Some progress on cabinets finally...

Been distracted by other things around the house and planning for my daughter's wedding next month. But finally got the wood parts assembled and some poly coating applied. Next is to put some drivers on the waveguides and take some measurements so I can work on a crossover.

Been distracted by other things around the house and planning for my daughter's wedding next month. But finally got the wood parts assembled and some poly coating applied. Next is to put some drivers on the waveguides and take some measurements so I can work on a crossover.

One of the crazy things about Synergy horns is that it's hard to appreciate how SMALL they are. Note that Bill's cabinet is just 2.5' tall.

Even the Danley Jerichos will fit into the bed of a pickup truck. Try doing THAT with a line array!

And as always, great work Bill, you legitimately make some of the greatest speakers I've ever heard.

Even the Danley Jerichos will fit into the bed of a pickup truck. Try doing THAT with a line array!

And as always, great work Bill, you legitimately make some of the greatest speakers I've ever heard.

One of the crazy things about Synergy horns is that it's hard to appreciate how SMALL they are. Note that Bill's cabinet is just 2.5' tall.

That's a great point, especially considering that they're not very deep either. I suspect they will be much easier to 'blend' into the decor of many living rooms.

That's a great point, especially considering that they're not very deep either. I suspect they will be much easier to 'blend' into the decor of many living rooms.

Unfortunately, that's the tricky part.

Here's an SH50 and a Gedlee Summa in the living room of my old house. Though the lack of a woofer makes the height of the cabinet much smaller, the narrow angle of the horn makes the cabinet quite deep.

The obvious solution is to narrow the angle of the horn. But if you do that, you lose output in the range from 750hz to 1500hz. Basically the narrow angle of the horn 'brings up' the output of the compression driver, since it's radiating into a narrower angle.

I think this is largely the reason that only the Jericho horns have a wide angle on the waveguide. You have to tackle that problem, and there's only a few solutions:

1) If you must have a wide angle, use a coaxial at the apex of the horn

2) If you must have a wide angle, use something to combine the output of multiple compression drivers. A layered combiner like in the Jerichos, or a Paraline like VTC uses

3) Or use a asymmetrical horn, like the SH64

Are you going to cover the front with grill cloth, or leave them exposed?

Thanks. There will be a grill. There are wood pieces that fit around that recessed/shaped area, and the grill cloth will be stretched over those pieces. The wood pieces have a cutout that the waveguide sticks out to almost the surface near the grill cloth. That way, the mouth of the horn doesn't have discontinuities until the top edge of the box or until the sides of the box that are behind the angled edges. Trying to minimize edge diffraction without making the cabinet ugly.

Thanks Patrick/John. There are a lot of us pushing this Unity/Synergy/Coentrant horn thing. As it is, about the only way to get these kinds of things is to build them (or put up with the big Danley pro horn boxes in the living room). I've yet to run into anyone who has heard them (mine or by others) that didn't like the sound.And as always, great work Bill, you legitimately make some of the greatest speakers I've ever heard.

--

If you do the math (Keele's math, that is, from his "What's so sacred about exponential horns" paper), a wider angle horn will have a lower control frequency for a given mouth size. A side benefit is that it will also be the shortest horn for both that mouth size and for that control frequency, both of which can work well with domestic installation of Synergy horn. Domestic Synergies are an untapped market for Danley, and a gem still amazingly undiscovered by the commercial-product obsessed "Hi End" audio crowd.

I personally think wide (like 90 degree) horns sound better too, and shorter horns seem to resist any tendency to "honk" (not that many conical horns do that anyway).

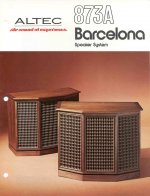

I love the "classic shape" of your cabinets. They do remind me of the Altec Barcelona's my next door neighbor had for years... (might have mentioned it before  )

)

He eventually replaced them with a pair of Kef's. I preferred the old speakers. Both in sound and looks.

Yours will probably sound even better, new technology within a classic shape.

He eventually replaced them with a pair of Kef's. I preferred the old speakers. Both in sound and looks.

Yours will probably sound even better, new technology within a classic shape.

Attachments

A bit off topic from the thread title but hopefully still of interest to the OP.

Has anyone looked carefully at the measurements in the link?

They appear to be contaminated by floor bounce despite the "acoustic foam" placed there.

Still some data of interest, my main concern is that the problem doesn't seem to have been even noticed.

I could be mistaken, of course, any comments from the test mavens?

Best wishes

David

I recall conversations between Earl and others... they show up in...http://mariobon.com/Articoli_storici/Horns_measurements_ETF2010d.pdf

...One issue is that HOMs would be very hard to separate from very early internal reflections...

Has anyone looked carefully at the measurements in the link?

They appear to be contaminated by floor bounce despite the "acoustic foam" placed there.

Still some data of interest, my main concern is that the problem doesn't seem to have been even noticed.

I could be mistaken, of course, any comments from the test mavens?

Best wishes

David

Horns and grilles mounted

Haven't gotten to measurements of anything yet. The grilles took some time figuring out a way to stretch the screen and keep it attached to the grille frame. Probably won't have time to do much till next month.

