Hi!

Thought I'd share my setup. The speakers are driven with the DIY FW F5 amps I built with a lot of help from this forum earlier, along with an Accuphase A-45 and Icepower for bass duty.

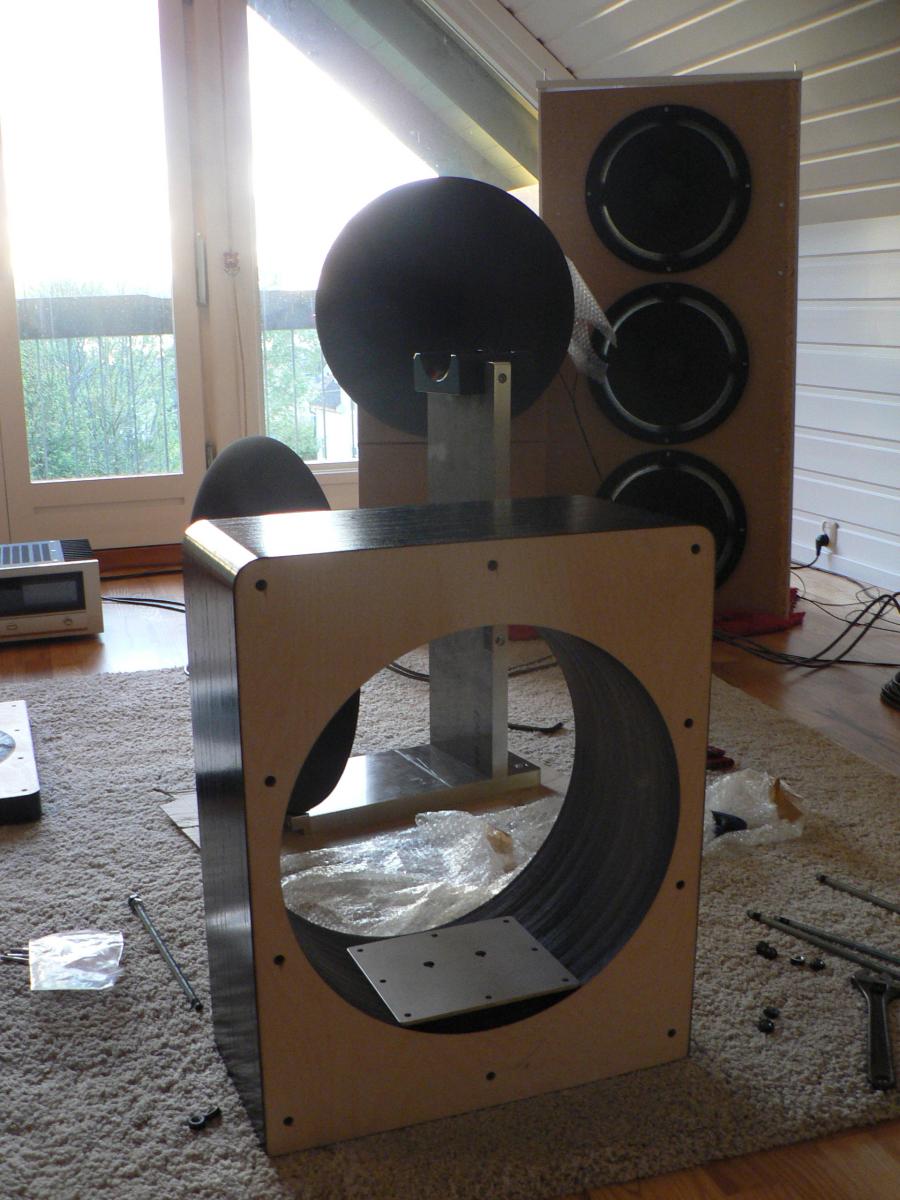

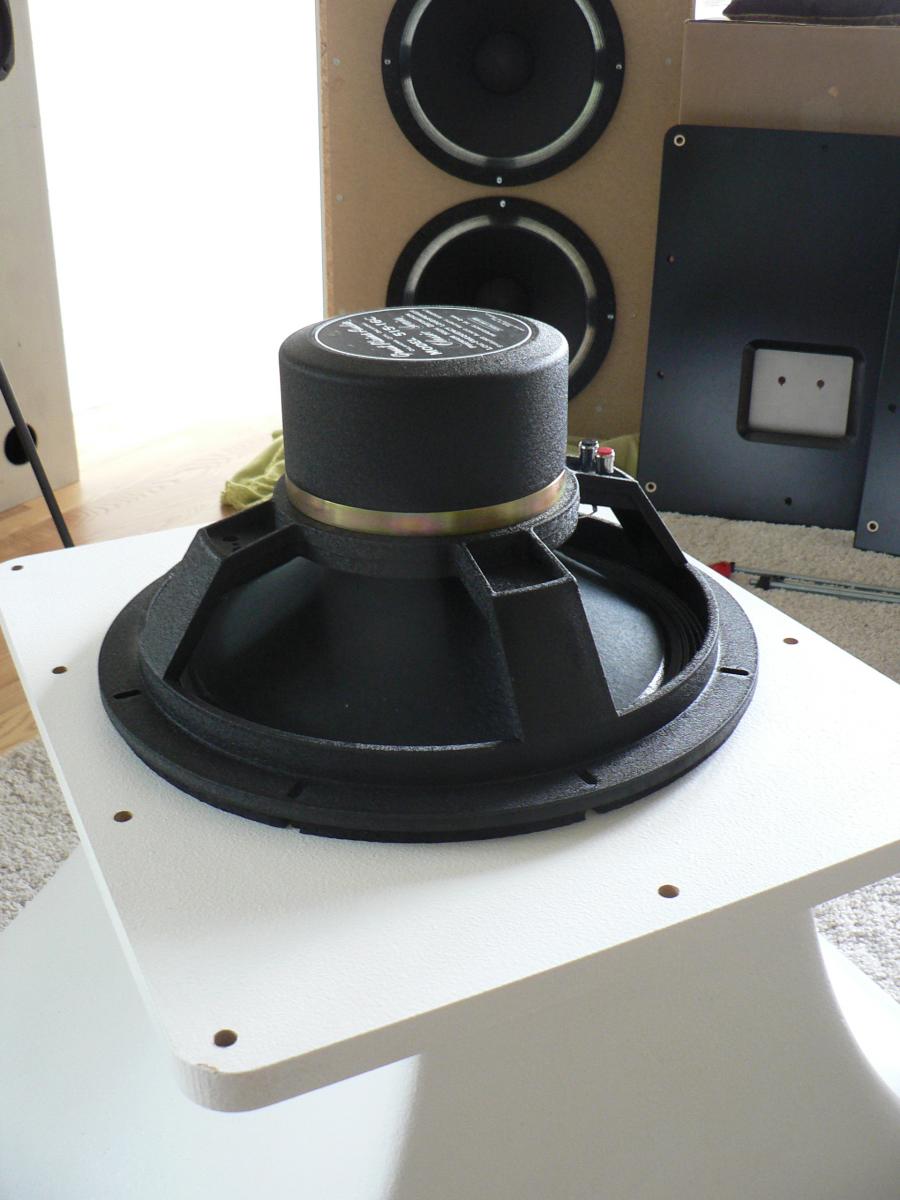

The system has an active crossover, so there are few\no components in the path. Tweeter and midrange is ALE compression drivers, the midbass is GPA 515C. Bass drivers are also GPA 515C in a SLOB configuration with a high compression.

Thought I'd share my setup. The speakers are driven with the DIY FW F5 amps I built with a lot of help from this forum earlier, along with an Accuphase A-45 and Icepower for bass duty.

