. In room, it measured 2.5 dB from 65Hz to 15kHz.

Later that year I was up in Canada for Al Wooley's RAW Fest where Dave and I decided to go the rest of the way. Dave (himself) installed the phase plugs and applied a couple coats of puzzle coat. After getting home I set up the speakers for an extended evaluation session. I was prepared to listen intently for "any" subtle changes, but it was so pronounced that, as I've mentioned before, my non-audiophile wife (Betty Boombox) mentioned that they sounded a lot better. I hadn't told her about any changes, but she picked up on it without solicitation. I had thought they sounded pretty good before (and they did!) but the phase plugs and puzzle coat really made them sound even better. I entered them in the recent "Puget Sound! contest this last summer and they placed 10th overall. Not bad for a $27.00/pair set of speakers. They even beat a pair of ScanSpeak TMM floor standers, in which the builder had spent $1300.00 USD on drivers and Crossover componets (cabinets aren't counted in overall cost).

I think that all this will serve to illustrate that Dapper Dave of Planet 10 (AKA: "The Living God of Garage Sales") hasn't neglected the humble 1197 driver.

Best Regards,

TerryO

Is there a reason you don't add duct seal to the leg of the frame for a small driver like the 40-1197 or FE127E? I applied ductseal to the legs on the Radio Shack 40-1197 but I never made a comparison to the a driver without ductseal.

Another idea would be to use something rigid like epoxy to fill the gap between the motor and frame.

On some stamped frame drivers where the leg is rather wide, like the Radio Shack 40-1271, I found that using ductseal on the inside of the legs helped reduce reflections back through the cone.

Felt on the back of driver with a large magnet seems like a good idea too: http://www.humblehomemadehifi.com/Solo206.html>>

Hi,

I don't presume to speak for Dave, however we've done all of the above to my "HiTweek Black Box Speaker" which uses a Radio Schack 40-1197 blue box driver. I've mentioned it so many times that I'm afraid that most here are getting a little tired of hearing about it.

To wit: Felt was glued to the inside of the legs with Aleene's Tacky Glue. Then the junction between the magnet and frame was epoxied to add strength followed (originally) with oil-based modelling clay to the legs and up to the magnet. This was replaced later with Dave's Duct Seal. The entire Magnet structure was then covered with a "Felt Hat" that was carefully cut to completely wrap around the sides of the magnet. Glued with a fair amount of Aleene's, the sides were held in place with an Audiophile approved rubber band, which has been left in place all these years. I don't know when TonyG first tried the felt, and there may have been others in the past, but at the time I hadn't seen anyone else doing this. Dave subsequently tried it out on a 103/1197 driver and measured a slight improvement, so at least we know it's an improvement. That was the state of the driver when I entered it in "The Puget Sound! DIY Speaker Contest" about 2 1/2 years ago. In the Bass Reflex box I designed for myself, it was one of the top 3 in the contest for flat FR, as measured by Dan Wiggins of Adire Audio using Praxis. In room, it measured 2.5 dB from 65Hz to 15kHz.

Later that year I was up in Canada for Al Wooley's RAW Fest where Dave and I decided to go the rest of the way. Dave (himself) installed the phase plugs and applied a couple coats of puzzle coat. After getting home I set up the speakers for an extended evaluation session. I was prepared to listen intently for "any" subtle changes, but it was so pronounced that, as I've mentioned before, my non-audiophile wife (Betty Boombox) mentioned that they sounded a lot better. I hadn't told her about any changes, but she picked up on it without solicitation. I had thought they sounded pretty good before (and they did!) but the phase plugs and puzzle coat really made them sound even better. I entered them in the recent "Puget Sound! contest this last summer and they placed 10th overall. Not bad for a $27.00/pair set of speakers. They even beat a pair of ScanSpeak TMM floor standers, in which the builder had spent $1300.00 USD on drivers and Crossover componets (cabinets aren't counted in overall cost).

I think that all this will serve to illustrate that Dapper Dave of Planet 10 (AKA: "The Living God of Garage Sales") hasn't neglected the humble 1197 driver.

Best Regards,

TerryO

Re: Air drying oils..

Can you give us more detail wrt that Moray... i can find some copper around here.

dave

moray james said:ou might try a shorted turn around the outside edge of the magnet disk. I have used both solid copper wraps as well as copper foil soldered together for this. While this is a long way from the voice coil it is better than a kick in the pants and costs next to nothing. Any help to squeezr a little extra bandwidth is ok by me even if it is only a db or two.

Can you give us more detail wrt that Moray... i can find some copper around here.

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- 4 inchers modded within an inch of their lives