But they're coming along, however slowly!

Haven't gotten to measurements of anything yet. The grilles took some time figuring out a way to stretch the screen and keep it attached to the grille frame. Probably won't have time to do much till next month.

But they're coming along, however slowly!

The woofers wouldn't likely fit onto the horn, but you could do the same setup as was done on the SmallSyns (woofers partially behind and exiting just below the horn) probably. Assuming the 1" throat version of SEOS-18.

There would be a lot of modifying of the SEOS, though. Midranges (and woofers if they'd fit) need a flat surface to mount to, and you'd probably have some trial and error adjusting the midrange holes.

There would be a lot of modifying of the SEOS, though. Midranges (and woofers if they'd fit) need a flat surface to mount to, and you'd probably have some trial and error adjusting the midrange holes.

Last edited:

Thanks Bill.

I spent the morning with my 1" throat SEOS-18 and some rough midrange driver "placeholders" cut out of cardboard. I also have a pair of plastic SEOS-15s which I have earmarked for a probable small syns build. As you can imagine, the biggest disadvantage of reworking the 18 vs the 15 is the added hazards of drilling through fiberglass vs plastic. And you're correct, the 18 doesn't really have the depth of your printed waveguide that allows the room for a pair of woofers behind the horn as well. Stepping up to to a SEOS-24 would probably allow this but at the penalty of a 1.4" throat diameter, and a 1.4" to 1" adapter would just increase the center-to-center distance between the HF and the mids.

So congrats on the fine looking horn, Bill! Not only does it meet the criteria many other horns cannot but it looks great as well. I'm going to follow this thread with interest as I look forward to your impressions vs the small syns.

I spent the morning with my 1" throat SEOS-18 and some rough midrange driver "placeholders" cut out of cardboard. I also have a pair of plastic SEOS-15s which I have earmarked for a probable small syns build. As you can imagine, the biggest disadvantage of reworking the 18 vs the 15 is the added hazards of drilling through fiberglass vs plastic. And you're correct, the 18 doesn't really have the depth of your printed waveguide that allows the room for a pair of woofers behind the horn as well. Stepping up to to a SEOS-24 would probably allow this but at the penalty of a 1.4" throat diameter, and a 1.4" to 1" adapter would just increase the center-to-center distance between the HF and the mids.

So congrats on the fine looking horn, Bill! Not only does it meet the criteria many other horns cannot but it looks great as well. I'm going to follow this thread with interest as I look forward to your impressions vs the small syns.

Thanks Brinkman,

After (if?) I get this working well, I'll probably post a link for the waveguide's STL file. Then it would be possible to send the file to any of about a thousand "3D hub"s to get it printed by them. But I want to make sure there aren't any major "gotchas" first.

I wouldn't cut holes in the SEOs18, it wouldn't be all that much better than the SEOS15, and the holes and mounts are already worked out for that one.

After (if?) I get this working well, I'll probably post a link for the waveguide's STL file. Then it would be possible to send the file to any of about a thousand "3D hub"s to get it printed by them. But I want to make sure there aren't any major "gotchas" first.

I wouldn't cut holes in the SEOs18, it wouldn't be all that much better than the SEOS15, and the holes and mounts are already worked out for that one.

Last edited:

A freely available STL file would be pretty amazing, Bill. It'll also be helpful to see the range of price quotes folks are getting for the printing of a pair of these.

If I was ever really considering drilling holes in the SEOS-18 I have more or less have decided against it and your points are well taken. The last few years since the original SEOS-12 group buy have been a strange trip for me with a lot of unexpected but fortunate turns. Your own designs with these horns has always been a goal but my previous lack of tools and skills have self-selected only the kits with available flat packs. At this point, having heard both the SEOS-15 (as used in the 88 Specials) and the SEOS-12 (as used in the Fusion 12) I am VERY eager to hear a co-entrant SEOS waveguide.

Not to be too presumptuous, but can we assume that you're going to cook up a passive crossover when the time comes to release this into the wild?

If I was ever really considering drilling holes in the SEOS-18 I have more or less have decided against it and your points are well taken. The last few years since the original SEOS-12 group buy have been a strange trip for me with a lot of unexpected but fortunate turns. Your own designs with these horns has always been a goal but my previous lack of tools and skills have self-selected only the kits with available flat packs. At this point, having heard both the SEOS-15 (as used in the 88 Specials) and the SEOS-12 (as used in the Fusion 12) I am VERY eager to hear a co-entrant SEOS waveguide.

Not to be too presumptuous, but can we assume that you're going to cook up a passive crossover when the time comes to release this into the wild?

Sure, I can do that. Shouldn't be too hard of a crossover since there will be so much overlap between the drivers. But I'm not shooting for a "linear phase" crossover, that takes way too many parts and I'm not sure many people can really hear it (tests I've done with audio club here and FIR filters seemed to indicate that most don't even claim to hear a difference and of the ones that do only about half thought linear phase is preferable). Besides if linear phase is wanted, it's a lot easier to do it with the FIR filter than in a passive crossover.

- Home

- Loudspeakers

- Multi-Way

- 3D printing 1/2 of a waveguide