Joel Wesseling,

I like your turntable. Can you start a new thread about your 3R turntable?

In regards to getting a good tonearm, please contact ChrisG139. He is a member here and he has made a lot of different tonearms.

I will start a thread.. Thanks for suggesting it..

I'll look for ChrisG139

Joel

Hi again Ed and thanks for all of your TA details buddy..

The distance between us is a little far but maybe a trade at some point.. Plinth in exchange for a tonearm maybeJust hobby ideas..

Your Dentist skills must be Awesome!

The paint on my table is done by the same guy who applied the Piano finish on all the Energy Veritas speakers.. The table is sprayed but not made into piano finish but Planning to make one without the grooves then he can do piano..

Talk to you later.. Outdoor project is waiting for me..

Keep posting.. Really enjoy it..

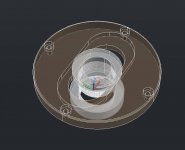

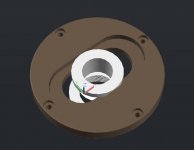

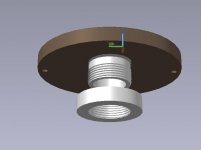

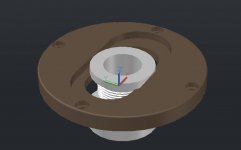

Here is idea I had for arm board for Rb300 threaded style arm mounts.. The center piece is solid and user drill for the arm.. The bottom washer compresses against the main piece..

Joel

i don't know ,what is my draw fail or less?

i don't know ,what is my draw fail or less?

Sorry,Not sure I understand...

I like you drawing better than mine.. No offense taken..

You improved my idea because now we can incorporate screw down arm by keeping center shaft solid material..

Your head shell is really cool.. add required weight in the cup?

Lifter is real nice

More to come..

i have tried drawing.. i add hole screw and my draw must be replacement add rotate 45 degree.

i give head shell a cup for placement "shell weight " pressure cartridge.

weight of the cup: 1.79 gram

weight: i made two , large and small

placement on the cup:

Last edited:

The long arm makes sense..

I'm no expert on arms .. For Plinths I'm going for Mass Damping, just seems to to work best... My Nottingham Hyperspace on 200 pound stand sounds Hyper revealing like CD's .. Ooops, Better than cd's but clear like cd's

.

Heavy plinth give mass damping become more of the best bass and detail.

Your Nottingham hyperspace are very heavyweight,

I'm imagining is certainly a very nice voice with no vibration. It is sure very good and better from cd...

I don't know why i have obsession with along arm. i think this give linier morel than the short arm. But a long arm can give a problems of add mass in pivot , add friction on the bearing, little triger on pivot should be vibration at ended rod ( the longer distance will provide greater amplitude at the end of tonearm).

I'm sorry if my write wrong . My English not good.

Last edited:

Here is consonance painted...low rez photo..

very nice... prefect... super white ..clean... i like ....

i see you tone arm with wooden rod. what ?

have a nice best turn table. it is sure good.

may you share stage what you have done of DIY TT R3

i hope you share all your device.......

Heavy plinth give mass damping become more of the best bass and detail.

Your Nottingham hyperspace are very heavyweight,

I'm imagining is certainly a very nice voice with no vibration. It is sure very good and better from cd...

I don't know why i have obsession with along arm. i think this give linier morel than the short arm. But a long arm can give a problems of add mass in pivot , add friction on the bearing, little triger on pivot should be vibration at ended rod ( the longer distance will provide greater amplitude at the end of tonearm).

I'm sorry if my write wrong . My English not good.

Your english is fine.. Keep up the good work

If a long arm is beneficial, then maybe I could make a plinth with a larger mounting distance.. Maybe the arm could be a separate base..

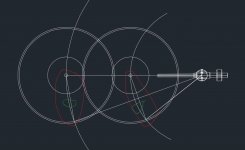

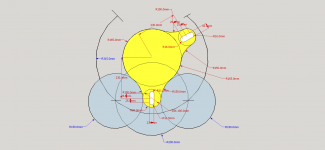

Here is how I made the shape for tangent circles, but I'd like a standard shape to make a cnc template for cutting.. My preference is to have aluminum arm board(s) inserted.. 3R thread, we can discuss all details..

Edit: I use free Google sketchup.. sorry it's a little crude but gets the job done.. I'm ready to download better software, just don't know which one..

