Putting together a relay attenuator with virtually immeasurable distortion is trivial, it boils down to resistor distortion and very simple choices. Benchmark may have spent some time scratching their heads how to make the steps silent and smooth but certainly not fighting distortions.

The practically complete lack of distortion in most resistor based switching attenuators does not in any way mean they sound the same or even similar, but this is of course not a topic for this thread.

So noted! I will dig up the manufacturers comment which is on the hardcopy version of the Stereophile review.

That being said, I have seen at least a few preamps whose measurements point to worse and worse performance at greater levels of attenuation. Which defeats the purpose.

Now with the UB pictures, even I am planning getting at least a few! Looking forward to Tom’s VC implementation and his measurements.

Best,

Anand.

Very nice Tom.

Very nice Tom!!!

Sweet board Tom

gorgeous

Thank you! I appreciate it.

Putting together a relay attenuator with virtually immeasurable distortion is trivial, it boils down to resistor distortion and very simple choices.

Yes and no. The resistor distortion will be immeasurable if you use leaded metal film resistors. If you use surface mounted resistors, you do have to pay attention to which resistors you buy. From there, the resistor noice is a solved problem.

You're then on to worrying about relay-induced distortion and such. You also need to pay attention to the PCB layout so you can get good channel separation and good attenuation especially near the "off" end of the attenuator.

It's not rocket science, but at the same time, it's not something you can just slap together and throw in a box either. At least not if you want good performance.

Benchmark may have spent some time scratching their heads how to make the steps silent and smooth but certainly not fighting distortions.

I bet that's what they did. It also gave them a nice marketing blurb about fancy FPGA control. They could probably have implemented the same functionality with 7400-series logic, but nobody does that anymore.

Looking forward to Tom’s VC implementation and his measurements.

I doubt I'll do anything fancier than an Alps RK271-series pot. I would prefer to not have to support a DIY software project.

Tom

Actually, Benchmark spent some amount of time on noise and distortion. They chose very low-noise and low-distortion op-amps that were able to drive/buffer a low-impedance attenuator to minimize noise contribution. Not rocket science and doubtful that there was any significant circuit topology innovation -- just good, thorough engineering.

There is a warm spot in MY heart for 7400 logic.

There is a warm spot in MY heart for 7400 logic.

There is a warm spot in MY heart for 7400 logic.

In mine too. I used quite a bit of "glue logic" in my ISS. I had fun designing the timing circuit that drives the TRIAC and relay.

Tom

Lead-free. Everything is ROHS compliant.

The PCB is designed, manufactured, and assembled in Canada. The PCB was fully electrically tested prior to assembly. All parts came from Mouser (except the ICs, which I bought directly from TI). My local assembly facility is rock solid and the folks there take quality very seriously. The boards undergo an automated 3D optical inspection after assembly to catch any assembly issues. They examine the quality of the solder joints to the exposed pads on the LME49724 by X-ray imaging. At the end, the boards are washed to clean off the flux and packaged in ESD bags.

I'm so glad I found those guys. Quality is very important to me. It also helps that it's only a 15-minute drive from my house and that one of the guys there got me into a recreational hockey league for folks in the electronics industry.

Tom

The PCB is designed, manufactured, and assembled in Canada. The PCB was fully electrically tested prior to assembly. All parts came from Mouser (except the ICs, which I bought directly from TI). My local assembly facility is rock solid and the folks there take quality very seriously. The boards undergo an automated 3D optical inspection after assembly to catch any assembly issues. They examine the quality of the solder joints to the exposed pads on the LME49724 by X-ray imaging. At the end, the boards are washed to clean off the flux and packaged in ESD bags.

I'm so glad I found those guys. Quality is very important to me. It also helps that it's only a 15-minute drive from my house and that one of the guys there got me into a recreational hockey league for folks in the electronics industry.

Tom

If you could publish all the same specs into a 600R load, it would be very useful information for many of the use cases of this board.

Some may argue that any source gear competent enough to drive the 50K load of this buffer, would already be competent enough to drive the 100k load this board is subjected to in your testing. Putting into question the benefits of adding the extra circuitry into the signal path.

Some may argue that any source gear competent enough to drive the 50K load of this buffer, would already be competent enough to drive the 100k load this board is subjected to in your testing. Putting into question the benefits of adding the extra circuitry into the signal path.

Last edited:

one of the guys there got me into a recreational hockey league for folks in the electronics industry.

Wow that sounds super niche sporting!

Great looking product - keen to get one to convert balanced output from existing preamp to SE for input into amp.

My existing (commercial) tube preamp has sub-optimal earthing arrangement which is impacting it's SE outputs. This is partially mitigated by a 'ground loop breaker (diodes, R, C)' but seeking an alternative option.

If you could publish all the same specs into a 600R load, it would be very useful information for many of the use cases of this board.

Yes, this. My situation is power amps with 5k input impedance. Would be interesting to see some measurements for both some gain and a tougher load than 100k.

Yes, this. My situation is power amps with 5k input impedance. Would be interesting to see some measurements for both some gain and a tougher load than 100k.

