Hello,

I like the concept of *heater bias* with Rod Coleman Filament Regulators which has been shown as viable for eliminating cathode bypass caps in *indirectly heated triode* driver stages...thinking of doing this for C3g triode driving 300B as a two stage amp. It's *filament bias* for heater valves, no?

Can we do this with pentodes as well? ...could be a boon! I'm thinking of applying it to a WE 310A driver in a 91 amp with the 300B filament fed by a Tent Labs filament regulator. Even though the current WE user manual says that AC heating is "optimal". ???

Sorry, I'm EE challenged, just thinking I'm having a sudden insight...please correct me if I'm wrong.

RC

I like the concept of *heater bias* with Rod Coleman Filament Regulators which has been shown as viable for eliminating cathode bypass caps in *indirectly heated triode* driver stages...thinking of doing this for C3g triode driving 300B as a two stage amp. It's *filament bias* for heater valves, no?

Can we do this with pentodes as well? ...could be a boon! I'm thinking of applying it to a WE 310A driver in a 91 amp with the 300B filament fed by a Tent Labs filament regulator. Even though the current WE user manual says that AC heating is "optimal". ???

Sorry, I'm EE challenged, just thinking I'm having a sudden insight...please correct me if I'm wrong.

RC

Yes, it makes no difference to have a pentode, and the WE310A has low heater current (ca. 300mA) and low bias voltage (ca. 3V) that makes "heater bias" a reasonable prospect, without large heat dissipation.

If you try to do this with Guido's (Tentlabs) module, allow for the fact it stabilizes the output voltage, and that adding an extra 3V to the output is not automatically accommodated, as it is with my regulator - which stabilizes current.

AC heating is not "optimal" if good sound is your objective!

If you try to do this with Guido's (Tentlabs) module, allow for the fact it stabilizes the output voltage, and that adding an extra 3V to the output is not automatically accommodated, as it is with my regulator - which stabilizes current.

AC heating is not "optimal" if good sound is your objective!

I use this on all IDHT tubes also on a c3o pentode. Manfred Huber made a shoout on with different bias methodes on ETF.

European Triode Festival 2004 - Tube Festival Report on TNT-Audio - www.triodefestival.net - [English]

European Triode Festival 2004 - Tube Festival Report on TNT-Audio - www.triodefestival.net - [English]

One of the classic old tube studio microphones used heater bias. Can't remember which - probably Neumann, AKG or one of the Germans. One of the microphone gurus here would probably remember which one.

Speaking of Manfred Huber - do you have a link to his lecture or similar?

Speaking of Manfred Huber - do you have a link to his lecture or similar?

I am wondering about Colemans versus tent regulators, Coleman specifies 5uV? or so current noise from what i read, this implies that over resistances of 40 ohms or more, the tentlabs modules should beat the Colemans in therms of noise. Est 200uV noise+hum from the measurements i did on the circuit.

About noise and filament bias:

The self-noise of my RC-V8 regulator is below 5µV rms (20-20kHz) for moderate currents, <2A, in a real circuit, with cables. If you build the Raw DC according to the sections in the manual, and choose a standard industrial EI power transformer, you will get a 100/120Hz spur of 7-14µV depending on the current. Depending on the rms algorithm you use, the total noise in a real circuit, with a long output cable will still be <25µV.

For the example of the OP's WE310A, with 9.3V output: 6.3V heater + 10Ω bias resistor connected as "heater bias" (so, output negative to ground) the noise will be <10µV.

With the RC-V8, using high values of filament/heater resistor (say, 470-1kΩ) makes little difference to the self-noise, but does render the circuit susceptible to line fundamental (50 or 60Hz). The exact same effect (with the exact same amplitude of 50Hz spur) appears with a Tentlabs unit, as Ale discovered when measuring RE084 circuits.

As a result of Ale's tests, I have developed the RC-V9 version of the regulator, that fixes this problem completely (<1µV at 50Hz, for 200mA and 910Ω bias resistor), along with other improvements.

The self-noise of my RC-V8 regulator is below 5µV rms (20-20kHz) for moderate currents, <2A, in a real circuit, with cables. If you build the Raw DC according to the sections in the manual, and choose a standard industrial EI power transformer, you will get a 100/120Hz spur of 7-14µV depending on the current. Depending on the rms algorithm you use, the total noise in a real circuit, with a long output cable will still be <25µV.

For the example of the OP's WE310A, with 9.3V output: 6.3V heater + 10Ω bias resistor connected as "heater bias" (so, output negative to ground) the noise will be <10µV.

With the RC-V8, using high values of filament/heater resistor (say, 470-1kΩ) makes little difference to the self-noise, but does render the circuit susceptible to line fundamental (50 or 60Hz). The exact same effect (with the exact same amplitude of 50Hz spur) appears with a Tentlabs unit, as Ale discovered when measuring RE084 circuits.

As a result of Ale's tests, I have developed the RC-V9 version of the regulator, that fixes this problem completely (<1µV at 50Hz, for 200mA and 910Ω bias resistor), along with other improvements.

