Can't believe new for old caps could change the sound,.... I am using Duelund cable for the jumpers to the new pot as it's not PCB mount, and that does take time to run in - but in my experience using it as an interconnect it was not flat at first, just a bit messy and untidy with plenty of dynamics and a little bass shy to begin with.

This tells me everything I need to know to diagnose the problem.

However, several others have already identified it.

To test a stereo pot, parallel both halves, apply some voltage to them, and connect DVM to their whippers. Rotate it and check how close to zero is the voltage, all the way. It is how I test pots. It should not jump, and be as close to zero as possible. Tracking matters, quality of contact matters. The rest is for another forum, about sorcery and fairy tales.

Well thanks everyone for the help, ideas and of course the charming critique

Well this update will not sit well with those members having severs snake oil allergies...but it seems the brand new HT capacitors needed time to run in. I spoke to a few more contacts locally and a number told me to leave it on for a day or so and let the capacitors run in. Thankfully the bass, warmth and dynamics have returned; actually quite dramatically.

on another note for those with more technical prowess, I swapped these caps in an attempt to finally remove some residual hum, thinking 35 year old electrolytic caps might not be smoothing as required.

However hum has not changed.

So far I have to reasonable effect added a shield to DC heater cables and some AC cables that are running nearby signal/valves. I have also added some steel plates to shield/partition the mains transformer. All of these changes have made incremental differences, but after the caps I can't think of anything else to try?

Any ideas?

Well this update will not sit well with those members having severs snake oil allergies...but it seems the brand new HT capacitors needed time to run in. I spoke to a few more contacts locally and a number told me to leave it on for a day or so and let the capacitors run in. Thankfully the bass, warmth and dynamics have returned; actually quite dramatically.

on another note for those with more technical prowess, I swapped these caps in an attempt to finally remove some residual hum, thinking 35 year old electrolytic caps might not be smoothing as required.

However hum has not changed.

So far I have to reasonable effect added a shield to DC heater cables and some AC cables that are running nearby signal/valves. I have also added some steel plates to shield/partition the mains transformer. All of these changes have made incremental differences, but after the caps I can't think of anything else to try?

Any ideas?

Just two words - "desoldering needles"

Like $4-5 for a set including shipping from China

Oh WOW!!!

I wasn't aware of this most significant breakthrough of the century, and immediately ordered a bunch. I've got 8 noval tube sockets to replace on a plate-through PCB, and that's no fun.

Thanks!!!

... Tracking matters, quality of contact matters. The rest is for another forum, about sorcery and fairy tales.

Contact rectification is very real, even for the ophidiophobic (yeah, look it up) non-believers. I've measured THD of the order of a percent from some old CTS and AB pots. Unfortunately, it changes unpredictably with age, always for the worse; that's why I value subjective inputs, but, of course, I filter them.

It's a pity the OP has not done a direct comparison between the old and new pots.

This would have been a useful contribution. Same as the issue of pot break in about which i personally know nothing. Doing more than one swap at a time and allowing it to settle down before the next move brings nothing useful.

This would have been a useful contribution. Same as the issue of pot break in about which i personally know nothing. Doing more than one swap at a time and allowing it to settle down before the next move brings nothing useful.

From a technical point of view, the only unwanted parameters I can think of a variable reistance comprised of a resistive track with a mechanical slider are inductance, capacitance and thermal noise generated by the finite amount of randomly moving free electrons in the resistance. The other occasional 'parasitic' is unstable contact resistance of the slider which is often caused by aging and dirt. The latter, is readily corrected by using a contact cleaner.

Last edited:

... The other occasional 'parasitic' is unstable contact resistance of the slider which is often caused by aging and dirt. The latter, is readily corrected by using a contact cleaner.

That's just a temporary hack. It'll come back, and soon, believe me.

Contact rectification is very real, even for the ophidiophobic (yeah, look it up) non-believers. I've measured THD of the order of a percent from some old CTS and AB pots. Unfortunately, it changes unpredictably with age, always for the worse; that's why I value subjective inputs, but, of course, I filter them.

Sure, copper oxide is a semiconductor. Such pots are also "scratchy". Garbage.

I used to have vintage Siemens pots. They had a silver plated bronze spring with a hole, and a graphite "nail" in it. What a beauty they were!

It is a well known fact that capacitors with a shelf life of a couple of years come to their full ability after many hours (weeks) of use. Probably the alu oxide to elektrolyte contact chemically changes, affecting internal resistance.... it seems the brand new HT capacitors needed time to run in. I spoke to a few more contacts locally and a number told me to leave it on for a day or so and let the capacitors run in. Thankfully the bass, warmth and dynamics have returned; actually quite dramatically.

On another note for those with more technical prowess, I swapped these caps in an attempt to finally remove some residual hum, thinking 35 year old electrolytic caps might not be smoothing as required.

However hum has not changed.

So far I have to reasonable effect added a shield to DC heater cables and some AC cables that are running nearby signal/valves. I have also added some steel plates to shield/partition the mains transformer. All of these changes have made incremental differences, but after the caps I can't think of anything else to try?

Any ideas?

Humm can have several origins. Can you put up a picture of your build, both from under the deck as above?

Not only capacitors.

My Gustard AK4499 DAC sounds noticeably better after a full week of breaking-in.

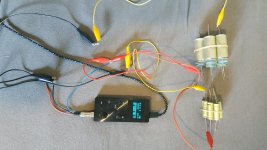

No big deal, play of loop of music, switch off the power amp, and come back later. Here's how I break my PS caps. Eric Clapton’s No Reason to Cry works great

My Gustard AK4499 DAC sounds noticeably better after a full week of breaking-in.

No big deal, play of loop of music, switch off the power amp, and come back later. Here's how I break my PS caps. Eric Clapton’s No Reason to Cry works great

Attachments

Zung said:That's just a temporary hack. It'll come back, and soon, believe me.edbarx said:... The other occasional 'parasitic' is unstable contact resistance of the slider which is often caused by aging and dirt. The latter, is readily corrected by using a contact cleaner.

If the contact surface is damaged replacement is the only solution but cleaning does help when there is no damage.

Last edited:

It is a well known fact that capacitors with a shelf life of a couple of years come to their full ability after many hours (weeks) of use. Probably the alu oxide to elektrolyte contact chemically changes, affecting internal resistance.

Humm can have several origins. Can you put up a picture of your build, both from under the deck as above?

Here is the latest build it's an old ARC SP8

I have added a switch that did not give any benefit so I will remove (it bypasses the mode selector switch and balance wheel) to take signal either in bypass or after the balance wheel. I have a friend who has an SP10 and the bypass on his amp (for phono only) makes a valuable benefit. The hum is the same before and after this switch, done the same time as the PS caps. There is logically a chance that the bypass added new hum and the caps removed the old hum I guess!

The shielding is shown and is sort of temporary to see and progress things, but will stay and get finalised properly once it's all solved (if I can get there)

Attachments

Thermionic valves need a current to power their heaters which is usually AC. This can inject a hum signal into the genuine signal path. To avoid such hum injection, the valve heaters' supply wires are twisted and displaced away from the circuit board in the form of flat arches. I have seen this technique being employed by Uncle Doug on youtube to correct hum issues of guitar amplifiers.

I'm pretty much a numbers guy, yet I believe pots matter for reasons I don't understand. Tracking is more important than most people think because slight balance problems are audible. Pots vary in noise, but I can't see how that matters here. I usually end up going with a stepped attenuator made from decent resistors because pot quality is variable and the good ones can be expensive.

I've had SP8's and SP10's before, and hum has never been a problem.

In order to find what's wrong with yours, download the schematic, highlight the parts you've replaced, and post it here. Also, it would help if you had some test equipment, an oscilloscope would be ideal.

Meanwhile, here's a check list:

In order to find what's wrong with yours, download the schematic, highlight the parts you've replaced, and post it here. Also, it would help if you had some test equipment, an oscilloscope would be ideal.

Meanwhile, here's a check list:

- Disconnect the preamp all together. Any hum only from the power amp?

- Reconnect the preamp, but disconnect all the inputs. Is the hum still present? Phono? Line?

- Check if your preamp and your amp have a grounded AC plug for a possible ground loop

Thermionic valves need a current to power their heaters which is usually AC. This can inject a hum signal into the genuine signal path...

Uh-uh: the SP8 has DC heater.

Those Spraque Atoms (blue caps, for DC heaters probably?) are very near the yellow interstage coupling caps. If there is high ripple on those blue caps they might couple to the interstage coupling caps (I presume those yellow ones have this function). Try to separate them for a test. If successful, reverse their orientation to keep the outerfoil on the lower impedance of the circuit.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Potentiometer sound quality