Flipped the belt around and now it doesn't fall off when cleaning the pulley, which is good.

I notice that the wobbling in the belt as it heads toward the step pulley decreases when I adjust the speed pitch control clockwise, not sure what this indicates.

We will see if it holds steady speed now that the belt doesn't fall off

I notice that the wobbling in the belt as it heads toward the step pulley decreases when I adjust the speed pitch control clockwise, not sure what this indicates.

We will see if it holds steady speed now that the belt doesn't fall off

Step Pulley Noise

Hello, I’m hoping I can get some help here. I’ve owned my 124 Mk I for 40+ years now and usually clean and lubricate it every year or so. This year I replaced my OEM idler wheel with the Audiosilente precision ground idler wheel and my 3 year old Hanze HiFi belt with the Audiosilente belt that came with the wheel. At the same time, I did the usual cleaning of pulleys and bearings and relubed them with 3n1 electrical motor oil. The turntable started out quieter than it has ever been, but after about 2-3 hours of continuous use, I got a faint chatter that didn’t go away until the table had been left off for an extended period (temperature related?). I went back in and isolated the noise to the step pulley. I then double checked the eddy brake and it is fine. I also relubed the step pulley bearing (my turntable is the version with a bearing well) and cleaned everything again, but got the same chatter after extended play. Any idea what the problem might be? I plan to go back in a third time and thoroughly clean and relube the step pulley bearing well and replace the belt with a spare new Hanze belt I’ve got, but figured I’d ask this group for any other ideas before I do that. I hate separating the platter from the spindle any more than I have to. Thanks in advance for your advice. John.

P.S. What’s the current thinking on the best way to clean the bearing well? Alcohol or lighter fluid? I’ve got lint free swabs.

Hello, I’m hoping I can get some help here. I’ve owned my 124 Mk I for 40+ years now and usually clean and lubricate it every year or so. This year I replaced my OEM idler wheel with the Audiosilente precision ground idler wheel and my 3 year old Hanze HiFi belt with the Audiosilente belt that came with the wheel. At the same time, I did the usual cleaning of pulleys and bearings and relubed them with 3n1 electrical motor oil. The turntable started out quieter than it has ever been, but after about 2-3 hours of continuous use, I got a faint chatter that didn’t go away until the table had been left off for an extended period (temperature related?). I went back in and isolated the noise to the step pulley. I then double checked the eddy brake and it is fine. I also relubed the step pulley bearing (my turntable is the version with a bearing well) and cleaned everything again, but got the same chatter after extended play. Any idea what the problem might be? I plan to go back in a third time and thoroughly clean and relube the step pulley bearing well and replace the belt with a spare new Hanze belt I’ve got, but figured I’d ask this group for any other ideas before I do that. I hate separating the platter from the spindle any more than I have to. Thanks in advance for your advice. John.

P.S. What’s the current thinking on the best way to clean the bearing well? Alcohol or lighter fluid? I’ve got lint free swabs.

but after about 2-3 hours of continuous use, I got a faint chatter that didn’t go away until the table had been left off for an extended period (temperature related?). I went back in and isolated the noise to the step pulley. I then double checked the eddy brake and it is fine. I also relubed the step pulley bearing (my turntable is the version with a bearing well) and cleaned everything again,

John, I've got the same issue as you. If I put a drop of 3-1 electric oil in the well it will quiet down for 1-2 days with 4-5 hours paying per day, but it then returns. I feel no play what so ever in the bearing/spindle interface. My thought now is to check the spindle top the 4mm bb rides on to see if it is smooth or has some texture. Then replace the 4mm bb with another G5 ceramic bearing. Hoping that may solve the issues. Did you make any progress in your case?

I guess another possible cause is the belt riding a bit off and causing the step pully to vibrate a bit? I use an audio silente belt currently. I'll also be looking at that.

