Technical books online Tube theory & circuit design

Electron Tube Design, RCA 1963 943 pages!

Vacuum Tube Design, RCA 1940 260 pages

------------------------------------------------------

Or just use Tubelab's approach: heat until plate glows, then de-rate.

Which I would suggest maybe amending to:

de-rate a known similar (cheap) tube to find the de-rate ratio for getting the datasheet rating, then apply the same ratio to de-rating the unknown tube (providing you have a cheap one to test up to red-plate). Maybe adjust the de-rate ratio upward, the cheaper the tubes are. $1 tubes at 70% of red-plate.

just askin'.....what would be the long term harm to any tube that is allowed to red plate? how much or how many or how long would red plating cause ireversible damage?

Looks like the answer is outgassing.

https://www.diyaudio.com/forums/tubes-valves/241425-pushing-el36-2.html#post3610896

https://www.diyaudio.com/forums/tubes-valves/241425-pushing-el36-2.html#post3610896

how much or how many or how long would red plating cause ireversible damage?

When tubes are made the vacuum is imperfect, and nothing inside is completely pure. Some of the impurities are inert, and others are capable of ionization. The hotter a tube is run, the more likely impurities inherent in the elements are dislodged, thus becoming free to interfere with normal operation.

Run that plate red hot, and something is boiling off of, or out of it. When those metal ions combine with electrons and wind up bonding to the cathode, a tiny bit of emission is lost. When ions attack the grid, they combine with an electron stealing it from the grid, causing grid current, and thus making the grid ever so slightly more positive.

This is why there is a maximum grid circuit resistance spec. This unwanted current flow will upset the bias, and as the tube ages, more impurities will pollute the vacuum, further upsetting the bias, and eventually the tube will lose emission, or go into runaway.

If a tube is built correctly the plate will heat evenly. When you crank it, it glows red evenly, no hot spots. Bent grids, unevenly coated cathodes, misalignment.....all lead to hot spots which will severely shorten the tube's life.

When I'm selecting tubes out of a bunch for a high powered amp, I'll bring them to the edge of glow in a dark room. Look for even heat on both sides of the plate, and nothing red or blue (ionization) inside the plate.

So how hard can you hammer those tubes? The answer lies in how well they were made in the first place. Good clean and pure guts with a real good vacuum that doesn't leak, bring it on! Modern new production, or stuff made at the end of the tube era where cost is the prime directive, well POOF!

There was a period of tome about 8 years ago when you had to buy 2 or 3 new production 5AR4's to get a good one, and they don't even have grids. The cathode coatings weren't uniform. all the current flows through the thin spots as the tube heats up because they heat up first. Then the arc starts there because the maximum current density was exceeded.

I have seen some tubes run with their plates red for a long time, while others with one red spot will blow in a week. Some old TV sets from the 60's ran the horizontal sweep tube in the red zone and they lasted about a year each. The Magnavox B&W TV we had when I was a kid needed a new one every summer.

A hotter plate also means hotter envelope glass, which also outgasses.

The outgassing molecules from plate and glass contaminate the vacuum - with the increase in concentration of molecules related to the level of over-temperature, and with red-plate operating time. The getter slowly saves the day by reducing the concentration of molecules, but that takes time, and active getter material is consumed during this process. The amount of getter material in a tube is a commercial decision aimed to allow the valve to operate nominally for a certain number of hours/years. Once the active getter material is used up then the valve just gets gassier over time.

So red-plating reduces service life - but you may not see that immediately, and may not be able to measure that until the getter is on its last legs.

The outgassing molecules from plate and glass contaminate the vacuum - with the increase in concentration of molecules related to the level of over-temperature, and with red-plate operating time. The getter slowly saves the day by reducing the concentration of molecules, but that takes time, and active getter material is consumed during this process. The amount of getter material in a tube is a commercial decision aimed to allow the valve to operate nominally for a certain number of hours/years. Once the active getter material is used up then the valve just gets gassier over time.

So red-plating reduces service life - but you may not see that immediately, and may not be able to measure that until the getter is on its last legs.

500 Watt amp for $16.02USD

Well... here you go... $16.02 USD for the amp, $34.95 USD for the +/- 65VDC power supply.

IRS2092S 500W Mono Channel Digital Amplifier Class D HIFI Power Amp Board- US$16.02 online shopping | NewFrog.com

I'm looking to build a 500 watt per channel stereo tube amp. You don't need 500 watts of plate dissipation for that.

Well... here you go... $16.02 USD for the amp, $34.95 USD for the +/- 65VDC power supply.