The system has an active crossover, so there are few\no components in the path. Tweeter and midrange is ALE compression drivers, the midbass is GPA 515C. Bass drivers are also GPA 515C in a SLOB configuration with a high compression.

Hi! Been a while.

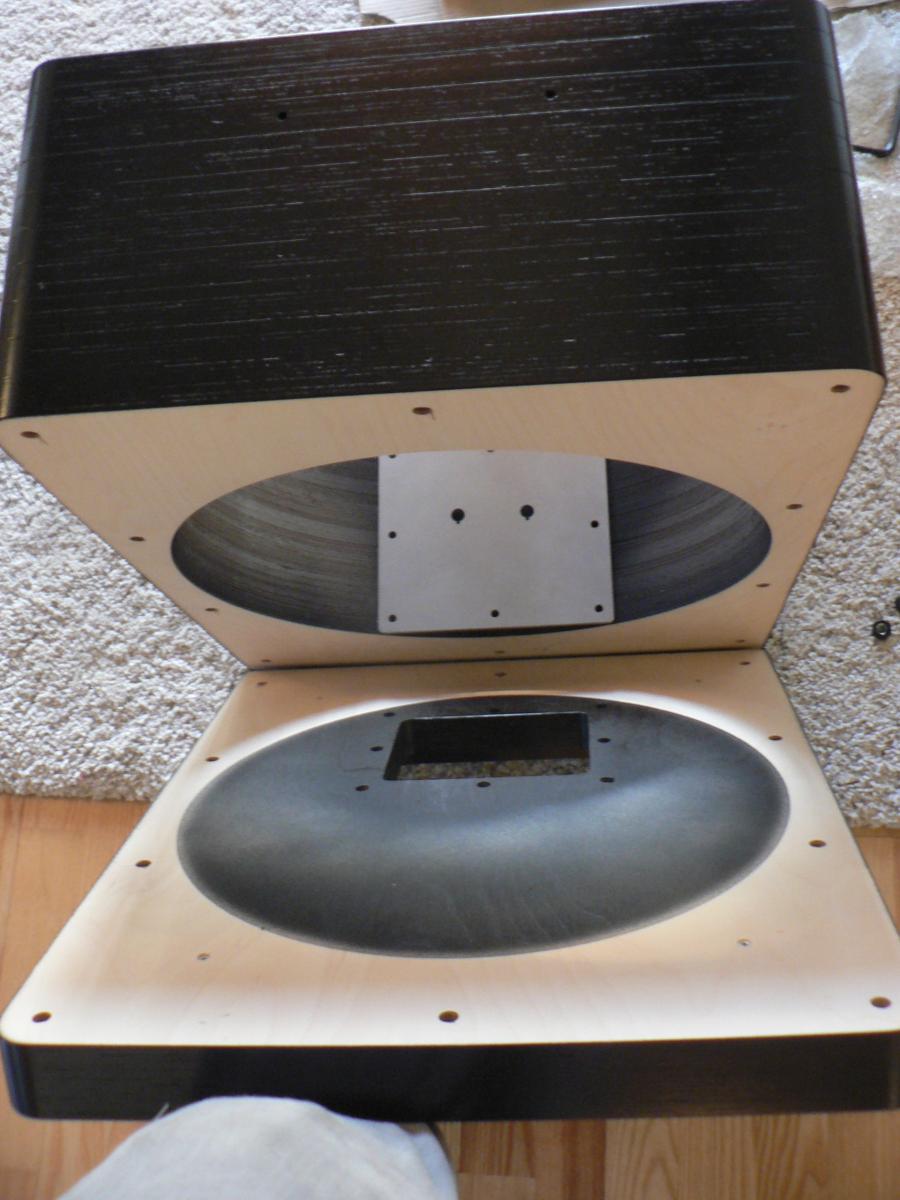

Here are some more pics of the building process:

