Hey everyone,

This will be my first speaker build and I am building a speaker for my dad's birthday. I chose to build a pair of 3 way floorstanding speakers. I would just like for someones opinion if anything seems out of place before I order everything. I hope the speaker will play well since he loves music and hasn't had a good pair of speakers for the past 10 years.

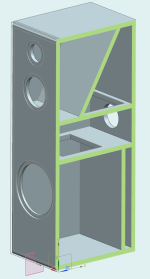

Sub: SB Acoustics SB23MFCL45-4

Mid: Dayton Audio Reference RS150-8

Tweeter: Dayton Audio Reference RST28F-4

AMP: Hypex FA123 FusionAmp

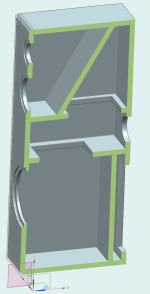

The woofer volume is about 62l, the mid woofer volume is about 17.2l The rear port will be D68mm x 160mm.

Thank you for your help and happy easter,

Cheers Nic

This will be my first speaker build and I am building a speaker for my dad's birthday. I chose to build a pair of 3 way floorstanding speakers. I would just like for someones opinion if anything seems out of place before I order everything. I hope the speaker will play well since he loves music and hasn't had a good pair of speakers for the past 10 years.

Sub: SB Acoustics SB23MFCL45-4

Mid: Dayton Audio Reference RS150-8

Tweeter: Dayton Audio Reference RST28F-4

AMP: Hypex FA123 FusionAmp

The woofer volume is about 62l, the mid woofer volume is about 17.2l The rear port will be D68mm x 160mm.

Thank you for your help and happy easter,

Cheers Nic

Attachments

Just a thought - if this is your first build, would it be worth building an existing design or kit? There's always risk in a fresh design - it might work really well, but it might not. (And although using a Hypex fusion will be simpler than designing a passive crossover, the process is still not simple.)

If you are absolutely determined to build a fresh design, have you modelled the response in software?

I don't want to kill your buzz, but when it's going to be a gift, I'd imagine you want to be confident of the results.

If you are absolutely determined to build a fresh design, have you modelled the response in software?

I don't want to kill your buzz, but when it's going to be a gift, I'd imagine you want to be confident of the results.

When will that be?dad's birthday

Depending on your expectations (and you dad's!) developing a 3way will take quite some time, as far as i know. Mostly acquiring knowledge how to measure correctly, simulate and interpret results.

That!if this is your first build, would it be worth building an existing design or kit?

thank you for the quick reply!

I am not set on this exact combination of driver but I have seen some similar builds online with speakers that have similar responses and good reviews.

A kit kinda seems like a boring option and I wanted to dip my toes in figuring it out myself. Not saying it‘s a bad idea but I love engineering and tinkering with stuff. I‘ll also buy a measurement mic to measure the response of the whole speaker and adjust it in the software of the hyperx amp

And I have more than a month to do it with the help of a woodworker friend of mine

I have designed the woofer stuff in winISD. Which program should I have a look at to model everything?If you are absolutely determined to build a fresh design, have you modelled the response in software?

I am not set on this exact combination of driver but I have seen some similar builds online with speakers that have similar responses and good reviews.

A kit kinda seems like a boring option and I wanted to dip my toes in figuring it out myself. Not saying it‘s a bad idea but I love engineering and tinkering with stuff. I‘ll also buy a measurement mic to measure the response of the whole speaker and adjust it in the software of the hyperx amp

And I have more than a month to do it with the help of a woodworker friend of mine

Maybe others can chip in? I've never used winISD. Can it model the baffle/box effects, and the crossover?

I tend to use Basta for quick modelling - it takes account of driver parameters, box type and volume, baffle dimensions, passive & active crossovers, vents etc. However the active crossover modelling is very limited - no equalisation capability. For more detailed work, Vituixcad is good, but there is more to learn.

A month or two is not long for a project like this! Maybe you'll be faster than me, though.

I tend to use Basta for quick modelling - it takes account of driver parameters, box type and volume, baffle dimensions, passive & active crossovers, vents etc. However the active crossover modelling is very limited - no equalisation capability. For more detailed work, Vituixcad is good, but there is more to learn.

