Hey all,

First disclaimer: I'm aware there are other "Beginner" threads. However, many of these are years out of date. While that may not seem significant, sometimes website links changes, designs and kits no longer supported, or new designs come along. Additionally, the needs/wants of the builder, as well as their budget, can vary dramatically.

So without further ado... what would be a recommendation for a good DIY amplifier for a beginner?

For the "Why," I have never heard the "tube magic" in my system and I think I would find it desirable. Qualities I've heard imparted to tube systems are the natural timbre of instruments, the "air" and spacing of instruments, excellent soundstaging and "musicality."

For the "What," My speakers are of moderate efficiency (92 dB), my listening space is large, 25x15x10, volume levels are low to moderate, and music style varies from indie folk to classic rock to pop to electronica to hip hop.

Regarding "How," well, it gets a little convoluted. I have a SS integrated 50 wpc amplifier which has ample power to drive my speakers. What I feel is lacking is clarity, cohesiveness, realism and engagement of the listening experience. I was considering a tube preamp to my integrated SS as a power amp. Alternatively, I've considered a tube integrated amp. However, I would estimate I need at least 8W, perhaps more, to power my system to listening levels I am accustomed to.

As far as price is concerned, the target would be $250. The maximum budget would be $500. My ability to read circuit diagrams is well above average, although my soldering skills are about 10 years rusty. My access to tools (such as a lathe) is limited, so my capability/desire to punch holes in an aluminum chassis is low.

Thanks.

First disclaimer: I'm aware there are other "Beginner" threads. However, many of these are years out of date. While that may not seem significant, sometimes website links changes, designs and kits no longer supported, or new designs come along. Additionally, the needs/wants of the builder, as well as their budget, can vary dramatically.

So without further ado... what would be a recommendation for a good DIY amplifier for a beginner?

For the "Why," I have never heard the "tube magic" in my system and I think I would find it desirable. Qualities I've heard imparted to tube systems are the natural timbre of instruments, the "air" and spacing of instruments, excellent soundstaging and "musicality."

For the "What," My speakers are of moderate efficiency (92 dB), my listening space is large, 25x15x10, volume levels are low to moderate, and music style varies from indie folk to classic rock to pop to electronica to hip hop.

Regarding "How," well, it gets a little convoluted. I have a SS integrated 50 wpc amplifier which has ample power to drive my speakers. What I feel is lacking is clarity, cohesiveness, realism and engagement of the listening experience. I was considering a tube preamp to my integrated SS as a power amp. Alternatively, I've considered a tube integrated amp. However, I would estimate I need at least 8W, perhaps more, to power my system to listening levels I am accustomed to.

As far as price is concerned, the target would be $250. The maximum budget would be $500. My ability to read circuit diagrams is well above average, although my soldering skills are about 10 years rusty. My access to tools (such as a lathe) is limited, so my capability/desire to punch holes in an aluminum chassis is low.

Thanks.

An "El Cheapo" wired ultra-linear (UL), instead of triode, will yield approx. 12 WPC. Any 6V6 family tube works with parts values shown. Nice 6V6s are being produced currently. The 6CM6 is a low cost NOS type, but you have to lay stock away.

Magnetics have never been truly inexpensive and the run up in the cost of copper, etc., over the last few years has made the situation worse. To stay "close" to a $250 total cash outlay, use Edcor's CXPP25-MS-8K O/P transformer. A complete set of power "iron" can be ordered from Allied, for under $100.

No preamp is necessary, if a "standard" CDP is the signal source.

Jim McShane sells kits of parts suited to execution of the project.

BTW, I suggest that triode/UL mode switches be part of the build. Triode is "more refined" and 6 WPC is enough for stuff like a small Jazz combo or a string quartet.

Magnetics have never been truly inexpensive and the run up in the cost of copper, etc., over the last few years has made the situation worse. To stay "close" to a $250 total cash outlay, use Edcor's CXPP25-MS-8K O/P transformer. A complete set of power "iron" can be ordered from Allied, for under $100.

