You were disputing the claim that damping loss was higher at higher frequencies but David's plots clearly show the cabinet motion is substantially smaller at higher frequencies. Perhaps it isn't due to damping being more effective at higher frequencies but if not what is removing more of the work the driver is putting into those frequencies and/or preventing it from radiating to the far field? If the motion is linear there is no mechanism for the energy to move to other frequencies.Have you estimated the Qs ? That's what i was talking about solely.

Level and audibility is a different kind of fish.

Please be so kind: Estimate the Qs of the lower and the higher resonances.

You will learn something important concerning bending waves and structure born sound:

Just do it.

That is true, mainly becauce excitation is smaller at higher frequencies. It is important to grasp that cabinet walls are providing a filter function which is applied to mechanical exciation.

What you see in most graphs e.g "absolute wall velocity" is not the filter function acccording to constant velocity excitation at the baffle.

So

1) what you see is not what you describe here

2) what you describe is not due to wall stiffness or wall structure at all

You simply run (and are stucked) in a misconception, which leads to those discussions in all audio forums all over the world. This story runs in circles over and over again.

It ends up with the advocators of stiff an thick walls even for wideband cabinets keeping their opinion and finding "graphs and data" supporting their view.

Keep your view of things, i am fine with it, no problem.

You will learn something important concerning bending waves and structure born sound:

Just do it.

andy19191 said:cabinet motion is substantially smaller at higher frequencies.

That is true, mainly becauce excitation is smaller at higher frequencies. It is important to grasp that cabinet walls are providing a filter function which is applied to mechanical exciation.

What you see in most graphs e.g "absolute wall velocity" is not the filter function acccording to constant velocity excitation at the baffle.

So

1) what you see is not what you describe here

2) what you describe is not due to wall stiffness or wall structure at all

You simply run (and are stucked) in a misconception, which leads to those discussions in all audio forums all over the world. This story runs in circles over and over again.

It ends up with the advocators of stiff an thick walls even for wideband cabinets keeping their opinion and finding "graphs and data" supporting their view.

Keep your view of things, i am fine with it, no problem.

Last edited:

wesayso said:before they ever reach the walls to vibrate them,

... this is not the main and not the only mechanism of excitation in a loudspeaker cabinet.

There is direct excitation via driver's basket and baffle.

Your mental picture is based on excitation via the air vibrating in the cabinet solely.

Wrong mechanism supposed as being the major one > wrong conclusion about effective countermeasures.

Damping the cabinet air volume to damp standing (air) waves is still very important. But can usually not be achieved in the upper bass by using thin linings directly at the cabinet walls. You are way off here concerning dimensions and wavelengths under question.

Last edited:

You were disputing the claim that damping loss was higher at higher frequencies but David's plots clearly show the cabinet motion is substantially smaller at higher frequencies. Perhaps it isn't due to damping being more effective at higher frequencies but if not what is removing more of the work the driver is putting into those frequencies and/or preventing it from radiating to the far field? If the motion is linear there is no mechanism for the energy to move to other frequencies.

The Harwood figures show the energy topping out around 2 kHz. This was similar between his thin wall and thick wall examples. This would be a function of his particular setup and is likely just the frequency where the woofer energy starts to fall. The real issue is the lower midrange resonances, most audible around 500 Hz. His stiffer cabinet puts the primary resonances squarely in that range and does nothing to reduce their level. If we try to apply damping to the two cabinets, then it will have less impact on the stiffer, heavier cabinet.

What everybody has trouble with is that it seems so sensible that thicker/stiffer must equate to less overall vibration. In truth, if I push resonances up an Octave I will have less peak to peak vibration. Unfortunately, SPL is more proportional to acceleration and acceleration is not reduced by increasing stiffness.

As to damping effect of materials improving at high frequencies, I have seen no data to support that.

David

@David: I can support your findings.

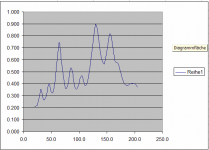

This diagram is proportional to the driving point velocity of a rectangular panel form PP structure, that is fixed at two edges and exited with offset from the middle using an electrodynamic exciter.

PP is a material known for high damping ...

What you can see here is that the Q of lower and higher order modes is about the same. That is a common behaviour with all kinds of materials and also composites: There is no increase in damping with frequency rising.

I made these measurements at a prototype sheet to be applied in a bending wave panel. What you see is modal overlap rising with frequency of course.

In Addition to the diagram i posted some pictures showing, how the corresponding modes looked like ...

The white regions represent node lines of low (or zero) velocity. Node lines are separating zones of opposite phase of motion on that sheet of material.

These are phpotographs of powder, that has been used, to make the nodelines of the vibrational modes visible. Basis method is about 200 Years old and is according to Ernst Chladni.

http://de.wikipedia.org/wiki/Ernst_Florens_Friedrich_Chladni

http://de.wikipedia.org/wiki/Chladnische_Klangfigur

Kind regards

This diagram is proportional to the driving point velocity of a rectangular panel form PP structure, that is fixed at two edges and exited with offset from the middle using an electrodynamic exciter.

PP is a material known for high damping ...

What you can see here is that the Q of lower and higher order modes is about the same. That is a common behaviour with all kinds of materials and also composites: There is no increase in damping with frequency rising.

I made these measurements at a prototype sheet to be applied in a bending wave panel. What you see is modal overlap rising with frequency of course.

In Addition to the diagram i posted some pictures showing, how the corresponding modes looked like ...

The white regions represent node lines of low (or zero) velocity. Node lines are separating zones of opposite phase of motion on that sheet of material.

These are phpotographs of powder, that has been used, to make the nodelines of the vibrational modes visible. Basis method is about 200 Years old and is according to Ernst Chladni.

http://de.wikipedia.org/wiki/Ernst_Florens_Friedrich_Chladni

http://de.wikipedia.org/wiki/Chladnische_Klangfigur

Kind regards

Attachments

-

V_d.PNG13.7 KB · Views: 295

V_d.PNG13.7 KB · Views: 295 -

Membran_1_G_140_Hz.jpg278.2 KB · Views: 38

Membran_1_G_140_Hz.jpg278.2 KB · Views: 38 -

Membran_1_F_115_Hz.jpg260.2 KB · Views: 38

Membran_1_F_115_Hz.jpg260.2 KB · Views: 38 -

Membran_1_E_105_Hz.jpg239.1 KB · Views: 38

Membran_1_E_105_Hz.jpg239.1 KB · Views: 38 -

Membran_1_D_83_Hz.jpg170 KB · Views: 44

Membran_1_D_83_Hz.jpg170 KB · Views: 44 -

Membran_1_C_74_Hz.jpg114 KB · Views: 41

Membran_1_C_74_Hz.jpg114 KB · Views: 41 -

Membran_1_B_56_Hz.jpg136.3 KB · Views: 295

Membran_1_B_56_Hz.jpg136.3 KB · Views: 295 -

Membran_1_A_27_Hz.jpg138.9 KB · Views: 293

Membran_1_A_27_Hz.jpg138.9 KB · Views: 293 -

Membran_1_H_175_Hz.jpg211.3 KB · Views: 40

Membran_1_H_175_Hz.jpg211.3 KB · Views: 40

Last edited:

The Harwood figures show the energy topping out around 2 kHz. This was similar between his thin wall and thick wall examples. This would be a function of his particular setup and is likely just the frequency where the woofer energy starts to fall.

In which case wouldn't the line showing the SPL of the woofer output also fall?

The real issue is the lower midrange resonances, most audible around 500 Hz. His stiffer cabinet puts the primary resonances squarely in that range and does nothing to reduce their level.

If we try to apply damping to the two cabinets, then it will have less impact on the stiffer, heavier cabinet.

Damping appropriate for thin walls, thick walls or just damping?

What everybody has trouble with is that it seems so sensible that thicker/stiffer must equate to less overall vibration. In truth, if I push resonances up an Octave I will have less peak to peak vibration. Unfortunately, SPL is more proportional to acceleration and acceleration is not reduced by increasing stiffness.

I thought you had agreed in your previous post that although true at low frequencies this scaling was not true once the frequency was high enough for a typical cabinet to start resonating?

When a cabinet starts resonating it no longer moves as a simple source and so scalings based on this assumption are unlikely to be useful anyway. For example, as the mode number rises the resonant motion changes from monopolish, to more like dipolish, to quadrupolish, to higher multipolish,... These are increasingly inefficient motions for radiating sound into the far field and so this may be part of the explanation. If the woofer has a thin stamped steel basket it's compliance may be starting to play a role. Plus no doubt other explanations involving and not involving damping.

As to damping effect of materials improving at high frequencies, I have seen no data to support that.

If more efficient damping is not responsible for the lower level of sound radiation from the cabinet at higher frequencies as shown in the plots you posted what is?

In which case wouldn't the line showing the SPL of the woofer output also fall?

Not sure what you mean here.

Damping appropriate for thin walls, thick walls or just damping?

Just damping. Damping appropriate for thick walls is a thicker version of damping for thin walls, which is the main point.

I thought you had agreed in your previous post that although true at low frequencies this scaling was not true once the frequency was high enough for a typical cabinet to start resonating?

SPL will either be proportional to wall acceleration (lower frequencies) or velocity (perhaps, at higher frequencies). It will not be proportional to displacement, so increasing stiffness will not be the simple answer that some expect. Both Harwood and Barlow clearly show equal strength at various resonances even when wall thickness is doubled. That's pretty clear, isn't it?

When a cabinet starts resonating it no longer moves as a simple source and so scalings based on this assumption are unlikely to be useful anyway. For example, as the mode number rises the resonant motion changes from monopolish, to more like dipolish, to quadrupolish, to higher multipolish,... These are increasingly inefficient motions for radiating sound into the far field and so this may be part of the explanation. If the woofer has a thin stamped steel basket it's compliance may be starting to play a role. Plus no doubt other explanations involving and not involving damping.

We are discussing thin vs. thick walls. It is safe to assume that the same modes with the same radiation patterns occur as wall thickness increases, simply moved up in frequency. Since they are not reduced in level the expected improvement from stiffer/heavier walls is not realized.

If more efficient damping is not responsible for the lower level of sound radiation from the cabinet at higher frequencies as shown in the plots you posted what is?

I believe Harwood's graph is of a woofer only, in a cabinet. It is possible that the chassis eventually decouples at some frequency, that the energy naturally rolls off (it follows the driver power response instead of axial frequency response) or perhaps the material better absorbs the higher frequencies. I would guess the second option is most likely. Mass reaction driving the cabinet walls is the largest contributor to panel vibration so internal acoustic absorption gives little improvement to this particular problem.

I only make one claim in these discussions: that increasing wall thickness is not the cure that many assume. In spite of increasing stiffness and mass together, it has no effect on the strength of output at resonances. The real cure is considerable application of damping and the effectivness of damping diminishes as wall stiffness goes up. There is no magic damping that works better as the resonances go higher and worse yet, it seems we are more sensitive to resonances as they rise in frequency.

If you have any data that refutes any of this I would love to see it.

David S

andy19191 said:These are increasingly inefficient motions for radiating sound into the far field and so this may be part of the explanation.

Modes are not "increasingly inefficient" in radiation with mode number rising.

In the contrary efficiency in radiation rises when coming closer to the coincidence frequency or exceed it. That is you basically have inefficient radiation for the low frequency modes.

Whether a certain mode radiates "good" (bad for a loudspeaker cabinet) or "bad" (good for a loudspeaker cabinet) depends also on the particular shape of the mode.

Sometimes uneven order modes +-+ are said to radiate more efficient in tendency than even numbered modes +-+-, but this may be just a tendency, radiation depends on the shape of the mode and the relation of propagation speed of bending waves to the speed of sound in the surrounding air.

Andy i feel you are mixing up things although we provided enough information - being it from literature or from own and authentic measurements - that you could check your assumptions by yourself.

What you state is simply not in line with knowledge on bending waves and structure born sound.

You keep insisting that nature must follow human (your) intuition that "thick rigid walls are the best insulation (to whatever form of energy) that you can think of: The more thick the better."

Knowledge and facts cannot convince someone who has very strong preconcepts, which he is not willing to review.

It is not my task to review your your own preconcepts, i think it is yours instead: Facts and hints (also concerning common misinterpretations of facts) can be found more than enough in the latest posts.

I strongly recommend reading a standard textbook e.g. on structure born sound like Cremer/Heckl.

Kind regards

Last edited:

The real cure is considerable application of damping and the effectivness of damping diminishes as wall stiffness goes up.

The work dissipated is the area of the loop on the stress-strain diagram. If the strain is small then one would change to a more appropriate stiffer damping material. Does your comment follow from experience with something like green glue intended for the larger strains of walls?

There is no magic damping that works better as the resonances go higher and worse yet, it seems we are more sensitive to resonances as they rise in frequency.

If you have any data that refutes any of this I would love to see it.

Here is an example of loss factor vs frequency for an industrial acoustical panel. Does this refute anything?

andy19191 said:stiffer damping material.

... a prototypical damping material has no stiffness at all, only mechanical resistance due to deformation: It does not "spring back". A typical dampening mat may also have mass.

Of course resistance in real worlds materials and structures may also vary with frequency on the larger scale.

A structure which is exposed to a long term deformation may not "flex back" completely but keep that deformation gradually.

After only short short term deformation into the same shape, that structure may recover the old shape completely.

But this common observation points us to the opposite direction you are argumenting:

In short term deformation it is the spring component which may rise in a given structure, and it is the plastic component, which may be reduced: Damping of (much) higher frequencies (resonances, modes) e.g. in a composite material thus can be even worse, than for the lower frequencies.

So nature and real materials behave even contrary to what you are still claiming ...

This is why you may need a much more resistive damper - not "stiffer" in terms of lower (spring) compliance - for much higher frequencies. But this is only of relevance if you look at structures, that are excited in a very wideband manner.

If you would design panels for fullrange bending wave loudspeakers - like i used to do - you would ocassionally run into those peculiarities. It is not a typical issue when testing damping mats in loudspeaker cabinets from say 100Hz to 2Khz.

Kind regards

Last edited:

Of course that pure resistance of a dampening coat or layer can be enhanced, if the same amount of material is applied as a foam or at some distance using a "spacing structure" to the walls or panels to be damped.

This is because the strain in the dampening layer can be enhanced for the same deformation of the underlying wall (e.g. "wooden panel").

Also a constraint layer structure is of advantage.

But increasing just thickness of the walls (the MDF part e.g., here's the "stiffness") without incrasing thickness of the damping layer will worsen the result.

With increased thickness of the wood you need also more mass, to bring the resonant modes down in frequency and lower the propagation speed of bending waves on the cabinet: Otherwise bending wave radiation will be more efficient than before. The coincidence frequency should not fall when making the wooden part any thicker and thus stiffer.

This is also why making the damping coat thicker by e.g. foaming solely will not be sufficient to compensate for a stiffer wooden part:

You need more layers of the same dampening mat (or a thicker version of the same material).

David already said what to do:

- Calculate the cabinet mass you can afford.

- Then design the walls ("stiff part") for the minimum stiffness needed.

- Invest the remaining budget (in mass or cost) into mass and thickness of the dampening layer solely.

Notes from my side, as said before:

- Constraint layer structures may increase the efficiency of a damping layer

- Subwoofer's cabinets may be constructed different (based mainly on stiffness).

Kind regards

This is because the strain in the dampening layer can be enhanced for the same deformation of the underlying wall (e.g. "wooden panel").

Also a constraint layer structure is of advantage.

But increasing just thickness of the walls (the MDF part e.g., here's the "stiffness") without incrasing thickness of the damping layer will worsen the result.

With increased thickness of the wood you need also more mass, to bring the resonant modes down in frequency and lower the propagation speed of bending waves on the cabinet: Otherwise bending wave radiation will be more efficient than before. The coincidence frequency should not fall when making the wooden part any thicker and thus stiffer.

This is also why making the damping coat thicker by e.g. foaming solely will not be sufficient to compensate for a stiffer wooden part:

You need more layers of the same dampening mat (or a thicker version of the same material).

David already said what to do:

- Calculate the cabinet mass you can afford.

- Then design the walls ("stiff part") for the minimum stiffness needed.

- Invest the remaining budget (in mass or cost) into mass and thickness of the dampening layer solely.

Notes from my side, as said before:

- Constraint layer structures may increase the efficiency of a damping layer

- Subwoofer's cabinets may be constructed different (based mainly on stiffness).

Kind regards

Last edited:

Harwood is preceeded by studies by BBC. They found that midrange resonances were more objectionable than bass resonances. So for boxes with the same driver taking care of both bass and midrange lowering the resonance freq. Spendor BC 1 is one example.

The Harwood paper is the study at the BBC.

The work dissipated is the area of the loop on the stress-strain diagram. If the strain is small then one would change to a more appropriate stiffer damping material. Does your comment follow from experience with something like green glue intended for the larger strains of walls?

I haven't used green glue although we used "Noise Killer Yellow" for constrained layer damping at Snell.

Here is an example of loss factor vs frequency for an industrial acoustical panel. Does this refute anything?

Thanks, thats an interesting reference, although it doesn't benefit your point. They are actually showing the total performance of a constrained layer system (the MPM metal damping sandwich). It shows a slight rise with frequency towards a max at 1kHz.

In the case of doubling our wall thickness we have doubled our mass and gone to 8 times our stiffness. From this our resonances double in frequency (both the Harwood and Barlow curves clearly show this). Q is always determined by reactance divided by resistance at resonance. Reactance at resonance is 4 times and your material damping is about 20% increased. You are fighting a losing battle!

Of course most people in the camp of "lets make the walls really thick" (or stiff, or massive) have no intention of applying damping. They are convinced that stiffness (or mass) will prevent vibration and don't have a clue about the nature of resonances.

At each resonance mass reactance and stiffness cancel out. They cease to exist and the only thing preventing total cabinet transparency is damping.

David S.

Thanks, thats an interesting reference, although it doesn't benefit your point.

What point would that be? As far as I am aware I have been unsuccessfully trying to prompt discussion on the effectiveness of damping at higher frequencies and after several unsuccessful pages I think I should perhaps just accept defeat.

Speaker Dave said:...

Q is always determined by reactance divided by resistance at resonance. Reactance at resonance is 4 times and your material damping is about 20% increased. You are fighting a losing battle!

which can also be seen as

"energy stored within one period of vibration" divided by

"energy dissipated within one period of vibration"

Thus advocating thick walls in the stiff part mostly made from MDF and the like means advocating walls having high storage of energy.

(As David pointed out above.)

To me there may be 2 "figures of merit" to walls of loudspeakers cabinets that is

1) Q of resonant modes

2) coincidence frequency

1) The Q - which tends to be similar for all relevant vibrational modes in a given cabinet structure - tells us something about how long it takes for a excited mode to decay and how high the peak in average velocity of the cabinet's vibrating walls will be.

2) The coincidence frequency fc tells us something about the efficiency of radiation from that cabinet in a certain range of frequency. In fact we do not want efficient radiation of modes from a loudspeaker cabinet: We want the driver's cone to be the only source of sound, maybe also the reflex port if present ...

Esxamples for modal frequencies f ...

f << fc : rather ineffective radiation

f < fc : noteable radiation

f >= fc : effective radiation

Thus it is advantegeous to use a cabinet (far) below its coincidence frequency fc, if resonant modes within the used frequency band cannot be avoided (as it is only possible in a well constructed subwoofer cabinet).

Example walls

a) wall having high stiffness and low mass per area has high propagation speed of bending waves.

b) wall having low stiffness and high mass per area has low propagation speed of bending waves.

In both cases propagation of bending waves is getting faster with frequency: This effect is called dispersion. Bending waves are dispersive, while sound in air is not.

But the frequency where bending wave propagation will be as fast as sound in air (that is at fc) is much higher for wall material b).

Making a wall e.g. from MDF - which has low damping - just thicker without applying damping and additional mass will

a) increase Q=reactance/resistance for all vibrational modes as David pointed out already

b) increases the frequency of the modes as mass per area goes linear with thickness but stiffness goes cubic (for thin walls) as David pointed out already

c) decreases fc as i pointed out already

The combination of b) and c) means, that vibrational modes which were far below fc might now come close to fc or even exceed it: Radiation is more efficient. At the same time we rose a) the peaks in cabinet's vibrational modes ...

As one can see, all these 3 effects combine in a most detrimental way, so we can say that thick walled (MDF, or wood) loudspeaker cabinets are a very very unklug cabinet design, if used in a usual multiway speaker cabinet and especially without sufficient "damping and mass".

A sufficient "damping and mass" layer is needed for vibration control and keeping also the radiation as low as possible.

(Subwoofers are still special, because of their upper frequency limit ...)

Last edited:

Been following this thread - mostly as I have some KEF T27 & B110 drivers in KEF Concerto cabinets. I am in the process of preparing to fit new crossovers from Falcon Acoustics, rewiring, & bi-wire terminals. I would like to fit some dampening panels.

It looks like the LS3/5A cab with its thin wall and dampening is taking the right approach.

One improvement put forward is to decouple the driver from the cabinet. How would one mount a KEF B110 to achieve this?

It looks like the LS3/5A cab with its thin wall and dampening is taking the right approach.

One improvement put forward is to decouple the driver from the cabinet. How would one mount a KEF B110 to achieve this?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Can one build a better (non) LS3/5A speaker based on T27s & B110s?

![sound[1].gif](/community/data/attachments/429/429548-de2c2263b9f33f275ce52bd18aa50268.jpg)