If anyone is willing to help devise a new layout I would greatly appreciate it. I have all the components set up in sections on terminal strips so I can easily rearrange them if I cut a new top. I would really appreciate anyone willing to help me create a new layout and wiring layout for the amp

Edit: or it would be even better to come up with new wiring using the layout I already have.

Edit: or it would be even better to come up with new wiring using the layout I already have.

Last edited:

I have rewired the power section of the amplifier. No change. I shortened the wires and moved the DC heaters for the 2A3 and AC heater for the 6SN7 to the outside out the layout. I trimmed excess power wires and did more testing, with no results.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

New development, there is an audible hum coming from the transformer. This is audible without headphones connected. I have another transformer with similar voltage ratings but when I initially tested it, it was very noisy. I will try to see what I can do to solve the issue.

ok. your last picture is looking a bit neater. Its hard to tell exactly which sire is ground to be honest - I personally use different colored wires for ground, and use a star formation - only ONE point, not two or three daisy chained along.... all wires go to THAT screw, on little soldered O-nutz. It works for me. Many other builders use a bus - i.e. a strip of solid copper wire that all grounds get soldered to. I can highly advise using different colored wire for your ground, but its just advice.

So what to do? unhook your HT+ input, safely tape that end of wire and turn it on. Only the heaters will be on. Does it hum then?

If your mains transformer is the source of hum then maybe something is not wired right... or its just not good. got a picture of it?

Even the best of us manage to wire a choke incorrectly and creat a great vibrating resistor.

Ian

So what to do? unhook your HT+ input, safely tape that end of wire and turn it on. Only the heaters will be on. Does it hum then?

If your mains transformer is the source of hum then maybe something is not wired right... or its just not good. got a picture of it?

Even the best of us manage to wire a choke incorrectly and creat a great vibrating resistor.

Ian

I disconnected the B+ power transformer entirely, so no the only thing connected is the filament, and it still hums. I don't think it is straight hum tho, it has some other harmonics, not just 60hz. I will try to use AC instead of the regulated supplies and see if that changes anything. If not, could it be the tubes? They are new so I would be very surprised if they were the issue.

Yup, just what I thought might be the case.

Did you try moving the transformers away from each other? Or at least rotating them 90 degrees to each other? are the OPT's close to the Mains transformer?

It could simply be that AC noise from your heaters is being transferred via stray capacitance to your speakers. Often this is the case if the OPT is of the inexpensive variety...

Or it could be that the Mains transformer vibrations are being translated to the OPT or the 2a3 and you are hearing this... lots of possibilities!

If you are getting non-standard hum then it could easily be heater noise. This often happens if the output tubes are of the inexpensive variety too..

I bet if you "float" the 2a3 heaters (don't attach the B+ when you do this!), I bet it will be dead silent.

Did you try moving the transformers away from each other? Or at least rotating them 90 degrees to each other? are the OPT's close to the Mains transformer?

It could simply be that AC noise from your heaters is being transferred via stray capacitance to your speakers. Often this is the case if the OPT is of the inexpensive variety...

Or it could be that the Mains transformer vibrations are being translated to the OPT or the 2a3 and you are hearing this... lots of possibilities!

If you are getting non-standard hum then it could easily be heater noise. This often happens if the output tubes are of the inexpensive variety too..

I bet if you "float" the 2a3 heaters (don't attach the B+ when you do this!), I bet it will be dead silent.

I have the heaters floated now, and it's noisy. The noise increased when I turned on the B+ but didn't connect it to the tubes, so maybe the transformers are creating the noise.

I have a 2-20V bench supply I will try to use to heat the tubes, I will also try AC to see if that helps.

My OPT are Electraprint, so that isn't cheap. The 2a3's are Shuguang 2A3c which are about 75 each, and my power trannys are Edcor XPR182 and 2 Hammond 6.3V filament transformers (one feeds each DC supply)

I think I have the transformers rotated properly

I have a 2-20V bench supply I will try to use to heat the tubes, I will also try AC to see if that helps.

My OPT are Electraprint, so that isn't cheap. The 2a3's are Shuguang 2A3c which are about 75 each, and my power trannys are Edcor XPR182 and 2 Hammond 6.3V filament transformers (one feeds each DC supply)

I think I have the transformers rotated properly

The heaters make noise even when truly floating?? are you sure there is no by-pass cap attached either?

sheesh.. what is your iron? lets see some pictures of the top of this amp if you can manage that.... also what are the tubes? is the iron hammond or even cheaper? Are you using 20 year old chinese 2a3's ?

truly honest when I say you shouldn't need to do AC. but if you are running AC then it won't hurt.

