I never really liked a turbo car or all wheel drive until I got to drive a friends Subaru Forester at a few race events. Genuine 450hp at all 4 wheels makes for an amazingly fun ride.

I have seen a few Tesla’s at the track. They are fast but often can’t charge the batteries quickly enough between sessions.

I have seen a few Tesla’s at the track. They are fast but often can’t charge the batteries quickly enough between sessions.

Well I've finished my review of the 400mL Floureon ultrasonic cleaner.

It is completely worthless for cleaning car parts. The cavitation action of the "ultrasonic" cleaner is so weak that I cannot even get the dirt buildup out of the pintle caps of my fuel injectors even with the fuel injectors resting the pintle caps directly onto the base of the ultrasonic cleaner tank where the transducer is located.

I suspect that DIY cleaning of fuel injectors is actually a fools errand and I will be sending my fuel injectors off for professional cleaning.

I don't recommend that anybody else do it themselves because:

1) You need a powerful 2L or 3L ultrasonic cleaner that will stick around after you're done with it. $69.99

2) You don't have access to the professional cleaning solutions which are used in cleaning fuel injectors, which is half of the battle when it comes to cleaning fuel injectors. $$

3) You need to do before and after flow rate tests on fuel injectors to confirm that you have indeed cleaned the inside of the fuel injector, this is not possible at home without yet another piece of equipment that you must build yourself. All of this equipment does take up a LOT of room. $$$

4) You need to buy an EM276 fuel injector pulse generator. $42.88

Total cost is well over $120.

Also. I just got a few quotes for fuel injector cleaning for six fuel injectors:

Bursons: $350

My local mechanic: $120

I will be going the route of my regular mechanic to get these cleaned and probably using this ultrasonic cleaner for some other minor tasks.

As an example, I've attached some pictures showing before and after pictures and after a simple prick cleaning with a needle. All pictures are the same fuel injector.

First pic is before ultrasonic cleaning.

Second pic is after ultrasonic cleaning for 15 minutes.

Third pic is after a prick cleaning and after the ultrasonic cleaning.

Needless to say this ultrasonic cleaner didn't even remove the mound of dirt located in a hole of the pintle cap, only a prick cleaning did the job.

It is completely worthless for cleaning car parts. The cavitation action of the "ultrasonic" cleaner is so weak that I cannot even get the dirt buildup out of the pintle caps of my fuel injectors even with the fuel injectors resting the pintle caps directly onto the base of the ultrasonic cleaner tank where the transducer is located.

I suspect that DIY cleaning of fuel injectors is actually a fools errand and I will be sending my fuel injectors off for professional cleaning.

I don't recommend that anybody else do it themselves because:

1) You need a powerful 2L or 3L ultrasonic cleaner that will stick around after you're done with it. $69.99

2) You don't have access to the professional cleaning solutions which are used in cleaning fuel injectors, which is half of the battle when it comes to cleaning fuel injectors. $$

3) You need to do before and after flow rate tests on fuel injectors to confirm that you have indeed cleaned the inside of the fuel injector, this is not possible at home without yet another piece of equipment that you must build yourself. All of this equipment does take up a LOT of room. $$$

4) You need to buy an EM276 fuel injector pulse generator. $42.88

Total cost is well over $120.

Also. I just got a few quotes for fuel injector cleaning for six fuel injectors:

Bursons: $350

My local mechanic: $120

I will be going the route of my regular mechanic to get these cleaned and probably using this ultrasonic cleaner for some other minor tasks.

As an example, I've attached some pictures showing before and after pictures and after a simple prick cleaning with a needle. All pictures are the same fuel injector.

First pic is before ultrasonic cleaning.

Second pic is after ultrasonic cleaning for 15 minutes.

Third pic is after a prick cleaning and after the ultrasonic cleaning.

Needless to say this ultrasonic cleaner didn't even remove the mound of dirt located in a hole of the pintle cap, only a prick cleaning did the job.

Attachments

Last edited:

Putin's new batmobile... wonder what kind of audio system goes into it?

That is a damn good question.