No preamp is necessary, if a "standard" CDP is the signal source.

Jim McShane sells kits of parts suited to execution of the project.

BTW, I suggest that triode/UL mode switches be part of the build. Triode is "more refined" and 6 WPC is enough for stuff like a small Jazz combo or a string quartet.

Attachments

Thanks for the suggestions. Is there any calculator or rule of thumb for predicting listening levels, based on speaker sensitivity, output wattages, and room size? I have heard that tube watts are bigger than SS watts. I would hate to build an amp that is too low powered for my needs. (I would rather not also build/purchase high efficiency speakers... I need to stick to one project at a time).

Thanks for the suggestions. Is there any calculator or rule of thumb for predicting listening levels, based on speaker sensitivity, output wattages, and room size? I have heard that tube watts are bigger than SS watts. I would hate to build an amp that is too low powered for my needs. (I would rather not also build/purchase high efficiency speakers... I need to stick to one project at a time).

A watt is a watt, regardless of the technology used to obtain it. What is different between tubes and SS is that you can safely take a tube amp up right to the point of clipping. SS amps clip hard. Hard clipping damages tweeters.

Tube amps compress, before hard clipping sets in.

Tube amps compress, before hard clipping sets in.Paul Joppa has provided us with a useful rule of thumb for mating amps to speakers. Joppa's Rule states that in listening room of "typical" volume, each channel of an amp/speaker combo should be capable of producing 102 dB. SPL peaks at a 1 M. distance. Adjust up or down, depending on room volume and listening habits.

You stated your speakers are 92 dB. sensitive. What is their nominal impedance? Can you provide a link to the impedance curve of the speakers?

Speaker manufacturers provide specifications that make them look good. Remember, 2.83 V. into 4 ohms is 2 W., not 1 W. and such a claimed sensitivity has to be derated by 3 dB. Another reason for derating speaker sensitivity is large dips in the impedance curve, particularly in the deep bass region. A tube amp's power O/P does not "double", when switched from 8 ohms to 4 ohms.

Eli,

I have requested the impedance curve from the manufacturer. If they furnish this, I will provide it. Based on the limited information currently available on their website (https://www.aperionaudio.com/manuals/Manual_VerusGrandTower.pdf), they are 6 ohm nominal impedance. And prior to looking it up, I would have sworn they were 8 ohm.

I have requested the impedance curve from the manufacturer. If they furnish this, I will provide it. Based on the limited information currently available on their website (https://www.aperionaudio.com/manuals/Manual_VerusGrandTower.pdf), they are 6 ohm nominal impedance. And prior to looking it up, I would have sworn they were 8 ohm.

A tube amp, an sca-35 for instance, has several taps on theEli,

I have requested the impedance curve from the manufacturer. If they furnish this, I will provide it. Based on the limited information currently available on their website (https://www.aperionaudio.com/manuals/Manual_VerusGrandTower.pdf), they are 6 ohm nominal impedance. And prior to looking it up, I would have sworn they were 8 ohm.

output transformer where one can select the best matching impedance.

If your speakers are 8 ohm, choose the 8 ohm tap and let the amp deliver

it's full capacity.

Transistor amps on the other hand are designed to drive 4 ohm, when used with 8 ohm speakers you loose power.

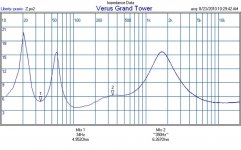

Impedance Curve

Found an impedance curve for my speakers. (Source: Aperion Verus Grand Tower Overview and Measurements | Audioholics)

Looks to be a 4 ohm dip in the ~100 Hz range.

Found an impedance curve for my speakers. (Source: Aperion Verus Grand Tower Overview and Measurements | Audioholics)

Looks to be a 4 ohm dip in the ~100 Hz range.

Attachments

A complete set of power "iron" can be ordered from Allied, for under $100.

