To compare individual gu48 tubes, the following test setup was assembled:

15 Ohm resistor is connected to each filament pin. The opposite ends of these resistors are connected together, at this point we have the midpoint of the filament voltage. The midpoint is then connected to ground with 200 ohm resistor. Plate voltage was adjusted for each tube, at which plate current comes to 135 mA. At the same time, due to the autobias on the resulting cathode resistance of 208 Ohms, the negative grid bias is 28 volts.

In other words, one can say, that for each tube example, an individual value of the plate voltage was determined, at which the bias on the grid consists -28V and the plate current was 135 mA.

If we divide the range of measured plate voltages Ua into segments of 50 volts, we get the following distribution of the number of tubes along these segments:

1550-1600 volts - 4.4%

1600-1650 volts - 15.5%

1650-1700 volts - 20%

1700-1750 volts - 20%

1750-1800 volts - 20%

1800-1850 volts - 15.5%

The best examples of tubes for obtaining maximum output power in A1 mode are in the 1550-1600 volts group, and the worst examples belong to the 1800-1850 volts group.

15 Ohm resistor is connected to each filament pin. The opposite ends of these resistors are connected together, at this point we have the midpoint of the filament voltage. The midpoint is then connected to ground with 200 ohm resistor. Plate voltage was adjusted for each tube, at which plate current comes to 135 mA. At the same time, due to the autobias on the resulting cathode resistance of 208 Ohms, the negative grid bias is 28 volts.

In other words, one can say, that for each tube example, an individual value of the plate voltage was determined, at which the bias on the grid consists -28V and the plate current was 135 mA.

If we divide the range of measured plate voltages Ua into segments of 50 volts, we get the following distribution of the number of tubes along these segments:

1550-1600 volts - 4.4%

1600-1650 volts - 15.5%

1650-1700 volts - 20%

1700-1750 volts - 20%

1750-1800 volts - 20%

1800-1850 volts - 15.5%

The best examples of tubes for obtaining maximum output power in A1 mode are in the 1550-1600 volts group, and the worst examples belong to the 1800-1850 volts group.

Also, the GU-46 tube is good for the output units of powerful single-ended amplifiers.

The maximum power dissipated at the anode is 500 W, in a triode connection the voltage gain is about 5, the internal plate resistance is 500-700 Ohm, depending on the operating point.

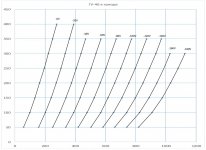

I enclose the results of preliminary (incomplete) measurements of the GU-46 in the triode connection (because of limited power of my test anode transformer). With SE output stage, one can easily get an output power of 70-100 W in A1. Big output transformers will be more simple in design, than for GU-48.

The maximum power dissipated at the anode is 500 W, in a triode connection the voltage gain is about 5, the internal plate resistance is 500-700 Ohm, depending on the operating point.

I enclose the results of preliminary (incomplete) measurements of the GU-46 in the triode connection (because of limited power of my test anode transformer). With SE output stage, one can easily get an output power of 70-100 W in A1. Big output transformers will be more simple in design, than for GU-48.

Attachments

Speaking about tube socket for GU46, it is easier to go with self-made "socket", like in these photo. Also I intend to use assembled cathode resistor, made of 12 wire resistors, 10W each. In spite of all disadvantages, I prefer to go with autobiased stage.

Attachments

Hi VladimirK, I think you will know that most high power triodes need solid socket contacts for a bit of cooling too. After all, the heater uses a lot of curent and a possible poor or less secure heater connection may damage the tube.

I have used Philips QB / TB triodes and tetrodes in diy, using air and watercooling... I used heater voltage stabilisation too.

Regards, Gerrit

I have used Philips QB / TB triodes and tetrodes in diy, using air and watercooling... I used heater voltage stabilisation too.

Regards, Gerrit

Absolutely, the contact resistance to the filament pins should be minimal, and heat should be removed from the contact point. If we talk about GU48, a standard tube socket and top caps made in China have been used. The amplifier is in use for about a year, there are no issues with overheating. With GU46, the situation is more complicated, the filament pins have a diameter of only 4mm. But a copper plate 90x10x0.5mm is used as a current-carrying conductor, which squeezes the filament leg as tightly as possible. Clamping is provided by two M3 screws, nuts and spring washers. Even if the contact resistance is 0.01 Ohm (in reality it is less), it is not a problem to dissipate about 1 W of heat for the indicated copper plate.

If there will be overheating during prolonged operation of GU46, it will be necessary to increase the width of the copper plate.

If there will be overheating during prolonged operation of GU46, it will be necessary to increase the width of the copper plate.

I would like to note an unclear point that is present in the description of technical characteristics of tube amplifiers. Manufacturers usually indicate amplifier outputs, which are intended for connection of various speakers - 4, 8 and 16 ohms. At the same time, they do not indicate the value of dumping factor, or the value of output resistance. Moreover, manufacturers even confuse the consumer, when they write - the output resistance is 4, 8 and 16 ohms, which is simply an unacceptable mistake. The question arises, what useful information does this data carry? In my opinion, none. At the 4 ohms output, one manufacturer may have an output impedance of 1.4 ohms, another - 2.4 ohms, and a third - 0.8 ohms, which indicates the absence of any technical idea to optimize the output impedance for 4 ohm speakers. In such a situation, a user has no information about what dumping factor might be for his particular speakers. For example, my PMC EB1i speakers has impedance curve, that drops to 3.6 ohms at about 100 Hz frequency, and it is highly undesirable for me to purchase amplifier with 2.4 ohms output impedance. But, I cannot find such information in the technical specifications from manufacturers.

I mention this unclear point here as some additional ground, why one needs to use powerful tube designs for big 4 Ohms speakers. Only big output tubes allow to get enough output power, and good damping factor at the same time.

I mention this unclear point here as some additional ground, why one needs to use powerful tube designs for big 4 Ohms speakers. Only big output tubes allow to get enough output power, and good damping factor at the same time.

A few days ago, I had a discussion with a colleague about the reliability of transmission tubes. We both agree, that most US and UK tubes are reliable and very good for sound. This is when it comes to low power tubes, 417, 6SN7, 2A3, 6B4G, etc. The old Soviet analogs of such tubes are inferior to them in sound quality, although they are not inferior in reliability (presence of gases, stability, service life). Some Soviet tubes are excellent in sound quality (for example, YO186).

But, one can't be sure about the quality of old high-power USA made transmission tubes. This conclusion was also mentioned by some participants at this forum. Few years ago I have bought three pairs of 4E27 tubes from various sellers in USA. I really wanted to use them as output tubes and to test sound quality. But, it was not possible to select a working pair of tubes. There were problems with gases, instability of work point, some of the tubes have totally lost emission in the process of fighting with gases. The two tubes, which have come to stable operation, are very different in parameters.

I am not writing this information to advertise old Soviet tubes, which are not taken seriously by many. Please understand correctly. But, in my experience of measuring a large number (more than hundred) of powerful old Soviet transmission tubes, such as gm70, gk71, gu48, gu46, gu81m, there was not a single case when the tube ended up without a vacuum and did not come into working condition. At the very beginning, there may be a slight change in the operating mode, but stabilization is achieved in 3-5-10 minutes. About half of the tubes are stable immediately after they switched on. I can assure, that gu48 and gu46 are quite worthy candidates for use.

But, one can't be sure about the quality of old high-power USA made transmission tubes. This conclusion was also mentioned by some participants at this forum. Few years ago I have bought three pairs of 4E27 tubes from various sellers in USA. I really wanted to use them as output tubes and to test sound quality. But, it was not possible to select a working pair of tubes. There were problems with gases, instability of work point, some of the tubes have totally lost emission in the process of fighting with gases. The two tubes, which have come to stable operation, are very different in parameters.

I am not writing this information to advertise old Soviet tubes, which are not taken seriously by many. Please understand correctly. But, in my experience of measuring a large number (more than hundred) of powerful old Soviet transmission tubes, such as gm70, gk71, gu48, gu46, gu81m, there was not a single case when the tube ended up without a vacuum and did not come into working condition. At the very beginning, there may be a slight change in the operating mode, but stabilization is achieved in 3-5-10 minutes. About half of the tubes are stable immediately after they switched on. I can assure, that gu48 and gu46 are quite worthy candidates for use.

Copper plate GM70 has the same ceramics and supports (mechanical structure) as a graphite plate tube, but sounds better, because of the metal plate.

However, the "Iron" plate GM70, moreover, has much rigid mechanical structure, four vertical supports. Therefore they are considered to be "Queens" among GM70 family.

However, the "Iron" plate GM70, moreover, has much rigid mechanical structure, four vertical supports. Therefore they are considered to be "Queens" among GM70 family.

Attachments

The woodwork on the 833A amps is beautiful. You could spend $350,000 for a WAVAC 833A stereo and you could never have the custom style and you probably would not get a better output transformer than a Hammond 1642SE rated at 300ma and solidly built be an experienced company or engineers. The 833A for most of us is for DIY people and trying to sell more affordable 833A amps is far more complicated than knowing how to build them.

I have used Philips QB / TB triodes and tetrodes in diy.

I would say, you've lucky location. There were plenty perfect tube types produced by Philips starting from 30th and earlier. I believe even nowadays such tubes much easier to find at motherland.

Nice job, Vladimir!

I never saw this thread because it mentioned the model of speaker but not the type of vacuum tube. I suppose you've seen my thread on the Midlife Crisis 833C amps. I too wanted to drive big, inefficient speakers (Infinity RSIIb) full-range with an SET, so high-voltage transmitter tubes became the solution. Enjoy!

At 2300V anode and 160mA, I get 40W Class A1 and up to 200W in Class A2. Mostly I stay in A1 but transients definitely push me well into A2. Very powerful, yet definitely SET sound. I went for the Monolith OPTs, expensive but they are great-sounding!

I never saw this thread because it mentioned the model of speaker but not the type of vacuum tube. I suppose you've seen my thread on the Midlife Crisis 833C amps. I too wanted to drive big, inefficient speakers (Infinity RSIIb) full-range with an SET, so high-voltage transmitter tubes became the solution. Enjoy!

At 2300V anode and 160mA, I get 40W Class A1 and up to 200W in Class A2. Mostly I stay in A1 but transients definitely push me well into A2. Very powerful, yet definitely SET sound. I went for the Monolith OPTs, expensive but they are great-sounding!

Attachments

Last edited:

Mine is more modest. I only use 1000 Volts and zero grid bias which draws 120 ma through a transformer rated for 300 ma. Using a poor man's way to measure how linear it is I put flash light batteries between grid and ground, reverse polarity, and the increase in current positive bias measures the same as decrease in current at negative bias. It also sounds gorgeous and is more than loud enough through Magnapans turned about half way up.

Newer understood advantages for use 833a at such conditions. Pair of 211 or one GM-70 looks much more convenient.

Perhaps, but there is a coolness overkill factor to the 833C that I found irresistable. Dangerous voltages, massive iron, and the lack of others going that route just encourages me.

Maybe that's also why I drive a 717HP Hellcat with a manual transmission...it's a sickness.

Attachments

It might be so, but the less aggressively you drive a tube the less the distortion and an 833A does not have to be driven as hard as a smaller tube. However I suspect the difference in sound becomes a matter of preference. In both cases you get that sublime SET sound. And 833A's are for me more fun.

Message above was not about you. It was reply to next one.Perhaps, but there is a coolness overkill factor to the 833C that I found irresistable.

I've not much against these tubes itself and nothing against your operating point. I was using GU-48 years ago with similar voltage, but less current. These tubes really overheated my room and I dissembled amps finally. That's why I choose tubes with less power consumption now, but spend close to 600W per channel any way.

I don't see much interest spend 100W for heating tube operates at 120W plate. You can find many candidates with lower internal resistance for such job. Really I can imagine single answer - Yes, 833A is really cool

Last edited:

Message above was not about you. It was reply to next one.

I've not much against these tubes itself and nothing against your operating point. I was using GU-48 years ago with similar voltage, but less current. These tubes really overheated my room and I dissembled amps finally. That's why I choose tubes with less power consumption now, but spend close to 600W per channel any way.

I don't see much interest spend 100W for heating tube operates at 120W plate. You can find many candidates with lower internal resistance for such job. Really I can imagine single answer - Yes, 833A is really cool

Got it. Thanks for clarifying. ;-)

- Home

- Amplifiers

- Tubes / Valves

- Tube amplifiers with PMC EB1i speakers