Attachments

Last edited:

very nice... prefect... super white ..clean... i like ....

i see you tone arm with wooden rod. what ?

have a nice best turn table. it is sure good.

may you share stage what you have done of DIY TT R3

i hope you share all your device.......

The arm is Cosonance composite..

Many aspects to discuss.. MDF or Hardwood for plinth for one example..

Here is one for Yamaha 3R top and How I veneer the side.

Going to try shellac sprayed.. Hope I don't screw it up

Attachments

3R PLINTH from Joel

Yes, used a long arm need a large plinth , that not efience for placement.

i have done..

your image are enough clear, i see your make that full geometric and extra calculation. you are working by cnc machine , very helpfully thorough and accurate job.such as your plinth 3R is very good.

i like your plinth ergonomic of you arm base.. balance..

hole for armbase flexible for using other TA. why you not fixed ?

yes, sorry i have not knowledge about other TA . i have seen, that the Cosonance tone arm and rod of TA made from composite material. are correct?

first time i see you pic , i look like wood. i'm wrong.

how about sound of that? compare with your SME , i hope not fail

MDF is compact and flat easy to work, and solid hardwood in my opinin better from mdf.

wooden venner is giving the impression of natural.

have a nice day to you

regards

ed

Your english is fine.. Keep up the good work

If a long arm is beneficial, then maybe I could make a plinth with a larger mounting distance.. Maybe the arm could be a separate base..

Here is how I made the shape for tangent circles, but I'd like a standard shape to make a cnc template for cutting.. My preference is to have aluminum arm board(s) inserted.. 3R thread, we can discuss all details..

Edit: I use free Google sketchup.. sorry it's a little crude but gets the job done.. I'm ready to download better software, just don't know which one..

Yes, used a long arm need a large plinth , that not efience for placement.

i have done..

your image are enough clear, i see your make that full geometric and extra calculation. you are working by cnc machine , very helpfully thorough and accurate job.such as your plinth 3R is very good.

i like your plinth ergonomic of you arm base.. balance..

hole for armbase flexible for using other TA. why you not fixed ?

The arm is Cosonance composite..

Many aspects to discuss.. MDF or Hardwood for plinth for one example..

Here is one for Yamaha 3R top and How I veneer the side.

Going to try shellac sprayed.. Hope I don't screw it up

yes, sorry i have not knowledge about other TA . i have seen, that the Cosonance tone arm and rod of TA made from composite material. are correct?

first time i see you pic , i look like wood. i'm wrong.

how about sound of that? compare with your SME , i hope not fail

MDF is compact and flat easy to work, and solid hardwood in my opinin better from mdf.

wooden venner is giving the impression of natural.

have a nice day to you

regards

ed

Last edited:

Thinking about long arm placement..Hmmm, have to play around with drawing..

Do you think fixed arm is better? You could be right.. a simple round aluminum blank is likely inexpensive in quantities..

To be honest I feel my upgraded Rb300 is better than The SME..

I also like simple well made arms like yours and I'm sure better that Rb300..

Cheers.

Do you think fixed arm is better? You could be right.. a simple round aluminum blank is likely inexpensive in quantities..

To be honest I feel my upgraded Rb300 is better than The SME..

I also like simple well made arms like yours and I'm sure better that Rb300..

Cheers.

http://www.diyaudio.com/forums/anal...sion-reclaim-rework-relisten.html#post4328105

Turntable discussion

Turntable discussion

You can use the motor for dumping add a resistor betwen imputs

and by a multimeter select

Dear gumo,

I'm soory to late for quote your posting, because i fear to give a statement and a question. Wrong a question. ..

Can you give me explain about used the motor for dumping add a resistor".

Regards

Ed

Hi Joel,

I am folowing your thread .....

Have a nice day

Ed

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Tonearm from part HD computers, why not..?

![PhotoGrid_1431455122202[1].jpg PhotoGrid_1431455122202[1].jpg](https://www.diyaudio.com/community/data/attachments/453/453337-7739a3ae2440f0b734c59ae5ecaab957.jpg)

![PhotoGrid_1431455516732[1].jpg PhotoGrid_1431455516732[1].jpg](https://www.diyaudio.com/community/data/attachments/453/453344-c250fa9e50a58cf503b4d4c7ff8df32f.jpg)

![PhotoGrid_1431455570205[1].jpg PhotoGrid_1431455570205[1].jpg](https://www.diyaudio.com/community/data/attachments/453/453351-d627f53e0b5da431890022d433f93442.jpg)