I'm assuming this refers to a soldering iron? Are you suggesting my $20 RadioShack soldering iron (which I lost in my recent move) isn't adequate?

My concern for any build is the enclosure. Either woodwork or metalwork sounds somewhere between difficult and untenable in my current situation.

"Iron" is a buzzword for transformers and chokes. If you need to buy new soldering tools, look for 30 W. The solder lugs you will be working with are not flimsy. You can, and should, heat sink SS parts, when they are being soldered in.

The impedance curve of the Varus Grand Tower speakers is not terrible. We will treat them as 4 Ω and 90 dB. sensitive.

A 12 W. UL mode "El Cheapo" is not quite enough amp, especially in a high volume listening space. OTOH, a 30 W. "El Cheapo Grande" will not "run out of gas". The "Grande" uses 7591 O/P tubes. Use Edcor's CXPP60-MS-6.6K O/P transformer. Check out this thread, where a Hungarian member is working on an "El Cheapo Grande".

$250 is not realistic for a "Grande", but I will do my level best to bring the project in at or under $500. Some metal work will be necessary to keep costs down. A heavy walled, commercial kitchen, aluminum baking pan makes a nice, budget, chassis. If the builder supplies plenty of "elbow grease", a hand held drill, a nibbling tool, and files are sufficient to make all the necessary openings. Spend money on better tooling, such as hole saws, and step bits, to reduce the amount of labor needed.

The impedance curve of the Varus Grand Tower speakers is not terrible. We will treat them as 4 Ω and 90 dB. sensitive.

A 12 W. UL mode "El Cheapo" is not quite enough amp, especially in a high volume listening space. OTOH, a 30 W. "El Cheapo Grande" will not "run out of gas". The "Grande" uses 7591 O/P tubes. Use Edcor's CXPP60-MS-6.6K O/P transformer. Check out this thread, where a Hungarian member is working on an "El Cheapo Grande".

$250 is not realistic for a "Grande", but I will do my level best to bring the project in at or under $500. Some metal work will be necessary to keep costs down. A heavy walled, commercial kitchen, aluminum baking pan makes a nice, budget, chassis. If the builder supplies plenty of "elbow grease", a hand held drill, a nibbling tool, and files are sufficient to make all the necessary openings. Spend money on better tooling, such as hole saws, and step bits, to reduce the amount of labor needed.

If you want a tube amp for the music experience see

Vintage Dynaco Dynakit St 35 Stereo Tube Power Amplifier ST35 | eBay

it's currently in $99 range.

And best of all, it's original and may be sold whenever your want something else.

Vintage Dynaco Dynakit St 35 Stereo Tube Power Amplifier ST35 | eBay

it's currently in $99 range.

And best of all, it's original and may be sold whenever your want something else.

If you want a tube amp for the music experience see

Vintage Dynaco Dynakit St 35 Stereo Tube Power Amplifier ST35 | eBay

it's currently in $99 range.

And best of all, it's original and may be sold whenever your want something else.

It is already on my Watch List. I anticipate the price will increase, however, prior to closing.

I have a suggestion for you. There's a thread in one of the speaker forums here, titled "A Test. How much Voltage (power) do your speakers need?"

I followed the directions there and found that in my living room and with my 90dB/1W/1m speakers, I really only need 15 watts per channel of power. I'm actually running only 6 watts per channel, but it seems to work well enough.

The basic steps in this test are:

First, download the test files you'll find in that thread. They're pre-calibrated to play at the correct level for the measurements that will follow. Burn them onto an audio CD-R to play in your CD player.

Play a favorite few music CD's (not the test CD-R) on your stereo at the top volume you ever plan to use it. Note the position of the volume control.

Get a good RMS-reading voltmeter. Play the -12dB track on the test CD-R, with the volume setting you used to play your music really loudly. Measure the voltage across the + and - terminals on your speakers while you're playing that track.