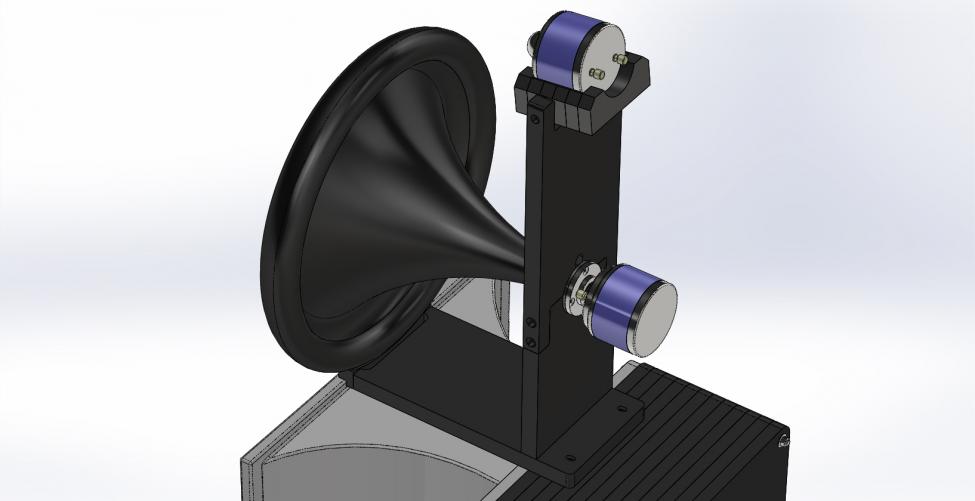

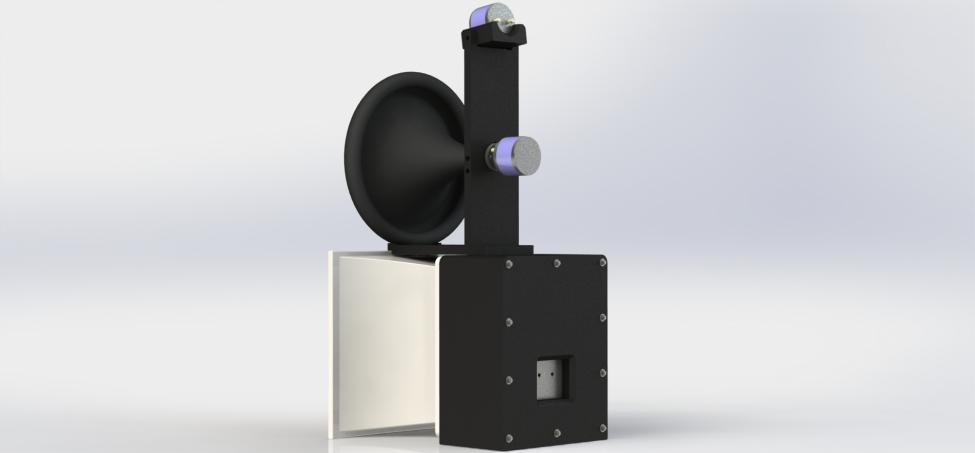

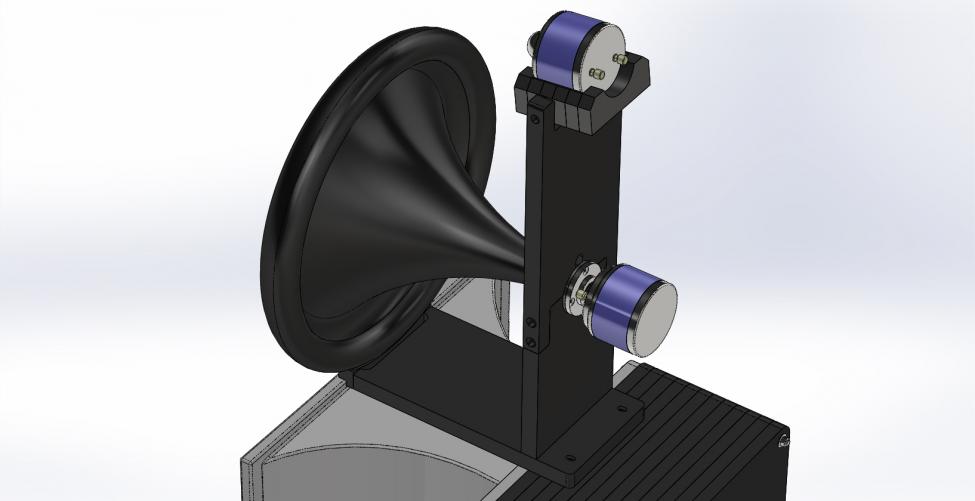

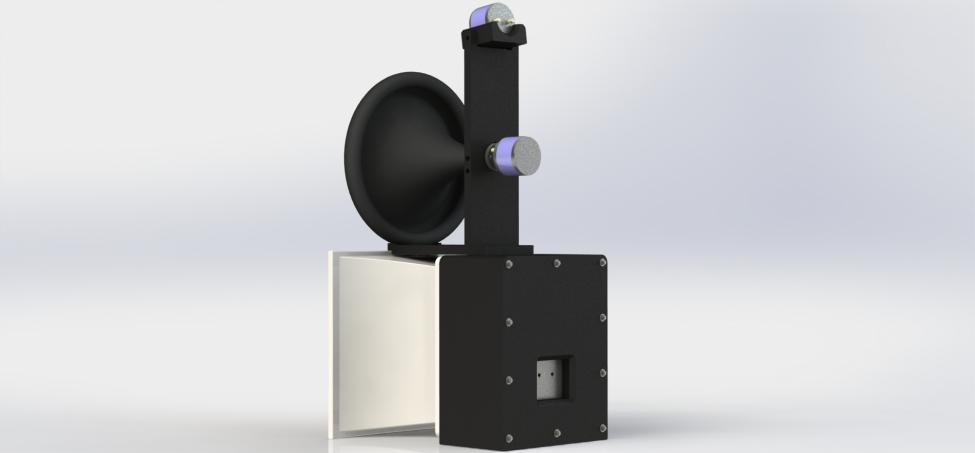

I tried and made a lot of 3D-models of different kinds of holders for the mid and tweeters to fit on top of the J-horn. I ended up with this solution made out of 30mm aluminum, as simple as possible, form-follows-function kind of deal. Easy to produce with as few parts as possible:

A render of the complete 3D assembly started really looking good in my opinion. I had used a lot of time without really being satisfied. This came together in a good fashion I think:

