Question for the audio experts. Last night I did more testing with REW and just one panel. I brought it out from the wall a bit, and then tried making the response flatter with EQ. Doesn't work. That's an interesting result because it either means a) my setup is wrong, it's not really EQing the test signal, or b) there is some fundamental principle of sound I don't understand.

I'm using a freeware effects processor called DeskFX. If I listen to music, adjusting the bands results in drastic response. But adjusting the bands makes almost no difference to the test signal. The db meter shows the signal is passing through the effect processor, and it seems like I can make small effects. If I push the sagging highs up to the max, and then pull anything around 1.5khz to the very bottom, the curve flattens a little. The result is unlistenable. Later today I will try fresh to convince myself that DeskFX is really processing the test signal. If it is, then the relationship between the measure from a test signal and real listening is not straightforward.

Any ideas what's going on?

I'm using a freeware effects processor called DeskFX. If I listen to music, adjusting the bands results in drastic response. But adjusting the bands makes almost no difference to the test signal. The db meter shows the signal is passing through the effect processor, and it seems like I can make small effects. If I push the sagging highs up to the max, and then pull anything around 1.5khz to the very bottom, the curve flattens a little. The result is unlistenable. Later today I will try fresh to convince myself that DeskFX is really processing the test signal. If it is, then the relationship between the measure from a test signal and real listening is not straightforward.

Any ideas what's going on?

Unless Ben Stecker and his boys have invented an anti gravity machine that has been applied to those exciters, get ready for sag. What did Einstein say about doing the same thing over and over again and expecting different results? Are you sure that you really know better than him? This quote will soon enough apply to you and you'll be back crying about defects soon enough when just some common sense could save you all the hassle.Like I said, not according to the manufacturer and distributor, and the design doesn't provide any way to support them.

Are you sure that you really know better than Ben Stecker and soundimports specialist on exciters?

I'm not so sure about that, and like I mentioned before I prefer to keep warranty intact, which means following their recommendations.

Everything will sag with time, even a sheet of glass. Basic physics , but question is how quickly. Woofers sag as well, but good designs should not sag enough to start distorting within normal life time. Why would exciters be different?

Last edited:

Guys,

For the record, it's Ben Zenker, not Stecker.

https://www.researchgate.net/profile/Benjamin-Zenker-2

For the record, it's Ben Zenker, not Stecker.

https://www.researchgate.net/profile/Benjamin-Zenker-2

I'm glad that Leob is going to put these Xcite exciters through the ringer on his PA/Event system (which I think is pretty bad-*** by the way) and am looking forward to the results. I hope they pass with flying colors, but I believe in science....gravity. If these things don't sag without a spine from being hammered along with 3 others beside them then it truly will be a miracle. Those exciters are using the same motor and spider design as the Daytons that were trashed when he hammered those without spines. Unless this company has come up with a new spider material that has zero stretch during break in and beyond then it's still just square one. If they have, I'm sure they could make more $ selling the patent to NASA. It looks to me like they're using that same ol' "mustard" colored stuff everyone else uses, if so, no go!

Really looking forward to what other's using them single on smaller panels of EPS have to say, that's what will warrant my cash.

Really looking forward to what other's using them single on smaller panels of EPS have to say, that's what will warrant my cash.

Last edited:

Maybe they have. Look on their website:Those exciters are using the same motor and spider design as the Daytons that were trashed when he hammered those without spines. Unless this company has come up with a new spider material

" The XT32-4 is xtreme reliable - designed to avoid bottoming out combined with a heat-resistant and low loss yellow conex spider."

It looks to me like they're using that same ol' "mustard" colored stuff everyone else uses, if so, no go!

. Those exciters are using the same motor and spider design as the Daytons that were trashed when he hammered those without spines. Unless this company has come up with a new spider material that has zero stretch during break in

I have found myself a little confused regarding 'the different types of spiders'." The XT32-4 is xtreme reliable - designed to avoid bottoming out combined with a heat-resistant and low loss yellow conex spider."