With no B+ and only heaters, truly floating you get hum? really??? If so then please take the mains transformer physically OFF the board (put it somewhere safe, not in your hand) and tell me if it still hums with only the floating heaters running.... please.

btw - this is why I breadboard every single one of my designs before I get the wild idea to build a chassis...

sheesh.. what is your iron? lets see some pictures of the top of this amp if you can manage that.... also what are the tubes? is the iron hammond or even cheaper? Are you using 20 year old chinese 2a3's ?

truly honest when I say you shouldn't need to do AC. but if you are running AC then it won't hurt.

With no B+ and only heaters, truly floating you get hum? really??? If so then please take the mains transformer physically OFF the board (put it somewhere safe, not in your hand) and tell me if it still hums with only the floating heaters running.... please.

btw - this is why I breadboard every single one of my designs before I get the wild idea to build a chassis...

Last edited:

no filaments, no B+, this means there should be nothing happening... Touching the cathode makes the hum go away? This must be some kind of fields problem between the OPT and mains transormer.

The only thing I can think to try is to try to take the mains or OPT's off board or rotate one of them 90 degrees and see if it is better.

btw - I would really prefer to see you not use wood for your top plate. Especially when you have important heat sinks below it.

Ian

The only thing I can think to try is to try to take the mains or OPT's off board or rotate one of them 90 degrees and see if it is better.

btw - I would really prefer to see you not use wood for your top plate. Especially when you have important heat sinks below it.

Ian

Take the time to study and plan your project

If I may be candid, here's my assessment:

You thought you could slap a bunch of modules (PS, filament, CCS) together on a couple bits of Masonite with a hank of wire and it would just work. Life and electronics aren't that simple. You need the proper tools to do the job. If you are going to prototype you need a couple of meters, a signal generator, and a 'scope; they are part of the cost of getting into the hobby. You need to understand about parts that are properly engineered for the job to which they are intended. Unless I am mistaken your coupling cap is an electrolytic and the cathode resistor appears to be 1W. You need to study how others have constructed their projects; check out the Photo Gallery 'Sticky' at the top of the tubes-valves page. Finally, take the time to study and plan your project and get a real chassis and build an amp using craftsmanship that will make you proud to show it to other DIY enthusiasts.

If I may be candid, here's my assessment:

You thought you could slap a bunch of modules (PS, filament, CCS) together on a couple bits of Masonite with a hank of wire and it would just work. Life and electronics aren't that simple. You need the proper tools to do the job. If you are going to prototype you need a couple of meters, a signal generator, and a 'scope; they are part of the cost of getting into the hobby. You need to understand about parts that are properly engineered for the job to which they are intended. Unless I am mistaken your coupling cap is an electrolytic and the cathode resistor appears to be 1W. You need to study how others have constructed their projects; check out the Photo Gallery 'Sticky' at the top of the tubes-valves page. Finally, take the time to study and plan your project and get a real chassis and build an amp using craftsmanship that will make you proud to show it to other DIY enthusiasts.

I am fairly confident that the amplifier will function in its current configuration if I fix the issue causing me to need to hold the ground wire to reduce the buzz. When I move the transformers far away the hum goes down so I think if I can resolder everything tonight, I'll be able to get it functioning.

Even tho I did a poor job overall, I am 3 weeks away from the deadline and don't have time to rearrange everything.

Even tho I did a poor job overall, I am 3 weeks away from the deadline and don't have time to rearrange everything.

good to hear you are getting closer to the source of your hum and buzz. You are making your poor job better every day it seems, so who knows?

Sometimes just rotating transformers 90 degrees or even 45 degrees works. You are learning that layout is very important.

Using a ground BUS might be prudent as well. Just one big fat solid piece of copper wire that runs through the middle - where each ground connection directly goes to.

Ian

Sometimes just rotating transformers 90 degrees or even 45 degrees works. You are learning that layout is very important.

Using a ground BUS might be prudent as well. Just one big fat solid piece of copper wire that runs through the middle - where each ground connection directly goes to.

Ian

When I touch the cathode on the 2a3, him goes away. Filaments are disconnected still, as is the b+

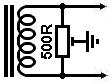

I did not read all posts but this may help if not said before.

The Valve Wizard

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 2A3 Hum Problems in SE (Please Help!)