I saw the construction's video. I guess, the total length of conductor is cca. 14,2 - 14,5m, but only 50% is immersed into full intensity (and well directioned) magnetic field: 3 traces out of 5 run perfectly between magnet rows (there is about 140mT induction). Length: 3*6*40cm=7,2m. The remaining 2 traces is fitted non optimal for push-pull, because the B vector and membrane aren't parallel. And the returning traces (4*25cm) are free from magnetic fields, cannot generate driving force. There is useable B at the loops around magnet rows, but not full intensity. My estimated B*l product is 1,3 T*m, the aluminium volume is cca. 1,5ml (4g) - I think, the conductors cross section is cca. 0,1mm2 (30 micron*3,5mm?)

Where can ensure improvement?

These modifications can bring 3-4dB improvement of sensitivity.

Thicker steel plate (better closed magnetic circuit) can bring 1-1,5dB.

Double sided traces: further 3dB (only when put between rows 2*5 traces). (50 micron but narrover)

The Qes will half, if the sensitivity 3dB higher. At 6dB, the Qes will quarter, compared original

Where can ensure improvement?

- all of traces need to run between magnet rows

- the 4*25cm big loop can be wider, because these are neutral position at the membrane (will be less parasitic resistance)

- the small loops are OKs

These modifications can bring 3-4dB improvement of sensitivity.

Thicker steel plate (better closed magnetic circuit) can bring 1-1,5dB.

Double sided traces: further 3dB (only when put between rows 2*5 traces). (50 micron but narrover)

The Qes will half, if the sensitivity 3dB higher. At 6dB, the Qes will quarter, compared original

I made a mistake at #132. Correctly: 100g/m2 order of magnitude and 10g/m2.he air mass is the dominant part of moving mass at big planars (100g order of magnitude at your bass panel). A few times 10g weight increment generates little change of mechanical parameters

But the ratio was correct...

OK so i did some tests.

theory is nice ! but measuring it/hearing it is even better since it makes me understand better then formulas

since it makes me understand better then formulas  (to bad)

(to bad)

So i wanted to see the exact WIN in SPL for single ended vs the push pull. as mentioned by some this theory of 6dB wont be happening in the lower end, my last measurement was compared to the dual foil. so that one did 6-7 dB, but thats more because the dual one was really low in efficiency.

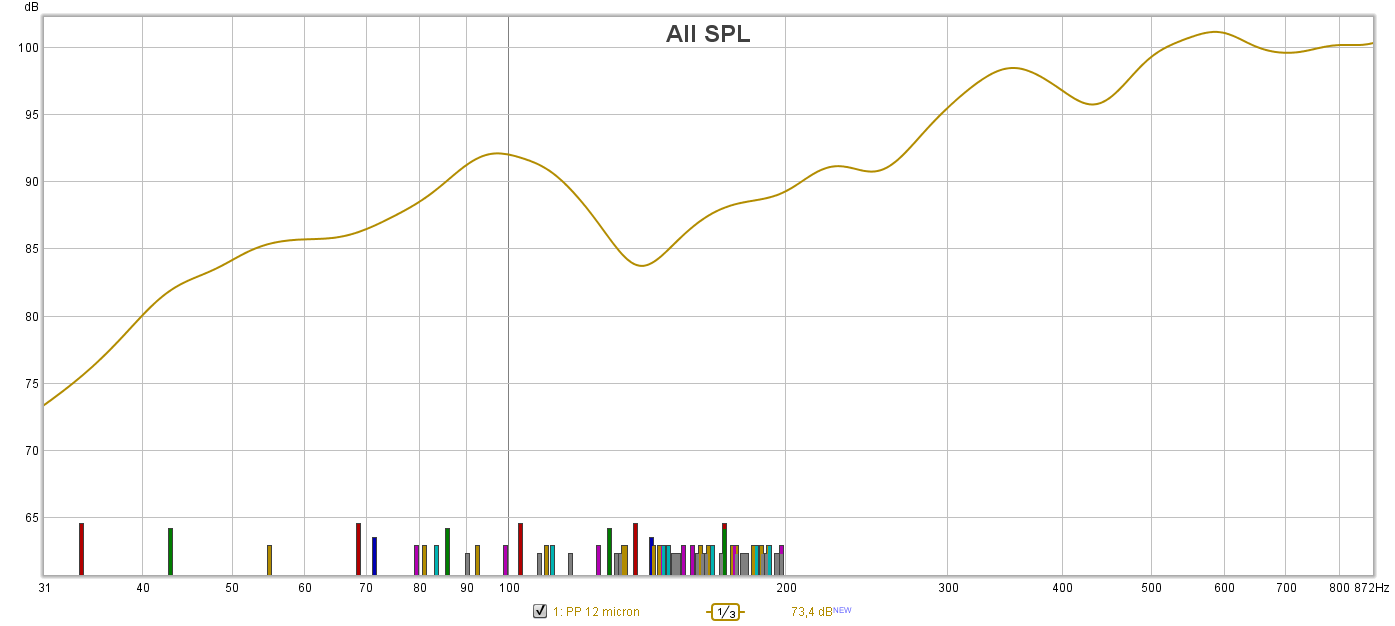

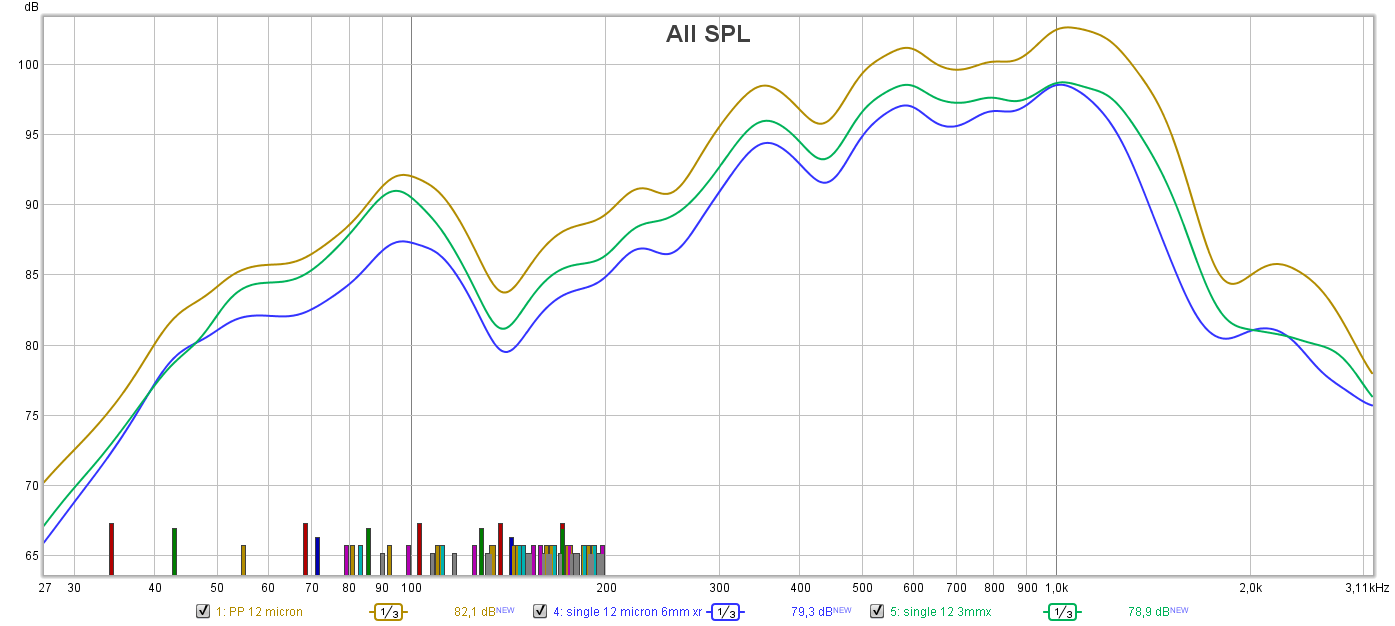

Here is the Push Pulll foil as comparison to all the other measurements at 1 meter spl this time is calibrated. not sure what voltage. dont care either

Push pull FR

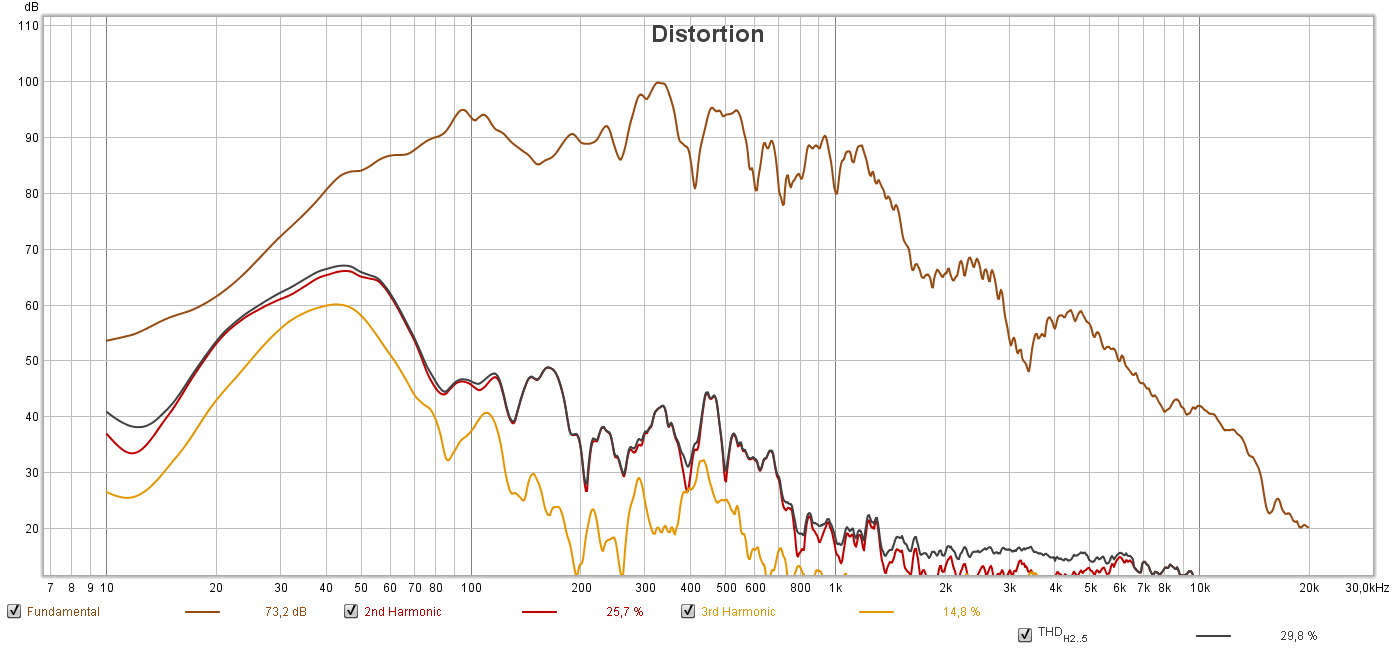

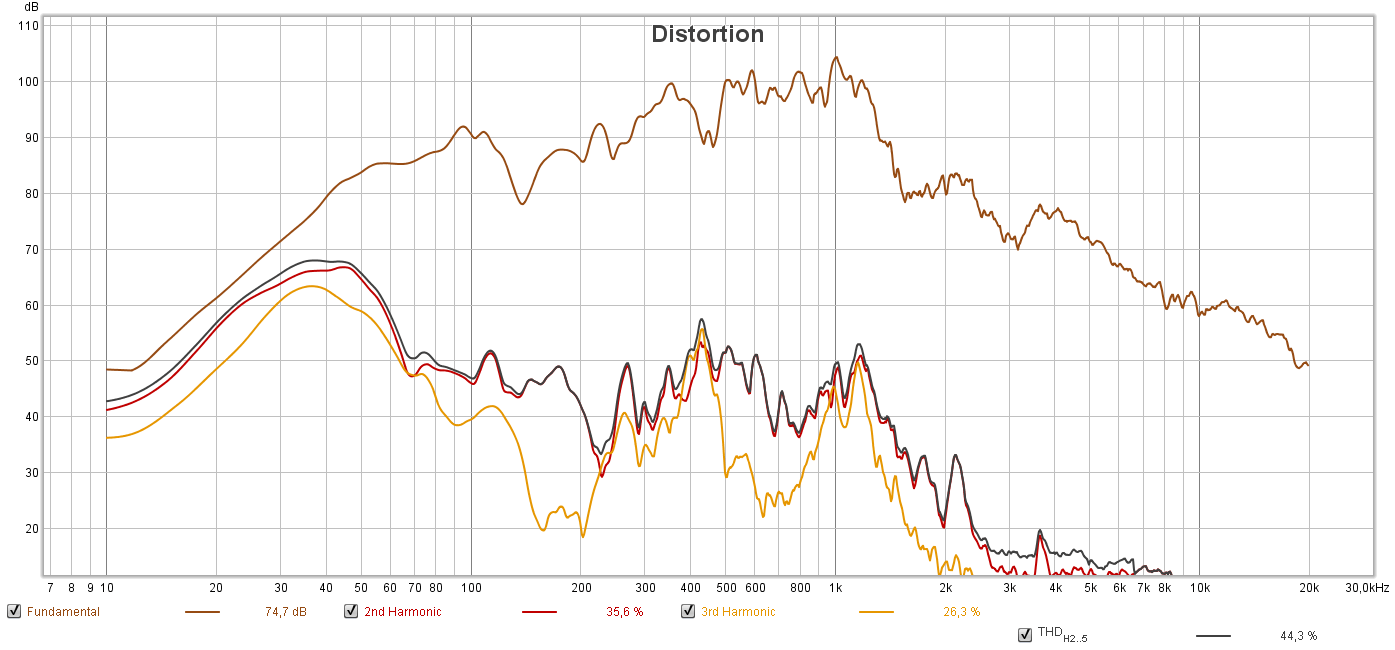

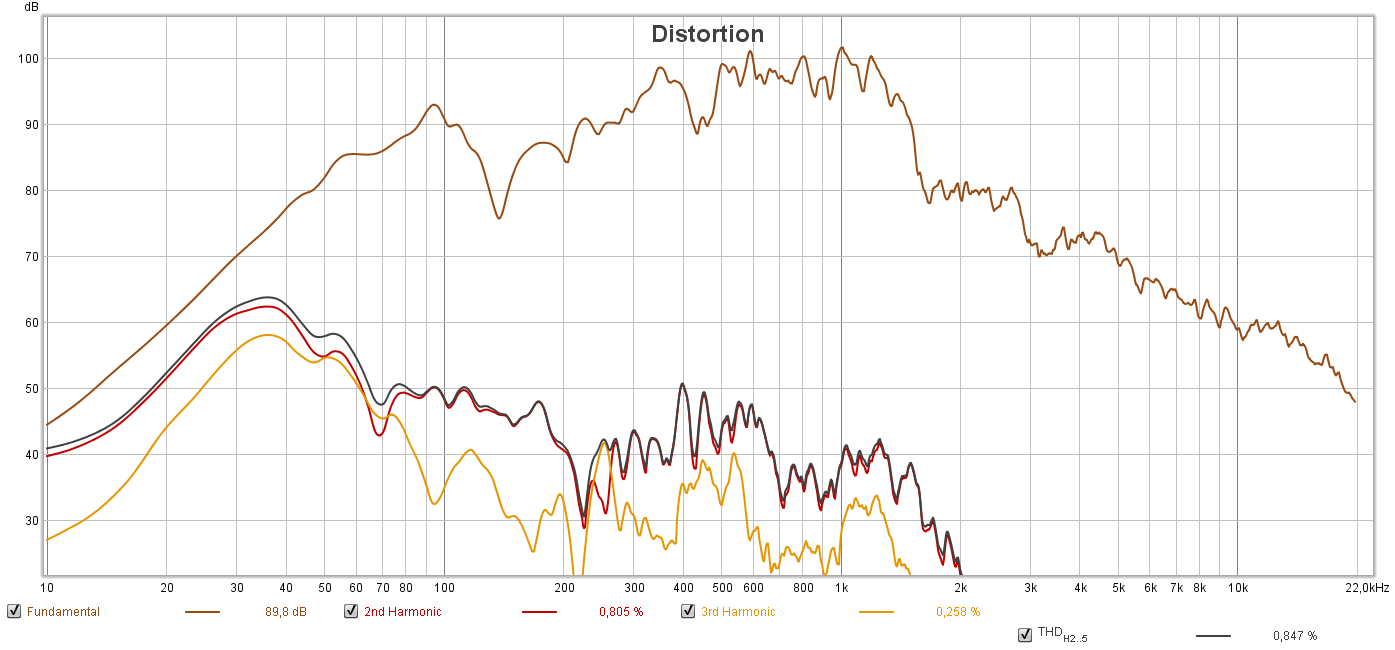

Push pull distortion, there is some nasty poo@400 that im pretty sure is created by the small amount of traces VS undriven foil.

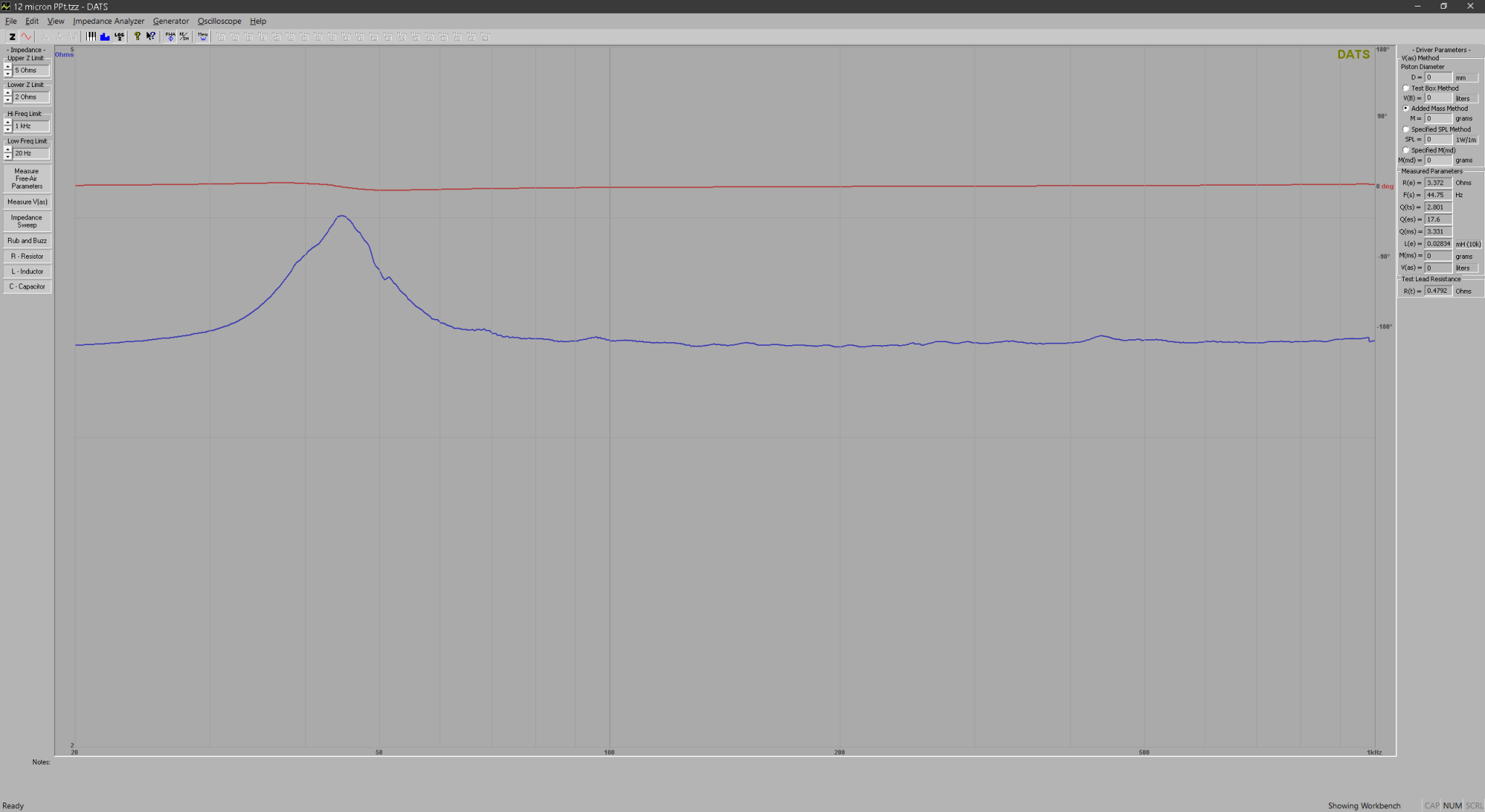

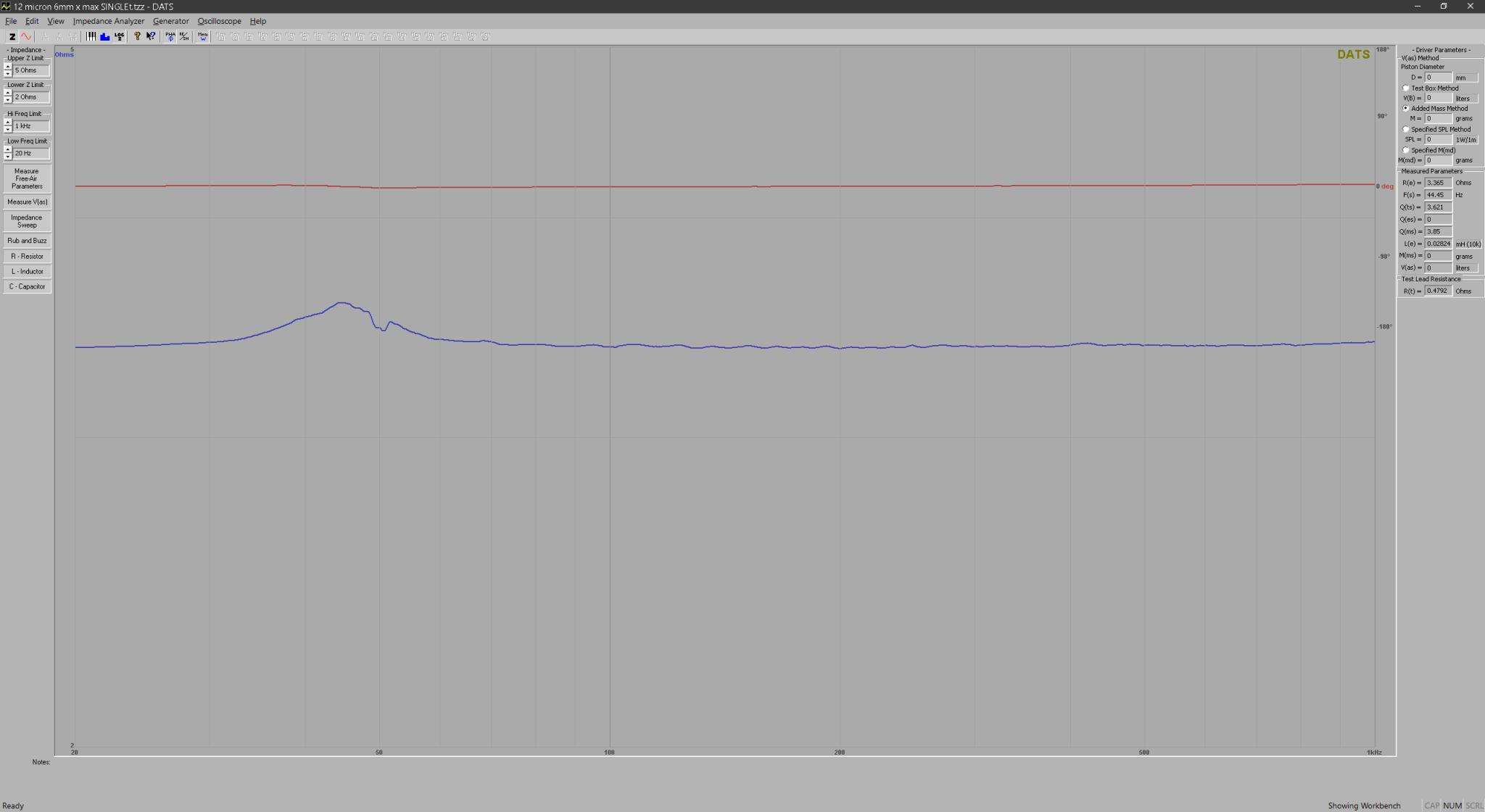

And the free air parameters of the PP

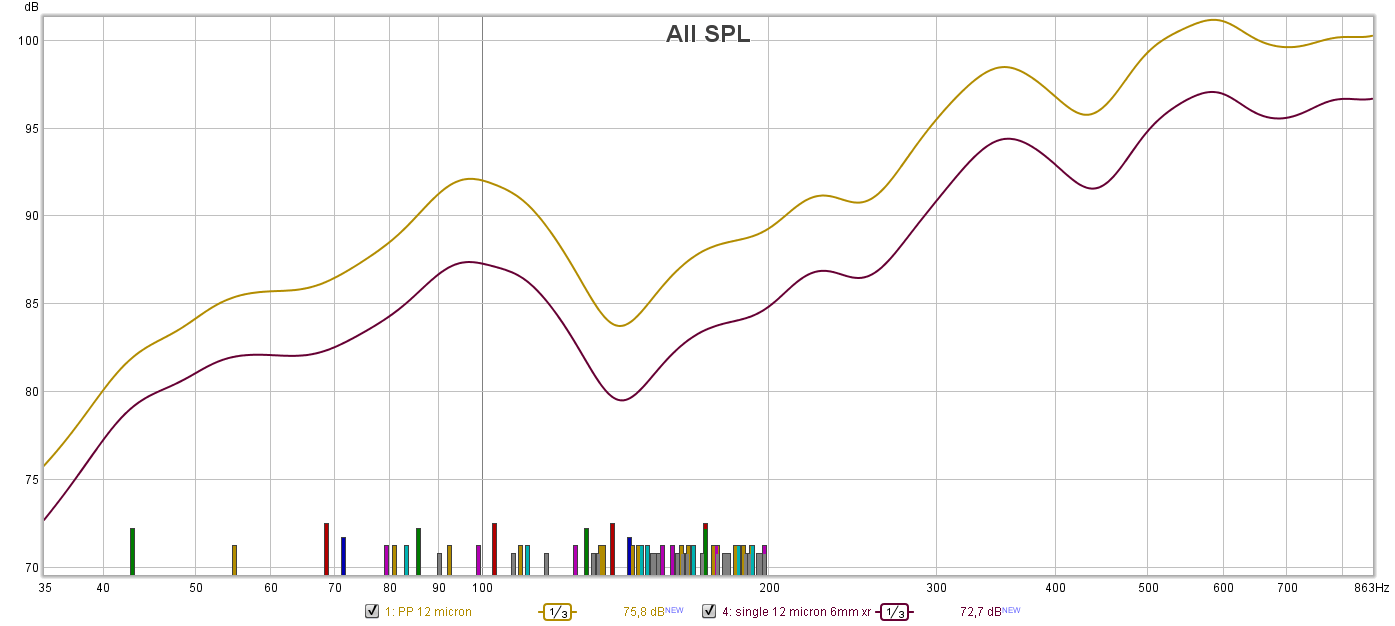

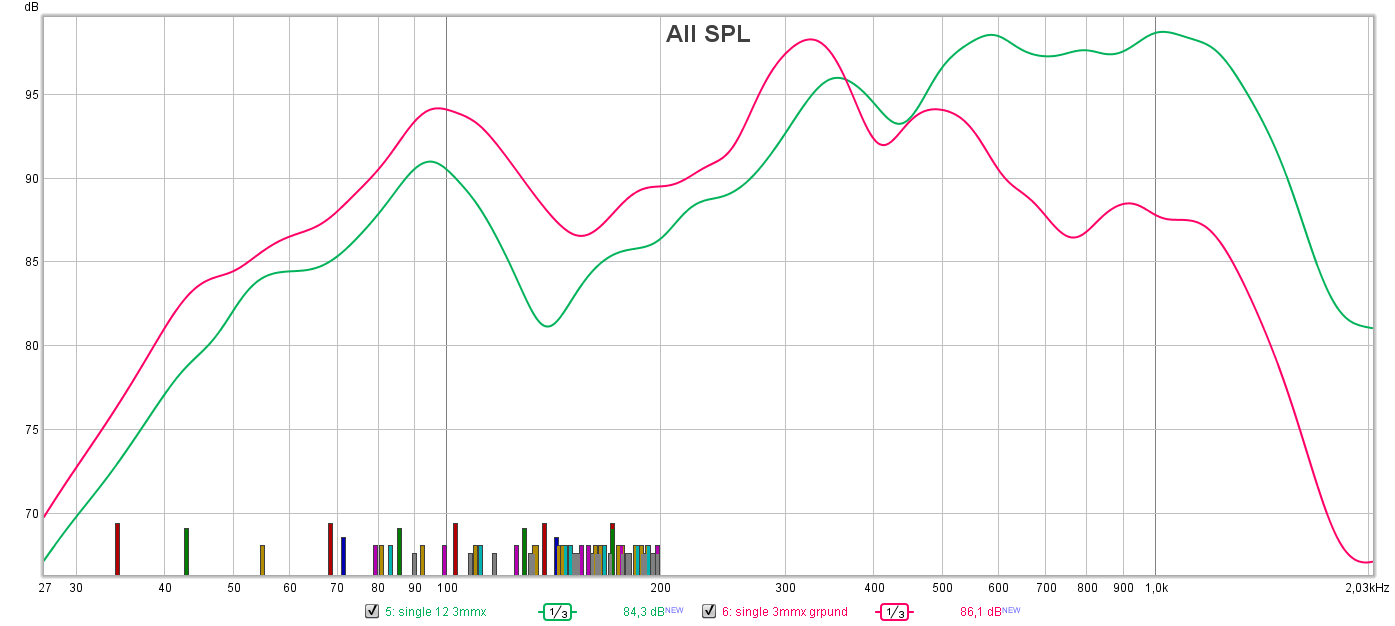

I then removed 1 of the metal plates + magnet and see what it does in single ended (still 6mm xmax ) vs pp Brown PP Dark brown single ended

Distortion of single ended 6mm xmax playing as loud as the Push pull to see what distortion does (same lever else its not fair), the crap around 400 becomes more of a problem

hard to see but 2e order in the bass region is almost twice as high, while 3th order remains the same or is even slightly lower, so total THD only becomes 1% higher give or take.

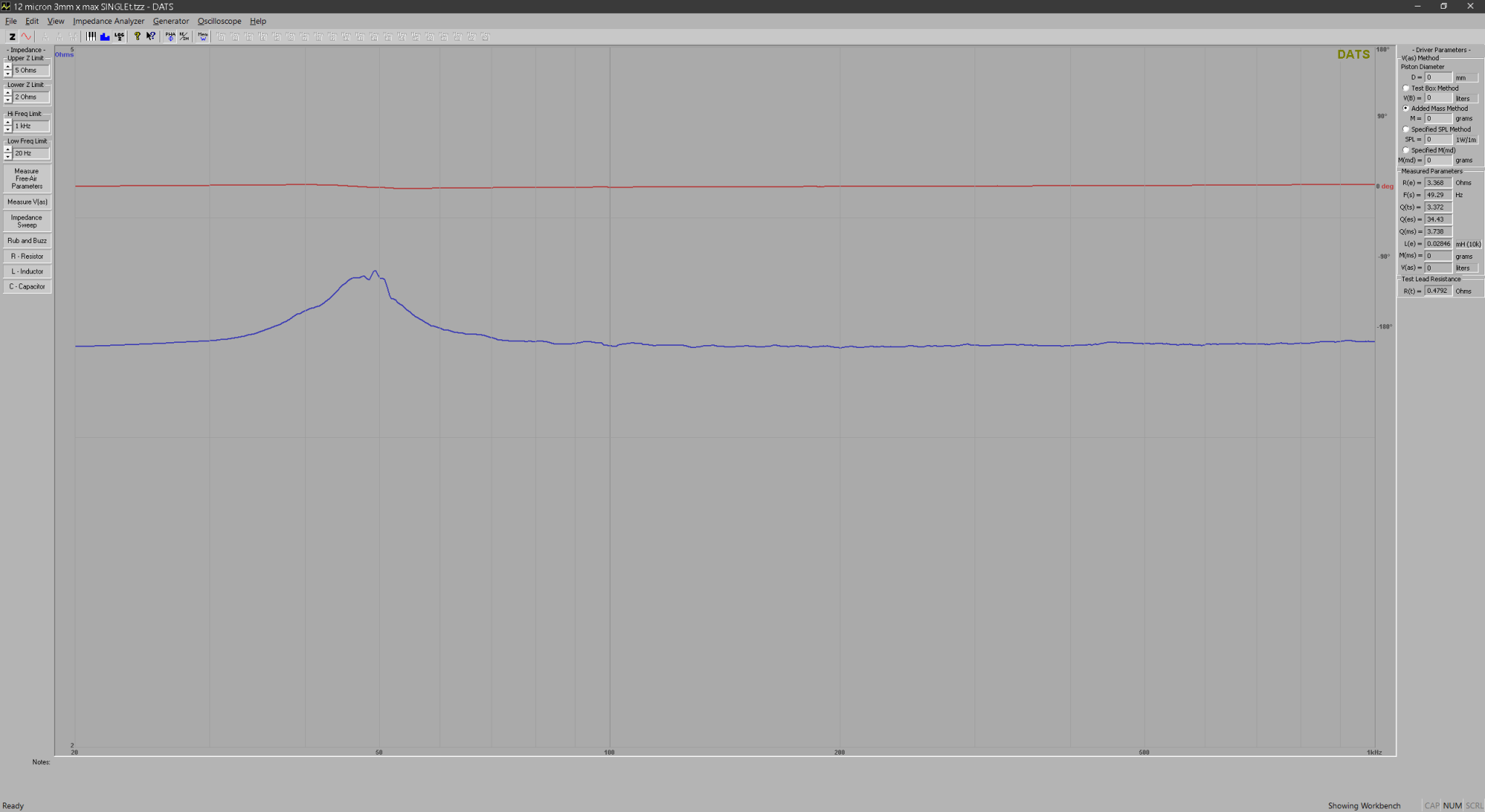

And the free air parameters of the 6mm xmax single ended, you can see Qes is gone again probably to high

probably to high

I then made a spacer so the same foil in single ended has only 3 mm xmax.

Brown PP, Green single ended 3mm xmax and blue 6mm xmax

And distortion of the 3mm single ended at the same volume as the PP. now whats interesting is again 3th harmonics are the same as the PP and sometimes slightly lower sometimes slightly higher. 2e order is higher when you go up in frequency100-300hz but below that it comes close to the push pull, and is much better then the 6mm xmax.

And the free air parameters for the 3mm single ended. Qes is back again, but of course much higher then in the Push pull variant. like twice as high, but at least it has a figure unlike the 6mm xmax.

As extra i wanted to know how much gain i would get if you put this panel on the ground, instead of sitting on my speaker stand. The gain is around 3 dB down low, under 250hz

Now, a few things are interesting. push pull gives some extra output +-3 in the lower frequencies of interest (under 100 hz). and 6 in the region im not interested in.

When using half the xmax , 3mm xmax its more like 1.5dB , if you would make the panel twice as big, @3mm xmax. so you have the same amount of air been moved. distortion will be lower then the push pull with big xmax. for my projects that still would be the way to go, since i also gain more db's because of the larger baffle. and is just cheaper and less work, and will perform better then a small PP high xmax driver. not a real surprise ! but nice to be confirmed. even if the specs in DATS look worse. like Qes

theory is nice ! but measuring it/hearing it is even better

So i wanted to see the exact WIN in SPL for single ended vs the push pull. as mentioned by some this theory of 6dB wont be happening in the lower end, my last measurement was compared to the dual foil. so that one did 6-7 dB, but thats more because the dual one was really low in efficiency.

Here is the Push Pulll foil as comparison to all the other measurements at 1 meter spl this time is calibrated. not sure what voltage. dont care either

Push pull FR

Push pull distortion, there is some nasty poo@400 that im pretty sure is created by the small amount of traces VS undriven foil.

And the free air parameters of the PP

I then removed 1 of the metal plates + magnet and see what it does in single ended (still 6mm xmax ) vs pp Brown PP Dark brown single ended

Distortion of single ended 6mm xmax playing as loud as the Push pull to see what distortion does (same lever else its not fair), the crap around 400 becomes more of a problem

hard to see but 2e order in the bass region is almost twice as high, while 3th order remains the same or is even slightly lower, so total THD only becomes 1% higher give or take.

And the free air parameters of the 6mm xmax single ended, you can see Qes is gone again

I then made a spacer so the same foil in single ended has only 3 mm xmax.

Brown PP, Green single ended 3mm xmax and blue 6mm xmax

And distortion of the 3mm single ended at the same volume as the PP. now whats interesting is again 3th harmonics are the same as the PP and sometimes slightly lower sometimes slightly higher. 2e order is higher when you go up in frequency100-300hz but below that it comes close to the push pull, and is much better then the 6mm xmax.

And the free air parameters for the 3mm single ended. Qes is back again, but of course much higher then in the Push pull variant. like twice as high, but at least it has a figure unlike the 6mm xmax.

As extra i wanted to know how much gain i would get if you put this panel on the ground, instead of sitting on my speaker stand. The gain is around 3 dB down low, under 250hz

Now, a few things are interesting. push pull gives some extra output +-3 in the lower frequencies of interest (under 100 hz). and 6 in the region im not interested in.

When using half the xmax , 3mm xmax its more like 1.5dB , if you would make the panel twice as big, @3mm xmax. so you have the same amount of air been moved. distortion will be lower then the push pull with big xmax. for my projects that still would be the way to go, since i also gain more db's because of the larger baffle. and is just cheaper and less work, and will perform better then a small PP high xmax driver. not a real surprise ! but nice to be confirmed. even if the specs in DATS look worse. like Qes

next up would be creating more of a classic coil design, i usually make. so wider coils. so there is less undriven area (i aways do this in my tweeters it cleans up the top end allot, since i do not care much about efficiency stats, rather have it smoother). this will hurt efficiency, but not by much but im pretty sure it will clean up the distortion 300-600hz more. to regain some SPL, a dual coil could be an option (having a coil on the front of the mylar and on the backl) this should in theory if all else would be the same add 3dB. and might completely compensate for the losses of making the coil wider. i could even add a slight overlap so there is hardly any undriven area

by the way its insane to see how much you lose in the open baffle design... almost 100dB at700Hz and only 86dB at 70 hz for the push pull.

big baffle would have quite some potential, in efficiency but also lowering distortion, without spending more on magnets. (also the reason why single ended half the xmax , but twice the size is a very interesting cost wise)

by the way its insane to see how much you lose in the open baffle design... almost 100dB at700Hz and only 86dB at 70 hz for the push pull.

big baffle would have quite some potential, in efficiency but also lowering distortion, without spending more on magnets. (also the reason why single ended half the xmax , but twice the size is a very interesting cost wise)

Last edited:

well yes and noI saw the construction's video. I guess, the total length of conductor is cca. 14,2 - 14,5m, but only 50% is immersed into full intensity (and well directioned) magnetic field: 3 traces out of 5 run perfectly between magnet rows (there is about 140mT induction). Length: 3*6*40cm=7,2m. The remaining 2 traces is fitted non optimal for push-pull, because the B vector and membrane aren't parallel. And the returning traces (4*25cm) are free from magnetic fields, cannot generate driving force. There is useable B at the loops around magnet rows, but not full intensity. My estimated B*l product is 1,3 T*m, the aluminium volume is cca. 1,5ml (4g) - I think, the conductors cross section is cca. 0,1mm2 (30 micron*3,5mm?)

Where can ensure improvement?

- all of traces need to run between magnet rows

- the 4*25cm big loop can be wider, because these are neutral position at the membrane (will be less parasitic resistance)

- the small loops are OKs

These modifications can bring 3-4dB improvement of sensitivity.

Thicker steel plate (better closed magnetic circuit) can bring 1-1,5dB.

Double sided traces: further 3dB (only when put between rows 2*5 traces). (50 micron but narrover)

The Qes will half, if the sensitivity 3dB higher. At 6dB, the Qes will quarter, compared original

i used in this case 50 micron alu trace is 3mm wide. in the future i will go back to 30 since it cuts much nicer. 4-5mm wide or something depending on if i use dual coil. but i must admit not looking forward to dual coil. cutting coils making foils is a huge part of time spend , if i weigh time spend vs materials.. it sometimes is better to spend money instead of wasting my time , and potential failures. i am not for trowing money at a project as you may know , but sometimes its a wise choice  i am not sure when there will be a diy meeting again, hopefully soon, but then i will make at least a bigger panel with these magnets.. single or push pull. i recon single though

i am not sure when there will be a diy meeting again, hopefully soon, but then i will make at least a bigger panel with these magnets.. single or push pull. i recon single though  (if i enlarged my current cnc at least)

(if i enlarged my current cnc at least)

This is an important sentence!big baffle would have quite some potential, in efficiency but also lowering distortion, without spending more on magnets. (also the reason why single ended half the xmax , but twice the size is a very interesting cost wise)

The efficiency - at bass region! - will increased by wider baffle, and this is true at bigger panel too, because the panel is itself a baffle too. Big panel and big baffle=big bass!

and its a cost thing / workload, i mean the push pull can have a higher xmax so the panel could be smaller. then again its twice the costs for its same size, while the single ended but larger might have more or the same bass output when made twice as big , and less costs because it is less work, while coming really close to the push pull in terms of distortion. and might have better upper end due to an open front. (also looks nicer  )

)

of course same size push pull. would be even better, at a greater cost. and been more of an industrial looking thing. Then again there are a few commercial designs using some sort of push pull lately Diptique and Alsyvox, while the last one has such insane prices... it really does not matter what you made cost wise. for the cheapest model been 70K... you could make something insane none the less, by just trowing money at it

for the cheapest model been 70K... you could make something insane none the less, by just trowing money at it

of course same size push pull. would be even better, at a greater cost. and been more of an industrial looking thing. Then again there are a few commercial designs using some sort of push pull lately Diptique and Alsyvox, while the last one has such insane prices... it really does not matter what you made cost wise.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Dual membrane planar magnetic (both active driven)