We are splitting hairs i think, anything below 1mV is inaudible on most systems. Unless you drop 25K on field coil horns there is no way on gods green earth a 94db driver is going to hum excessively.

But this is just a solution waiting for a problem, its wasteful of energy diminishes the MTBF of the circuits at hand.

The same or better noise results will be obtained with a Lithium Ion battery pack, and a 780X You can get those 5000mAH Lithium ion power packs for cheap

This is a interesting part if one wants to build something with a switchmode prereg, Ultralow Noise and Ultrahigh PSRR - YouTube

//OT Rant on.

I think more energy should be directed towards getting rid of inductors and power transformers in general. If common mode noise issues can be overcome, switchers make a far better alternative to bulky, expensive mains transformers.

Electronic chokes make a far better alternative to bulky multi-Henry inductors with boatloads of stay capacitance.

//OT rant off.

Im not gonna even try to argue the cult, In this particular case it may be feasible, but its higher noise than two Red Leds or a resistor, wastes power and if not implemented correctly can be counterproductive.

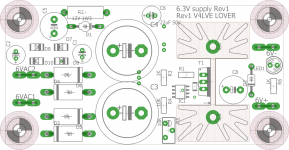

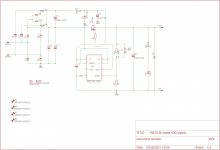

Attached are the gerbers for a simple board using the MIC5156 LDO controller in SOIC-8 to provide 3A of 6.3VAC input 6,3VDC output* This is what you want when efficiency is the goal.

*from a 6A AC 6.3V winding.

An improved version exists with a DIP8/TH version of the controller, but id rather see the geriatric ward struggle.

I like MELFS and i cannot Lie.

But this is just a solution waiting for a problem, its wasteful of energy diminishes the MTBF of the circuits at hand.

The same or better noise results will be obtained with a Lithium Ion battery pack, and a 780X You can get those 5000mAH Lithium ion power packs for cheap

This is a interesting part if one wants to build something with a switchmode prereg, Ultralow Noise and Ultrahigh PSRR - YouTube

//OT Rant on.

I think more energy should be directed towards getting rid of inductors and power transformers in general. If common mode noise issues can be overcome, switchers make a far better alternative to bulky, expensive mains transformers.

Electronic chokes make a far better alternative to bulky multi-Henry inductors with boatloads of stay capacitance.

//OT rant off.

Im not gonna even try to argue the cult, In this particular case it may be feasible, but its higher noise than two Red Leds or a resistor, wastes power and if not implemented correctly can be counterproductive.

Attached are the gerbers for a simple board using the MIC5156 LDO controller in SOIC-8 to provide 3A of 6.3VAC input 6,3VDC output* This is what you want when efficiency is the goal.

*from a 6A AC 6.3V winding.

An improved version exists with a DIP8/TH version of the controller, but id rather see the geriatric ward struggle.

I like MELFS and i cannot Lie.

Attachments

I cant wait when V9 is available

A few more tests to do, and it will be released. The board is working well...

Damn, I'm behind the times, still on V4 in my preamp and amps. The good news is that they both sound great, and are rock-solid reliable. Great job, Rod!

Glad to hear the regulators are still giving good service after all these years - thanks, Bob!

> We are splitting hairs i think, anything below 1mV is inaudible on most systems. Unless you drop 25K on field coil horns there is no way on gods green earth a 94db driver is going to hum excessively.

> but id rather see the geriatric ward struggle.

Well Florick, you were promoting low noise earlier, when you thought it might look bad for my solution. Are you sliding back into trolling & derailing threads involving my work again?

Do you mean the Shunt Cascode? Apologies for the delay. It's coming, but I have had to design around some parts shortages. You're on my list for updates, when I have a fully tested kit....Also having a hard time waiting for the new Source Follower Kit.

Best,

RC

Well Florick, you were promoting low noise earlier, when you thought it might look bad for my solution. Are you sliding back into trolling & derailing threads involving my work again?

Not really, or i'd have put in more effort. The nuclear option would have been to repeat some of J*** claims again. My coleman VS tent remark was because you specified current noise on your website . I just applied Ohms law

if my reasoning is correct there are instances where your current noise over a high value resistor will produce more voltage noise than a simpler solution.would. And i wrote it in such a clumsy way you'd be the only one to get what i was getting at.

I am quite certain that a RC/capacitor multiplied preregulated LM317 based supply, with red led bias is going to be lower noise in this particular case (Small signal tube bias)

Coming back to Ales work, there is no comparison between the two modules, the tentlabs modules need their shunt resistor replaced by a 10X value if you are going to heat a low current RE084? with it because otherwise the error signal from the sense resistor is way too low to give optimal noise suppression from the current source. This is because the current sense resistor is optimized for efficiency. I dont know what current versions use for opamps but the 358 small signal gain isn't great and such a low value of shunt is going to adversely affect noise performance.

Okay, i will ask him.