A month or two is not long for a project like this! Maybe you'll be faster than me, though.

WinISD only simulates enclosure response (low end without any baffle effects), as far as i know.

Vituixcad would probably be the best and complete option.

Which program

Vituixcad would probably be the best and complete option.

Hi,

At what frequency cross over is planned so that mid woofer needs 17l of volume ? : ). IMO 5L or so should be plenty for most purposes, leaving more volume for main woofer. Alos such a volume and big mid bass driver could perhaps accomodate a 10" or even 12" woofer, if box dimensions can be changed

Regards

At what frequency cross over is planned so that mid woofer needs 17l of volume ? : ). IMO 5L or so should be plenty for most purposes, leaving more volume for main woofer. Alos such a volume and big mid bass driver could perhaps accomodate a 10" or even 12" woofer, if box dimensions can be changed

Regards

It looks under-woofered and would likely benefit from another (2 x 8 ohm ones in parallel). It may be OKish with just one but if you look at commercial examples they nearly all have two because the low frequencies radiate in all directions and not just forward towards the listener. Hence there is a need for more low frequency output to get a flat response at the listening position. This is often referred to as "baffle step correction" because the baffle size influences the frequency range over which it occurs. Several posters above are also pointing you in this direction.

My plan is to cross over at around 300 and then 1.5k or 2k. I just took the volume for the mid woofer from the data sheet.

I can theoretically boost the bass by running the mid woofer lower, no?

Adding another 8inch woofer will be difficult but not impossible. But would that work with the amp tho? I would have to run both off of one 125 W @4ohm / 75W @ 8ohm. Or I could size up and get the hypex 253 that has 2x 250 and run both woofers off of 250W @4 ohm / 125 W at 8 ohm. What‘s the better option?

It looks under-woofered and would likely benefit from another (2 x 8 ohm ones in parallel

I can theoretically boost the bass by running the mid woofer lower, no?

Adding another 8inch woofer will be difficult but not impossible. But would that work with the amp tho? I would have to run both off of one 125 W @4ohm / 75W @ 8ohm. Or I could size up and get the hypex 253 that has 2x 250 and run both woofers off of 250W @4 ohm / 125 W at 8 ohm. What‘s the better option?

I‘ll check it out, thanks guys!Vituixcad would probably be the best and complete option.

My plan is to cross over at around 300 and then 1.5k or 2k. I just took the volume for the mid woofer from the data sheet.

I can theoretically boost the bass by running the mid woofer lower, no?

Adding another 8inch woofer will be difficult but not impossible. But would that work with the amp tho? I would have to run both off of one 125 W @4ohm / 75W @ 8ohm. Or I could size up and get the hypex 253 that has 2x 250 and run both woofers off of 250W @4 ohm / 125 W at 8 ohm. What‘s the better option?

If you put 125W into 2 woofers rather than 1 it will be louder not quieter (how much depends on 4/8 ohm and serial/parallel). There is less need to increase the power compared to 1 woofer. More power will increase the output even more and is likely worth doing if the output from 1 woofer is inadequate.

No you cannot increase the low frequency output by lowering the midrange crossover frequency but you may wish to lower/raise it in order to better match the baffle step. This should become clear when you find out more about the subject.

Hi,

It's still 8" woofers. Data sheet suggests 150W power handling for each but distortion level at this input is not specified. It's well possible to be just a power beforce mechanical or heat damage begins and not too useful of a number. 125W/ch amp should be good and can be used. With 250W you gain 3dB sensitivity(probably less because of power compression). So IMO amp selection is not critical here.

Regards

It's still 8" woofers. Data sheet suggests 150W power handling for each but distortion level at this input is not specified. It's well possible to be just a power beforce mechanical or heat damage begins and not too useful of a number. 125W/ch amp should be good and can be used. With 250W you gain 3dB sensitivity(probably less because of power compression). So IMO amp selection is not critical here.

Regards

The 8" you chose is very capable and robust, has a lot of Xmax and is very cautios rated with power. It will serve you well, maybe even in closed volume.