I have always considered even 'spring steel' as a form of spider. ( just by its action )

Call it 'dumb', but could some members please elaborate on the details of spiders

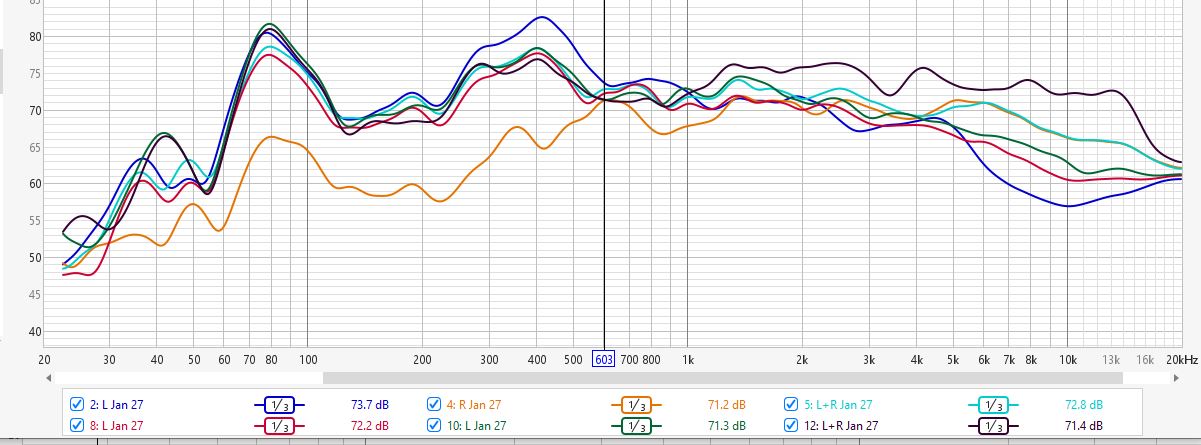

I brought out my pseudo-veleric build, the 14" Birch, put it in the middle of the room, and the mic pointed directly at the middle with no obstructions.

The brown line at the bottom is the DAEX25FHE-4. How different is it than Eric's panel?

https://www.diyaudio.com/community/...ll-range-speaker.272576/page-568#post-7549650

The main difference I see is that huge sag between 80 and 350. Is that explained by the difference in frame? I'll eventually have to try it with tape.

The purple line is the new, monstrous, EX32VBDS-4. Note that I am running through a xover, it's turned down to 50, but 50 is still 50. I have these two exciters attached next to each other on the panel, both slightly off center. Try and guess what the teal, red, and black are....

I think the teal line looks pretty good. In REW, you can set whether you want to test L, R, or L+R. So Purple is L, brown R, and Teal is L+R. So it appears that exciters of different capabilities can compensate for each other effectively. The red line is the two exciters wired in series. I ran several tests and they are comparable. Kind of annoying it drops out at 4k, but, since those two were in series, that left the R channel open, so I grabbed my DML tweeter, which is 1/4" XPS and made it R. So the black line is the combined effort of a exciter woofer, mid, and tweeter.

How does this translate to music? Well, the tweeter overpowers everything else, so it would need to be bi-amped, probably tri though if I were to go this route.

The brown line at the bottom is the DAEX25FHE-4. How different is it than Eric's panel?

https://www.diyaudio.com/community/...ll-range-speaker.272576/page-568#post-7549650

The main difference I see is that huge sag between 80 and 350. Is that explained by the difference in frame? I'll eventually have to try it with tape.

The purple line is the new, monstrous, EX32VBDS-4. Note that I am running through a xover, it's turned down to 50, but 50 is still 50. I have these two exciters attached next to each other on the panel, both slightly off center. Try and guess what the teal, red, and black are....

