Am am at the planning stage and parts gathering for an amp build.

2A3 pp amp to be specific.

I have some older OPT's that might work.

Is there any experience here I can draw on?

I have a pair of Dynaco ST70 transformers and a pair of Fisher 500C transformers.

Have also been looking at Lindahl, James, Hammond or ???

Thanks

Ed

2A3 pp amp to be specific.

I have some older OPT's that might work.

Is there any experience here I can draw on?

I have a pair of Dynaco ST70 transformers and a pair of Fisher 500C transformers.

Have also been looking at Lindahl, James, Hammond or ???

Thanks

Ed

Food for thought.

The way it was explained to me by a very well known transformer company.

Many of the old transformers are very good. However, I was advised that their

design life is coming to an end. The enamel coated wire is slowly deteriorating

on it own.

I would imagine this affects the power transformer windings more than the output

transformer windings. Nothing might give you a problem. According to a local

wire manufacturer, they hadn't been able to get the old enameled wire for some time.

You are probably fine with yours. Have fun.

Sync

The way it was explained to me by a very well known transformer company.

Many of the old transformers are very good. However, I was advised that their

design life is coming to an end. The enamel coated wire is slowly deteriorating

on it own.

I would imagine this affects the power transformer windings more than the output

transformer windings. Nothing might give you a problem. According to a local

wire manufacturer, they hadn't been able to get the old enameled wire for some time.

You are probably fine with yours. Have fun.

Sync

Food for thought.

The way it was explained to me by a very well known transformer company.

Many of the old transformers are very good. However, I was advised that their

design life is coming to an end. The enamel coated wire is slowly deteriorating

on it own.

I would imagine this affects the power transformer windings more than the output

transformer windings.

It's not quite the same situation because they never get hot, but I've restored a few radios from the early 20's and the original interstage and RF transformers were in fine shape at 90+ years. If they haven't got wet or been used as a nest area by mice (very common unfortunately) they seem to have a pretty long service life.

With due respect, that sounds like advertising cr*p by a well know transformer company who lives by making very expensive "authentic repros" of cherished old transformers used in famous Musical Instrument amplifiers in the 50`s and 60`s.explained to me by a very well known transformer company.

Many of the old transformers are very good. However, I was advised that their

design life is coming to an end. The enamel coated wire is slowly deteriorating

on it own.

Since those old transformers keep reliably working as when they were made half a century ago (and will continue ticking like the first day for many more years) and are "the real thing", some seed of doubt must be introduced inside Musician´s minds so they will buy the modern "clones".

Advertising 101: "now convince me on WHY should I buy YOUR product instead of the older, established one"

Won´t mention brands but their initials are very similar to a popular chocolate brand:

Morgan Jones commented that he "has recently seen a number of chokes and transformers whose aberrant behavior can only be explained by core material that has deteriorated."

Sowter offered this little bit of wisdom back in 1987: "When a transformer has been subjected to large values of direct current or has been in the vicinity of a strong permanent magnet, such as too near a loudspeaker, it will assume a polarized state or become magnetized. Fortunately this seldom has a permanently harmful effect on the core material, although in its magnetized state it will have higher distortion and reduced audio output. The process of demagnetizing is quite simple and consists of applying to one winding an alternating current (for example, at 50 Hz) of value appreciably exceeding that required for saturation. This current should then be reduced smoothly and gradually over a period of time, such as one-half to one minute. In its most elementary form this can be done with a suitable variable resistance, such as a potential divider capable of handling the large current. It is important to spend the bulk of the time on the low values of demagnetizing force, which should be reduced to absolute zero. Another demagnetizing method is to reverse direct current continuously while reducing its value to zero."

Sowter offered this little bit of wisdom back in 1987: "When a transformer has been subjected to large values of direct current or has been in the vicinity of a strong permanent magnet, such as too near a loudspeaker, it will assume a polarized state or become magnetized. Fortunately this seldom has a permanently harmful effect on the core material, although in its magnetized state it will have higher distortion and reduced audio output. The process of demagnetizing is quite simple and consists of applying to one winding an alternating current (for example, at 50 Hz) of value appreciably exceeding that required for saturation. This current should then be reduced smoothly and gradually over a period of time, such as one-half to one minute. In its most elementary form this can be done with a suitable variable resistance, such as a potential divider capable of handling the large current. It is important to spend the bulk of the time on the low values of demagnetizing force, which should be reduced to absolute zero. Another demagnetizing method is to reverse direct current continuously while reducing its value to zero."

today's opt's if wound using nomex are quite good,

better than yesteryear's kraft paper....

pinholes on the maqnetic wires causes adjacent turns short....

better than yesteryear's kraft paper....

pinholes on the maqnetic wires causes adjacent turns short....

Attachments

I can't imagine the them degrading with age unless as stated above moisture or current abuse.

Well, here's the thing: Salvaged output transformers often come from abused/damaged amplifiers. A failed output tube on one side of a push-pull pair could easily magnetize the core. How would you know? I was curious enough to poke around for more information and found these comments by Bill Whitlock (Jensen Transformers) in the Handbook for Sound Engineers (3rd Ed):

"Some subtle problems are created when transformer cores and/or their shield cans become magnetized. Generally, cores become magnetized by having dc flow in a winding, even for a fraction of a second. It can leave the core weakly magnetized. Steel cores, because of their wider hysteresis loops, are generally the most prone to such magnetization. The only way to know if the core has some permanent magnetization is to perform distortion measurements. A transformer with an un-magnetized core will exhibit nearly pure third harmonic distortion, with virtually no even order harmonic distortion while magnetized ones will show significant even order distortion, possibly with 2nd harmonic even exceeding 3rd. A test signal at a level about 30 or 40 dB below rated maximum operating level at 20 or 30 Hz is typically the most revealing because it maximizes the contribution of hysteresis distortion."

"Demagnetizing of low level transformers can generally be done with any audio generator having a continuously variable output It may take a booster of some sort to get enough level for output transformers (be sure there’s no dc offset at its output!). The idea is to drive the transformer deeply into saturation (5% THD or more) and slowly bring the level down to zero. Saturation will, of course, be easiest at a very low frequency. How much level it takes will depend on the transformer. If you’re lucky, the level required may not be hazardous to the surrounding electronics and the de-magnetizing can be accomplished without disconnecting the transformer. Start with the generator set to 20 Hz and its minimum output level, connect it to the transformer, then slowly (over a period of a few seconds) increase the level into saturation — maintain it for a few seconds — then slowly turn it back down to minimum. For the vast majority of transformers, this process will leave them in a demagnetized state."

I wonder if operating a properly biased amplifier at mega-blast level and then slowly reducing volume over a period of time would be an effective fix for magnetized iron. If so, this could explain some of the persistent burn-in folklore.

In no particular order:What new transformer would you recommend based on someone's experience.

Electra-Print

Transendar

Edcor

MagneQuest

Dynakit Parts

James

Maybe Hammond

First, Sorry for my English)))What new transformer would you recommend based on someone's experience.

Not a no expense spared build but willing to spend reasonable money for a good product.

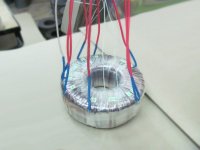

You may say you are kidding me, but many guys from my local forum (country) use toroidal transformers as I do.

Toroidal transformer has many advantages (inc. minimum dissipation field, best overall power of the core) also its price is below $48 for 125W core.

Attachments

However, I was advised that their

design life is coming to an end. The enamel coated wire is slowly deteriorating

on it own.

Have fun.

Sync

There is some truth to the above... The enamel used to coat the wire on transformers built today is much more durable and can take more abuse than the coating used on older (40+ year old) transformers. This is more of a problem in humid climates; the old insulation will have a tendency to "flake" off if it has been exposed to weathering. For the majority of transformers this will never present a problem, like stated by another poster.

Dennis Boyle from Dallas wrote a paper on how to "refurbish" old transformers where humidity or other adverse conditions would no longer have no bad effect on old transformers. Basically he recommended putting the transformer in a small oven and heat it up to around 250 degrees F (IIRC) for several hours and then attach new wires to the ends and re-varnish the whole unit to "weatherize" it. After this, the transformer would be as good as a new one...

Has anybody seen this article he wrote? It would be great if somebody still had a copy to post. I've been looking for a copy of it myself; it was in a word doc format. It was good info.

Last edited:

Basically he recommended putting the transformer in a small oven and heat it up to around 250 degrees F (IIRC) for several hours and then attach new wires to the ends and re-varnish the whole unit to "weatherize" it. After this, the transformer would be as good as a new one...

Has anybody seen this article he wrote? It would be great if somebody still had a copy to post. I've been looking for a copy of it myself; it was in a word doc format. It was good info.

This is known as dipping process: heating the transformer will help to get the varnish as deep as possible into the transformer. It isolates from the outside world but it does not guarantee complete varnishing.

A better process though is vacuum impregnating.

Has anybody seen this article he wrote? It would be great if somebody still had a copy to post. I've been looking for a copy of it myself; it was in a word doc format. It was good info.

Here's one

Attachments

On the subject of core magnetisation... If the transformer is used in push pull then there will be the possibility of hysteresis at the crossover point of the current flow and the residual magnetisation (if present) but what happens in the case of a single ended output stage where there is a constant DC flow in one direction only? There will of course be a polarised magnetic field set up.

SE OTs operate in degraded/magnetized mode all the time. That's why they have to be 3 or 4 times as big, so there will be enough functional flux left to operate. The reduced effective permeability from the air gap does help reduce the severity of the magnetic saturation lockup. So an operational AC signal can "de-magnetize" it easier. (not really de-magnetize it, just operate the residual AC flux)

Whenever AC causes flux changes in magnetic material, the functional flux domains still undergo hysteresis, no difference between P-P and SE, just the reduced permeability makes it less apparent. (the hysteresis related current becomes a small part of the larger primary inductance magnetizing current) Hysteresis is not really the problem anyway, magnetizing current is. Voltage transfer through the OT is not directly effected by either hysteresis or magnetizing current. But the source impedance allows the unwanted magnetizing + hysteresis current to corrupt the signal at the tube. That's why you want the primary inductance to be as large as possible, to reduce the magnetizing + hysteresis current.

Whenever AC causes flux changes in magnetic material, the functional flux domains still undergo hysteresis, no difference between P-P and SE, just the reduced permeability makes it less apparent. (the hysteresis related current becomes a small part of the larger primary inductance magnetizing current) Hysteresis is not really the problem anyway, magnetizing current is. Voltage transfer through the OT is not directly effected by either hysteresis or magnetizing current. But the source impedance allows the unwanted magnetizing + hysteresis current to corrupt the signal at the tube. That's why you want the primary inductance to be as large as possible, to reduce the magnetizing + hysteresis current.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- output transformer new vs vintage iron