There is a GREAT midrange from SB Acoustics too: SB15NBAC30-8

I personally like the 1" tweeters from Bliesma like T25A or S, depending on your listening preferences. They need to be crossed over at 2kHz, the small midrange can do that. I only would use a bigger tweeter when crossing lower.

The active DSP module is a great start - but you need to know how to do good acoustic measurements!

You also don't need to simulate the speaker. Get your volumes and reflex ports right (and TEST them! Prototype) and measure the drivers in the cabinet. Linearise them with EQ to about 1 octave over your crossover frequency (maybe not the tweeter ... ;-)) and then do your filters so they look identical in your acoustical measurements (this sometimes needs different slopes electrical!). Then invert polarity of the midrange and play with the delays until you get maximum chancellation. Back to normal polarity and give it a listen. When you don't like what you hear - do it again ...

There is a GREAT midrange from SB Acoustics too: SB15NBAC30-8

I personally like the 1" tweeters from Bliesma like T25A or S, depending on your listening preferences. They need to be crossed over at 2kHz, the small midrange can do that. I only would use a bigger tweeter when crossing lower.

The active DSP module is a great start - but you need to know how to do good acoustic measurements!

You also don't need to simulate the speaker. Get your volumes and reflex ports right (and TEST them! Prototype) and measure the drivers in the cabinet. Linearise them with EQ to about 1 octave over your crossover frequency (maybe not the tweeter ... ;-)) and then do your filters so they look identical in your acoustical measurements (this sometimes needs different slopes electrical!). Then invert polarity of the midrange and play with the delays until you get maximum chancellation. Back to normal polarity and give it a listen. When you don't like what you hear - do it again ...

Apologies for repeating myself, but my best advice would be to build an existing design or kit. If you were doing this just for your own enjoyment and education, and without a deadline, then working up your own design would be great. But with a deadline, and for someone else, a kit is a good option. There's still plenty of learning and challenge in that.

(Why not something like Troels Gravesen's SBA 861 PFCR? Only 342 Euros for the kit, including drivers, passive crossover components and other essentials, with cabinet costs on top. Then your dad only needs a single stereo amp.)

(Why not something like Troels Gravesen's SBA 861 PFCR? Only 342 Euros for the kit, including drivers, passive crossover components and other essentials, with cabinet costs on top. Then your dad only needs a single stereo amp.)

Last edited:

I agree with the others, maybe use dual woofers, to use them in parallel I would recommend switching 8 ohm drivers. Either two SB23MFCL45-8 if you can find them or two SB23CACS45-8 would sound nice. I think your mid range choice would not have much problem keeping up with the dual 8 inch woofers after making the needed baffle step compensation. In my opinion there is no need crossing the mid to tweeter so low, you are building a three way, the mid looks clean up to 5khz and you could easily cross at or above 3khz with a 4th order acoustic slope . You need to start doing some preliminary modeling in VituixCAD before buying parts, crossing an 8" to a 6" to a 1" driver may or may not be the best approach. In fact you might find a 5" mid or even a 4" might yield better results. If you stick with Dayton maybe the SB23CACS45-8 would work better as a mid.

Based on your baffle drawing you are using 15mm sheet goods, I think you should use 18mm for the enclosure and use two layers for the baffle. 950mm tall panels made out 15mm material just seems a little flimsy to me.

Lastly I disagree with most people and say go ahead and build and design 3 ways, you will learn a lot if you are patient. Look at @hifijim build threads, he has mapped everything out for you to succeed.

Based on your baffle drawing you are using 15mm sheet goods, I think you should use 18mm for the enclosure and use two layers for the baffle. 950mm tall panels made out 15mm material just seems a little flimsy to me.

Lastly I disagree with most people and say go ahead and build and design 3 ways, you will learn a lot if you are patient. Look at @hifijim build threads, he has mapped everything out for you to succeed.

