If you are distributing DC to the heaters then there is no insurance needed, as there is no external field (electric or magnetic) to couple over to your audio signal - it is a mute point to consider. The question that may be more pertinent is how you generated the DC and whether that is coupling in to your audio.I have the cable and

it is already twisted and shielded. I am supplying DC for this phono-stage.

I thought shielding in addition to twisting might be good insurance.

There is effectively no disturbance that would couple into the dc circuit.

As indicated, the act of rectifying an ac winding on a transformer for the heater could plausibly couple noise in to other power supply rails (eg. B+) or into nearby audio circuitry - that form of noise is not generated if you just use ac heaters.

As indicated, the act of rectifying an ac winding on a transformer for the heater could plausibly couple noise in to other power supply rails (eg. B+) or into nearby audio circuitry - that form of noise is not generated if you just use ac heaters.

Pette Millet claims that common mode inductor / choke prevents coupling with B+/HV.I'll be using Pete Millett's DC filament supply boards.

Link

I was thinking the shielded wire would help prevent coupling.

The transformer will be un a separate chassis as will the power transformer.

I'm interested to use them because all voltages , HV + heaters will be generated from single toroid transformer, also for the phono.

In my latest build I used a switched mode power supply: 220V to 12V6.

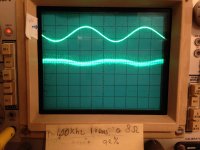

It had terrific noise on the ECC88/PCC88. The whole earth line was polluted as seen here in a distortion picture:

I had connected the 12V negative to the earth. It leaked somewhat via the filament.

Then I connected the V- of the fil supply to the plus of my 36V amplifier rail, the average VFil-cath negative became -42V. That stopped all leaking. I connected it with 10kΩ and a 6.8µF to the earth.

(100mVpp) It is clean now.

(100mVpp) It is clean now.

So the filament barrier of my Tesla tubes is very prone to leaking. I had not decoupled the 150 Ω cathode cap; that should have reduced it a bit.

It had terrific noise on the ECC88/PCC88. The whole earth line was polluted as seen here in a distortion picture:

I had connected the 12V negative to the earth. It leaked somewhat via the filament.

Then I connected the V- of the fil supply to the plus of my 36V amplifier rail, the average VFil-cath negative became -42V. That stopped all leaking. I connected it with 10kΩ and a 6.8µF to the earth.

(100mVpp) It is clean now.

(100mVpp) It is clean now.So the filament barrier of my Tesla tubes is very prone to leaking. I had not decoupled the 150 Ω cathode cap; that should have reduced it a bit.

I found out that with a switched supply you MUST ensure the two power lines have the same polarity and that live is indeed live and neutral indeed so too. It might then not be the Tesla tubes leaking but the SMPS that is leaking and making noise. When all is OK and I ensure the right polarity I have a output noise now of 0,1 mV RMS. Not bad for a tube.

I'm about to use a 6BK4 with Very high voltage 8kV+.

I don't know the construction of the tube.

Do I need to have any concern about

any HV arcing between heater and anode if, I use a grounder DC supply? (Grounded grid)

Although, I suspect I can have two isolated supplies without any common ground.

I'll probably just use a 6.3V transformer if I can find one local.

Thanks, Mikek

I don't know the construction of the tube.

Do I need to have any concern about

any HV arcing between heater and anode if, I use a grounder DC supply? (Grounded grid)

Although, I suspect I can have two isolated supplies without any common ground.

I'll probably just use a 6.3V transformer if I can find one local.

Thanks, Mikek

You'll definitely want to reference heater voltage to somewhere very near cathode voltage. The anodes on these beam regulator triodes have their own pin at the top of the glass envelope, for which you'll need a dedicated connector, which isolates anode voltages from everything else.

All good fortune,

Chris

All good fortune,

Chris

It would seem obvious that any such circuit would need over-voltage protection on every aspect, with design showing all failure modes are managed, including basic arcing within the tube to any of its base terminals (due to going gassy).

PS, I see multiple posts by Qmavam11 on this general topic - that makes it very difficult collate forum comments in to one thread - perhaps ask the mods to pull everything into one thread.

PS, I see multiple posts by Qmavam11 on this general topic - that makes it very difficult collate forum comments in to one thread - perhaps ask the mods to pull everything into one thread.