I think the teal line looks pretty good. In REW, you can set whether you want to test L, R, or L+R. So Purple is L, brown R, and Teal is L+R. So it appears that exciters of different capabilities can compensate for each other effectively. The red line is the two exciters wired in series. I ran several tests and they are comparable. Kind of annoying it drops out at 4k, but, since those two were in series, that left the R channel open, so I grabbed my DML tweeter, which is 1/4" XPS and made it R. So the black line is the combined effort of a exciter woofer, mid, and tweeter.

How does this translate to music? Well, the tweeter overpowers everything else, so it would need to be bi-amped, probably tri though if I were to go this route.

Indeed, but in this case a simple rotation time to time is effective. I do that in my normal drivers also, although much more spaced in time.(...) Everything will sag with time, (....)

I posted this someway back in this thread.I have found myself a little confused regarding 'the different types of spiders'.

I have always considered even 'spring steel' as a form of spider. ( just by its action )

Call it 'dumb', but could some members please elaborate on the details of spiders

There were in the olden days, different shapes of spider 🕷 depending upon manufacturing company .

They looked a little like spiders, hence the name, and it has stuck.

Attachments

https://drive.google.com/file/d/1kdh1yNhkZY9F1waNljSoVIBvRwwy2Uj0/view?usp=sharing&authuser=0Three things >

*1. I guess I should clarify what I imagined as PA use. I was thinking of small Clubs & Bars for Duo's & Trio's

where excluding Kik & Vox. most of the sound comes direct from stage. Subs can easily be pushed up to 300Hz.

Backing-tracks could probably sound quite good using DML's, but for LOUD large-stage Rock bands, I don't think DML's

would be the way to go. There is sort of PA and PA.

*2. In the end analysis, all the frequency response charts we see have peaks & dips that appear to be inherent with DML's.

This is why I encourage all builders to incorporate EQ > even as simple as Graphic Equalizers, they are almost ideal.

*3. I once mentioned "semi-rigid bracing" of the exciter body. IF sag is in fact an inevitable outcome, just imagine how

an 'X style' flexible brace might greatly extend the expected life-span.

Strangely, I think of something like hose affixed using strong epoxy

This is a link to Leobs panels doing a sound check 😄

I am very sorry for the very poor low quality of the recording 🤮

But I think it gives you the idea of the sort of sound eps can give.

Try and imagine this in a small venue 🫣

Eps is the most efficient material I know of so far, and can play realistic machine gun fire in my room ,at ear shattering levels.

This is with my 10watt exciters.

A random picture of one of my panels.

Why do I need EQ if I roll off the frequency at say 100hz ?

I suppose I could take a few db off above 10k if I felt it needed it.

Steve.

Attachments

I got around to trying out the UMM-6 and REW.

Awesome. REW is a great tool. I've been using it for a few years now, but still feel like a newbie myself. We don't talk much about REW details on this thread, only a few of us seem to use it. I can share a few thoughts of my own, but would like to hear the input of others, especially if their practice and use differ from mine.But? I really don't know what to look for, I have zero experience here so any and all feedback is most welcome.

Andre's suggestions were spot on. I have not made measurements outdoors yet, but if you can do it without much difficulty, I think it would be great to try. Room effects have a big impact on measurements, and it can be hard to tell what comes from the room and what comes from the speaker with an indoor measurement.

One alert here. For piston speakers there is a method of stitching together measurements made at very close and far range (say 1 cm and 1m?) to create a "quasi-anechoic" result. But I do not believe that methodology is valid for DMLs.

For my most basic SPL measurement I set the mic 1 meter from the center of the panel, however, it is worthwhile to look at results with the mic closer or farther away, and at various angles. Usually I test only a single panel, mainly because I'm usually testing prototypes and don't bother to build a second one unless the first one is really great.

I typically use a sweep length of 256k, which takes about 5.5 seconds, I used to use longer sweeps, but I don't think I gained much from it.

