Dear all,

Thanks again for the support. I finally found out the reason for the blowing fuse.

There is a modificaiton on the b+ supply that goes from the preamp to one of the modules. There are a couple electrolytic capacitors towards gnd to reduce ripple. So when reassembling, after the socket/heatsink job, I inverted the connectors of that cable in a way that + and - on the caps were inverted and this caused the fuse to blow. The caps don't seem to be damaged as everything appears to be ok.

Sort of a newbie error...but I am learning fast! ;-)

Thanks again,

Fabrizio

Thanks again for the support. I finally found out the reason for the blowing fuse.

There is a modificaiton on the b+ supply that goes from the preamp to one of the modules. There are a couple electrolytic capacitors towards gnd to reduce ripple. So when reassembling, after the socket/heatsink job, I inverted the connectors of that cable in a way that + and - on the caps were inverted and this caused the fuse to blow. The caps don't seem to be damaged as everything appears to be ok.

Sort of a newbie error...but I am learning fast! ;-)

Thanks again,

Fabrizio

Knob cracking on AMC CVT3030

Dear all,

After some extensive fixing of my hybrid amp AMC CVT3030 I am now facing the final challenge.

When I turn the knob Direct/Normal/Phones(Mute) I hear a rather loud cracking noise which eventually fades out after around 10mins of operation.

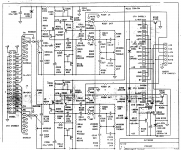

The knob is on the solid state preamp section (see schematic attached).

I have already replaced all the elcos on the signal path (C309/C311/C313 and C310/C312/C314) with Elna Silmic II. In parallel to these caps there are 0.2uF Wima film caps.

In addition, I also replaced other elcos such as C305/C306, C325, C324 (all Elna Silmic).

I also measured the voltage over time at the switch (top of R323/R324) and here are the results. Values are in mV.

Measure Point R323 (L)

30sec: 230

1min: 110

3min: 70

5min: 55

Measure Point R324 (R)

30sec: -290

1min: -240

3min: -65

5min: -7

Any suggestions where else to look?

Thanks again

Fabrizio

Dear all,

After some extensive fixing of my hybrid amp AMC CVT3030 I am now facing the final challenge.

When I turn the knob Direct/Normal/Phones(Mute) I hear a rather loud cracking noise which eventually fades out after around 10mins of operation.

The knob is on the solid state preamp section (see schematic attached).

I have already replaced all the elcos on the signal path (C309/C311/C313 and C310/C312/C314) with Elna Silmic II. In parallel to these caps there are 0.2uF Wima film caps.

In addition, I also replaced other elcos such as C305/C306, C325, C324 (all Elna Silmic).

I also measured the voltage over time at the switch (top of R323/R324) and here are the results. Values are in mV.

Measure Point R323 (L)

30sec: 230

1min: 110

3min: 70

5min: 55

Measure Point R324 (R)

30sec: -290

1min: -240

3min: -65

5min: -7

Any suggestions where else to look?

Thanks again

Fabrizio

Attachments

Please do NOT start multiple threads on the same project, your threads have been merged.

Oh I see, I wasn’t aware of that. Thanks for letting me know.

Fabrizio

Dear all,

After some extensive fixing of my hybrid amp AMC CVT3030 I am now facing the final challenge.

When I turn the knob Direct/Normal/Phones(Mute) I hear a rather loud cracking noise which eventually fades out after around 10mins of operation.

The knob is on the solid state preamp section (see schematic attached).

I have already replaced all the elcos on the signal path (C309/C311/C313 and C310/C312/C314) with Elna Silmic II. In parallel to these caps there are 0.2uF Wima film caps.

In addition, I also replaced other elcos such as C305/C306, C325, C324 (all Elna Silmic).

I also measured the voltage over time at the switch (top of R323/R324) and here are the results. Values are in mV.

Measure Point R323 (L)

30sec: 230

1min: 110

3min: 70

5min: 55

Measure Point R324 (R)

30sec: -290

1min: -240

3min: -65

5min: -7

Any suggestions where else to look?

Thanks again

Fabrizio

Hi everyone, any feedback on this?

Thanks

Fabrizio

you don't need R1 or R8, it will work better without either.

I would use 3 * 470k ( R8,R9,R10 ) for the bias resistors. 1/2w each.

Try some contact cleaner on the pots and switches before replacing them.

Thanks, you mean R308/R310 and R307/R309?

The output valves will need to be sacrificed. Just wiggle them via the glass bulb until the glue bond to the plastic base, fatigues and continue until the lead out wires to the pins give way. .

People advocating the destruction of the valves in order to succeed in removing them are perhaps forgetting that the whole idea is to fit sockets - not destroy half the amp in the process, which isn’t that valuable to begin with (relatively speaking). Besides, the original valves are usually Siemens and thus are probably more valuable second hand than the entire amp itself.

This amp is a bit of nightmare in terms of construction design. If I chose to sacrifice something, it would be the valve pcbs - not the valves. Best way to desolder them in my opinion would be by using a small cheap solder pot (of the type you can get nowadays for 50 bucks, that have a round solder pot usually not containing more than a spoonful of solder).

If you don’t want to buy one, then perseverance, a lot of solder wick and an open window are required. Having already done this myself, I’d buy the pot every time. You run the very high risk of damaging the pcb tracks (I did) and the valve pins/base (I did that too). The valve bases can be replaced, if you are suitably skilled but that’s adding to the overall cost and the hassle is significant - ditto for damaging the pcbs.

stelios, you are making an assumption that the O/P valves were in good working order. I serviced the AMC amplifier as the Sovtek EL34G,s fitted to the pcb were red plating as a result of a bias cct. failure. I tried using de-soldering braid and a solder sucker and these were only of limited success. The pcb was already showing signs of heat damage from the valve base and at risk of being burnt by further de-soldering attempts.

stelios, you are making an assumption that the O/P valves were in good working order. I serviced the AMC amplifier as the Sovtek EL34G,s fitted to the pcb were red plating as a result of a bias cct. failure. I tried using de-soldering braid and a solder sucker and these were only of limited success. The pcb was already showing signs of heat damage from the valve base and at risk of being burnt by further de-soldering attempts.

I was unaware the valves were toast as I had not read the previously exchanged messages in the thread. Apologies for that.

The pcb's I de-soldered the EL34's from already had badly burnt spots as well as some of the nearby roasted molex connectors. It's poorly designed in my opinion as there's a lot of hot parts crammed in a small space. I'm not sure why they oriented the valves horizontally which necessitated the use of fans and the aluminium heat shields/air chimneys. I'd prefer a taller case that could fit the valves standing upright. Why they chose this far more elaborate, more expensive and prone to failure solution baffles me. Not having valve sockets is inexcusable.

I ended up using an entire roll of solder braid (it ain't cheap!), lots of wiggling and repeated re-soldering and solder sucking. A couple of valve pins, a valve base and some pcb tracks were damaged and my patience was depleted.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- AMC CVT3030