I measured about 4V RMS at my speaker terminals. 4 squared is 16, and that's how many watts I need (per channel), according to this method.

The trick is to be honest when you assess how loud you actually play your stereo. If you really crank it, then conduct the test at that 'cranked' level setting on your volume control.

I feel your pain. I hate metalwork. It really helps to have decent tools. Greenlee chassis punches make life so much easier. You basically need two -- one for making the holes for octal tubes, the other for making holes for 9-pin miniature tubes. According to this post, a 1-1/8" punch will work for most octal sockets, while a 3/4" punch will work for most 9-pin mini sockets (and most 7-pin mini sockets too).

Greenlee standard 1-1/8" knockout punch

Greenlee 3/4" knockout punch

I don't know if those are available somewhere else for less money. I do know they're available from Grainger (that's where I got mine).

The smaller holes can be made with a hand-held power drill. Just make sure to get decent bits, designed for metalwork... and be careful using them. It helps to use cutting oil when you're drilling the holes or making holes with punches, which keeps the cutting edges from heating up too much.

I hope that helps.

--

I followed the directions there and found that in my living room and with my 90dB/1W/1m speakers, I really only need 15 watts per channel of power. I'm actually running only 6 watts per channel, but it seems to work well enough.

The basic steps in this test are:

First, download the test files you'll find in that thread. They're pre-calibrated to play at the correct level for the measurements that will follow. Burn them onto an audio CD-R to play in your CD player.

Play a favorite few music CD's (not the test CD-R) on your stereo at the top volume you ever plan to use it. Note the position of the volume control.

Get a good RMS-reading voltmeter. Play the -12dB track on the test CD-R, with the volume setting you used to play your music really loudly. Measure the voltage across the + and - terminals on your speakers while you're playing that track.

I measured about 4V RMS at my speaker terminals. 4 squared is 16, and that's how many watts I need (per channel), according to this method.

The trick is to be honest when you assess how loud you actually play your stereo. If you really crank it, then conduct the test at that 'cranked' level setting on your volume control.

My concern for any build is the enclosure. Either woodwork or metalwork sounds somewhere between difficult and untenable in my current situation.

I feel your pain. I hate metalwork. It really helps to have decent tools. Greenlee chassis punches make life so much easier. You basically need two -- one for making the holes for octal tubes, the other for making holes for 9-pin miniature tubes. According to this post, a 1-1/8" punch will work for most octal sockets, while a 3/4" punch will work for most 9-pin mini sockets (and most 7-pin mini sockets too).

Greenlee standard 1-1/8" knockout punch

Greenlee 3/4" knockout punch

I don't know if those are available somewhere else for less money. I do know they're available from Grainger (that's where I got mine).

The smaller holes can be made with a hand-held power drill. Just make sure to get decent bits, designed for metalwork... and be careful using them. It helps to use cutting oil when you're drilling the holes or making holes with punches, which keeps the cutting edges from heating up too much.

I hope that helps.

--

Transcendar offers better PP output transformers for not much more $ for El Cheapo/Grande Or Dynaco ST-35 clones etc and really nice SE ones if you end up going that way.

Push-Pull Transformers - Transcendar Audio Transformers

Also check out tubelab.com for nice affordable amps using PCB's and he has a very helpful Forum on this site.

Tubelab | Dedicated to advancing the state of the art in affordable high end audio.

Remember that the Output Transformer is what really defines the sonics of tube amp so invest in the best you can afford.

Push-Pull Transformers - Transcendar Audio Transformers

Also check out tubelab.com for nice affordable amps using PCB's and he has a very helpful Forum on this site.

Tubelab | Dedicated to advancing the state of the art in affordable high end audio.

Remember that the Output Transformer is what really defines the sonics of tube amp so invest in the best you can afford.

Last edited:

I have a suggestion for you. There's a thread in one of the speaker forums here, titled "A Test. How much Voltage (power) do your speakers need?"