YouTube

From that video it has a significant touchscreen entertainment system. At the front of the vehicle for the driver the instrument cluster is made up of two split LCD panels and then there are a further set of two larger panels over on the passengers side with one of them in the very center.

With one in the center console in the rear limo section, with obvious icons showing in the poor quality photo.

One of them looks like it might be for GPS navigation, no doubt using the russian gps system as a primary source for signal.

We probably have a good idea of who made the car, but as for the car audio entertainment system, not entirely sure, its silicon might be Chinese. As for the speakers, who knows, might be locally made.

As far as speculation goes I think it would be a safe bet that the entertainment system is purely in-house and designed and manufactured by the Russian military. I say this because I highly doubt that the GPS system on that land yaught is anything but military, so they would want the rest of the system to be military too. And there is lots of communication equipment onboard according to wiki. All of that would have to work together.

New Russian Luxury Limo Spied Testing Ahead Of 2018 Debut

Presidential state car (Russia - Wikipedia)

NAMI (automotive institute - Wikipedia)

NAMI is who developed and built the car.

Last edited:

Any issues with oil starvation in the corners?.....The new civic has no oil pressure gauge but if it senses low oil pressure it goes into "limp mode" .

On old style V8 engines the first sign of oil starvation was rattling hydraulic lifters (if so equipped). Hard cornering would allow the oil pickup to suck a vortex stream of air like a bathtub drain. This didn't show much drop on the gauge if it wasn't bad, but the air turned some of the oil to a froth which wound up accumulating in the lifters several seconds after the turns. Often the rattling wasn't heard due to the exhaust of a full throttled V8 in the straight that followed the turn. A deep sump oil pan or a full on remote sump / scavenger system were the usual cures. Most Hondas that I have seen use a mechanical non adjustable valve train that's noisy anyway so this may not be noticed. Note. I haven't raced anything in 20 years or so, so I'm not up on current tech.

Generally, I like to boost HP/TRQ on engines with either turbo, supercharger or Nitrous.

My only nitrous experience was blowing up a lawnmower engine with what was left in the NOS bottle I pulled out of the 1973 Dodge Challenger I had bought. Whoever built that car had no clue. Time slips found in the glove box showed 1/4 mile times in the mid 14's. With 440 cubic inches and NOS, they should have been low 12's or faster if the track allowed it (no roll bar or cage). A bone stock 440 in that car without NOS will do mid 13's.

In the mid 80's I built a ugly looking turbo 2.2L FWD 1982 Dodge Charger (a 2 door Omni). With a turbo engine from a 1984 Daytona, advice and several kilodollars worth of parts from Carroll Shelby I made it fast, and handle well enough to surprise some $$$ cars. This was before the FWD "sport compact" craze started and subsequently died.

The process took several rebuilds of the engine and transaxle before I got the power and reliability right. O-ringing the block was needed to contain the boost! Turbo II internals were used to allow 7200 RPM. Bracing the transaxle case was needed to prevent blown bearings due to case flex, and Carroll made me a set of half shafts that "couldn't be broken" (Daytona shafts cut to Charger length, $650).

I installed the brakes and suspension components from a Charger GLHS that had been rolled in an autocross race. My friend stuck the GLHS engine in his OMNI GLH. My car was faster, but he often beat me in races.

My Charger went mid to high 13's at the 1/4 mile drags with a full exhaust, and low 13's if I removed the cat, running an open down pipe after the turbo. I was about 50 / 50 W/L against the 5.0 L Mustangs of the day. The difference was driver skill and luck. My FWD car was unpredictable traction wise, and a win required a precise 1-2 shift. I needed to be over 7000 RPM to keep pulling in second, but the Shelby imposed rev limiter killed the fun at 7200. This was 80's 8 bit ECU tech running at 4 MHz, so the rev limiter was an abrupt fuel cut with hysteresis to about 6600 before fuel injection was restored. There was some hit or miss there too. The 1/4 mile was done in 4 gears (tall tires), but with the right tires (205 VR 55 14) the car could sometimes touch the 7200 RPM rev limiter in 5th, a calculated 154 MPH. The Speedo only went to a Reganized 85 MPH.

I also ran it in the SCCA solo autocross events (AKA parking lot grand prix) in the 80's and 90's. Unfortunately it had to run in a modified class, so it was not competitive in its class, but I had loads of fun and smoked a lot of $$$$ cars.

SCCA autocross was a timed single car (or widely spaced cars) on the track running against the clock. Car to car racing was not allowed. The tracks were created by setting up cones in large parking lots. Handling was paramount and maximum speeds were usually below 40 MPH. I could run some of the smaller courses entirely in second gear after the initial launch.

There were also a few non SCCA events where speeds got high, but racing was still one car against the clock. A Miami car club held autocross events at the 1/4 mile dragstrip, starting with a sprint down the track followed by an abrupt U-turn and a cone course set up down the strip's return lane. I could hit about 75 MPH (top of 3rd gear) before slowing to make that U-turn which was assisted by a yank of the hand brake and a screaming clutch pop in second gear. I turned in faster times than most of the field in this event. A friend tried my technique in a RWD V8 Chevy Monza resulting in a crash.

There were some events held on abandoned road course tracks from the 70's but most of these tracks were in serious disrepair limiting speeds. One was on old airport runways, and I actually wasn't fast enough for that one. New (80's) Vettes, turbo Supras and RX7's were king there.

Last edited:

One crack or hit with a rock and its done for and leaking all over the ground.

And one properly sized bolt covered in JB weld screwed in that hole along with a serious coating of the whole area in JB weld fixed that leak. Volvo wanted $300 for a new pan and it would require some serious disassembly to change it. The car ran for several years, after that repair, and was still fine when I sold it.

Cast aluminum does not flex like stamped steel. It is usually an integral part of the block "system" and all modeled up on a computer when the engine is designed.

Modern engine designs benefit from computer design in many ways. Vibration is minimized by careful examination of the fundamental and harmonic modes of all moving parts. The oil pan and often the valve cover are parts of the "tuned assembly." A 4 cylinder inline auto engine is worse case vibration wise, since all piston motion stops and reverses on every revolution. At least one piston is always moving on every other engine design.

The first large step function improvement in ICE efficiency came when we learned to model air flow. The second when when we could model flame front propagation. These two are the major reasons we now have 4 cylinder engines that make more power than 60's era V8's. Direct injection and vibration control were the results of all this computer power being thrown at the ICE.

In the 50's and 60's all V8 engines used the same firing order, 18436572, although Ford numbered the cylinders differently so their published sequence was different. In the mid 80's Ford took their venerable 302 CID V8, added a roller camshaft and other mods for more power, then renamed the engine the 5.0. Several old Mustang enthusiasts dressed these new engines up in "old clothes" (accessories, manifolds, carbs....) and passed them off as 289's to fool the competition at the drag strip. Ford had a vibration problem in the 302 and its relatives that had always been there but became a problem with the power increase, so the old firing order was changed. Thst's why you could identify an 80's 5.0 Mustang from its exhaust sound.

I believe most modern V8's from all car companies have since changed their firing order.

I've measured the ignition leads on my toyota v6 and the longest ignition lead at approx 1m was 12k ohms! I've measured another ignition lead too, the one coming from the coil to the distributor center pins, the old one measured at 6.32k ohm and the new one measured at 408 ohms or 0.40k ohm. A significant difference. I suspect that the old ignition leads have increased in resistance over time, they are as old as the car is, dated 1997.

I've also removed the number 6 spark plug (from the front furthest right cylinder nearest to the battery.) and inspected it, there is a bit of carbon buildup on the spark plug despite them being almost brand new. After watching this video: YouTube I think its being caused by either a set of worn ignition leads or worn ignition coil or both.

I've already bought new ignition leads and I've inspected them for build quality, Eagle Australia appears to have done a good job in regards to build quality. There is sufficient coverage of the spark plugs when inserted into the boots to prevent any sort of arcing and the insertion of the spark plug into the spark plug tube is sufficiently tight that excellent pulling of the top of the boot is made against the top of the tappet cover to prevent water ingress into the spark plug tubes.

The male plugs when inserted in the distributor cap do provide a sufficient amount of length to make contact however I would have preffered that they were the exact OEM length, they are slightly shorter at 1mm or 2mm shorter, But its not significant and I doubt it will make much if any difference to the performance of the leads.

I've found that they should provide a good replacement/substitute for the OEM leads which I am replacing.

I've also removed the number 6 spark plug (from the front furthest right cylinder nearest to the battery.) and inspected it, there is a bit of carbon buildup on the spark plug despite them being almost brand new. After watching this video: YouTube I think its being caused by either a set of worn ignition leads or worn ignition coil or both.

I've already bought new ignition leads and I've inspected them for build quality, Eagle Australia appears to have done a good job in regards to build quality. There is sufficient coverage of the spark plugs when inserted into the boots to prevent any sort of arcing and the insertion of the spark plug into the spark plug tube is sufficiently tight that excellent pulling of the top of the boot is made against the top of the tappet cover to prevent water ingress into the spark plug tubes.

The male plugs when inserted in the distributor cap do provide a sufficient amount of length to make contact however I would have preffered that they were the exact OEM length, they are slightly shorter at 1mm or 2mm shorter, But its not significant and I doubt it will make much if any difference to the performance of the leads.

I've found that they should provide a good replacement/substitute for the OEM leads which I am replacing.

Attachments

-

031-diyaudio.jpg127.1 KB · Views: 27

031-diyaudio.jpg127.1 KB · Views: 27 -

030-diyaudio.jpg143.9 KB · Views: 30

030-diyaudio.jpg143.9 KB · Views: 30 -

029-diyaudio.jpg133.8 KB · Views: 30

029-diyaudio.jpg133.8 KB · Views: 30 -

028-diyaudio.jpg134.9 KB · Views: 32

028-diyaudio.jpg134.9 KB · Views: 32 -

027-diyaudio.jpg136.3 KB · Views: 35

027-diyaudio.jpg136.3 KB · Views: 35 -

026-diyaudio.jpg156.2 KB · Views: 33

026-diyaudio.jpg156.2 KB · Views: 33 -

025-diyaudio.jpg166.3 KB · Views: 35

025-diyaudio.jpg166.3 KB · Views: 35 -

024-diyaudio.jpg166.6 KB · Views: 34

024-diyaudio.jpg166.6 KB · Views: 34 -

023-diyaudio.jpg162 KB · Views: 74

023-diyaudio.jpg162 KB · Views: 74

Last edited:

I also dynamatted the entire floorpan underneath the rear passengers seats. It did have factory soundproofing in place but I felt it was inadequate and decided to add my own.

It has contributed a large amount of overall sound deadening to the car, whenever I slam shut my drivers side door it no longer reverberates underneath the car anymore, most of the remaining sound is coming from the drivers side door now instead of the underneath of the car.

Strange as it sounds but I think the floorpan underneath the rear passengers seat was being an outlet for a majority of the sound coming from whenever a door is slammed shut.

Well worth it. Especially if I ever drive across rocky road, adding noise dampening material to this area will cut down greatly on the contribution of road noise from dirt and rocky roads, which in australia can be hundreds of km's in length.

It has contributed a large amount of overall sound deadening to the car, whenever I slam shut my drivers side door it no longer reverberates underneath the car anymore, most of the remaining sound is coming from the drivers side door now instead of the underneath of the car.

Strange as it sounds but I think the floorpan underneath the rear passengers seat was being an outlet for a majority of the sound coming from whenever a door is slammed shut.

Well worth it. Especially if I ever drive across rocky road, adding noise dampening material to this area will cut down greatly on the contribution of road noise from dirt and rocky roads, which in australia can be hundreds of km's in length.

Attachments

Last edited:

A lot of the always-broke VW guys swear that adhesive roofing insulation (quick roof) is every bit as good as dyna mat or boom mat. I don't like the idea of smelling roofing tar as the stuff ages though. When I finally get around to painting my car I was planning on putting some dyna mat down in a few place, mostly on the roof under the headliner, in the doors, and on the inside rear luggage compartment/firewall area.

If you add dynamat to any car then just do the floor pan and maybe the doors if you need more sound dampening and nowhere else.

Add it to the floorpans then check it to see if you like the results, then add it to the doors.

That way your center of gravity stays as low as possible. This stuff is very heavy, a whole car dynamatted is about as heavy as an extra spare steel wheel/tyre in the boot.

I ended up removing as much as I could off the rear parcel shelf, mainly because it won't do much good being there as the entire area is structurally sound and there are very little large pieces of sheet steel which aren't braced with welds and additional layers of structural bracing.

Basically only put dynamat in areas where there are large unbraced pieces of flat sheet steel and nowhere else. Otherwise you are just adding more weight for nothing.

I'm going to be leaving the dynamat on the floorpan beneath the seats as that is considered a large flat piece of sheet steel that is unbraced anywhere.

I'm also probably going to skip covering/lining the boot in dynamat, this stuff is heavy as stated previously, if you can add as little as possible of it to your car then that is a good thing.

Add it to the floorpans then check it to see if you like the results, then add it to the doors.

That way your center of gravity stays as low as possible. This stuff is very heavy, a whole car dynamatted is about as heavy as an extra spare steel wheel/tyre in the boot.

I ended up removing as much as I could off the rear parcel shelf, mainly because it won't do much good being there as the entire area is structurally sound and there are very little large pieces of sheet steel which aren't braced with welds and additional layers of structural bracing.

Basically only put dynamat in areas where there are large unbraced pieces of flat sheet steel and nowhere else. Otherwise you are just adding more weight for nothing.

I'm going to be leaving the dynamat on the floorpan beneath the seats as that is considered a large flat piece of sheet steel that is unbraced anywhere.

I'm also probably going to skip covering/lining the boot in dynamat, this stuff is heavy as stated previously, if you can add as little as possible of it to your car then that is a good thing.

Last edited:

I don't really know, but heat transfer may be part of the reason? I don't imagine weight would be a factor as aluminum sumps tend to be a lot thicker than pressed steel ones!

Tony.

I would agree.

Pics from 60's-80's Alfa Romeo 2-liter 4-cyl. 7 quarts of oil in a large, flat, finned pan were definitely employed to keep oil temp down.

As far as cast aluminum durability goes, mine has survived 43 years.

Attachments

Good grief check out the outputs of these Alfa engines:

Australian specs for Alfa Romeo Giulia lineup announced | PerformanceDrive

Alfa Romeo Giulia (952) - Wikipedia

Australian specs for Alfa Romeo Giulia lineup announced | PerformanceDrive

2.0-litre turbocharged four-cylinder engine (147kW/330Nm)

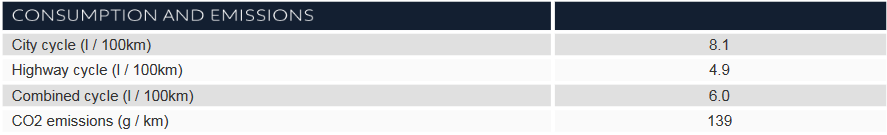

206kW/400Nm 2.0-litre turbocharged four-cylinder offered in the Giulia Veloce. With a 0-100km/h sprint of 5.8 seconds, it manages a fairly economical 6.1L/100km combined cycle.

The Quadrifoglio’s 2.9-litre twin-turbocharged V6 produces 375kW/600Nm, taking it from 0-100km/h in just 3.9 seconds, and on to a top speed of 307km/h.

Alfa Romeo Giulia (952) - Wikipedia

Last edited:

Good grief check out the outputs of these Alfa engines:

They've been building hot rods for a long time.

Blown dual-cam aluminum straight 8 from 1930 (see pics below):

Alfa 8C2300 having fun

Attachments

Last edited:

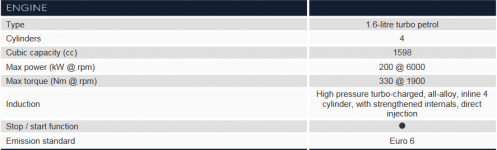

I'm more concerned about its power and torque curves wintermute. If the majority of the power comes out of the engine at only the high end and the engine remains at <100hp below 4000 rpm then what is the point. And what is the point of stating that it has 300> nm of torque when all of that torque is at the top end...

- Home

- Member Areas

- The Lounge

- The car thread