If the input resistor is 82k to 100k, then a 1uF cap gives an LF roll off about a decade below the 20Hz start of the Audio band.

A 1uF MKP, or MKT, will cost much less than $11.30

If one retains the 22k for the input resistor to suit BJT LTP, then you are stuck with 4u7F for the decade wider passband.

However if the jFET LTP were adopted, then there is no reason to use the 22k input resistance. Use 82k, or 91k, or 100k.

A 1uF MKP, or MKT, will cost much less than $11.30

If one retains the 22k for the input resistor to suit BJT LTP, then you are stuck with 4u7F for the decade wider passband.

However if the jFET LTP were adopted, then there is no reason to use the 22k input resistance. Use 82k, or 91k, or 100k.

Somehow I never did order (or couldn't find) the relay for the new Symasym BB Rev2 boards. Except for the silkscreen I can't find the full part number or spec. It was left off the BOM and it's not mentioned anywhere in the builder's guide. Just want to confirm this is the correct one before I order. Is it in fact a 24v relay?

Rick

Rick

I have bought cristi289's Symasym TO264 power amplifier (pot and attenuator removed). I believe Rudi built it some time ago. It sounds great.

Are there any upgrades i could make to the amp that members have tried that would make an improvement in sound quality?

Are there any upgrades i could make to the amp that members have tried that would make an improvement in sound quality?

Attachments

Maybe installing some 2sk170 on input ?I have bought cristi289's Symasym TO264 power amplifier (pot and attenuator removed). I believe Rudi built it some time ago. It sounds great.

Are there any upgrades i could make to the amp that members have tried that would make an improvement in sound quality?

Maybe installing some 2sk170 on input ?

Thanks for suggestion. Will do a bit of research

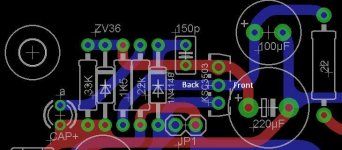

A bit more progress on the project. Completed most of the second board this weekend. Was having second thoughts on the Q80 (KSC3503) and Q81 ( KSA1381) orientation, and had to follow the schematic to make sure. Glad I did, because I had them backwards on the first board.  On those particular plastic TO-126 package it's difficult to know what's the front and back, as there's no distinct markings and the pins are only slightly offset. And I had some trouble with the silkscreen on the PCBs too. But I figured it out.

On those particular plastic TO-126 package it's difficult to know what's the front and back, as there's no distinct markings and the pins are only slightly offset. And I had some trouble with the silkscreen on the PCBs too. But I figured it out.

I'm waiting on the chassis and heat-sinks now, so I can prep them for installation and testing.

I'm waiting on the chassis and heat-sinks now, so I can prep them for installation and testing.

Attachments

Refer to this BoM please:

https://secure.reichelt.de/index.html?&ACTION=20&AWKID=1056168&PROVID=2084

Best regards - Rudi

https://secure.reichelt.de/index.html?&ACTION=20&AWKID=1056168&PROVID=2084

Best regards - Rudi

I agree. In this situation I was clearly blaming the part for not being well marked and the data sheet did not help. It's not always the silkscreen either. I was trying to place some radial electrolytics for another project and neither side was marked with a negative or positive sign! I don't think you should have to resort to the length of the leads to determine proper orientation. They could have been cut for any number of reasons or might be axial leads. And there should be global standards too.Printing the "e" of every transistor on the silk screen would help all Builders.

Even the T092 devices would benefit from the lack of ambiguity.

Last edited:

I used a little transistor testing rig I have to ultimately figure out what the pins were. Then using the schematic, the proper orientation.I habitually test the hFE of every BJT I intend using in an amp assembly.

Using the hFE test facility of a cheap DMM solves your identification issue. It is a non problem.

record your hFE and use it to check base current in your testing of the circuit.

- Home

- Group Buys

- TO-3 SYMASYM