"If you want to impair the lifetime of you tubes, you must use those modules, which heat up the tube extremely slow, in a false attempt to do it "better". Really, tube technology is 100 years old, and when you read good books about vacuum tube design of those days, you will realise how much they knew about it. This is extremely impressing. At least it is for me. We all know, modern Getters are made of Barium, and that is because it has gas absorbing capabiltiy. However that capability at room temperature is low. For what we call "high vacuum", the getter must be in between 180°C and 600°C. Above 600° the getter reverses partially, it will begin to release small fractions of it's gas again. Here comes the problem with slow heat up. The heater is also Barium coated, and the heater will act as a getter, if below 600°C. Actually like a very good getter, because the slow heating "specialists" will keep the tubes for 20 or 40 seconds in that ideal range. So the cathode will absorb any gas residue. We call that cathode poisoning. So yes, it is nice when the heater removes that gas, only... the pure Barium, which we so carefully constructed at it's surface will be turned into an some other composit, like Bariumoxide, Bariumcarbonate, or whatever the gas residue was. The reverse process (above 600°C when normal orange color appears) is slow and incomplete, so as an avarage, gas will stay attached to the cathode, and damage it's surface.

I do this business since 1995, and there is a lot of ignorance with people who construct those electronic modules. Such modules can be good, but only if they are designed with knowledge about what tubes need, and this is simply FAST heat up, but avoid excessive fast heat up, and avoid slow heat up ALWAYS. The best has always been the natural current limiting, like an AC heater winding provides, like just 2...3 seconds and then already the heater voltage is close to 90%, and much above 600°C, and we are out of that danger zone as quick as we can. "

Emission Labs. Information about life time of electron tubes.

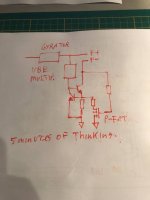

I would seriously consider some mechanism in your next current source to provide 125-150% of rated current during start up to avoid these problems, I suggest a P channel FET that switches in another current sense resistor in parallel to the existing 1VBE current sense resistor, in the ratio R:2R. You can then drive the fet gate out of conduction with the voltage coming out of the gyrator stage. Its a two parts solution.

"If you want to impair the lifetime of you tubes, you must use those modules, which heat up the tube extremely slow, in a false attempt to do it "better". Really, tube technology is 100 years old, and when you read good books about vacuum tube design of those days, you will realise how much they knew about it. This is extremely impressing. At least it is for me. We all know, modern Getters are made of Barium, and that is because it has gas absorbing capabiltiy. However that capability at room temperature is low. For what we call "high vacuum", the getter must be in between 180°C and 600°C. Above 600° the getter reverses partially, it will begin to release small fractions of it's gas again. Here comes the problem with slow heat up. The heater is also Barium coated, and the heater will act as a getter, if below 600°C. Actually like a very good getter, because the slow heating "specialists" will keep the tubes for 20 or 40 seconds in that ideal range. So the cathode will absorb any gas residue. We call that cathode poisoning. So yes, it is nice when the heater removes that gas, only... the pure Barium, which we so carefully constructed at it's surface will be turned into an some other composit, like Bariumoxide, Bariumcarbonate, or whatever the gas residue was. The reverse process (above 600°C when normal orange color appears) is slow and incomplete, so as an avarage, gas will stay attached to the cathode, and damage it's surface.

I do this business since 1995, and there is a lot of ignorance with people who construct those electronic modules. Such modules can be good, but only if they are designed with knowledge about what tubes need, and this is simply FAST heat up, but avoid excessive fast heat up, and avoid slow heat up ALWAYS. The best has always been the natural current limiting, like an AC heater winding provides, like just 2...3 seconds and then already the heater voltage is close to 90%, and much above 600°C, and we are out of that danger zone as quick as we can. "

Emission Labs. Information about life time of electron tubes.

I would seriously consider some mechanism in your next current source to provide 125-150% of rated current during start up to avoid these problems, I suggest a P channel FET that switches in another current sense resistor in parallel to the existing 1VBE current sense resistor, in the ratio R:2R. You can then drive the fet gate out of conduction with the voltage coming out of the gyrator stage. Its a two parts solution.

Attachments

Last edited:

Yawn. What's this got to do with the thread? Just More trolling and misinterpretation.

Jac's concern applies only when the full anode voltage is present at the start of warm-up.

He agreed with me in discussion that if the dht is biased OFF (which is what my Bias Regulator does) or if the anode supply is off - slow start is actually better.

Jac's concern applies only when the full anode voltage is present at the start of warm-up.

He agreed with me in discussion that if the dht is biased OFF (which is what my Bias Regulator does) or if the anode supply is off - slow start is actually better.

Last edited:

Do your customers know? You seem to gloss over the downsides of your own products far to often. Call me a troll if you like, but Jac is right and you are wrong.

You are right about delayed HV, its what tektronix did with their scopes after all and the tubes in those live forever. but unless this tiny bit of information is included in the sales package people are going to use it wrong. And pushing another product to limit the potential damage of your other product is not sound engineering, or ethical.

You are right about delayed HV, its what tektronix did with their scopes after all and the tubes in those live forever. but unless this tiny bit of information is included in the sales package people are going to use it wrong. And pushing another product to limit the potential damage of your other product is not sound engineering, or ethical.

- Home

- Amplifiers

- Tubes / Valves

- Heater Bias with Rod Coleman Fil Regs