follow his advice and crush them... but don't complain about hum pickup in your preamp.

Put them on and don't complain about the short lifetime of your tubes. That's the criticism.

Yes, things like these were used in the good old days. These have a cost in terms of tube lifetime.

You can buy ones that actually improve the lifetime of your tubes.

Look at the damn things. We're not talking about the ones with vents. We're talking about the unpainted ones in the pictures, that don't make good contact with the glass. It should be obvious to a low grade moron that a tube is going to run hotter inside one of these.

You need to stop mindlessly defending your practices or those of other bodies, manufacturers, etc. and focus on the fact that you can get shielding and heatsinking in a properly designed device.

Jeez...

Before anybody else points out that some manufacturers used this type, just bear in mind that hum is obvious to a buyer, tube lifetime is not.

These were used in some instances as a cheap fix, to get the product out of the door. Manufacturers didn't suddenly get unscrupulous in the present day, there have always been people like that.

These were used in some instances as a cheap fix, to get the product out of the door. Manufacturers didn't suddenly get unscrupulous in the present day, there have always been people like that.

Well, it isn't just some, it's many. Not just old consumer audio, but industrial, commercial and military. I've spent several deacdes buying and selling government surplus back when one could buy directly from Uncle Sam. I've seen the inside of countless pieces of electronic equipment such as test equipment, communications receivers & transmitters, aircraft componets and things you cannot imagine. If the military thought that these tube shields were detrimental they most assuredly wouldn't have used them in the equipment. But they did. And they also used the tight fitting black shields as well.Before anybody else points out that some manufacturers used this type, just bear in mind that hum is obvious to a buyer, tube lifetime is not.

I think the overlooked idea here is that small signal tubes, unless they are pushed to their maximum dissipation, do not develope enough heat to do themselves damage. Even with these loose fitting shields. And for what minuscule amount of life that may be lost, the benefits outweigh it. So if MJ dislikes these shields and chooses to poo-poo and crush them, it should not be taken as gospel. History has him far outweighed. And this is in no way a shot at Mr. Jones. I have his books and respect his expertise

Maybe someone else mentioned this, but all of the cans on the various old tube equipment I've collected (guitar amps, o-scope, old hi-fi amps, etc) have small vent holes/notches on the bottom, so air gets pulled through like a chimney. I've never seen the completely solid ones. Maybe that's the crush/no crush difference.

Well, it isn't just some, it's many. Not just old consumer audio, but industrial, commercial and military. I've spent several deacdes buying and selling government surplus back when one could buy directly from Uncle Sam. I've seen the inside of countless pieces of electronic equipment such as test equipment, communications receivers & transmitters, aircraft componets and things you cannot imagine. If the military thought that these tube shields were detrimental they most assuredly wouldn't have used them in the equipment. But they did. And they also used the tight fitting black shields as well.

I think the overlooked idea here is that small signal tubes, unless they are pushed to their maximum dissipation, do not develope enough heat to do themselves damage. Even with these loose fitting shields. And for what minuscule amount of life that may be lost, the benefits outweigh it. So if MJ dislikes these shields and chooses to poo-poo and crush them, it should not be taken as gospel. History has him far outweighed. And this is in no way a shot at Mr. Jones. I have his books and respect his expertise

Yes, but as SY has pointed out, economic priorities have changed. What was considered economic sense then, is not economic sense now.

You choose to characterize the loss of lifetime as minimal, because it suits your defence of this type, but it is nevertheless a fact that operating temperature is the major variable affecting tube life.

Whatever the facts of the case, there can be no dispute that this type is inferior to all other types.

Your protestations notwithstanding, you nevertheless chose to characterize his opinions as 'colourful', which in my view amounts to an ad hominem attack. Not only is this characteristic of a weak arguing position, but it reveals an underlying tendency to self-deception which further disinclines me to trust your opinions above his.

Oh, and do not presume to know the limits of my imagination.

Look at the damn things. We're not talking about the ones with vents. We're talking about the unpainted ones in the pictures, that don't make good contact with the glass. It should be obvious to a low grade moron that a tube is going to run hotter inside one of these.

You need to stop mindlessly defending your practices or those of other bodies, manufacturers, etc. and focus on the fact that you can get shielding and heatsinking in a properly designed device.

Jeez...

Small signal tubes don't run that hot. What is your reasoning that running small signal tubes at cooler temperatures prolongs the lifespan?