You are absolutely right. I'll switch to a Reference RS125-4, so a 5 inch mid-woofer and then have two subwoofers (the ones I planned). I'm not yet sure how to properly use VituixCAD but I just downloaded it and will play around with it some more.You need to start doing some preliminary modeling in VituixCAD before buying parts, crossing an 8" to a 6" to a 1" driver may or may not be the best approach. In fact you might find a 5" mid or even a 4" might yield better results. If you stick with Dayton maybe the SB23CACS45-8 would work better as a mid.

It's very similar to the woofer from SB as wellThere is a GREAT midrange from SB Acoustics too: SB15NBAC30-8

I will be using black 19mm mdf and I will go for 8ohm and run them in parallel. thank you for the heads upI agree with the others, maybe use dual woofers, to use them in parallel I would recommend switching 8 ohm drivers.

Based on your baffle drawing you are using 15mm sheet goods, I think you should use 18mm for the enclosure and use two layers for the baffle. 950mm tall panels made out 15mm material just seems a little flimsy to me.

Well, as always, a wide range of advice to choose from, which is good.

Of course you'll learn a lot if you design your own. You'll learn to model systems in some software that's new to you. (Vituixcad is great, but there's a lot to get your head round.) As you do that, you'll start to get some idea of how the different driver suggestions being made here will affect the design. You'll learn how box and baffle changes affect things.

You'll make your driver choices and order them. You'll build your cabinets and mount the drivers. You'll measure the drivers in the boxes, (maybe near field and quasi-anechoic, maybe off-axis as well as on). (Oh, and you'll be learning to use measuring software.) You'll learn to use the Hypex software and design your crossover. (Also, I'm wondering: are you choosing the Hypex option because it's what your dad wants, or because it'll work for you?)

You'll have spent somewhere approaching 2,000 euros or the equivalent in francs. (I must show this to my sons - they need to up their game when my next birthday comes! 😄) You've got a month or so to do all this, and you need to get it right first time, since it's a gift.

I'm not saying don't do it - I just want to make sure you realise the scale of the challenge.

PS see https://www.diyaudio.com/community/...-design-your-own-speaker-from-scratch.332688/

PPS The link on that page to Paul Carmody's 'Proven Designs' FAQ seems to be broken. Try this: https://sites.google.com/site/undefinition/diy-speaker-faqs/diy-faqs-provendesigns?authuser=0

Of course you'll learn a lot if you design your own. You'll learn to model systems in some software that's new to you. (Vituixcad is great, but there's a lot to get your head round.) As you do that, you'll start to get some idea of how the different driver suggestions being made here will affect the design. You'll learn how box and baffle changes affect things.

You'll make your driver choices and order them. You'll build your cabinets and mount the drivers. You'll measure the drivers in the boxes, (maybe near field and quasi-anechoic, maybe off-axis as well as on). (Oh, and you'll be learning to use measuring software.) You'll learn to use the Hypex software and design your crossover. (Also, I'm wondering: are you choosing the Hypex option because it's what your dad wants, or because it'll work for you?)

You'll have spent somewhere approaching 2,000 euros or the equivalent in francs. (I must show this to my sons - they need to up their game when my next birthday comes! 😄) You've got a month or so to do all this, and you need to get it right first time, since it's a gift.

I'm not saying don't do it - I just want to make sure you realise the scale of the challenge.

PS see https://www.diyaudio.com/community/...-design-your-own-speaker-from-scratch.332688/

PPS The link on that page to Paul Carmody's 'Proven Designs' FAQ seems to be broken. Try this: https://sites.google.com/site/undefinition/diy-speaker-faqs/diy-faqs-provendesigns?authuser=0

Last edited:

Hi,I will be using black 19mm mdf and I will go for 8ohm and run them in parallel. thank you for the heads up

19 is already much better. I would choose 22 mm, mainly for convenience while joining boards with glue as it holds good with a simple butt joint.

No joint is allowed to be or become loose, as it will rattle for sure, know this from personal experience. So choose some really good glue for that, maybe elastic polyurethane(messy to work) or variety of thick PVA. Surprisingly, silicone also works here and does not detach even from thinner boards because it's flexible.

Regards.

- Home

- Loudspeakers

- Multi-Way

- 3 way active floorstanding speaker - dad's birthday