I've merged the two other threads - https://www.diyaudio.com/community/threads/hv-pulse-amplifier-help-6bk4.399314/perhaps ask the mods to pull everything into one thread.

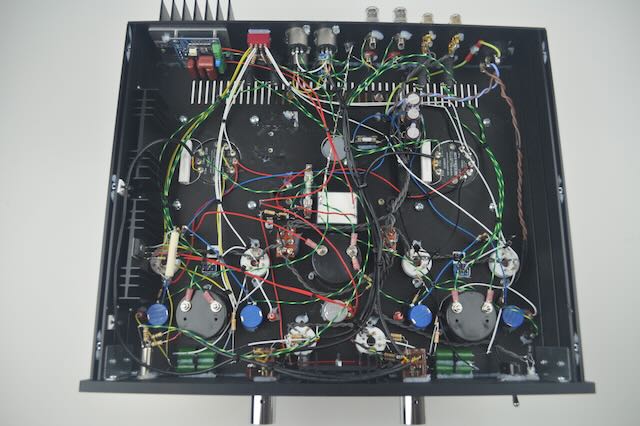

Don't know if this would be considered good, bad, or ugly but thought I'd share because I think it is unique. I commissioned my amp through Ultrasonic Labs (RIP Tomas) to my audiophool specifications. It's a fairly conventional push pull amp but I wanted to be able to use many different kinds of tubes so he made it with a variable B+. More interestingly, he made it with a unique heater arrangement. If you simply turn on the amp all the tubes are given the standard 6.3v on the heaters. He also put two pairs of banana jacks on the rear panel, one for the input tubes and one for the output tubes. There are heater switches for both. If I want to use something other than 6v I flip one of those switches before the main power.

It has been a lot of fun! I have a smattering of 12v output tubes but I have a slew of different voltages for the input tubes. 4, 6, 12, 20, and 25 volts. I use some inexpensive DC power supplies that can go up to 30v/10a and they work well. Here's the inside of the amp.

It has been a lot of fun! I have a smattering of 12v output tubes but I have a slew of different voltages for the input tubes. 4, 6, 12, 20, and 25 volts. I use some inexpensive DC power supplies that can go up to 30v/10a and they work well. Here's the inside of the amp.

@OldHector that's because it's already at full resolution. Instead you might open it separately and use Ctrl and + to zoom in on it.

with >8kV B+, you should check the isolation of your transformers. mostly the PUR insulation of the magnet wire is not rated for such high voltages. neither are the plastics used to separate primaries and secondaries. i assume you're using a greinacher voltage multiplyer circuit to create the HV i.e. the secondary voltage is not that high. but still, you are very likely using parts at least partially beyond their specification.I'm about to use a 6BK4 with Very high voltage 8kV+.

[…]

I'll probably just use a 6.3V transformer if I can find one local.

Thanks, Mikek

in your postition, i would use a double C-core transformer with the primaries and secondaries on separate bobbins or an EI with double electrostatic screens between pri and sec. even if the currents involved are very low – if you accidentally create a short, you risk to melt the insulation of the magnet wire. if primary and secondary are just wound on top of each other (as usual for tight magnetic coupling), this could result in a spectacular display of sparks accompanied by the inimitable fragrance of magic smoke.

still, i recommend plenty of respect, one hand in your pocket, and working very, very careful with these high voltages. (actually, already 1850 Vdc B+ gave me the such jeepers that i gave an oath to myself not to use any B+ voltage higher than an arbitrarily, round figure of 1kV). consult the reference text books about the minimum distances at 8 kV to prevent arcing or creepage. and consider how many Joules even a 100 nF cap can store at 8 kV.

and if this is the first time you're dealing with such high voltages, you might even reconsider your project.

just saying… hth

Here’s a larger versionI tried to open it in full screen to see a more detailed view but its size is fixed. Maybe just by laptop browser.

And here are pictures of the top and back to help orient you.

The large central meter is the B+, the switch for the input heaters is to the left of that and the output heaters are to the right. On the back you can see the banana jacks for the heaters to the right of the speaker jacks.