I've seen some tube shields from military items that had mesh "fingers" inside to make good contact with the glass. The shell was still black anodized aluminum though.

This style of push-on tube shield has been used successfully by industry and the military for many decades. They are meant for small signal tubes that do not generate the high heat that power tubes do. They serve to both shield the tube from external interference and keep the tube seated in it's socket. No one, but no one, puts them on power tubes because they are simply not needed. In fact this style, while they come in three heights, will not fit on most taller 9-pin power tubes. And if a power tube should need this type of hold down shield, there is a vented version with openings in the side. I'd post a picture but mine are packed away somewhere. MJ has a right to his colorful opinions, but he is not the final word.

I always thought that there were two different sizes, one for the 7 pins and one size for the 9 pin tubes and I've seen both types in tv sets and radios, not just small signal tubes. and way back when they even had ones for coke bottle tubes in 1940s radios. I didn't know there were 3 sizes, wow.

and the reason why a tube mightve gotten crushed was because the springs had been in place for so long that their springs had conformed to the exact height of that paticular tube, so if I went and pulled off all of the 9 pin shields and swapped them around none of them would fit the other 9 pin tubes.

Think about it, what happens to a spring when you heat it up? ok now put the spring ontop of a hot vacuum tube for 40 years and see what happens, I bet that the spring will end up turning rock hard and go back into solid steel after 40 years.

I used to work in Valve tv sets and I encountered these style of tube shields quite a lot.

It only happened once with me, swapped a shield around and it popped while heating up.

After this occured I started making a map ontop of the set with the shield covers and making sure that they all went back to their original spot afterwoods.

This was done for your visual inspection of the heaters to spot any obviously dead ones or shorted ones.

Last edited:

I think the overlooked idea here is that small signal tubes, unless they are pushed to their maximum dissipation, do not develop enough heat to do themselves damage. Even with these loose fitting shields.

+1.

This thread is yet another case of people throwing assertions around as if they are fact. Just because they are 'obviously' bad, does not actually make it so. It may be that they make no significant difference at all to the surface temp of the average preamp valve. Or maybe they even reduce the temp, by soaking up some radiant heat. Or maybe they really are awful...

In any case, it should be trivially easy to test using a thermocouple, which many multimeters come with. Please, someone here try measuring the surface temp of a few tubes with and without shields! I know the idea of actually measuring something is regarded as a bit old fashioned on this forum, but please let's try? Pretty please?

Hi fellow DIY'ers,

Thank you so far for the discussion, I learned a lot. Now, a few more things.

Sorry all for the very first picture of the screening can. As I searched, I find better ones which touches the tube with some springy parts inside. The are clearly better at heat reduction, and if I had attached a picture of better design before, it would definitely have helped the "heat" in the thread

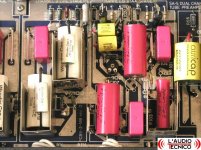

Now, we talked before that, if the tubes are inside the metal chassis no more screening is necessary (since my transformer is out of the main chassis). Would you please see the attached picture below. This is a generic internet picture of my pre-amplifier. Have you noticed the the screen cans around the capacitors? They are input and output coupling caps of the RIAA and Line stage. In fact this was the reason to consider screening cans for my tubes. Even some caps have them, why not tubes? Am I comparing apples and oranges here?

Thank you so far for the discussion, I learned a lot. Now, a few more things.

Sorry all for the very first picture of the screening can. As I searched, I find better ones which touches the tube with some springy parts inside. The are clearly better at heat reduction, and if I had attached a picture of better design before, it would definitely have helped the "heat" in the thread

Now, we talked before that, if the tubes are inside the metal chassis no more screening is necessary (since my transformer is out of the main chassis). Would you please see the attached picture below. This is a generic internet picture of my pre-amplifier. Have you noticed the the screen cans around the capacitors? They are input and output coupling caps of the RIAA and Line stage. In fact this was the reason to consider screening cans for my tubes. Even some caps have them, why not tubes? Am I comparing apples and oranges here?

Attachments

No, not apples and oranges, but rather fashion voodoo versus engineering.

Is this a Counterpoint?

Yes, it is. SA-5.1, to be specific.

Well, more than one member here on Diyaudio who are quite Counterpoint experts, recommends usage of them. l wish l could be happy with an iPod

Well,

Tube screening cans were industry standard..They were always used on low level signal tubes/radio and transmitters..without them the circuit would drift..the added bonus was that they kept the tubes in place in rough handling and vibration.

I did drill one once with four holes to help with cooling just above the base ..however it was in a very hot environment..You can get them with a damper inside and these help transfer the heat to the outside..AKA pearl..however much better..

I think the mounting of tubes upside down is worse (dry joints on the base) and is guitar amp standard..and has been for many years..

I do screen signal caps with aluminium foil and a drain wire (wrap with masking tape)..people say use copper why??<<<aluminium is non magnetic and cheaper!

So they have their place and always will have a use in low level signal and high gain!

NB, Most of the ones I have seen have a hole each side in the base section by the mounting tab so they act as a chimney..and can help cool the tube..because its connected to the can by the spring.. Look close at the base in the Ebay picture..

http://www.ebay.co.uk/itm/4-x-NOS-B7G-valve-bases-chassis-mount-with-skirt-and-screening-cans-ham-radio-/230885087401?_trksid=p2047675.l2557&_trkparms=aid=222002&algo=SIC.FIT&ao=1&asc=11&meid=3647054743691959517&pid=100011&prg=1005&rk=5&sd=130545103917&&nma=true&si=pyErinKOayjxAJpJzMcqu%2B31P7A%3D&orig_cvip=true&rt=nc

In answer to post 1# if they dont have these vents don't use them..

Regards

M. Gregg

Tube screening cans were industry standard..They were always used on low level signal tubes/radio and transmitters..without them the circuit would drift..the added bonus was that they kept the tubes in place in rough handling and vibration.

I did drill one once with four holes to help with cooling just above the base ..however it was in a very hot environment..You can get them with a damper inside and these help transfer the heat to the outside..AKA pearl..however much better..

I think the mounting of tubes upside down is worse (dry joints on the base) and is guitar amp standard..and has been for many years..

I do screen signal caps with aluminium foil and a drain wire (wrap with masking tape)..people say use copper why??<<<aluminium is non magnetic and cheaper!

So they have their place and always will have a use in low level signal and high gain!

NB, Most of the ones I have seen have a hole each side in the base section by the mounting tab so they act as a chimney..and can help cool the tube..because its connected to the can by the spring.. Look close at the base in the Ebay picture..

http://www.ebay.co.uk/itm/4-x-NOS-B7G-valve-bases-chassis-mount-with-skirt-and-screening-cans-ham-radio-/230885087401?_trksid=p2047675.l2557&_trkparms=aid=222002&algo=SIC.FIT&ao=1&asc=11&meid=3647054743691959517&pid=100011&prg=1005&rk=5&sd=130545103917&&nma=true&si=pyErinKOayjxAJpJzMcqu%2B31P7A%3D&orig_cvip=true&rt=nc

In answer to post 1# if they dont have these vents don't use them..

Regards

M. Gregg

Last edited:

Making temperature measurements on a glass surface could be tricky, and may lead to suspect results, especially if people want to take away a particular view on the 'whole' matter.

Some aspects of concern for a measurement are:

- the glass is not a great thermal conductor, especially as it can be quite thin.

- a significant percentage of the radiant anode heat is transmitted through the glass, so applying any local thermocouple will change the temperature in that region as it will change the local transmittance. Although, for low signal anodes, the anode temperature is relatively low and so the spectrum is much more biased in to the infrared, for which the glass is much more opaque. Also I reckon the small 9-pin tubes have thicker glass than the big output valves, and so they would absorb more.

- the radiant anode heat spectrum is very dependant on the anode temperature.

- the thermocouple must be insulated from the ambient air temp, but that also removes the ability for the local glass to dissipate, and the thermocouple wire could end up being the main thermal path out of the area.

In general, a very very small thin guage thermocouple would be a good start.

Some aspects of concern for a measurement are:

- the glass is not a great thermal conductor, especially as it can be quite thin.

- a significant percentage of the radiant anode heat is transmitted through the glass, so applying any local thermocouple will change the temperature in that region as it will change the local transmittance. Although, for low signal anodes, the anode temperature is relatively low and so the spectrum is much more biased in to the infrared, for which the glass is much more opaque. Also I reckon the small 9-pin tubes have thicker glass than the big output valves, and so they would absorb more.

- the radiant anode heat spectrum is very dependant on the anode temperature.

- the thermocouple must be insulated from the ambient air temp, but that also removes the ability for the local glass to dissipate, and the thermocouple wire could end up being the main thermal path out of the area.

In general, a very very small thin guage thermocouple would be a good start.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Tube Screening Cans