I acquired some transmitting tubes; the kind where the plate is supposed to glow red and act as the getter in normal operation.

I want to test them and make sure they aren't gassy. What is the best way to run them up? Do I need to let them run for a period of time at a high-ish dissipation to allow the plate to absorb stray gas molecules?

How can I maximize my chance of not causing any harm on first power-up?

I want to test them and make sure they aren't gassy. What is the best way to run them up? Do I need to let them run for a period of time at a high-ish dissipation to allow the plate to absorb stray gas molecules?

How can I maximize my chance of not causing any harm on first power-up?

I guess it depends on the type of tube. I used big and bigger tubes like 813, TB4/1250, QB3/750, and even TBW6/6000 water cooled. First I would just apply the filament voltage for a few hours. Make sure you don’t have too much voltage. Then add the B+ very slowly, without drawing much current. Later I use the full B+ and draw more current. This whole process will keep you busy for hours and hours... Fuses installed!

Regards, Gerrit

Regards, Gerrit

Please be specific on what you have and I'll tell you what I know from my years of testing.

826s

I was thinking of putting 450V on the plate and 0V on the grid at first and see how much current they draw. Should be like 20mA.

I have an old bench supply that can do 600V at a couple hundred milliamps. I will setup transmitting tubes like that and ground the grid to the ground in the power supply, ground one end of the filament, then heat up the filament for 20-30 seconds, then start turning up the DC voltage on the bench supply.

You'll either see the plates start to to glow red, or you'll see the colorful display of gas inside the tube.

You'll either see the plates start to to glow red, or you'll see the colorful display of gas inside the tube.

Hi, I think I would start with a higher negative voltage first (after a period of just filament power), for example minius 50 or 70 volt. You can then lower the voltage and see the current flow increasing.

Regards, Gerrit

I have a -75V adjustable bias supply that I can use and just slowly crank to 0. I just don't know how slow this process should go; how long to run the filaments, etc.

I have an old bench supply that can do 600V at a couple hundred milliamps. I will setup transmitting tubes like that and ground the grid to the ground in the power supply, ground one end of the filament, then heat up the filament for 20-30 seconds, then start turning up the DC voltage on the bench supply.

You'll either see the plates start to to glow red, or you'll see the colorful display of gas inside the tube.

Ok, I think I can set something like that up pretty easily. I'm assuming that sometimes a tube is too gassy to save, but that some with just a tiny amount of gas can be cleaned up by letting the tube "cook" for a while. I'm assuming that requires significant anode current to get the plate warm enough to do its gettering job, though.

Geesh, 826s are one of my least favorite tubes because I have found a large portion of them are air bottles and the rest are 50% too gassy to save. I check for gas with a high voltage "odin" type coil (below) which connects to a 10KV neon or oil burner transformer by just holding the spark against the glass in dim light.

If the filament lights up normally (without smoking) there is a simple DC emission test you can do. Light the filament and ground it. Connect the grid and plate together as a diode and put 100VDC across the tube right from the DC supply. A good tube should pull 500ma. Do this only long enough to get a reading. Also, quickly dropping the filament by 10% will indicate the overall condition. A strong tube not drop much, but a weak one will be very spongy in it's reaction. I normally test most all big tubes on my purpose built tester that's good to over 1KW dissipation. I think you will do OK to power up a tube with a bench supply as you mention above. You may need a little negative on the grid to control the current if it's a little gassy. Grid current will confirm this. And you are correct in that some tubes you can reduce the gas by baking with plate current and some will be beyond saving.

If the filament lights up normally (without smoking) there is a simple DC emission test you can do. Light the filament and ground it. Connect the grid and plate together as a diode and put 100VDC across the tube right from the DC supply. A good tube should pull 500ma. Do this only long enough to get a reading. Also, quickly dropping the filament by 10% will indicate the overall condition. A strong tube not drop much, but a weak one will be very spongy in it's reaction. I normally test most all big tubes on my purpose built tester that's good to over 1KW dissipation. I think you will do OK to power up a tube with a bench supply as you mention above. You may need a little negative on the grid to control the current if it's a little gassy. Grid current will confirm this. And you are correct in that some tubes you can reduce the gas by baking with plate current and some will be beyond saving.

Attachments

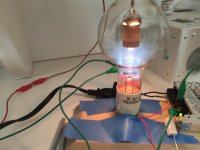

I normally test most all big tubes on my purpose built tester that's good to over 1KW dissipation.

Wow, that’s a nice rig for testing. Love those tubes too!

Regards, Gerrit

Tubes of this nature need a cherry red plate to recombine residual gas in the tube. Usually if a tube fails to degas in one or two hours it's pretty bad off. Monitoring tube current will indicate if it's coming down. Sometimes using forced air cooling with higher plate current helps. Some will come down while others just won't. So it's a judgement call based on experience. A big reason why I never liked this tube. Also Eimac tubes with green glass on the bottom are very problematic for gas content in my experience.

Sorry no. Never liked the code requirement back then. I know it's not required now for some levels but I just never felt the urge to get a license.@HollowState -- that's one impressive piece of gear -- ham radio op by chance?

Tubes of this nature need a cherry red plate to recombine residual gas in the tube. Usually if a tube fails to degas in one or two hours it's pretty bad off. Monitoring tube current will indicate if it's coming down. Sometimes using forced air cooling with higher plate current helps. Some will come down while others just won't. So it's a judgement call based on experience. A big reason why I never liked this tube. Also Eimac tubes with green glass on the bottom are very problematic for gas content in my experience.

Thanks, I really appreciate the help. I plan on doing the following:

1. Light filament. Smoke is a sign that tube is done for.

2. Connect Variac-driven DC supply to plate and -15V to grid. Light filament and see if tube draws significant current as plate supply slowly rises. Current should be pretty low up to 500V (<10mA).

3. Connect grid to 0V do the same and watch for plate current that roughly matches datasheet.

4. Connect grid to +15 and do the same and let tube sit at 90% rated power for up to two hours. Record current periodically and watch changes. Hope that current matches datasheet value at the end.

Does that look basically sound?

Yes sir.Does that look basically sound?

Next I noted that the tube was just not drawing much current. 550V and 0V of bias should be ~25mA or so of plate current.

To motivate the tube a bit, I hooked up my small 30V DC bench supply to bring the grid up above ground. With the grid at +30V, I would expect about 100mA of plate current to be drawn. The DC current has crept up slowly from about 5mA to now roughly 90mA over the last hour or so.

I will leave this going for quite a while (4-5 hours), then I will shut it down, let the tube cool off, then fire it back up to be sure the gas is still gone.

To motivate the tube a bit, I hooked up my small 30V DC bench supply to bring the grid up above ground. With the grid at +30V, I would expect about 100mA of plate current to be drawn. The DC current has crept up slowly from about 5mA to now roughly 90mA over the last hour or so.

I will leave this going for quite a while (4-5 hours), then I will shut it down, let the tube cool off, then fire it back up to be sure the gas is still gone.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Transmitter Tube Testing