Regarding SPL, the theoretical ideal is a "flatish" response between 20 Hz and 20 kHz, perhaps with a slight downward slope from low to high frequency. For me, I'm happy with 100 Hz to 12 kHz. IME it's hard to get flat response from a DML much below 100 Hz, and my hearing stops at 12 kHz, so that's good enough for me.

What is "flat enough" is up to you to decide. And it's complicated by how much smoothing you choose to use. I typically use a smoothing of 1/6 or 1/12 by default. If I get a result that's within a 10dB range across the target frequency range, with 1/6 smoothing I'm pretty happy. If I'm comparing variations of a build, etc, I'll often use more smoothing (say 1/3) which makes it easier to see general trends. If I'm trying to correlate SPL measurements with impedance tests or "tap test" results, I'll use 1/12 smoothing, or less, to improve the resolution.

I frankly haven't figured out how to interpret phase results, in terms of what's good or bad. Would love to hear others input on that.

The other result displays I find most informative are:

- distortion (% scale)

- impulse (% scale)

- spectrogram (wavelet mode, 1/6 smoothing, 20 ms before to 200 ms after)

- waterfall

For scaling displays, using the "fit to data" button under the "limits" tool is often a good place to start.

Finally, I'll add that I am finding impedance measurements to be extremely informative too. This requires a special rig (described in the REW Help) that you have to build yourself, however. I highly recommend it if you really want to understand how changes to a design effect the way a panel responds.

Eric

Rotating might help a bit, but it seems like the main issue is the suspension becoming softer with time and usage. When the suspension softened up too much, it will distort regardless of direction.Indeed, but in this case a simple rotation time to time is effective. I do that in my normal drivers also, although much more spaced in time.

At best I would think you can double the time you get before the issue develops, so in my case with the Dayton's, that would be two events instead of one before they need replacing.

jmproject,Is that explained by the difference in frame?

Yes. the frame is critical. Are you still just clamping the two long sides? To get a result like mine, the panel will need to be fixed to the frame along both the short and long sides. Having a sufficiently stiff frame, including the center frame brace, is critical too. Otherwise, all bets are off. I'm not saying there aren't others ways, just that if there are, I don't know them.

I'm eager to see where you end up eventually. Keep playing!

So the black line is the combined effort of a exciter woofer, mid, and tweeter.

When you say tweeter, I understand that you mean your XPS panel, but what do you mean by "exciter woofer and mid"?

Eric

veleric said:Andre's suggestions were spot on. I have not made measurements outdoors yet, but if you can do it without much difficulty, I think it would be great to try. Room effects have a big impact on measurements, and it can be hard to tell what comes from the room and what comes from the speaker with an indoor measurement.

veleric said:When you say tweeter, I understand that you mean your XPS panel, but what do you mean by "exciter woofer and mid"?

I'll kill two birds with one stone here. This morning, I tested outside. Mic set up in the doorway; mid panel height; 1 meter. Here is the main results:

orange = "midrange" = DAEX25FHE-4 = REW test Left channel

green = "woofer" = "EX32VBDS-4" = REW test Right channel.

teal = REW test Right + Left.

The BDS and FHE are mounted on the same birch panel, both offset a little from the center. Together, they make up for each others deficiencies and make a flatter curve.

Testing outside got rid of the severe hole, however that peak at 70 may very well be panel construction related. I will get control of the un-framed edges for the next round.

It sounds like we're barking up similar trees!I'm not aiming for super loud, but am more interested in the dipole and (claimed) diffuse nature of this speaker. I hope to get a more "natural" sound impression as opposed to a speaker that is screaming in your face.

I've been using my panels for live gigs. I'm just a one-man with acoustic guit, bass guit, voice and backing trax. I use three drivers per panel—one 30HESF-4 and two 25FHE's all wired series/parallel. Plenty loud enough if I roll off the bass at about 150Hz and use a separate sub.