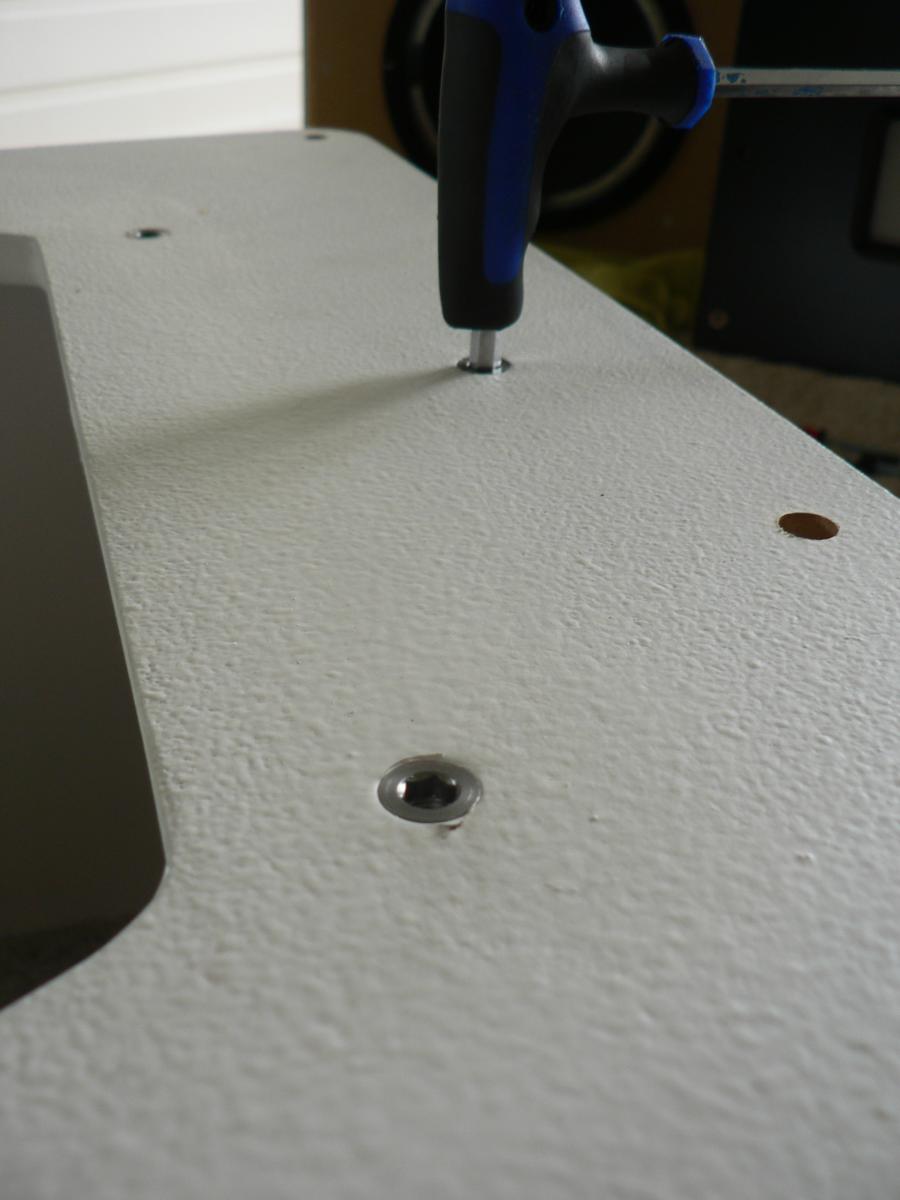

First the parts were cut with a waterjet. I cut all parts with 3mm excess material, since the waterjet cut is a bit rough and does not go through the material perfectly perpendicular. The plan was to CNC these parts to a perfect fit later on.

Here are some more pics of the building process:

I tried and made a lot of 3D-models of different kinds of holders for the mid and tweeters to fit on top of the J-horn. I ended up with this solution made out of 30mm aluminum, as simple as possible, form-follows-function kind of deal. Easy to produce with as few parts as possible:

A render of the complete 3D assembly started really looking good in my opinion. I had used a lot of time without really being satisfied. This came together in a good fashion I think:

First the parts were cut with a waterjet. I cut all parts with 3mm excess material, since the waterjet cut is a bit rough and does not go through the material perfectly perpendicular. The plan was to CNC these parts to a perfect fit later on.

I got the man who built the rear chambers to cnc a drilling template for the J-horn that made the job much easier.

I made room for some foam tape, and also made some small taps that were a tad oversize. They were sanded down to a perfect fit in the horn.

Here placed ans bolted on the horn.

I made room for some foam tape, and also made some small taps that were a tad oversize. They were sanded down to a perfect fit in the horn.

Here placed ans bolted on the horn.

It's also my first DIY build

Not bad for a beginner. Seriously, well done and thanks for sharing.

Little confused about referring to the midbass as a "J Horn". .. which to me implies a horn in the shape of a "J". Or am I just not informed in the art of "horn speak"?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- My DIY Horn setup