I have been reading many threads here but am still confused whether or not I should apply damping to the enclosure I am planning to build:

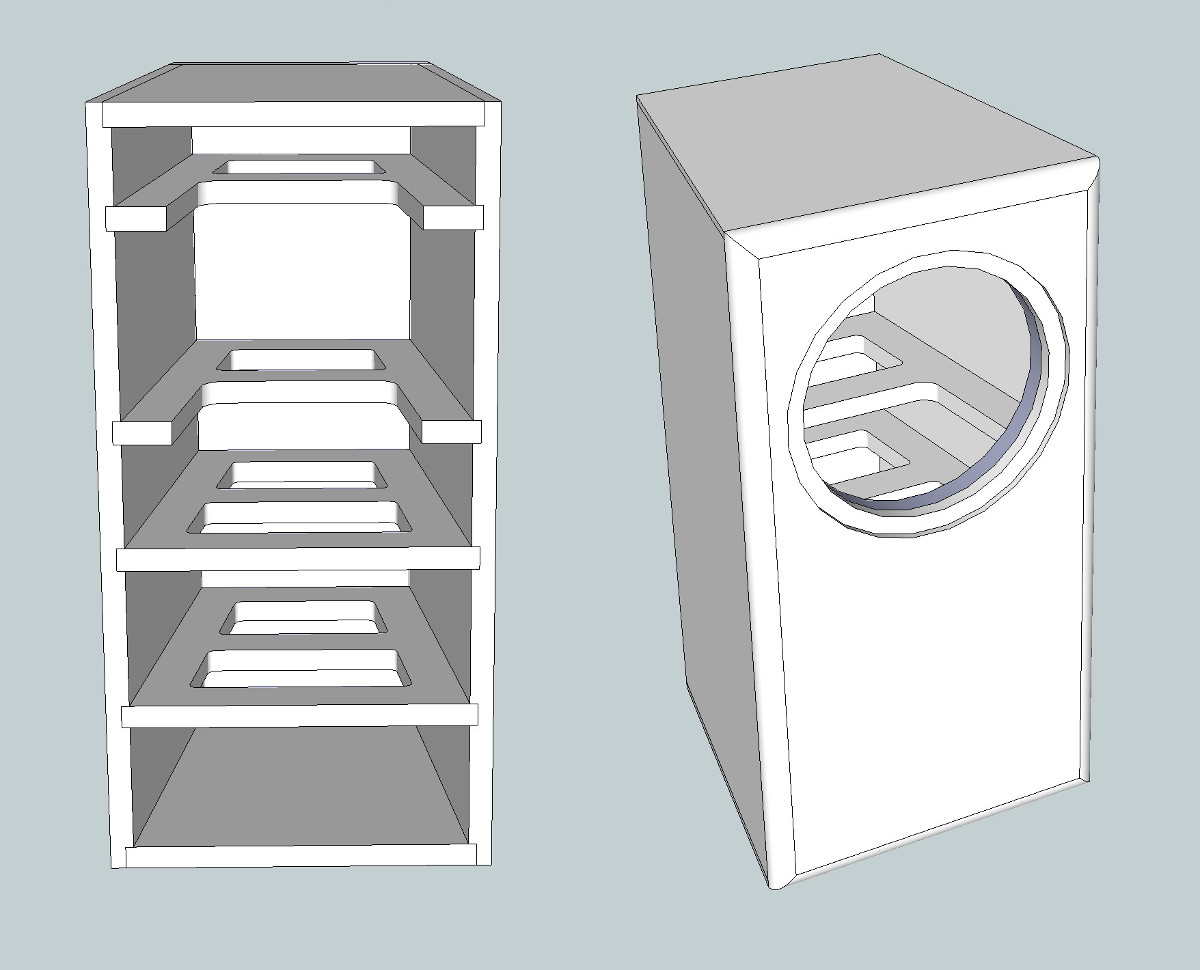

This is for a coaxial driver (Tannoy DC 2528), with a crossover at 1.5 kHz.

The enclosure is supposed to be sealed and filled with polyfill, inner volume is about 32.5 liters.

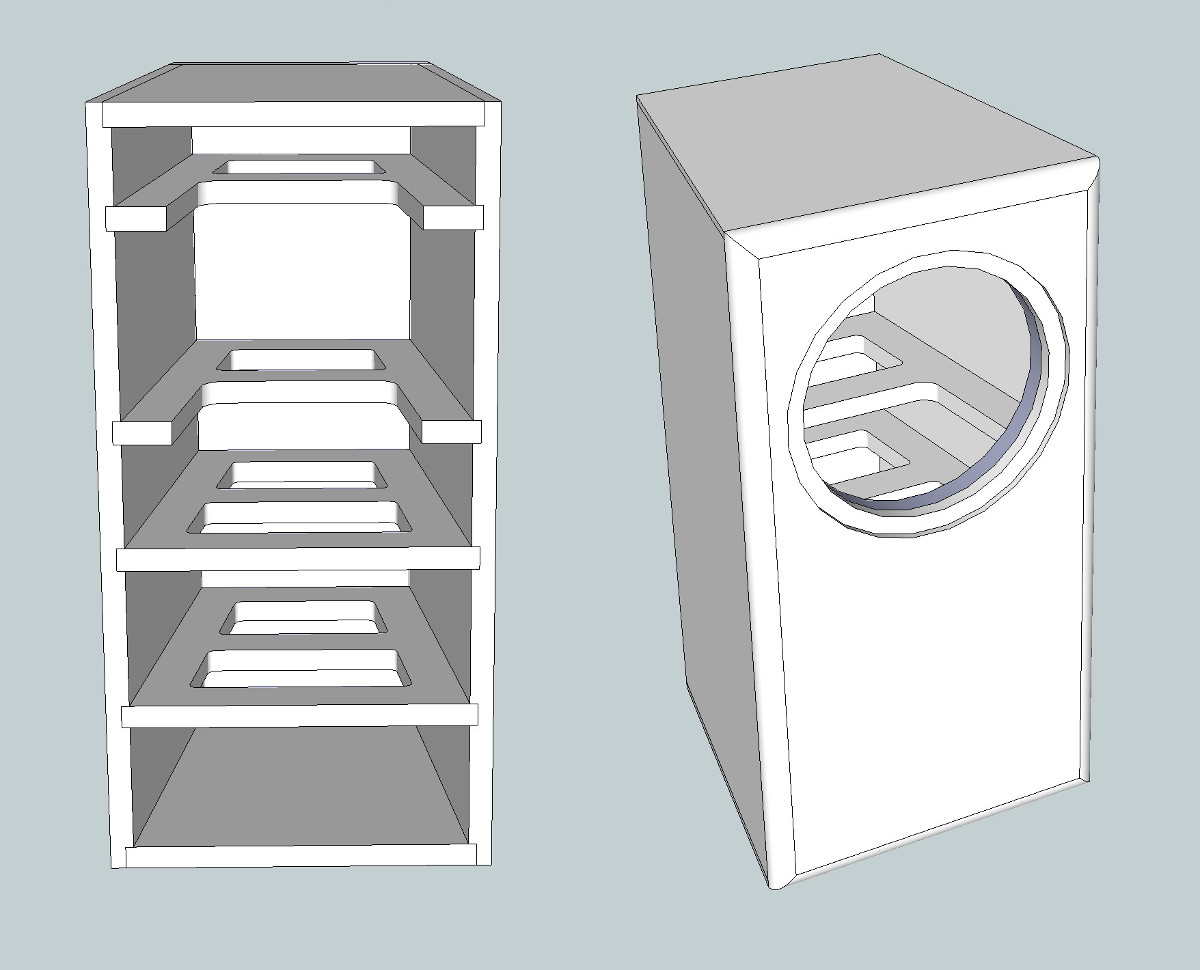

Braces are irregularly spaced. All material is 3/4" Baltic Birch, plus a "Veneer" that is actually made of 1/4" thick hardwood panels. The front "Veneer" however will be 3/4" thick hard wood, with a 3/4" round-over all around.

I understand that the bracing will raise the "Q".

I thought about using some vinyl sheet flooring pieces that I have to glue to the internal sides to add damping. But this would again lower the "Q" as far as I understand, and hence I wonder if that would even be a good idea.

What's better, to end up with a higher Q with bracing only, or a braced and stiff cabinet that also is damped? In particular for the use of a coaxial driver, that plays up to 1.5 kHz before the compression driver kicks in?

This is for a coaxial driver (Tannoy DC 2528), with a crossover at 1.5 kHz.

The enclosure is supposed to be sealed and filled with polyfill, inner volume is about 32.5 liters.

Braces are irregularly spaced. All material is 3/4" Baltic Birch, plus a "Veneer" that is actually made of 1/4" thick hardwood panels. The front "Veneer" however will be 3/4" thick hard wood, with a 3/4" round-over all around.

I understand that the bracing will raise the "Q".

I thought about using some vinyl sheet flooring pieces that I have to glue to the internal sides to add damping. But this would again lower the "Q" as far as I understand, and hence I wonder if that would even be a good idea.

What's better, to end up with a higher Q with bracing only, or a braced and stiff cabinet that also is damped? In particular for the use of a coaxial driver, that plays up to 1.5 kHz before the compression driver kicks in?

So, taking space away raises the Q, making the space act like a larger space lowers it.

Interestingly, adding loose to medium packed fiber fill (fiberglass, wool, etc.) actually makes the volume behave larger, so it lowers the Q. It's not really a big deal as too low a Q can be compensated by moving the speaker closer to the walls. I would build your cabinet as stiff as you can, and measure and "feel" your way around it with your hand while playing. Any areas that you can feel unusually high amounts of vibration should be damped. I like the multi-layer Sonic Barrier for this. Also lowers the Q somewhat.

More important IMHO is removing secondary resonances from the panels, minimizing surface area contact with floor or furniture and minimizing movement of the cabinet from the forces the woofer exerts, potentially rocking the entire cabinet back and forth while playing.

All of this however is subject to trial, measurement, and correction. That's your best way to proceed, as opposed to overthinking getting the Q "exactly right" as it's never "exactly right."

That's your best way to proceed, as opposed to overthinking getting the Q "exactly right" as it's never "exactly right."

Interestingly, adding loose to medium packed fiber fill (fiberglass, wool, etc.) actually makes the volume behave larger, so it lowers the Q. It's not really a big deal as too low a Q can be compensated by moving the speaker closer to the walls. I would build your cabinet as stiff as you can, and measure and "feel" your way around it with your hand while playing. Any areas that you can feel unusually high amounts of vibration should be damped. I like the multi-layer Sonic Barrier for this. Also lowers the Q somewhat.

More important IMHO is removing secondary resonances from the panels, minimizing surface area contact with floor or furniture and minimizing movement of the cabinet from the forces the woofer exerts, potentially rocking the entire cabinet back and forth while playing.

All of this however is subject to trial, measurement, and correction.

Thanks for these suggestions.So, taking space away raises the Q, making the space act like a larger space lowers it.

Interestingly, adding loose to medium packed fiber fill (fiberglass, wool, etc.) actually makes the volume behave larger, so it lowers the Q. It's not really a big deal as too low a Q can be compensated by moving the speaker closer to the walls. I would build your cabinet as stiff as you can, and measure and "feel" your way around it with your hand while playing. Any areas that you can feel unusually high amounts of vibration should be damped. I like the multi-layer Sonic Barrier for this. Also lowers the Q somewhat.

More important IMHO is removing secondary resonances from the panels, minimizing surface area contact with floor or furniture and minimizing movement of the cabinet from the forces the woofer exerts, potentially rocking the entire cabinet back and forth while playing.

All of this however is subject to trial, measurement, and correction.That's your best way to proceed, as opposed to overthinking getting the Q "exactly right" as it's never "exactly right."

The thing is, that the speakers will sit on top of my (quite large) desktop, which is "cornered" by walls and a large cabinet.

That is also why I decided to build a sealed enclosure rather than a BR, since the corner placement (and room) should raise the bass response quite a bit. Which is also why my current speakers sound very muddy...

I suppose building the enclosure without damping, and testing it then, would be the right approach. It's just that I wanted to permanently glue down the front, and only make the front baffle (the hardwood panel) removable... thus it would be difficult to get into the box later on

.

.That was the plan; if you look closely at the baffle in the image, you can see a "double" front baffle.

The idea was to reinforce the front, but also to provide more meat for mounting the driver (it has quite a thick flange).

I guess I could cut a couple of "access holes" into the first baffle, so that I can reach in there and add damping if necessary.

The idea was to reinforce the front, but also to provide more meat for mounting the driver (it has quite a thick flange).

I guess I could cut a couple of "access holes" into the first baffle, so that I can reach in there and add damping if necessary.

There are (at least) two Q factors to consider.

One is the Q of the driver/enclosure volume resonance, which is influenced by the stuffing of the enclosure volume. More stuffing (until it is compacted to absurd levels) lowers the Q.

The other is the Q of the panel resonances, which is influenced by the material properties of the enclosure walls and the bracing. More bracing raises the Q.

A high Q resonance rings horribly once excited, but on the other hand it takes more effort to excite it, both in terms of accuracy of frequency and number of repeated cycles at the frequency of interest.

A low Q resonance looks more benign in a frequency response plot but is "always there" when actually playing music through the thing.

Proper use of stuffing in the enclosure also helps towards reducing the amount of sound bouncing back towards (and through) the driver cone.

One is the Q of the driver/enclosure volume resonance, which is influenced by the stuffing of the enclosure volume. More stuffing (until it is compacted to absurd levels) lowers the Q.

The other is the Q of the panel resonances, which is influenced by the material properties of the enclosure walls and the bracing. More bracing raises the Q.

A high Q resonance rings horribly once excited, but on the other hand it takes more effort to excite it, both in terms of accuracy of frequency and number of repeated cycles at the frequency of interest.

A low Q resonance looks more benign in a frequency response plot but is "always there" when actually playing music through the thing.

Proper use of stuffing in the enclosure also helps towards reducing the amount of sound bouncing back towards (and through) the driver cone.

drtebi,

in the Harwood paper "Factors in the design of loudspeaker cabinets"

there is a test of panel resonance performed on a cabinet made of 18mm

panels with and without damping sheets (2 layers of Mutacell with adhesive)

and the difference was small, while the difference of a version with 9 mm

thick plywood panels was considerably greater. The conclusion is that for

the same effect, one would have to add additional layers of damping sheets

to arrive at the same result as with thin cabinet panels.

I am confident you won't have any problems with cabinet vibrations

that you have braced good enough, just damp the air resonances with stuffing.

in the Harwood paper "Factors in the design of loudspeaker cabinets"

there is a test of panel resonance performed on a cabinet made of 18mm

panels with and without damping sheets (2 layers of Mutacell with adhesive)

and the difference was small, while the difference of a version with 9 mm

thick plywood panels was considerably greater. The conclusion is that for

the same effect, one would have to add additional layers of damping sheets

to arrive at the same result as with thin cabinet panels.

I am confident you won't have any problems with cabinet vibrations

that you have braced good enough, just damp the air resonances with stuffing.

I think you have been given some slightly misleading information concerning cabinet damping. If, for example, the drive cone resonates then the resonance is at the level of the music and the business about low Q resonances being more intrusive than high Q ones generally holds. This is not the case for cabinet resonances which are below the level of the music and the objective is to push them down below the threshold where they can be heard. If you damp a high Q cabinet resonance you can lower the peak level of cabinet resonance by tens of dB. If you have a driven high Q cabinet resonance and the music stops the resonance continues. You do not want high Q cabinet resonances.I have been reading many threads here but am still confused whether or not I should apply damping to the enclosure I am planning to build:

[...]

What's better, to end up with a higher Q with bracing only, or a braced and stiff cabinet that also is damped? In particular for the use of a coaxial driver, that plays up to 1.5 kHz before the compression driver kicks in?

In your case you have a single cabinet and a single driver vibrating the cabinet and so you do not have the option to push the resonances out of the operating range of individual drivers. You will have cabinet resonances in the operating range and the objective is how to reduce them. Stiffness and mass do not reduce the level of resonances because at the resonance their forces are equal and opposite and cancel. The only thing that reduces resonances is effective damping although the stiffness and mass can change the resonant frequencies and the "base level" the resonances rise above.

In your case constrained layer damping would probably be the most effective reasonably viable approach. For a bit of enlightenment and encouragement concerning the effects of stiffness and damping on a real commercial cabinet have a look at the relevant section and Figures 9 and 10 here.

Your internal stiffening looks both overdone and not particularly effective. Most of the low frequency modes of a cabinet involve all the panels moving together and this is best opposed by stiffening all 3 directions and not just 1 or 2. If you pushed the top of your current cabinet side-to-side, back-to-front or twisted how effective are your panels at resisting the motion?

Thanks for your advice. According to the Unibox calculation I did I am getting a total Q of 0.61 with "minimal stuffing" already... so I probably shouldn't overdo the stuffing...drtebi,

in the Harwood paper "Factors in the design of loudspeaker cabinets"

there is a test of panel resonance performed on a cabinet made of 18mm

panels with and without damping sheets (2 layers of Mutacell with adhesive)

and the difference was small, while the difference of a version with 9 mm

thick plywood panels was considerably greater. The conclusion is that for

the same effect, one would have to add additional layers of damping sheets

to arrive at the same result as with thin cabinet panels.

I am confident you won't have any problems with cabinet vibrations

that you have braced good enough, just damp the air resonances with stuffing.

Thanks for your help. I will have to take a closer look at the document you linked to and try to understand it...I think you have been given some slightly misleading information concerning cabinet damping. If, for example, the drive cone resonates then the resonance is at the level of the music and the business about low Q resonances being more intrusive than high Q ones generally holds. This is not the case for cabinet resonances which are below the level of the music and the objective is to push them down below the threshold where they can be heard. If you damp a high Q cabinet resonance you can lower the peak level of cabinet resonance by tens of dB. If you have a driven high Q cabinet resonance and the music stops the resonance continues. You do not want high Q cabinet resonances.

In your case you have a single cabinet and a single driver vibrating the cabinet and so you do not have the option to push the resonances out of the operating range of individual drivers. You will have cabinet resonances in the operating range and the objective is how to reduce them. Stiffness and mass do not reduce the level of resonances because at the resonance their forces are equal and opposite and cancel. The only thing that reduces resonances is effective damping although the stiffness and mass can change the resonant frequencies and the "base level" the resonances rise above.

In your case constrained layer damping would probably be the most effective reasonably viable approach. For a bit of enlightenment and encouragement concerning the effects of stiffness and damping on a real commercial cabinet have a look at the relevant section and Figures 9 and 10 here.

Your internal stiffening looks both overdone and not particularly effective. Most of the low frequency modes of a cabinet involve all the panels moving together and this is best opposed by stiffening all 3 directions and not just 1 or 2. If you pushed the top of your current cabinet side-to-side, back-to-front or twisted how effective are your panels at resisting the motion?

Could you give me an example of where to put braces to be more effective? I don't exactly follow your "movements"...

Assuming the bracing is there to stiffen the cabinet and you want to use the minimum amount of material (DIYers don't always want what one might expect) then you need to add bracing to stiffen up the least stiff way the cabinet can deform. The mode shape of the lowest resonance will show you the easiest way to deform the cabinet and it is usually reasonably clear how to add struts to prevent the motion. In practice looking at the lowest few modes can help spot what is common.Could you give me an example of where to put braces to be more effective? I don't exactly follow your "movements"...

In your position I would start looking at perhaps 2:1 constrained layer damping for the box and then adding a few struts in all 3 directions and glued where they cross. And/or perhaps diagonal structs from panel to panel depending on the lowest mode shapes. Here is a commercial example (scroll down to the sectioned picture). Of course if you do not have the mode shapes one needs some intuition about how the cabinet will deform easily which was what I was trying to get at in the earlier post.

That was my idea. The braces in the drawing are all less than 6" apart. What I haven't implemented are braces between top and bottom.You need lateral bracing that connects the top, bottom, and braces together. As a rule of thumb, braces no more than 6" apart will result in a pretty inert cabinet.

As for stuffing, line the walls with denim insulation and lightly stuff.

I agree on the stuffing. Light stuffing is what I will try first. I already have some denim insulation at hand.

As mentioned in my previous post, I will change the design to implement more bracing that will attach to all three directions.Assuming the bracing is there to stiffen the cabinet and you want to use the minimum amount of material (DIYers don't always want what one might expect) then you need to add bracing to stiffen up the least stiff way the cabinet can deform. The mode shape of the lowest resonance will show you the easiest way to deform the cabinet and it is usually reasonably clear how to add struts to prevent the motion. In practice looking at the lowest few modes can help spot what is common.

In your position I would start looking at perhaps 2:1 constrained layer damping for the box and then adding a few struts in all 3 directions and glued where they cross. And/or perhaps diagonal structs from panel to panel depending on the lowest mode shapes. Here is a commercial example (scroll down to the sectioned picture). Of course if you do not have the mode shapes one needs some intuition about how the cabinet will deform easily which was what I was trying to get at in the earlier post.

I am not sure what you mean when you talk about "finding the mode shapes".

Regarding CLD, I was thinking about gluing vinyl panels (about 1/8" thick) to all interior panels, with a glue that stays flexible. That in a sense should be at least have a similar effect as true CLD panels.

What puzzles me a bit is, that there are apparently different opinions on what the right approach to bracing and damping is. I was under the impression that a good amount of damping, e.g. at least every 6", and at irregular distances, should make the box rigid enough to prevent it from resonating at low frequencies.

If I now add vinyl panels with flexible glue, it should provide a damping effect that would prevent the now higher resonance frequencies from "ringing".

Since I have to be concerned about frequencies up to 1.5 kHz, it would seem necessary to use some damping.

My theory is that the bracing brings up the cabinet resonance frequencies, and the damping prevents the panels from ringing. At least to the amount of inaudibility.

When the cabinet is vibrated by the driver the resulting motion of the cabinet can be viewed as a set of modes or resonances. Each mode is independent of the other modes and whatever energy is put into that mode by the driver will remain in that mode and not shift to other modes while the deformation is linear. Nearly all the energy put into the cabinet by the driver will go into the lowest few modes. By considering just a small number of the lowest frequency modes one at a time this will encompass most of the motion of the cabinet and so that is what an engineer will tend to do when considering the vibration of a structure like a speaker cabinet.I am not sure what you mean when you talk about "finding the mode shapes".

The mode shape is how a particular mode deforms the cabinet. I has a brief google to find an animation of the first few mode shapes of a cabinet or box but, surprisingly, failed to find any. Anyone?

No. CLD is effective damping and what you describe is ineffective damping. CLD creates high shear in an appropriate material (e.g. fairly stiff "rubbery" material) to generate a large damping force to oppose the motion creating the shear. What you describe is extensional damping which stretches rather than shears the material and this tends to produce a much weaker damping force. The oft quoted BBC approach to damping cabinets uses this approach but it involves thin walls, large wall motions and thick damping material.Regarding CLD, I was thinking about gluing vinyl panels (about 1/8" thick) to all interior panels, with a glue that stays flexible. That in a sense should be at least have a similar effect as true CLD panels.

Engineers will all say the same thing because they are following the science but non-engineers tend to come up with all sorts incorrect notions. Making a cabinet stiffer by, for example, doubling the thickness of the walls will shift the resonances higher in frequency but will not generally reduce the size (e.g. the figures in that KEF paper) and may even make the vibration easier to perceive. What reduces the size of the resonances is effective damping (e.g. the figures in that KEF paper). A lot of DIYers seem to want to build big thick heavy cabinets and it probably does no harm except possibly to their back and pockets.What puzzles me a bit is, that there are apparently different opinions on what the right approach to bracing and damping is. I was under the impression that a good amount of damping, e.g. at least every 6", and at irregular distances, should make the box rigid enough to prevent it from resonating at low frequencies.

It is likely to have a small beneficial effect but no where near that of properly implemented CLD. An approach and material that works well for the large walls of a room or the thin metal panels of cars and computer cases is unlikely to be optimum for the tiny vibrations of relatively stiff and heavy speaker cabinet walls.If I now add vinyl panels with flexible glue, it should provide a damping effect that would prevent the now higher resonance frequencies from "ringing".

Spectacle frames as shown in post1 are a very good way of bracing big panels.

It helps if the sizes of the panels either side of a bracing frame are different. It also helps if the frame is not parallel to the main surfaces.

It's the irregular shapes that prevent a dominant frequency of resonance.

I adopted a Q much lower than Butterworth after advice from this Forum. In hindsight that was very good advice. Your Q=0.6 sounds good.

BTW, as explained by a couple of Members, the Q of the cone and box volume is a different analysis from the resonant Q of a vibrating panel. Allow the cone to vibrate, that is the noise you want. Try to attenuate the panel vibrations.

It helps if the sizes of the panels either side of a bracing frame are different. It also helps if the frame is not parallel to the main surfaces.

It's the irregular shapes that prevent a dominant frequency of resonance.

I adopted a Q much lower than Butterworth after advice from this Forum. In hindsight that was very good advice. Your Q=0.6 sounds good.

BTW, as explained by a couple of Members, the Q of the cone and box volume is a different analysis from the resonant Q of a vibrating panel. Allow the cone to vibrate, that is the noise you want. Try to attenuate the panel vibrations.

Last edited:

When looking at the KEF LS50 white paper, it seems that they have used "specifically designed damping panels" all around the cabinet interior walls, and braces that support all three sides. The only significant difference I see in their design is that the braces itself are "CLD braces". The damping layer in the CLD brace is described asEngineers will all say the same thing because they are following the science but non-engineers tend to come up with all sorts incorrect notions. Making a cabinet stiffer by, for example, doubling the thickness of the walls will shift the resonances higher in frequency but will not generally reduce the size (e.g. the figures in that KEF paper) and may even make the vibration easier to perceive. What reduces the size of the resonances is effective damping (e.g. the figures in that KEF paper). A lot of DIYers seem to want to build big thick heavy cabinets and it probably does no harm except possibly to their back and pockets.

[...] material with high mechanical resistance and low stiffness[...]

Obviously they have spent a great amount of time and effort in figuring out all the details, but, besides the CLD braces, I don't really see a significant difference to any other bracing and damping methods.

They do not disclose what the ""specifically designed damping panels" are made off, but I wouldn't be surprised if it is some kind of bitumen, or mass loaded vinyl.

You seem to agree with most of my ideas, which is a reliefSpectacle frames as shown in post1 are a very good way of bracing big panels.

It helps if the sizes of the panels either side of a bracing frame are different. It also helps if the frame is not parallel to the main surfaces.

It's the irregular shapes that prevent a dominant frequency of resonance.

I adopted a Q much lower than Butterworth after advice from this Forum. In hindsight that was very good advice. Your Q=0.6 sounds good.

BTW, as explained by a couple of Members, the Q of the cone and box volume is a different analysis from the resonant Q of a vibrating panel. Allow the cone to vibrate, that is the noise you want. Try to attenuate the panel vibrations.

What would you suggest for panel damping?

Hi drtebi,

without reading the whole thread, just two (extended) remarks from my side:

>> An enclosure, that is operated widerange (that is not a subwoofer) up to the upper bass and/or midrange, cannot be made "low radiaton" (due to structure born sound) by making ist just "more stiff".

Thus making the walls (only from stiff material like wood, mdf ?) just "more thick" and apply "more bracing" is counterproductive in a wideband enclosure, as the coincidence frequency lowers (by doing so), leading to even more unwanted radiation from the cabinet in upper bass and midrange (*).

A subwoofer cabinet is different, as you can "push" the resonances of the cabinet's walls to higher frequencies fairly above the bandwitdh of the subwoofer cabinet just by

- making the walls more thick

- bracing and also by

- keeping the subwoofer "compact"

Subwoofers typically have an upper frequency limit of 70 ... 100Hz: Here you can "win the race" for a cabinet having low unwanted sound radiation just by "constructing for stiffness", while in a cabinet used wideband you practically cannot.

>> You will need damping material in the "body of air" enclosed by the cabinet anyhow, to avoid modes (resonances) of that "body of air" (space) in the enclosure, which may also occur near/above crossover frequency of a subwoofer.

Also a cabinet can be made considerably smaller, when filled with damping material, as the speed of sound lowers and the "effective acoustical volume" grows. That can save e.g. 20% of geometrical volume inside the box.

__________

(*) Overly thick walls made from "stiffness only" materials and overly stiff bracing are not "good" in a cabinet for "wideband purpose", but are "very silly". Nevertheless often tried even today, even in the industry ...

In an enclosure for wideband purpose (e.g. housing the woofer of a 2-way speaker) also mass and damping components (in the cabinet's walls, possibly made from composite materials) are important.

See also:

"FACTORS IN THE DESIGN OF LOUDSPEAKER CABINETS"

H.D. Harwood, B.Sc. R. Mathews, BBC 1977

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

without reading the whole thread, just two (extended) remarks from my side:

>> An enclosure, that is operated widerange (that is not a subwoofer) up to the upper bass and/or midrange, cannot be made "low radiaton" (due to structure born sound) by making ist just "more stiff".

Thus making the walls (only from stiff material like wood, mdf ?) just "more thick" and apply "more bracing" is counterproductive in a wideband enclosure, as the coincidence frequency lowers (by doing so), leading to even more unwanted radiation from the cabinet in upper bass and midrange (*).

A subwoofer cabinet is different, as you can "push" the resonances of the cabinet's walls to higher frequencies fairly above the bandwitdh of the subwoofer cabinet just by

- making the walls more thick

- bracing and also by

- keeping the subwoofer "compact"

Subwoofers typically have an upper frequency limit of 70 ... 100Hz: Here you can "win the race" for a cabinet having low unwanted sound radiation just by "constructing for stiffness", while in a cabinet used wideband you practically cannot.

>> You will need damping material in the "body of air" enclosed by the cabinet anyhow, to avoid modes (resonances) of that "body of air" (space) in the enclosure, which may also occur near/above crossover frequency of a subwoofer.

Also a cabinet can be made considerably smaller, when filled with damping material, as the speed of sound lowers and the "effective acoustical volume" grows. That can save e.g. 20% of geometrical volume inside the box.

__________

(*) Overly thick walls made from "stiffness only" materials and overly stiff bracing are not "good" in a cabinet for "wideband purpose", but are "very silly". Nevertheless often tried even today, even in the industry ...

In an enclosure for wideband purpose (e.g. housing the woofer of a 2-way speaker) also mass and damping components (in the cabinet's walls, possibly made from composite materials) are important.

See also:

"FACTORS IN THE DESIGN OF LOUDSPEAKER CABINETS"

H.D. Harwood, B.Sc. R. Mathews, BBC 1977

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

Last edited:

The only significant difference I see in their design is that the braces itself are "CLD braces".

At first this what it seems to me too, but as Andy already pointed they have choosen where to brace using a lot of simulation and analysis (FEA) to determine where to put braces to limit first panel mode, then find an adapted materiel to effectively create a cld brace to perform both tasks simultaneously.

I don't know if the panel material for the box are cld (in fact i doubt about it) but the cross-brace are linked to panel through a damping material creating a cld (Fig 21 in the LS50 white parper clearly show this) and this is a significant difference to other bracing/cld technique as far as i know.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- To damp or not to damp sealed enclosure, still confused!