Yes, I found that as well, and it's a massive advantage in some of the venues I work. Instead of using multiple cabs to cover the audience, I can use only two panels and get ultra-wide coverage without having to worry about dead spots, lobing, combing, directionality, sweet-spots or any of the other problems inherent in using different drivers, with different response curves, pointing in different directions.The panel was indeed a lot wider covering, and had less top end (but the meyer is quite extreme in that respect). The panel was sounding less direct/more difficult to pinpoint, but that could be mainly because of the dipole character.

Nice thing too is that I don't need floor monitors because even if I'm positioned "behind" the panels, I can still hear the mix perfectly clearly.

I actually found less reverb problems, possibly due to the diffuse nature of the wave-front?The "natural sound" I am after might have too much downsides (too much room reverb). I'll have to built a few more panels first to really try it for live reinforcement.

I use the panels with subs on stage. Of course, the 150Hz cross-over point takes care of the possible lack in that region if aligned correctly.My panel actually sounds quite good, but different (!). It is difficult to pinpoint what it is. It lacks in the 150-200 Hz region, but I only percieve that when comparing to other (floor monitor) speaker. When listening to music without comparing, it sounds good (to me). I have to test it singing through it. It may well be that the lack of midbass is awful/uncomfortable for PA use.

Also, when using cone speakers I almost always put a low-Q notch into the 200Hz region anyway to compensate for almost every indoor venue's upper-bass modes, and to get rid of the mud in the sound, and to bring out the vocals more clearly.

In the attached clip, I've rolled off the bass end for testing purposes while assembling the panels. .

You can see the perforated back panels standing around, waiting to be assembled into the frames. As you have, I've also mounted the drivers directly into the back for support purposes.

1. Yes, backing trax sound very awesome using DML's, and if they're rolled off nicely, then the sub easily takes care of kick and bass.Three things >

*1. I guess I should clarify what I imagined as PA use. I was thinking of small Clubs & Bars for Duo's & Trio's

where excluding Kik & Vox. most of the sound comes direct from stage. Subs can easily be pushed up to 300Hz.

Backing-tracks could probably sound quite good using DML's, but for LOUD large-stage Rock bands, I don't think DML's

would be the way to go. There is sort of PA and PA.

*2. In the end analysis, all the frequency response charts we see have peaks & dips that appear to be inherent with DML's.

This is why I encourage all builders to incorporate EQ > even as simple as Graphic Equalizers, they are almost ideal.

*3. I once mentioned "semi-rigid bracing" of the exciter body. IF sag is in fact an inevitable outcome, just imagine how

an 'X style' flexible brace might greatly extend the expected life-span.

Strangely, I think of something like hose affixed using strong epoxy

I have not yet had the opportunity to use my panels for a live four-piece, but from what I've experienced so far, I think a drum-kit will sound awesome.

2. I find that the peaks and dips in frequency response of panels are not obvious to the ear. Yes, there is a lack of HF, but a bit of EQ does compensate very adequately even with an analogue graphic EQ or even a tone control.

3. Agreed, I'm rather sceptical of the ability of the driver suspension's ability to carry the weight of the motor, especially long-term. This is also why I'm also a little sceptical of the suppliers' (Dayton, Parts Express etc) technical knowledge and know-how. From some of the interactions I've had with them, I've been surprised and maybe a little disappointed by their apparent lack of hands-on experience.

Nice! Are these the foam/veneer panels you made for the church? Or are you making a series of these panels now?In the attached clip, I've rolled off the bass end for testing purposes while assembling the panels. .

You can see the perforated back panels standing around, waiting to be assembled into the frames. As you have, I've also mounted the drivers directly into the back for support purposes.

View attachment 1266251

Yes, those are the ones for the church.Nice! Are these the foam/veneer panels you made for the church? Or are you making a series of these panels now?

But the foam/veneer plates are a veritable PIA to build, so I've used exactly the same build, but with polycarb twinwall for my own use.

The foam/veneer is rather fragile, and nicht fer gerfingerpoken, whereas the polycarb is very robust and can be abused quite freely.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker