Hello all,

who wants to compete for the most crazy design?

http://img710.imageshack.us/img710/1493/carton01m.jpg

http://img85.imageshack.us/img85/3036/carton02.jpg

http://img683.imageshack.us/img683/640/carton03.jpg

http://img704.imageshack.us/img704/1544/carton04.jpg

http://img704.imageshack.us/img704/8543/carton05.jpg

POL

who wants to compete for the most crazy design?

http://img710.imageshack.us/img710/1493/carton01m.jpg

http://img85.imageshack.us/img85/3036/carton02.jpg

http://img683.imageshack.us/img683/640/carton03.jpg

http://img704.imageshack.us/img704/1544/carton04.jpg

http://img704.imageshack.us/img704/8543/carton05.jpg

POL

Hi Markus,

yes modal density increases faster with frequency,

due to c being frequency dependent.

This effect allows sufficient reproduction quality in

the range > 10 modes/ocatve and above as a rule of thumb.

Unfortunately this statement is wrong.

Modal density would increase even more with frequency if c

(propagation velocity of bending waves)

would be frequency independent.

I took over this opinion from a paper without having

thought about it sufficiently.

Hi guys!

I'm a new poster on this forum, but have done some extensive builds on a dutch forum: forum.zelfbouwaudio.nl • Toon onderwerp - Proof of concept (8x 2" Tangband) and forum.zelfbouwaudio.nl • Toon onderwerp - Jordan JX92s / CSS SDX7 ontwerp (for you, just watch the pretty pictures, as all is in Dutch )

)

Okay, so I'm a big fan of full range drivers and came across the "Podium Sound" speakers. I bought 7 pairs of Dayton Daex 25's and started testing (after first reading through to page 26 of this topic!).

I like the challenge and different style speakers.

It seems that I got a hold of some sort of "Gatorboard". It's a dence foam type core with 1mm of paper on the front and back. When you tap it, it sounds dry and solid. The board cannot easily be bent. The exciter was placed 1/3th of the hight of the board.

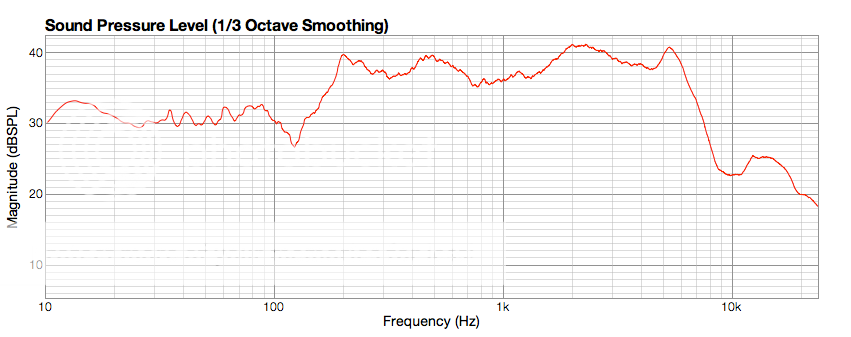

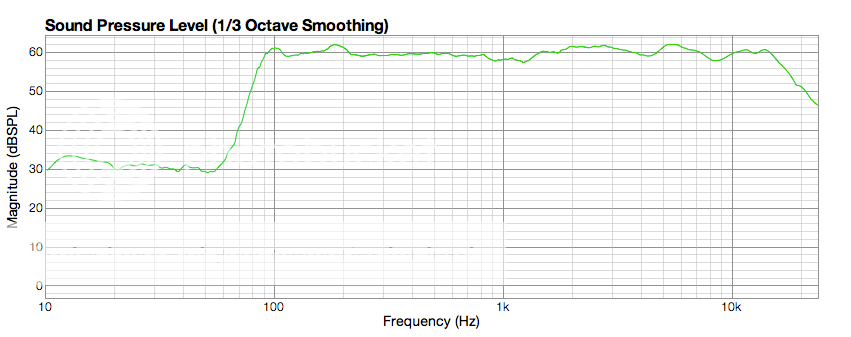

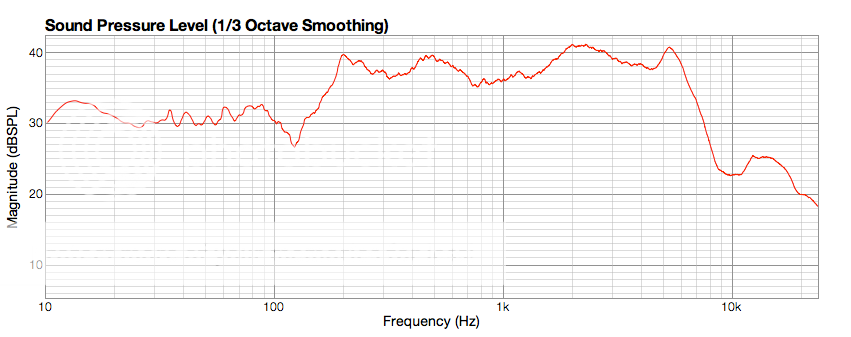

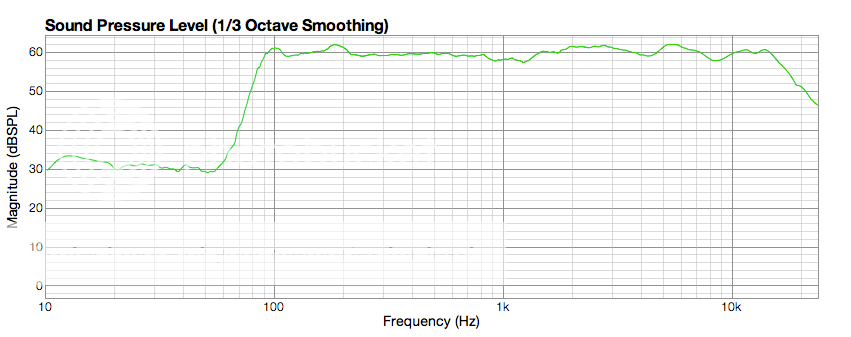

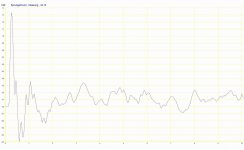

I've also done some measurements and see that with one exciter there is WAY to little highs. See the meaurement (red graph). One corrections have been made with a DSP the curve lookes like (green graph). Mind you: this measurement was done in the dead center, close proximity.

Do any of you use DSP? Do any of you do measurements? I would be very interested to see what kind of frequency response the large panels have.

I'm a new poster on this forum, but have done some extensive builds on a dutch forum: forum.zelfbouwaudio.nl • Toon onderwerp - Proof of concept (8x 2" Tangband) and forum.zelfbouwaudio.nl • Toon onderwerp - Jordan JX92s / CSS SDX7 ontwerp (for you, just watch the pretty pictures, as all is in Dutch

Okay, so I'm a big fan of full range drivers and came across the "Podium Sound" speakers. I bought 7 pairs of Dayton Daex 25's and started testing (after first reading through to page 26 of this topic!).

I like the challenge and different style speakers.

It seems that I got a hold of some sort of "Gatorboard". It's a dence foam type core with 1mm of paper on the front and back. When you tap it, it sounds dry and solid. The board cannot easily be bent. The exciter was placed 1/3th of the hight of the board.

I've also done some measurements and see that with one exciter there is WAY to little highs. See the meaurement (red graph). One corrections have been made with a DSP the curve lookes like (green graph). Mind you: this measurement was done in the dead center, close proximity.

Do any of you use DSP? Do any of you do measurements? I would be very interested to see what kind of frequency response the large panels have.

Hi Mikesbmw.

Interest in this topic seems to have fizzled out here, but it is still happening on the open baffle forum at Audiocircle. The current fave is expanded polystyrene sheet in a high-density grade. Paper-backed foamcore board has serious shortcomings, as you have discovered.

Interest in this topic seems to have fizzled out here, but it is still happening on the open baffle forum at Audiocircle. The current fave is expanded polystyrene sheet in a high-density grade. Paper-backed foamcore board has serious shortcomings, as you have discovered.

I saturated the paper of my foamcore with lacquer to harden it.

Improved, but still not hard like real Gatorboard... Which has an

almost veneer feel to the coverings. Gator paper shatters like a

thin layer of wood, if torn. Looks same at first glance, but made

of totally different stuff.

Improved, but still not hard like real Gatorboard... Which has an

almost veneer feel to the coverings. Gator paper shatters like a

thin layer of wood, if torn. Looks same at first glance, but made

of totally different stuff.

Last edited:

@Kenpeter

True, this core is softer. A collegue of mine pointed this out to me...

@LineArray

A totally different league!

Without DSP it sounded dull, lacking highs and voices sounded to much 'in your face'. Basically it would be okay for ambient sound, but not for everyday use. This is all easily seen in the first graph.

I'm definitely going to stick with DSP. All speakers I've build so far sounded better with it. True, you have to stick to the basic principles of speaker building or DML building, but that speaker or DML should always be assisted by DSP.

I for one, think that the 'Podium Speakers' could sound nice (haven't listened to them though), but they can and will sound better with DSP. I agree with Katz that you shouldn't use crossovers! Crossovers suck, even the digital ones. (if they are necessary try to cross as low as possible)

DSP has and will remain my holy grail

To bad I can't find what Gatorboard is called in the Netherlands...

True, this core is softer. A collegue of mine pointed this out to me...

@LineArray

A totally different league!

Without DSP it sounded dull, lacking highs and voices sounded to much 'in your face'. Basically it would be okay for ambient sound, but not for everyday use. This is all easily seen in the first graph.

I'm definitely going to stick with DSP. All speakers I've build so far sounded better with it. True, you have to stick to the basic principles of speaker building or DML building, but that speaker or DML should always be assisted by DSP.

I for one, think that the 'Podium Speakers' could sound nice (haven't listened to them though), but they can and will sound better with DSP. I agree with Katz that you shouldn't use crossovers! Crossovers suck, even the digital ones. (if they are necessary try to cross as low as possible)

DSP has and will remain my holy grail

To bad I can't find what Gatorboard is called in the Netherlands...

Last edited:

In the "Loudspeaker and room as a system" thread we had also

a discussion on DSP.

For the low frequency range below the schröder frequency of the room

DSP can be used to compensate for room modes but will be restricted

for optimizing the transfer function for a certain listening position.

A compromise can be found when averaging over more than one

listening position.

With DML you have strong deviations in the fine structure of the transfer

function even when the angle is only changed by small amounts.

The "ruler flat" result with DSP can - even for mid to high frequencies -

only be achieved for a certain listening position. The deviations of the

transfer function at small changes of angle are typical for DML and go

together with their virtues of radiating in an uncorrelated manner

especially in the off axis directions.

So i doubt that - given a DML which is somewhat more tamed and maturated

than your prototype - compensating the fine structure of the transfer function

above the schröder frequency of the room will really help that much.

The listener not being nailed to a sweet spot is one of the DML virtues,

but the fine structure can only be compensated for one listening position,

possibly making things worse for other positions.

Don't get me wrong: I am interested in DSP too. But currently i think

maybe a compromise is to be found:

For a conventional or DM- Loudspeaker operating below the schröder

frequency a DSP can be used to flatten the response over a couple

of preferred listening positions.

In the non modal range above the schröder frequency of the room, i guess

best for a DML is a smoothed compensation of the overall radiated power

into the room.

But this tends to be rather flat with a matured DML anyhow, because the

frequency dependent beaming does not occur like with a conventional

speaker.

Kind Regards

a discussion on DSP.

For the low frequency range below the schröder frequency of the room

DSP can be used to compensate for room modes but will be restricted

for optimizing the transfer function for a certain listening position.

A compromise can be found when averaging over more than one

listening position.

With DML you have strong deviations in the fine structure of the transfer

function even when the angle is only changed by small amounts.

The "ruler flat" result with DSP can - even for mid to high frequencies -

only be achieved for a certain listening position. The deviations of the

transfer function at small changes of angle are typical for DML and go

together with their virtues of radiating in an uncorrelated manner

especially in the off axis directions.

So i doubt that - given a DML which is somewhat more tamed and maturated

than your prototype - compensating the fine structure of the transfer function

above the schröder frequency of the room will really help that much.

The listener not being nailed to a sweet spot is one of the DML virtues,

but the fine structure can only be compensated for one listening position,

possibly making things worse for other positions.

Don't get me wrong: I am interested in DSP too. But currently i think

maybe a compromise is to be found:

For a conventional or DM- Loudspeaker operating below the schröder

frequency a DSP can be used to flatten the response over a couple

of preferred listening positions.

In the non modal range above the schröder frequency of the room, i guess

best for a DML is a smoothed compensation of the overall radiated power

into the room.

But this tends to be rather flat with a matured DML anyhow, because the

frequency dependent beaming does not occur like with a conventional

speaker.

Kind Regards

Hi Oliver,

There is truth in what you are saying about trying to compensate for more then one listening position (if they are not close to one another). This cannot be done. It is also true that compensation will, most likely, be mainly beneficial for low frequencies.

The corrections I do, are for one listening position. All the other positions are for easy listening only and for those it doesn't really matter if there are deviations.

Do you have any measurements for the different materials used? Most of the materials tested (in this thread) are done by ear (which together with the brain is the weakest link).

I'm not saying that one can simply use DSP to correct for everything, but in these simple and crude DML setups I very much doubt that the frequency plot would be within +/- 5dB between 200-15Khz.

There is truth in what you are saying about trying to compensate for more then one listening position (if they are not close to one another). This cannot be done. It is also true that compensation will, most likely, be mainly beneficial for low frequencies.

The corrections I do, are for one listening position. All the other positions are for easy listening only and for those it doesn't really matter if there are deviations.

Do you have any measurements for the different materials used? Most of the materials tested (in this thread) are done by ear (which together with the brain is the weakest link).

I'm not saying that one can simply use DSP to correct for everything, but in these simple and crude DML setups I very much doubt that the frequency plot would be within +/- 5dB between 200-15Khz.

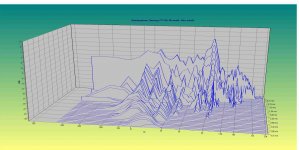

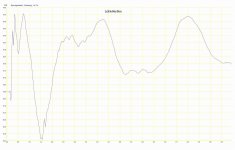

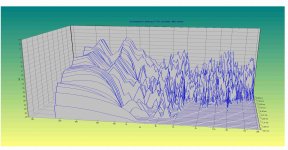

I do not have systematic measurements on different materials

under same conditions.

But the following called "A1" is from stamped aluminium sheet-

quite similar pattern like your prototype ...

And the one called "B1" is balsa wood.

As i said mounting conditions and measurement conditions are

not comparable, but may give a tendency.

under same conditions.

But the following called "A1" is from stamped aluminium sheet-

quite similar pattern like your prototype ...

And the one called "B1" is balsa wood.

As i said mounting conditions and measurement conditions are

not comparable, but may give a tendency.

Attachments

-

BendingTransducer_A1_Frequenzgang.JPG182.5 KB · Views: 626

BendingTransducer_A1_Frequenzgang.JPG182.5 KB · Views: 626 -

BendingTransducer_A1_Sprungantwort.JPG168.5 KB · Views: 557

BendingTransducer_A1_Sprungantwort.JPG168.5 KB · Views: 557 -

BendingTransducer_A1_Zerfallsspektrum.JPG325.3 KB · Views: 556

BendingTransducer_A1_Zerfallsspektrum.JPG325.3 KB · Views: 556 -

Frequenzgang_B1_1m_Bodennähe.JPG183.6 KB · Views: 536

Frequenzgang_B1_1m_Bodennähe.JPG183.6 KB · Views: 536 -

Sprungantwort_B1_1m_Bodennähe.JPG194.3 KB · Views: 519

Sprungantwort_B1_1m_Bodennähe.JPG194.3 KB · Views: 519 -

Zerfallsspektrum_B1_1m_BodenNähe.JPG355.4 KB · Views: 143

Zerfallsspektrum_B1_1m_BodenNähe.JPG355.4 KB · Views: 143

In my experience there are two possible reasons for

early (and steep) rolloff in highs:

- moved components of the exciter have too much mass

- membrane (core ? ) or glue is soft and thick, so there is

a compliance between the "listening side" surface of the

membrane and the voice coil, which is too high

Of course both factors can go together ...

early (and steep) rolloff in highs:

- moved components of the exciter have too much mass

- membrane (core ? ) or glue is soft and thick, so there is

a compliance between the "listening side" surface of the

membrane and the voice coil, which is too high

Of course both factors can go together ...

Interesting graphs!

I would not have guessed such a nice frequency response from both materials. Especially the aluminium looks nicer then expected.

After doing some further reading on BMR speakers I see I'm thinking of them acting like a piston too much eg. standard loudspeaker. I totally "forgot" about the propagation of sound through the panel material and then leaving the material at different intervals. Introducing lobbing, distortion and unfocussed sound. Excuse the layman's terms, I am no scientist

I'm currently at page 42 of this thread and I see that many of my questions and wanderings are the same as many of the contributors of the thread... I'll shut up a bit for now and read the rest of it first

I would not have guessed such a nice frequency response from both materials. Especially the aluminium looks nicer then expected.

After doing some further reading on BMR speakers I see I'm thinking of them acting like a piston too much eg. standard loudspeaker. I totally "forgot" about the propagation of sound through the panel material and then leaving the material at different intervals. Introducing lobbing, distortion and unfocussed sound. Excuse the layman's terms, I am no scientist

I'm currently at page 42 of this thread and I see that many of my questions and wanderings are the same as many of the contributors of the thread... I'll shut up a bit for now and read the rest of it first

Interesting graphs!

I would not have guessed such a nice frequency response from both materials. Especially the aluminium looks nicer then expected.

...

Hi mikesbmw,

that ALU prototype must also be burried somewhere in here ...

The AL sheet had little patterns like pyramids stamped on it, so it

does not sound like a flat sheet. Sonically it was OK up to the midrange

region. But it had rather sharp lobing, which caused severe changes in

presence and brillance region when you moved your head a little.

I tried to heal that with some kind of "phase plug" or diffuser. That

helped but the underlying problem remained.

The problem might have been, that the wave propagation on the

material is very fast at high freqiencies (large bending wavelength) and

the sheet was rather small (approx DIN A4). With smaller bending

wavelengths on slower materials the lobes get finer distributed over

listening angle, so they are in best case not detectable - auditively -

anymore as you move around.

As you can see, there is ringing even at the high frequencies, although

the sheet was clamped at its edges using highly damping materials.

So: The graph looks better than it sounded actually !

(And i bet, in that case the problem was even unhealable with DSP ...)

Kind Regards

Last edited:

In fact all manufacturers of good "modal" transducers

state that the right amount of damping is essential

and one of the most tricky parts.

The ideal would be surrounds (of the panels, membranes used)

which are free from reflection over the entire frequency range.

The Göbel website e.g. illustrates that in a demonstrative

manner.

state that the right amount of damping is essential

and one of the most tricky parts.

The ideal would be surrounds (of the panels, membranes used)

which are free from reflection over the entire frequency range.

The Göbel website e.g. illustrates that in a demonstrative

manner.

The ideal would be surrounds (of the panels, membranes used)

which are free from reflection over the entire frequency range.

Wouldn't that prevent a modal operation? This is more what the Manger is intended to do.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- PIEZO NXT type panel