I followed the directions there and found that in my living room and with my 90dB/1W/1m speakers, I really only need 15 watts per channel of power. I'm actually running only 6 watts per channel, but it seems to work well enough.

The basic steps in this test are:

First, download the test files you'll find in that thread. They're pre-calibrated to play at the correct level for the measurements that will follow. Burn them onto an audio CD-R to play in your CD player.

Play a favorite few music CD's (not the test CD-R) on your stereo at the top volume you ever plan to use it. Note the position of the volume control.

Get a good RMS-reading voltmeter. Play the -12dB track on the test CD-R, with the volume setting you used to play your music really loudly. Measure the voltage across the + and - terminals on your speakers while you're playing that track.

I measured about 4V RMS at my speaker terminals. 4 squared is 16, and that's how many watts I need (per channel), according to this method.

The trick is to be honest when you assess how loud you actually play your stereo. If you really crank it, then conduct the test at that 'cranked' level setting on your volume control.

I feel your pain. I hate metalwork. It really helps to have decent tools. Greenlee chassis punches make life so much easier. You basically need two -- one for making the holes for octal tubes, the other for making holes for 9-pin miniature tubes. According to this post, a 1-1/8" punch will work for most octal sockets, while a 3/4" punch will work for most 9-pin mini sockets (and most 7-pin mini sockets too).

Greenlee standard 1-1/8" knockout punch

Greenlee 3/4" knockout punch

I don't know if those are available somewhere else for less money. I do know they're available from Grainger (that's where I got mine).

The smaller holes can be made with a hand-held power drill. Just make sure to get decent bits, designed for metalwork... and be careful using them. It helps to use cutting oil when you're drilling the holes or making holes with punches, which keeps the cutting edges from heating up too much.

I hope that helps.

--

Thanks. Yeah I think I will test out the volume listening method.

Regarding the punches, that requires a punch press, right? I feel it might be more cost effective to draw up the plans for the metalwork in CAD and have it fabricated at a local shop. No idea how much that stuff costs but it would save me having to invest in a lot of tools, especially if this hobby doesn't continue.

Regarding the punches, that requires a punch press, right?

No, they are manually operated. Greenlee punches are the "Gold Standard" and are priced accordingly. This set is not as good, but, for the occasional builder, adequate.

... cheap... (Hammond, Edcor, easy to order for you)

Will fit the Hammond HWCHAS1310!

Dave's Homemade Audio Amplifier using a 12AX7 and 6N6

or this one?

DIY Single-Ended (SE) KT88 / 6L6 / EL34 / 6CA7 Tube Amplifier

(you can find some renders in my LTSPICE to EAGLE to SKETCHUP thread)

or this one? (one render attached)

Trion 34 Mk 2 - Röhrenklingklang

... but you will have problems to order the iron (location is Germany)

Will fit the Hammond HWCHAS1310!

Dave's Homemade Audio Amplifier using a 12AX7 and 6N6

or this one?

DIY Single-Ended (SE) KT88 / 6L6 / EL34 / 6CA7 Tube Amplifier

(you can find some renders in my LTSPICE to EAGLE to SKETCHUP thread)

or this one? (one render attached)

Trion 34 Mk 2 - Röhrenklingklang

... but you will have problems to order the iron (location is Germany)

Attachments

If you want a tube amp for the music experience see

Vintage Dynaco Dynakit St 35 Stereo Tube Power Amplifier ST35 | eBay

it's currently in $99 range.

And best of all, it's original and may be sold whenever your want something else.

It ended up going for $448 plus shipping. I'm not opposed to an inexpensive tube amp for the musical experience, but that is too expensive for a vintage amp which may need service/repairs or at the very least, new tubes.

Also check out tubelab.com for nice affordable amps using PCB's and he has a very helpful Forum on this site.

Tubelab | Dedicated to advancing the state of the art in affordable high end audio.

The detailed photos, step by step instructions, and best practices for soldering/etc. on Tubelab are excellent. Thanks!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Beginner DIY Amp