Have you checked the belt you are using, in some cases belt chatter will excite the pulley after it has run for a while. It is possible that the bearings need to be replaced or serviced. They depend on a film of oil for proper operation and if they are original the pores may be full of congealed oil. (You may be able to clean them in place. There were kits with the tool required to replace them at one time, not sure of the current status. Check the height of the motor pulley to make sure its positioned so that the belt rides right in the middle of the intermediate pulley. You may also want to consider the belt from Hanze HiFi, they seem to work better than most of the others I've tried.

Hi Kevin, today I flipped the belt so inside is now outside. Its an audio Silente belt. I plan on ordering a couple of Hanze belts. I cleaned the shaft of the step pully as good as I could, some small debris there and built up oil sludge. It looks like maybe there is a piece of felt like material between the upper and lower bushings, maybe to hold oil for the bronze bushings. I put it back together made sure the belt rides the center of the step pully. Added 30wt 3-1 motor oil to small cavity of top bushing and its quiet now, well see after 2 days if it remains so.Have you checked the belt you are using, in some cases belt chatter will excite the pulley after it has run for a while

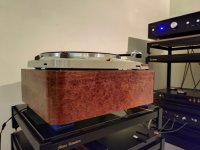

Finished veneering a moldova bare plywood plinth with Pommele Sappele wood and installed a new AudioMods series 6 arm, Boy it sure sounds good with a Goldring E3 cartridge which will be upgraded soon.

Yes, but that has nothing to do with the clutch. As Wntrmute2 described there are 3 screws with 3 nuts directly under where the clutch lifts the upper platter. loosen the 3 nuts and raise the screws a touch until it lifts upper platter and does not rub lower platter. Then tighten the 3 nuts. The woodsong bronze endcap is incredible.Anyone using the wonderful woodsong audio endcap?

Looks great, and I bet sounds as good. Hopefully the noise issue is resolved - I had a lot of problems with this with various different belts, then I didn't, and it hasn't returned. I have a TD-124 with a Papst 3 phase running on a modified VFD, and a MKII with the original E50. Both run fine, generally I use the 124 which has a terrible slate plinth, a Jelco TK-850L and a Mutech Hayabusa LOMC. The MKII has a Sorane ZA-12 prototype on it and a panasonic strain gauge. Oddly 90% of my listening is to digital, about 8% tape and 2% vinyl. I'm trying to do better. Damned Topping Dacs sound so good.. lolHi Kevin, today I flipped the belt so inside is now outside. Its an audio Silente belt. I plan on ordering a couple of Hanze belts. I cleaned the shaft of the step pully as good as I could, some small debris there and built up oil sludge. It looks like maybe there is a piece of felt like material between the upper and lower bushings, maybe to hold oil for the bronze bushings. I put it back together made sure the belt rides the center of the step pully. Added 30wt 3-1 motor oil to small cavity of top bushing and its quiet now, well see after 2 days if it remains so.

Finished veneering a moldova bare plywood plinth with Pommele Sappele wood and installed a new AudioMods series 6 arm, Boy it sure sounds good with a Goldring E3 cartridge which will be upgraded soon.

View attachment 1005174 View attachment 1005175 View attachment 1005176

They're likely the best out there at the moment, I have been planning to upgrade mine to the Woodsong when I do the next overhaul. (My tables have been running 10+ years now) I know Chris Harban, he makes good stuff.Anyone using the wonderful woodsong audio endcap? My clutch no longer stops the platter and I was wondering if anyone had any ideas on how to fix this? Looks like I need just a tad more height on the clutch pads to reach the platter to stop it.

One other thing I should mention is that I use the Audiosilente pulleys and recommend them highly (the ones that use O rings) they were perhaps the biggest single improvement I've made, no more thumps, rumbling or other odd noises. I have bought new production, NOS OEM and used and they're all noisy to some extent, the ones from Audiosilente run very quietly.

I run a audio Silente belt which seems quite good (I have 2 hanze belts on order), the chatter occasionally came back with the AS belt so last week I took everything apart in the drive train and cleaned the step pully internals as good as possible, inserted a new G5 ceramic BB and added oil to the MK 1 step pully well. When re-assembling I turned the AS belt inside out so now the old inner side is the outside. And for 4 listening sessions the table has been a quite as it every has been. Could it have been the belt inverting? Not sure but awfully glad the chatter has disappeared for now.Have you checked the belt you are using, in some cases belt chatter will excite the pulley after it has run for a while. It is possible that the bearings need to be replaced or serviced.