The large central meter is the B+, the switch for the input heaters is to the left of that and the output heaters are to the right. On the back you can see the banana jacks for the heaters to the right of the speaker jacks.

the only caps i see are the three small ones near the left OPT. are these really the main filter caps of the power supply? (does the amp hum?)

the wiring is … uh … slightly unconventional. are the heaters fed AC when using the internal voltage? if so, i would have liked to see the wires twisted more tightly and farther away from the signal leads. i see quite a few wires – dunno if B+ or signal – crossing above and below the heater wires. if the sloppily twisted heater wiring carries AC, you risk coupling 60 Hz hum into your signal or B+… interrupting the twist for the toggle switches is not ideal either, but hey, if it doesn't hum. so what? ;-)

what i would do: solder one end of a 100 nF cap (in a pinch, 220 or 470 nF are okay, too) directly to the pin of the tube socket that connects to the hot lead of the heater wiring and the other to GND at the nearest possible location (e.g. the 0V end of the cathode resistor). if the heater is AC and floating, you can do the same to the other heater pin, too. this helps to decouple the HF crud on the heater supply right at the point of where it starts to do harm. it's okay to use a high quality multilayer ceramic cap in this position. the voltage rating of the cap should cover the highest voltage you consider feeding to your heaters.

the wiring is … uh … slightly unconventional. are the heaters fed AC when using the internal voltage? if so, i would have liked to see the wires twisted more tightly and farther away from the signal leads. i see quite a few wires – dunno if B+ or signal – crossing above and below the heater wires. if the sloppily twisted heater wiring carries AC, you risk coupling 60 Hz hum into your signal or B+… interrupting the twist for the toggle switches is not ideal either, but hey, if it doesn't hum. so what? ;-)

what i would do: solder one end of a 100 nF cap (in a pinch, 220 or 470 nF are okay, too) directly to the pin of the tube socket that connects to the hot lead of the heater wiring and the other to GND at the nearest possible location (e.g. the 0V end of the cathode resistor). if the heater is AC and floating, you can do the same to the other heater pin, too. this helps to decouple the HF crud on the heater supply right at the point of where it starts to do harm. it's okay to use a high quality multilayer ceramic cap in this position. the voltage rating of the cap should cover the highest voltage you consider feeding to your heaters.

Pretty sure the 6v internal voltage is DC only because that is how he did all the other amps he made. On the other hand, this amp is unique and the use of a different PT might have changed that for the built in 6v. In any case, the amp is very quiet.

I too noticed the lack of caps and wondered about it. I don’t know a lot about amp design but I always expect to see large caps in amps both for the power supply and for coupling. The amp uses a “21st century Maida” regulator at the back of the chassis for the main power and has a secondary regulator on the left side of the image for the adjustable B+.

Tomas did ask that I not show the picture because he was worried about reactions to his “sloppy” wiring. He passed away at the end of February and so now is past caring about earthly worries like how his wiring looks. I‘m sharing it now because I stumbled across this post and thought my amp is different enough that you guys might get a kick out of it.

With the scarcity of the best NOS 6sn7 it is very useful to be able to use 25sn7, or even pairs of triode wired c3m instead. Originally he had gotten a fancy, custom wound power transformer with both 6v and 12 taps but there was a problem with it. I suggested the external supplies to simplify the power transformer situation. That allowed him to put in an absurdly capable toroidal transformer with 6v taps and allowed normal operation without external supplies. Incidentally, this is why the cover for the PT is offline with the OT. He moved the cover to cover up holes that had been drilled in the chassis for the first PT.

I too noticed the lack of caps and wondered about it. I don’t know a lot about amp design but I always expect to see large caps in amps both for the power supply and for coupling. The amp uses a “21st century Maida” regulator at the back of the chassis for the main power and has a secondary regulator on the left side of the image for the adjustable B+.

Tomas did ask that I not show the picture because he was worried about reactions to his “sloppy” wiring. He passed away at the end of February and so now is past caring about earthly worries like how his wiring looks. I‘m sharing it now because I stumbled across this post and thought my amp is different enough that you guys might get a kick out of it.

With the scarcity of the best NOS 6sn7 it is very useful to be able to use 25sn7, or even pairs of triode wired c3m instead. Originally he had gotten a fancy, custom wound power transformer with both 6v and 12 taps but there was a problem with it. I suggested the external supplies to simplify the power transformer situation. That allowed him to put in an absurdly capable toroidal transformer with 6v taps and allowed normal operation without external supplies. Incidentally, this is why the cover for the PT is offline with the OT. He moved the cover to cover up holes that had been drilled in the chassis for the first PT.

- Home

- Amplifiers

- Tubes / Valves

- Heater Wiring - the Good the Bad and the Ugly