IRS2092S 500W Mono Channel Digital Amplifier Class D HIFI Power Amp Board- US$16.02 online shopping | NewFrog.com

Attachments

Well, I already have one of these:

TI Class D EVM Board 50% Promotion

And I have successfully used it to rattle the drivers loose in both of my test speaker cabinets. It might find itself feeding a pair of big subwoofers some day, or maybe a tiny but LOUD guitar amp.

It sounded pretty wicked feeding these same speakers when driven by a small PC running TH3. Having learned to play the guitar on the surf music from the 60's, I'm a sucker for the reverb laden surf guitar sound it emulates. I never could make the real thing with my DIY tube amp skill set and budget in 1965.

Somehow "600 watts from a single chip and small SMPS power supply" just doesn't sound the same as "BIG A$$ kilowatt tube amp."

TI Class D EVM Board 50% Promotion

And I have successfully used it to rattle the drivers loose in both of my test speaker cabinets. It might find itself feeding a pair of big subwoofers some day, or maybe a tiny but LOUD guitar amp.

It sounded pretty wicked feeding these same speakers when driven by a small PC running TH3. Having learned to play the guitar on the surf music from the 60's, I'm a sucker for the reverb laden surf guitar sound it emulates. I never could make the real thing with my DIY tube amp skill set and budget in 1965.

Somehow "600 watts from a single chip and small SMPS power supply" just doesn't sound the same as "BIG A$$ kilowatt tube amp."

Attachments

Since I have been known to melt a few tubes, I stay far far away from things that cost more than I make in a week, and since I'm retired, that isn't much.

I'm looking to make that kilowatt with far less than $100 worth of tubes......but then I got them back when I was buying 45's for $5 each!

I may be called Tubelab, and I have melted a lot of tubes in my life, but overall I have fried far more silicon than vacuum tubes......and often got paid quite well to do it......OH, yeah that also applies to GaAs, GaN, SiC and even a good bit of Germanium back in the 60's. I have been known to pull the radio from a junked car just to get that TO-36 germanium "doorknob" transistor and it's OPT off the back of it. They made for some creamy sounding guitar amps......but didn't live long at my hands. "How many 6 volt lantern batteries in series will it take before it blows up?" "I don't know, lets find out." "Time for another trip to the junkyard."

I'm looking to make that kilowatt with far less than $100 worth of tubes......but then I got them back when I was buying 45's for $5 each!

I may be called Tubelab, and I have melted a lot of tubes in my life, but overall I have fried far more silicon than vacuum tubes......and often got paid quite well to do it......OH, yeah that also applies to GaAs, GaN, SiC and even a good bit of Germanium back in the 60's. I have been known to pull the radio from a junked car just to get that TO-36 germanium "doorknob" transistor and it's OPT off the back of it. They made for some creamy sounding guitar amps......but didn't live long at my hands. "How many 6 volt lantern batteries in series will it take before it blows up?" "I don't know, lets find out." "Time for another trip to the junkyard."

A hotter plate also means hotter envelope glass, which also outgasses.

The outgassing molecules from plate and glass contaminate the vacuum - with the increase in concentration of molecules related to the level of over-temperature, and with red-plate operating time. The getter slowly saves the day by reducing the concentration of molecules, but that takes time, and active getter material is consumed during this process. The amount of getter material in a tube is a commercial decision aimed to allow the valve to operate nominally for a certain number of hours/years. Once the active getter material is used up then the valve just gets gassier over time.

So red-plating reduces service life - but you may not see that immediately, and may not be able to measure that until the getter is on its last legs.

Also relevant is that the getter material does not react or absorb inert gasses, which continue to build up causing a glow as they ionise.

Does it cause a performance drop? I don't know, but it can look pretty!

I remember replacing a PCL81 in a TV where the thing had run so hot that the glass envelope had collapsed around the anode. The PCL81 had ceramic supports that made the internal structure almost cylindrical.

Attachments

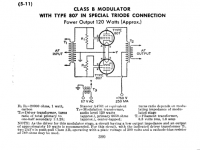

The attached is from the RCA Transmitting Tube Technical Manual TT-5. I think this circuit was discussed in the "ruminations" tread. As I recall, the upshot of the discussion was that the 807 wasn't a good choice for crazy drive due to the G2/G1 mu of 8 (being too high for practical crazy drive). I know someone who tried this, as a modulator, with 807's and had no luck with it, whereas screen grid driven sweep tubes, with G1 grounded, worked well for him.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Those Magnificent Television Tubes