Thanks for your replies. I went back in and reinstalled my OEM idler wheel and a new Hanze HiFi belt. That solved the problem for a while, but then the table started chattering again, although much more faintly. I'm pretty sure my bearings are clean and in good shape. Just got a borescope and may try to take a closer look at that though. I can live with the noise level for now, but plan to take another look before too long and will double check the step pulley height adjustment. I can't think of anything else to look at. Maybe I just need to learn to keep my ear a respectful distance from the turntable

I've been mainly using a TD125 lately, which is an interesting comparison. Needless to say the 125 is much quieter, but the 124 is more pleasing in some respects I can't really describe. It's hard to choose!

I've been mainly using a TD125 lately, which is an interesting comparison. Needless to say the 125 is much quieter, but the 124 is more pleasing in some respects I can't really describe. It's hard to choose!

I'm not aware of any chattering problems with either of my tables these days, perhaps I am just ignoring it, but I suspect that the AS idlers actually damp the vibrations so that they are not so audible. The other thing is I am using HH belt on one and a 5 decade old OEM on the other. Talcum powder does help, but only temporarily. The fact that they mention it in the owner/service manuals hints that this is a problem right from the beginning.

I recently ordered a 12 inch Corian armboard from Germany for use with my TK-850L arm and will be ordering a wood plinth from Moldova after the New Year.

It is probably time for me to do some maintenance on these machines again as the MKII has been running for almost 10 years.

I recently ordered a 12 inch Corian armboard from Germany for use with my TK-850L arm and will be ordering a wood plinth from Moldova after the New Year.

It is probably time for me to do some maintenance on these machines again as the MKII has been running for almost 10 years.

If you are getting your armboard from Stefan, I think you will be very happy. He’s made several for me (along with some heavier counterweights and other items) and his work is perfect.

I’ve pretty much reversed out all the modifications to my Thorens tables (except for most of the Schopper stuff and the Hanze motor springs). I finally concluded that the original designers knew best.

I’ve pretty much reversed out all the modifications to my Thorens tables (except for most of the Schopper stuff and the Hanze motor springs). I finally concluded that the original designers knew best.

I have the Hanze Hi-Fi springs on both tables and AS idlers on both tables. The MKII was all original and complete when I got it. The 124 was assembled from a bunch of parts acquired on eBay and else, it was basically a chassis in a box with a bunch of 121 parts, it took a long time to piece together all the bits to make it a runner.

The 124 differs from the MKII in that it has a non-magnetic stainless steel platter, and a Papst Aussenlaufer motor running on a VFD. Different arms and cartridges. Neither currently get much use.

The 124 differs from the MKII in that it has a non-magnetic stainless steel platter, and a Papst Aussenlaufer motor running on a VFD. Different arms and cartridges. Neither currently get much use.

Happy New Year All!And for 4 listening sessions the table has been a quite as it every has been. Could it have been the belt inverting? Not sure but awfully glad the chatter has disappeared for now.

Over 40 hours of the TT running and it is still as quiet as it ever has been, with stethoscope near the front of the arm board you can hear what I think is the AS Idler wheel running around the inner rim of the platter, near the tonearm it is virtually silent. No chatter what so ever, was it the belt inverting, the new G5 ceramic BB or combination of? I'll never know but it sure is nice to have this table run with no issues. I just focus on the beautiful music it makes. The more I listen to it the more I appreciate it and its qualities, My SME 30 never had this drive.

FYI, if anyone is interested I have a almost new Audio Silente main beating endcap, with 6mm AS G5 ceramic bearing, 3 thrust pads and once gasket available for sale for $40 not including shipping which can be under $5 with USPS first class with tracking. I moved to the woodsong endcap and no longer need the AS version. I used it for about 6 weeks before the switch. It is way better then the stock Thoren's endcap that's for sure.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII