Here are what the old worn out connectors looked like on an HK Award Series integrated amp:

HK vintage before by antennaguru uda, on Flickr

HK vintage before by antennaguru uda, on Flickr

Drilled out the rivets and installed aluminum plates with new connectors, even varying height to allow for the connector congestion:

HK vintage after by antennaguru uda, on Flickr

HK vintage after by antennaguru uda, on Flickr

HK vintage before by antennaguru uda, on Flickr

HK vintage before by antennaguru uda, on FlickrDrilled out the rivets and installed aluminum plates with new connectors, even varying height to allow for the connector congestion:

HK vintage after by antennaguru uda, on Flickr

HK vintage after by antennaguru uda, on FlickrOh,original connectors ere *floating*, giving designer freedom on choosing where to ground them, you replaced them with fully metallic ones, grounded "there and now" to grounded metal sheets ... not a good thing.

You should have used an acrylic or phenolic o fiberglass sheet instead of aluminum or at least insulate connectors from direct contact with ground by use of insulating washers ... and check body is really insulated from ground before actual wiring.

Same with output connectors: those on the phenolic strip look floating but reflections make the bottom ones confusing, *hope* they are not mounted straight to metal chassis.

You should have used an acrylic or phenolic o fiberglass sheet instead of aluminum or at least insulate connectors from direct contact with ground by use of insulating washers ... and check body is really insulated from ground before actual wiring.

Same with output connectors: those on the phenolic strip look floating but reflections make the bottom ones confusing, *hope* they are not mounted straight to metal chassis.

I try to avoid putting modern parts on vintage amplifiers because authenticity may be lost and the amplifier value will depreciate. Gold plated connectors are one of the worst offenders. Rhodium plated connectors have a look that more closely resembles the original. On low-end restorations I also use China sourced low-cost "silver" connectors. The original brown board can often be reused, without the need to drill out the rivets; this will preserve the vintage look. When the rivets are covered by rust, I use a rust removal product.

Well thanks for your diverse thoughts. You all obviously think differently than I do, which is fine.

First of all, the high quality CMC RCA connectors I used came with chassis insulating washers which I chose not to use because all of the signal grounds were tied together just inside the chassis to a chassis mounted stud next to the old flimsey phenolic plates with the tinned connectors. This means that I could do an even better job (from an EMC standpoint and reducing stray capacitance/inductance) and ground them directly at each connector. The phono stage which has both the RIAA and NARTB positions works very nicely with no hum, as does the tuner input.

Those speaker screw terminal banana plug adapters are the one of the greatest things I found for old gear with speaker screw terminals. I have used them widely to great success as I prefer banana plug speaker wires.

Finally, on the insides it's all re-capped with modern higher quality caps and I don't consider it over-restored, just brought up to the modern standard of higher quality connectors and caps. It's my view that's a big part of what makes "high end" gear better than mid-fi gear. Better quality connections and the internal parts, and that I brought this nice little amp up several clicks in quality was my goal. Different strokes for different folks though.

First of all, the high quality CMC RCA connectors I used came with chassis insulating washers which I chose not to use because all of the signal grounds were tied together just inside the chassis to a chassis mounted stud next to the old flimsey phenolic plates with the tinned connectors. This means that I could do an even better job (from an EMC standpoint and reducing stray capacitance/inductance) and ground them directly at each connector. The phono stage which has both the RIAA and NARTB positions works very nicely with no hum, as does the tuner input.

Those speaker screw terminal banana plug adapters are the one of the greatest things I found for old gear with speaker screw terminals. I have used them widely to great success as I prefer banana plug speaker wires.

Finally, on the insides it's all re-capped with modern higher quality caps and I don't consider it over-restored, just brought up to the modern standard of higher quality connectors and caps. It's my view that's a big part of what makes "high end" gear better than mid-fi gear. Better quality connections and the internal parts, and that I brought this nice little amp up several clicks in quality was my goal. Different strokes for different folks though.

The banana screw terminal adapters look like this and are inexpensive:

https://www.ebay.com/itm/AL-4pcs-Ba...=item3fafe4762a:g:nVYAAOxyOeBR0YWr:rk:21:pf:0

https://www.ebay.com/itm/AL-4pcs-Ba...=item3fafe4762a:g:nVYAAOxyOeBR0YWr:rk:21:pf:0

Nice work.

I Would probably cover the upper side and put all the connectors on the back insulated like this

https://www.google.com/search?q=rca...h=871#imgrc=yak7lQg-qWZSZM:&spf=1542138075630

I Would probably cover the upper side and put all the connectors on the back insulated like this

https://www.google.com/search?q=rca...h=871#imgrc=yak7lQg-qWZSZM:&spf=1542138075630

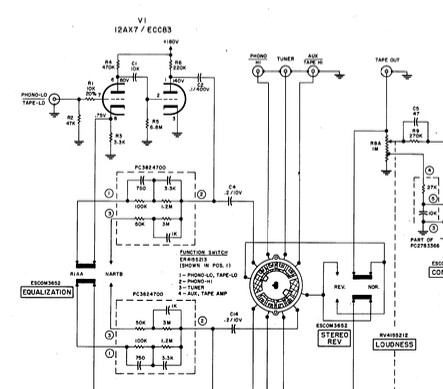

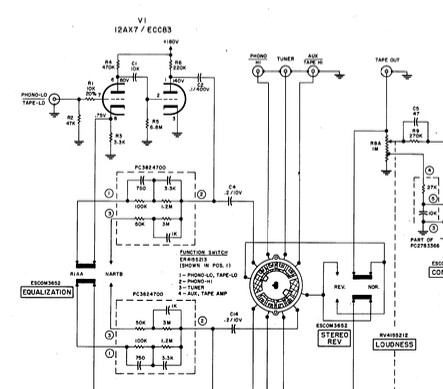

Note in the schematic how all of the RCA connectors are grounded to chassis right where the signal enters the chassis.

Screen Shot 2018-11-13 at 3.43.57 PM by antennaguru uda, on Flickr

Screen Shot 2018-11-13 at 3.43.57 PM by antennaguru uda, on Flickr

Yes indeed it's a A300 which is being used with a TD-150 and a Marantz tuner with a cool scope tuning meter, as a dining room system.

I agree it's weird how HK have the connectors for the two channels separated, and it means you have to use pretty flexible interconnects if you use the metal case as I do.

Vintage DR Gear by antennaguru uda, on Flickr

Vintage DR Gear by antennaguru uda, on Flickr

Screen Shot 2018-11-13 at 3.43.57 PM by antennaguru uda, on Flickr

Screen Shot 2018-11-13 at 3.43.57 PM by antennaguru uda, on FlickrYes indeed it's a A300 which is being used with a TD-150 and a Marantz tuner with a cool scope tuning meter, as a dining room system.

I agree it's weird how HK have the connectors for the two channels separated, and it means you have to use pretty flexible interconnects if you use the metal case as I do.

Vintage DR Gear by antennaguru uda, on Flickr

Vintage DR Gear by antennaguru uda, on Flickr

Last edited:

Looking good!

I really should follow your lead and replace the RCA sockets on my 60s valve amp.

The banana plug adaptors for vintage amplifiers are cool! I was not aware of their existence.

Here's a link to them for potential UK purchasers.

https://www.ebay.co.uk/itm/8-x-Y-Fo...h=item23623ce998:g:hC8AAOSwpzdWr1bq:rk:2:pf:0

I really should follow your lead and replace the RCA sockets on my 60s valve amp.

The banana plug adaptors for vintage amplifiers are cool! I was not aware of their existence.

Here's a link to them for potential UK purchasers.

https://www.ebay.co.uk/itm/8-x-Y-Fo...h=item23623ce998:g:hC8AAOSwpzdWr1bq:rk:2:pf:0

To me, it's a crime to hold back a great piece of equipment with the miserable POS connectors that were available at the time. I have a Heathkit AA-121. It's a nice amp. But you can't use modern RCA cables with it because the jacks are too close together. The screw terminals are even worse than what you see on cheap installation amps.

That's just my opinion, of course, and you're free to do whatever you want. If you want to solder your speaker wires directly to the back of your amp, go right ahead.

That's just my opinion, of course, and you're free to do whatever you want. If you want to solder your speaker wires directly to the back of your amp, go right ahead.

Last edited:

Note in the schematic how all of the RCA connectors are grounded to chassis right where the signal enters the chassis.

It actually does NOT show that. #1 that ground symbol is not indicative of a chassis connection, just a ground connection. #2 it's a schematic, if the ground wire was either 1" or 1000' long, it would still be drawn that way.

for hp screw connections, I often use that.

just remove the old screw and replace it with that, most of the time

without having to drill.

https://www.ebay.co.uk/itm/Speaker-...=item3cd015aee3:g:piUAAOxyCepScT6X:rk:13:pf:0

just remove the old screw and replace it with that, most of the time

without having to drill.

https://www.ebay.co.uk/itm/Speaker-...=item3cd015aee3:g:piUAAOxyCepScT6X:rk:13:pf:0

To me, it's a crime to hold back a great piece of equipment with the miserable POS connectors that were available at the time. I have a Heathkit AA-121. It's a nice amp. But you can't use modern RCA cables with it because the jacks are too close together. The screw terminals are even worse than what you see on cheap installation amps.

That's just my opinion, of course, and you're free to do whatever you want. If you want to solder your speaker wires directly to the back of your amp, go right ahead.

There's more than 1 way to deal with closely spaced RCA jacks on "vintage" equipment.

If the jacks are in acceptable condition and replacement is undesirable or if replacement at OEM spacing has been done, make interconnect cables from Neutrik/Rean NYS-352(B)G plugs for the vintage end and Canare F-10 plugs on the other end. Solder the connectors to Mogami 2549 bulk cable. The Neutrik/Rean plugs fit into some very tight situations, including a stock Dyna ST-70.

To use "modern fat" cabling, remove the OEM jack set(s), nibble out the sheet metal and mount copper clad FR4 PCB material in the opening(s) created. Drill the PCB material to accept well spaced new jacks. It's your choice whether you go ground plane or isolated.

These screw in parts are an alternative for using banana plugs in combination with terminal strip speaker connections.

Hey Leadbelly, I didn't take a picture of the insides when I was doing this work but if you look at the original "before" picture you will notice an unusual small slot in the chassis between the Electrolytic Can and the worn out triple connector phenolic plate. That is a three sided slot that HK bent inward to create a tab on the inside to tie all of the signal grounds to. That's why I didn't bother using the insulating washers on the new RCA connectors. The tab is right by those connectors, so in this case their schematic was quite accurate. It was a weird tab that they figured how to make directly solderable by tinning it. That tab was the common point signal ground to chassis connection.

Not only does it look great but it works great too!

Not only does it look great but it works great too!

The Neutrik/Rean plugs fit into some very tight situations.

Or Switchcraft.

https://www.markertek.com/product/sw3502abau/switchcraft-3502abau-longbody-rca-male-black-gold

There's more than 1 way to deal with closely spaced RCA jacks on "vintage" equipment.

If the jacks are in acceptable condition and replacement is undesirable or if replacement at OEM spacing has been done, make interconnect cables from Neutrik/Rean NYS-352(B)G plugs for the vintage end and Canare F-10 plugs on the other end. Solder the connectors to Mogami 2549 bulk cable. The Neutrik/Rean plugs fit into some very tight situations, including a stock Dyna ST-70.

To use "modern fat" cabling, remove the OEM jack set(s), nibble out the sheet metal and mount copper clad FR4 PCB material in the opening(s) created. Drill the PCB material to accept well spaced new jacks. It's your choice whether you go ground plane or isolated.

These screw in parts are an alternative for using banana plugs in combination with terminal strip speaker connections.

Yep, that's pretty much what I've had to use, but even they fit very tightly. I'm a big fan of Neutrik's connectors in general (I like their strain-relief system).

The AA-121 has some oddities with its back panel, including 32 ohm speaker taps (Need a 40WPC amp for low-impedance headphones, anyone?), and a "phase reversal" system that I struggle to see a use for (maybe just for marketing?).

For the new stuff I build, I like to use these RCA connectors that fit in a D cut-out. They're a little pricey, but it's easy to switch them out for an XLR or just about any connector you want.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Restoring Worn Out Connectors on Vintage Gear