What I thought might be a good reason for looking at direct (DC) coupling between driver and output stages in the particular case of a 300B amp might be the fact that we require a rather large voltage swing into the output tage. So slew-rate requirements between driver and output tube are bigger.

Furthrmore, since the output power is a bit limited, we would be pushing the amp into the upper regions more often as compared to higher powered amp. Consequently, good overload recovery would be an important design goal.

My understanding is that direct coupling of the output tube can. help with both of these aspects.

Furthrmore, since the output power is a bit limited, we would be pushing the amp into the upper regions more often as compared to higher powered amp. Consequently, good overload recovery would be an important design goal.

My understanding is that direct coupling of the output tube can. help with both of these aspects.

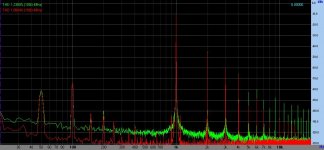

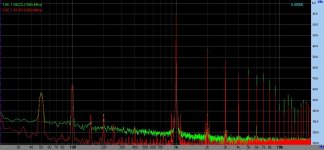

Measuring at 2013:Can you tell how much the distortions are ?

6W, 9W.

Attachments

Measuring at 2013:

6W, 9W.

Are these measured from an actual amp or simulation? Just curious.

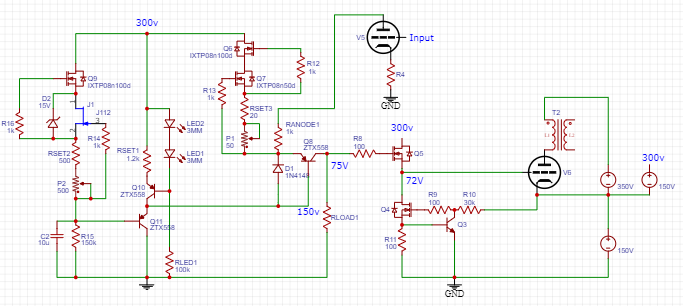

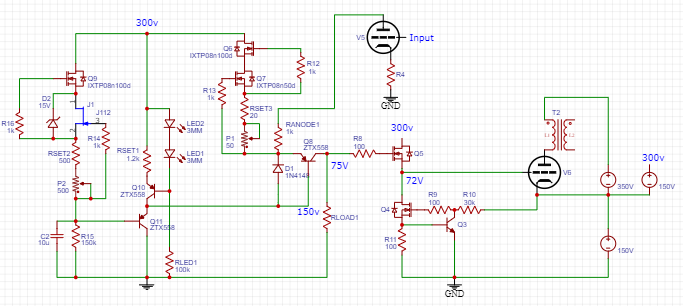

This is driver for the Electro Harmhttps://postimg.cc/BPW5JNg7onix 300b tube

Measuring at 2013:

6W, 9W.

Measured (VT-176 dual channel voltmeter, EMU0404 USB, Visual Analyser).

Cool thanks. I see so many posted simulations, it's nice to see an actual >measured from a real live amplifier< one

It was the best (low THD) pair of 300B (gold grid EH300B) which I have for decades. Sadly one of them died (filament interrupted) after few years.

Nowadays the SQ is much worse, so it's probably unrepeatable.

Yeah I noticed a big difference between the Psvane and the 300B-z tubes.

None of all 300B type suitable for A2.Why not buying one of the new WE 300B tubes instead?

Most of them reacts with growing distortion if grid swing approaching or exceeding 0V.

Robust metal anode and grid wire types (for example old ValveArt, Electro-Harmonix or JJ) can be used.

I'm not sure, that "boutique" production tube (NOS or replica WE, Elrog, EML etc.) worth it for testing.... as you can say it's only for rich kids.

Yes, the source follower DC coupled to power tube.to euro21

your schematic is a dc coupling to 300B? Walter

Attachments

I will try this one myself someday

Direct coupled SET proposal – wauwatosa tube factory

I will order and use Rod Coleman's new shunt cascode kit. I'm not sure if it is ready yet or not.

Direct coupled SET proposal – wauwatosa tube factory

I will order and use Rod Coleman's new shunt cascode kit. I'm not sure if it is ready yet or not.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Looking for a 300b SE design