tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

After jnewbold, several names disapeared from the list.

That should be corrected.

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

hmmm hkmmmm.. one more, pleas error orrr.

Ivo-Cici

Please fellow diyers copy the whole list if you add your name, we who have added our names do not want to be taken out

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

Please fellow diyers copy the whole list if you add your name, we who have added our names do not want to be taken out

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Tube 300 x3

Noo no i appeared agane..

Puck material

A core insert of Delrin or brass would solve the seasonal movement problem. Drill a hole and epoxy it in before turning the wood.

The thing to do with the puck is to have them cnc machined. I think plastic is the way to go for a group buy. Wood is going to tend to move after being cut and many machinists don't like to have the moisture on their machines. If I were doing this for myself alone, I might take a piece of ebony or hard rock maple, rough it into shape and then put it in a jar of tung oil for a couple months. That will guarentee it won't move once finished. But for a group buy, that isn't reasonable. The last thing we want is people without a lathe getting a puck for $100 that turns to junk as it dries and they have no way of fixing. Delrin is considered a replacement for metal when cost, corrosion and weight are concerns. It is also known for being very dimensionally stable. That would be my suggestion, as nobody wants a GB gone bad.

A core insert of Delrin or brass would solve the seasonal movement problem. Drill a hole and epoxy it in before turning the wood.

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

Spresto9

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

Spresto9

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici not valid!!!

Tube 300 x3

Spresto9

A core insert of Delrin or brass would solve the seasonal movement problem. Drill a hole and epoxy it in before turning the wood.

I don't think you got my point. Wood moves. It moves when it first dries and then again with humidity and heat. If one side moves more than the other or pulls, the disk will develop a vertical wobble. I have a wine glass turned from apple that is a perfect example. It was straight on the lathe. It moved when it dried and is now very crooked.

Using an insert inside a wood platform won't address what I am suggesting might be an issue. If people want wood, why not do a delrin or aluminum platform with a wood puck. The puck itself is merely for clamping force. But it is important that the platform be stable and consistant.

The thing to do with the puck is to have them cnc machined. I think plastic is the way to go for a group buy. Wood is going to tend to move after being cut and many machinists don't like to have the moisture on their machines. If I were doing this for myself alone, I might take a piece of ebony or hard rock maple, rough it into shape and then put it in a jar of tung oil for a couple months. That will guarentee it won't move once finished. But for a group buy, that isn't reasonable. The last thing we want is people without a lathe getting a puck for $100 that turns to junk as it dries and they have no way of fixing. Delrin is considered a replacement for metal when cost, corrosion and weight are concerns. It is also known for being very dimensionally stable. That would be my suggestion, as nobody wants a GB gone bad.

DaveM, I see what you are saying about cost/practicality, and you are probably right. Although personally, for various reasons, I would very much prefer any material BUT plastic.

@ Ed LaFontaine, c12mech - Thank you for your kind offers. I am sure more people will be interested in a wooden puck - can you give us an estimate of how much such puck might cost (made according to Peter's drawing)? Only the hardest of hardwoods will be suitable for this (lignum vitae / verawood, ebony, blackwood, box, rosewood) - lesser woods will machine poorly, or warp with time as DaveM pointed out.

An important thing to keep in mind is that any puck (wooden or not) has to be balanced, and, according to Peter, the only reliable way to do this is to lathe the puck while it is mounted on the mechanism's shaft.

Edit: @DaveM - You picked a wrong wood... Apple is fairly heavy, but particularly prone to warping and cracking. Ebony or lignum vitae on the other hand are incredibly (unbelievably) hard, they machine and polish like stone or metal, and are very stable even submerged. Clockwork mechanisms, propeller bearings in warships and other precision parts were successfully made from them before the modern alloys and plastics became widespread.

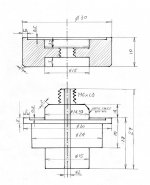

Attachments

Last edited:

I've been following this thread on and off for the last year or so. Now with the soon to be available boards I'd like to be counted in for 1 set. Thanks. But I have a question (since I probably missed it along the way): what is the recommended transport at this point? I didn't think the one that Peter used is available anymore? I'm sure the answer is in here somewhere, so if someone could point me in the right direction that would be great.

I've made a good number of pucks from african blackwood and ebony - a few of the fellas here have them. Warping when machined is an issue, and there is also the issue of how to mount the puck. I ended up making an M6 stud from brass rod and pressing it into the hole at the top of the existing platform. The ebony puck then screwed down onto that.

There are a couple of points worth remembering:

It ain't easy to make the platform and get it right. The history of this thread alone shows that, and that was using acrylic, not a material that moves like wood!!! The only way to get it right is to press it onto the shaft and then machine it true while mounted on the motor shaft. Back up the thread there is a pic from 47 labs where they show the machining of a platform already mounted on a motor.

You will need to rough turn the puck, re-turn it, and then re-turn it again after further seasoning indoors. Make the threaded bit as short as you can, the fewer threads the better. More threads means more resistance when you are trying to screw it on to the platform. With no way of holding the platform (other than the friction of the CD sitting on it), the puck better spin down very freely.

Its very easy to over-tighten the puck. Doing so causes the CD to warp and you end up with even more wobble. Barely tight enough to stop the CD slipping is the way to go.

Sonic gain over the magnetic puck from the EZ31 door is minimal. Its the last mod I'd be looking at (and thats from someone who has made them, and tried them out extensively). Ask Peter, Kevinkr, m.massimo and Erik for their opinion.... they have my pucks I think.

IMHO, the 3 ball transport avoids all that crap and I have a memory of someone trying them and saying that it did a very good job of removing wobble from CDs that previously did. This would be worth doing more research on. I have 2 x 3ball mechs here, but never got a chance to put them into use ..yet.

Just sayin' before someone ends up with a lot of work on their hands.

Fran

There are a couple of points worth remembering:

It ain't easy to make the platform and get it right. The history of this thread alone shows that, and that was using acrylic, not a material that moves like wood!!! The only way to get it right is to press it onto the shaft and then machine it true while mounted on the motor shaft. Back up the thread there is a pic from 47 labs where they show the machining of a platform already mounted on a motor.

You will need to rough turn the puck, re-turn it, and then re-turn it again after further seasoning indoors. Make the threaded bit as short as you can, the fewer threads the better. More threads means more resistance when you are trying to screw it on to the platform. With no way of holding the platform (other than the friction of the CD sitting on it), the puck better spin down very freely.

Its very easy to over-tighten the puck. Doing so causes the CD to warp and you end up with even more wobble. Barely tight enough to stop the CD slipping is the way to go.

Sonic gain over the magnetic puck from the EZ31 door is minimal. Its the last mod I'd be looking at (and thats from someone who has made them, and tried them out extensively). Ask Peter, Kevinkr, m.massimo and Erik for their opinion.... they have my pucks I think.

IMHO, the 3 ball transport avoids all that crap and I have a memory of someone trying them and saying that it did a very good job of removing wobble from CDs that previously did. This would be worth doing more research on. I have 2 x 3ball mechs here, but never got a chance to put them into use ..yet.

Just sayin' before someone ends up with a lot of work on their hands.

Fran

tvicol

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

Spresto9

Audiohifi x 1

uncle_leon

NOMDI x 3

syklab x 2

apoopoo999 US

CeeVee x 2

Lucylu

pchw x 2 US

Turbon x 2

DaveM US

Praudio Canada

kamaths US

timjac41

dillmeister x 2 Canada

BMW850 x 2

Erik van Voorst x 2

JimS x 2 US

IndyAudi x 3

ChicagoJTW US

tubo x 2

quan x1

Ivo-Cici x2

Pjotr27

Stixx

vgeorge

ilrapa x 2

sandbasser x 2 US

Angcl x 2

JBdV x 2

andrewgm x 1

zjaakco x 2

Tony X x2

buzzforb US

skippyboy

rikkert1978

valo

Ed LaFontaine x 2 US

Turbon

Puffin x2 (depending on cost)

BTW x 2

marcus1 X 2

jnewbold

rchomeless

Jean-Charles

Tham

ColinAlex

C12mech

secanbj x2

geoteam 777

RKH x2

lugia862 x5

TheGimp 1 (or two depending on price)

Ivo-Cici

Tube 300 x3

Spresto9

Audiohifi x 1

Those interested in this project please add yourself to this list.

https://docs.google.com/spreadsheet/ccc?key=0AsGrT4hW37cvdHQ2dXllWGJtYi1NU0lfNGhZSlNWR2c#gid=0

This will save a lot of space on the forum.

Regards,

Tibi

https://docs.google.com/spreadsheet/ccc?key=0AsGrT4hW37cvdHQ2dXllWGJtYi1NU0lfNGhZSlNWR2c#gid=0

This will save a lot of space on the forum.

Regards,

Tibi

Will EZ51 survive?

Guys, I am following the discussion here for some time now. I have got probably one of the lasts EZ51 in Europe in my hands - new&unopened. As the box was not cheap my question is if the radio and tape will stay functional after I gut the CD part out? Then I could have a high-end CD transport AND keep a simple radio boombox as a small side effect. Still considering if I should engage the screwdriver and solder or put it on the Bay...

Guys, I am following the discussion here for some time now. I have got probably one of the lasts EZ51 in Europe in my hands - new&unopened. As the box was not cheap my question is if the radio and tape will stay functional after I gut the CD part out? Then I could have a high-end CD transport AND keep a simple radio boombox as a small side effect. Still considering if I should engage the screwdriver and solder or put it on the Bay...

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story