Electronics magazine 1947-1948.

Multi-color rotogravure printing. Once known for printing the Sunday color comics, but also widely used for fine work on a variety of materials; this one prints on metal foil. You have to dynamically jiggle the gearing to make all the colors align even as the base web slips shrinks and snakes.

AND: the inks used for rotogravure must dry quickly (between one roller and the next), so are usually highly volatile. Explosive. Comics-printing presses used to blow-up a lot. Strict regulations came into effect.

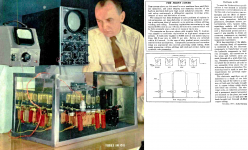

So this guy figured, if all the tubes were submerged in oil, that would meet the UL requirements. Oil-fill is routine in large transformers, also some underwater motors. It apparently works for tubes.

(Yes, I know the old ham trick of mounting a metal 6L6 in a can of oil so the ratings may be exceeded at least short-term. But I never saw a whole tube system in oil.)

https://www.americanradiohistory.com/Archive-Electronics/40s/Electronics-1947-11.pdf

https://www.americanradiohistory.com/Archive-Electronics/40s/Electronics-1948-03.pdf

Multi-color rotogravure printing. Once known for printing the Sunday color comics, but also widely used for fine work on a variety of materials; this one prints on metal foil. You have to dynamically jiggle the gearing to make all the colors align even as the base web slips shrinks and snakes.

AND: the inks used for rotogravure must dry quickly (between one roller and the next), so are usually highly volatile. Explosive. Comics-printing presses used to blow-up a lot. Strict regulations came into effect.

So this guy figured, if all the tubes were submerged in oil, that would meet the UL requirements. Oil-fill is routine in large transformers, also some underwater motors. It apparently works for tubes.

(Yes, I know the old ham trick of mounting a metal 6L6 in a can of oil so the ratings may be exceeded at least short-term. But I never saw a whole tube system in oil.)

https://www.americanradiohistory.com/Archive-Electronics/40s/Electronics-1947-11.pdf

https://www.americanradiohistory.com/Archive-Electronics/40s/Electronics-1948-03.pdf

Attachments

Last edited:

11 miles of print per hour in colour. That's pretty impressive for the time.

Roll forward 60 years and the rate of tree eating is now scary. The world’s biggest and fastest newspaper press apparantly the big mitsubishi presses can kick out 25 full colour newspapers a second.

Roll forward 60 years and the rate of tree eating is now scary. The world’s biggest and fastest newspaper press apparantly the big mitsubishi presses can kick out 25 full colour newspapers a second.

FWIW, the K&E drafting tools add caught my eye. That's what I was taught, long ago. I know nada about CAD/CAM.

BTW, intaglio printing is still used for the production of currency (paper money).

BTW, intaglio printing is still used for the production of currency (paper money).

> the K&E drafting tools ad caught my eye.

Yes; those CAD guys forget we drew plans for mighty fleets, fast tanks, and skyscrapers with batteryless tools that fit in a coat pocket.

More nostalgia:

ELECTRONICS: Electronics Engineering magazine beginning in 1930

Yes; those CAD guys forget we drew plans for mighty fleets, fast tanks, and skyscrapers with batteryless tools that fit in a coat pocket.

More nostalgia:

ELECTRONICS: Electronics Engineering magazine beginning in 1930

Attachments

11 miles of print per hour in colour. That's pretty impressive for the time.

Roll forward 60 years and the rate of tree eating is now scary. The world’s biggest and fastest newspaper press apparantly the big mitsubishi presses can kick out 25 full colour newspapers a second.

The Washington post had two of them near me. Now, they are offline. Dunno if they got sold. Tree eaters indeed, but I am not sure I know anyone who gets a printed paper anymore.

Tubes in oil makes me think pcb.

Before drafting by ink we had to learn to draft by pencils. They had to be clean, and lines had to be of different, appropriate thickness!

I hated that. We had 2 separate disciplines, "Engineering Graphics" and "Drafting Geometry".

Rotring was cool.

We too.

I was real happy when we reached the ink and pen level, later improved by Rotring pens , all of my pencil drawn plans were objected as being "grey", because of graphite smears.

Tubes in oil makes me think pcb.

PCB oil had a distinct yellow color. In the photo it is very clear, possibly mineral oil?

Old timey Hams would stick 6L6's or 1625's transmitter finals upside down in a bucket of used motor oil. Maybe so you couldn't see the plate color.

The ham rig I saw used metal 6L6's. They were supposed to be the trick tube for that job since their metal envelope conducted heat far better than glass.

In the photo it is very clear, possibly mineral oil?

The other item that comes to mind was the Heathkit Cantenna. It used a 50 watt non-inductive ceramic resistor mounted in a 1 gallon paint can which was to be filled with MINERAL OIL. Power rating was 1 KW for short periods of time. Automotive motor oil could be used at a lower power rating. There was a power VS time derating curve on the side of the can (for mineral oil).

Now if I can just get some neat heat sink fins for the 8 NOS metal 6V6's that I have......or maybe adapt one of those water cooling rigs from a high end gaming PC.....excuse me, I need to flush the radiator and change the coolant in my stereo......

Now if I can just get some neat heat sink fins for the 8 NOS metal 6V6's that I have......or maybe adapt one of those water cooling rigs from a high end gaming PC.....excuse me, I need to flush the radiator and change the coolant in my stereo......

!!

!!That electronic computer for the color press was sure something. Plenty of other good stuff in that issue. Mercury delay lines, mixing consoles, FM relay stations (thru some stations that still exist), coax TV networks and thanks to an advert, I now know who made the metal case for my old Halicrafters SW radio.

It looks like a ball-park comparison of free air convection compared to transformer oil conduction, indicates thermal heat transfer away from a glass envelope valve is at least an order of magnitude better for an oil cooled valve.

Transformer oil thermal conductivity can have a wide range due to specific type of oil, and operating temp and viscosity, so not just one generic value.

There is probably not much difference with respect to radiation cooling contribution as transformer oil is pretty clear, and only a portion of heat transfers directly through the glass by radiation.

Due to the 4th power or radiation cooling from the plate, if plate was 425C and glass was 160C (eg. glass in air), then the plate would be about 17C cooler if the glass was in 60C oil (using the 6L6 example in 1962 RCA reference).

Transformer oil thermal conductivity can have a wide range due to specific type of oil, and operating temp and viscosity, so not just one generic value.

There is probably not much difference with respect to radiation cooling contribution as transformer oil is pretty clear, and only a portion of heat transfers directly through the glass by radiation.

Due to the 4th power or radiation cooling from the plate, if plate was 425C and glass was 160C (eg. glass in air), then the plate would be about 17C cooler if the glass was in 60C oil (using the 6L6 example in 1962 RCA reference).

Last edited:

I still get two dead-tree newspapers.

There is still one newspaper press in the area; the weekly rag has a press probably as old as the head pressman who retired last month.

The daily rag used to print at Bangor, on Bangor-market pulp. Things are tough all over. They just moved printing to a press shared with the semi-competitor downstate. AFAIK all paper comes from Canada. Papermills closing all over, or shifting to "specialty" paper which is not so special that some faraway mill can't steal the market.

The machine in post #1 is not oil-cooled, except incidentally. Electricity in explosive-vapor areas (gasoline pumps, rotogravure presses) has to either seal the explosive vapors OUT, or be bomb-proof.

Yes, maintenance would be a mess.

One does wonder why not longer wires and the computer moved outside the hazardous vapor room.

The capacity of that giant newspaper press is staggering. 25 a second?? I used to bundle tie and stack 200 papers a minute off a weekly-shopper press.

There is still one newspaper press in the area; the weekly rag has a press probably as old as the head pressman who retired last month.

The daily rag used to print at Bangor, on Bangor-market pulp. Things are tough all over. They just moved printing to a press shared with the semi-competitor downstate. AFAIK all paper comes from Canada. Papermills closing all over, or shifting to "specialty" paper which is not so special that some faraway mill can't steal the market.

The machine in post #1 is not oil-cooled, except incidentally. Electricity in explosive-vapor areas (gasoline pumps, rotogravure presses) has to either seal the explosive vapors OUT, or be bomb-proof.

Yes, maintenance would be a mess.

One does wonder why not longer wires and the computer moved outside the hazardous vapor room.

The capacity of that giant newspaper press is staggering. 25 a second?? I used to bundle tie and stack 200 papers a minute off a weekly-shopper press.

In the UK there were one or two models of domestic TV that had the sweep transformer and rectifier tube sealed into a can of oil. Murphy V410 Oil filled LOPT surgery - UK Vintage Radio Repair and Restoration Discussion Forum

Kerosene Cooled Transistors!

Yes, a transistor in a tube (read caption); I'm not going to post this in the transistor section, they won't dig it. Belongs here with the oiled tubes.

Kerosene Cooled Transistors!

Not modern transistors. Point Contact. Even at 3mA, the "point" ran at 3,000 Amperes per Square Inch, an astonishing density. The point heat made their multivibrator drift bad. They hacked the case open, took out the thermal grease, and filled with kerosene (they say why too).

Yes, a transistor in a tube (read caption); I'm not going to post this in the transistor section, they won't dig it. Belongs here with the oiled tubes.

Kerosene Cooled Transistors!

Not modern transistors. Point Contact. Even at 3mA, the "point" ran at 3,000 Amperes per Square Inch, an astonishing density. The point heat made their multivibrator drift bad. They hacked the case open, took out the thermal grease, and filled with kerosene (they say why too).

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Tubes In Oil