Yes the 2v output and 100K input measured results are great for getting a bunch of oooh's and ahhhh's from the numbers guys. But certainly doesn't reflect a real world application. I'd like to see 600R with 10V output.

Kinda like saying your car can do 200mph. But only when doing a burnout on an ice patch.

Last edited:

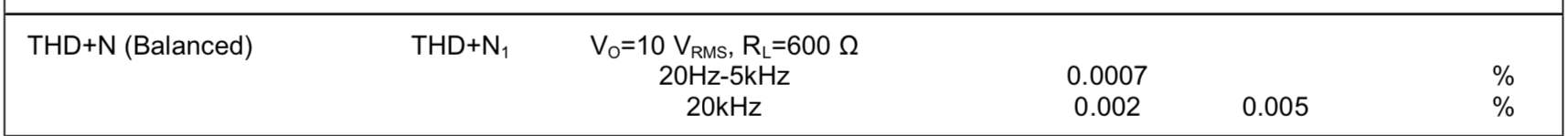

10v and 600R is a pretty standard test condition. If we look at the That 1646 for example, that's what they use in the data sheet:

http://www.thatcorp.com/datashts/THAT_1606-1646_Datasheet.pdf

http://www.thatcorp.com/datashts/THAT_1606-1646_Datasheet.pdf

Attachments

Yes the 2v output and 100K input measured results are great for getting a bunch of oooh's and ahhhh's from the numbers guys. But certainly doesn't reflect a real world application.

No? Common input impedances for amps tend to sit around 47-48 kΩ. As you pointed out earlier, the difference between that and 100 kΩ is largely academic.

I'd like to see 600R with 10V output.

Your four posts requesting this clearly indicate your interest in this data point. Will you allow me to measure it for you or do you intend to continue to throw my product under the bus with your trolling?

Kinda like saying your car can do 200mph. But only when doing a burnout on an ice patch.

What evidence do you have to suggest that's the case for the Universal Buffer?

Oh, and welcome to DIY Audio, by the way. Or should I say, "congratulations on your reincarnation on DIY Audio"?

Anyway. So far, I have two action items regarding the Universal Buffer:

- THD+N vs output level at various gains

- THD+N vs output level at 600 Ω load

Tom

It was just a simple request to see what this board can do under industry standard test conditions. Not sure how that is "throwing it under the bus"??

Not sure why anyone would need this buffer to drive 2v into a 100k load. What source gear that can drive the 50k input impedance of this board can't do that already? I'm a bit confused.

It appears many people have plans to use this buffer in front of the Purifi amp kit. Which means it will need to drive 10v into a 2200R load. 600R is a standard input impedance test level, and likely a preset already in your analyzer. Which is why I picked it.

Not sure why anyone would need this buffer to drive 2v into a 100k load. What source gear that can drive the 50k input impedance of this board can't do that already? I'm a bit confused.

It appears many people have plans to use this buffer in front of the Purifi amp kit. Which means it will need to drive 10v into a 2200R load. 600R is a standard input impedance test level, and likely a preset already in your analyzer. Which is why I picked it.

OK. So five requests for testing with 600 Ω load. Got it!

Please see Post #116 where I've committed to taking that measurement. I'll add 2 kΩ load as well. Do we need to argue further or will you allow me time to perform the testing?

Tom

Just inquiring on why those test conditions where chosen to showoff what this board can do. That's all.

If you could provide an example of a typical use cause where this board would be used under those conditions, and why this buffer would be beneficial in this particular application, it would clarify things a bit more for me.

Light load will always show the best performance, so I chose that operating point to start. As you can see in Post #116 and #118, I am adding other data points.

There is only one of me and only 24 hours in my day. I have other competing priorities as well. Making five requests and demanding justification for anything you happen to read between the lines will only distract me from taking the measurements. If your goal is to have those measurements provided, I hope that you are able to see that you are working against yourself here. Unless you're trolling, or have a competing product to sell. In those cases, it would obviously be in your best interest to keep me distracted.

A typical use case would be a preamp with differential output: Source -> Volume Pot -> Universal Buffer. In that case, the Buffer is likely to see a 48 kΩ differential load.

Tom

There is only one of me and only 24 hours in my day. I have other competing priorities as well. Making five requests and demanding justification for anything you happen to read between the lines will only distract me from taking the measurements. If your goal is to have those measurements provided, I hope that you are able to see that you are working against yourself here. Unless you're trolling, or have a competing product to sell. In those cases, it would obviously be in your best interest to keep me distracted.

A typical use case would be a preamp with differential output: Source -> Volume Pot -> Universal Buffer. In that case, the Buffer is likely to see a 48 kΩ differential load.

Tom

You can just say that the real reason for those test conditions is because you wanted the sensationalized headlines ( Universal Buffer achieving -140 dBc (0.00001 %) THD) and that most potential buyers would never question the measured results anyways. That honest answer would have worked. Considering there was 108 posts before mine and nobody else questioned this, your strategy had some merit.

Last edited:

- Home

- Vendor's Bazaar

- Universal Buffer achieving -140 dBc (0.00001 %) THD