... I sure like those 46s; maybe not better than 45s, but they sure are spritely in triode connection. ...

47 makes a real nice triode also, and easier and cheaper to source than 46. Should plug right in to your 5 to 4 adapter.

Looking forward to the commercial release of the UNSET. As long as we're on the subject of five pinners, I wonder what 807 or 307A would do?

Or 6146B?

Mentioning the 6146B on audio forums is a Spontaneous Ham Reflex, I think.

Just Can't Hep It.

I have exactly one set of 6146Bs, finals in an ancient Kenwood Closet Queen transceiver. For all that she's been touched in last 30 years, she's probably claiming to be a Virgin Closet Queen at this point.

I vaguely remember that they (6146Bs) are extremely linear, but require a SUBSTANTIAL B+; isn't that right?

Has anybody ever HEARD a 6146B audio amp? On paper, it SHOULD sound great...and I seem to remember seeing current production advertised somewhere.

Hams & Guitar players, we'd be lost without 'em.

Re: 47s

Understood; for some reason (probably a screaming eBay deal 15-20 years ago) I have all these identical boxed 46s, and not a single 47 or 807.

"Make-do" was the phrase I heard from the Depression generation...

de K5HAR

PS is "JAG" a vanity call sign, on account of that Juris Doctor appendage you carry around? Just curious.

Just Can't Hep It.

I have exactly one set of 6146Bs, finals in an ancient Kenwood Closet Queen transceiver. For all that she's been touched in last 30 years, she's probably claiming to be a Virgin Closet Queen at this point.

I vaguely remember that they (6146Bs) are extremely linear, but require a SUBSTANTIAL B+; isn't that right?

Has anybody ever HEARD a 6146B audio amp? On paper, it SHOULD sound great...and I seem to remember seeing current production advertised somewhere.

Hams & Guitar players, we'd be lost without 'em.

Re: 47s

Understood; for some reason (probably a screaming eBay deal 15-20 years ago) I have all these identical boxed 46s, and not a single 47 or 807.

"Make-do" was the phrase I heard from the Depression generation...

de K5HAR

PS is "JAG" a vanity call sign, on account of that Juris Doctor appendage you carry around? Just curious.

Last edited:

Objects May Appear Bigger on a 25" OMM (Old Man Monitor).

PLUS, the 6BQ6GA I happened to have had on my desk is the SKINNY bottle version, so it's even wimpier looking than your Fat Bottle.

Even though we are the same age, my old man eyes needed a 32 inch screen for PC board layout 10 years ago, and that went to my current 43 inch size when Sams club ran a 43 inch Hisense 4K TV on Black Friday for $229 about 4 years ago. Now I need the big screen AND glasses.

Objects do appear really big.....even when you don't want them to.

Even so I still got a diode in backwards on the UNSET silkscreen layer. I Don't know what is is with me and diodes. Getting them backwards or using the wrong one has caused me more blown up stuff than any other part.

Attachments

Curiously, I ALWAYS get diodes (and MOSFET and CCSs) installed correctly. Except NOW that I've said that, I'm gonna blow something up tomorrow. After working with Cajuns (almost said the impolite term) all these years, you'd think I would understand the Bad Gri-Gri.

Could be the difference between Mech Engineering and EE. I can do 3D & 4D (imagine a 3D movie) in my head, but still have to scratch numbers on a pad to determine cathode bias...

PS Hard variable focus contact lenses. Nowadays I only wear reading glasses to get the chicks. Well, like Golden Girls chicks...

Could be the difference between Mech Engineering and EE. I can do 3D & 4D (imagine a 3D movie) in my head, but still have to scratch numbers on a pad to determine cathode bias...

PS Hard variable focus contact lenses. Nowadays I only wear reading glasses to get the chicks. Well, like Golden Girls chicks...

Last edited:

... Has anybody ever HEARD a 6146B audio amp? ...

Sure. 6146 and 2E26 are drop ins on the SSE. There's a thread here in the sub forum on them. 6146 needs a screen supply, but 2E26 works pretty well as a triode. The first 6146 data sheet had triode operating points, but they dropped those on subsequent sheets.

... PS is "JAG" a vanity call sign, on account of that Juris Doctor appendage you carry around? Just curious.

Sort of, not really. My original call, WN5KOM and WB5KOM, were tedious on CW, so I wanted something a little snappier, and since Ham call plates are no extra cost here in Arkansas, it also made a cheap vanity plate for my now "antique" twelve cylinder Jaguar, that I drive whenever atmospheric CO2 levels need a boost, and premium fuel stocks need to be depleted.

It works for the JD thing, but that is just coincidence.

edit: at 61 my eyes are actually still holding up pretty well. I've mostly converted over to SMD/SMT and can do down to 0603 without any visual assistance; I do sometimes use a cheap magnifying glass to double check soldering or for shorts. 0402 is mostly too small.

Last edited:

W5JAG said: " I've mostly converted over to SMD/SMT and can do down to 0603 without any visual assistance."

I literally convulsed when I read that sentence. I can't even PICK UP an SMD part without dropping it on the floor; LOST FOREVER.

Re: 6146

SO, how do they sound? I don't detect a big sway over to 6146 SE amps; of course the top-cap is seen as a BUG not a FEATURE by most of the unenlightened.

And by unenlightened, I mean folks that haven't dragged their left hand over a nice big fully charged 450V capacitor...

BTW you got a link or cc of the old 6146 data sheet with triode op points? That sounds like something I need. EDIT: Never Mind, found it. RCA 1952.

PS Ham Plates are not free in Texas, but very cheap. They DO have a requirement that you actually have a ham radio IN THE VEHICLE (as if anybody is going to check), but a hand-held would suffice. I've got a BaoFeng here somewhere...I was going to get Ham Plates for the Airstream, but had second thoughts that folks can easily look-up your home QTH and make themselves comfortable while you're stuck in the sand at South Padre. The Texas "Amateur Radio Operator" plates DO have a nice lightning bolt in the middle, though.

I literally convulsed when I read that sentence. I can't even PICK UP an SMD part without dropping it on the floor; LOST FOREVER.

Re: 6146

SO, how do they sound? I don't detect a big sway over to 6146 SE amps; of course the top-cap is seen as a BUG not a FEATURE by most of the unenlightened.

And by unenlightened, I mean folks that haven't dragged their left hand over a nice big fully charged 450V capacitor...

BTW you got a link or cc of the old 6146 data sheet with triode op points? That sounds like something I need. EDIT: Never Mind, found it. RCA 1952.

PS Ham Plates are not free in Texas, but very cheap. They DO have a requirement that you actually have a ham radio IN THE VEHICLE (as if anybody is going to check), but a hand-held would suffice. I've got a BaoFeng here somewhere...I was going to get Ham Plates for the Airstream, but had second thoughts that folks can easily look-up your home QTH and make themselves comfortable while you're stuck in the sand at South Padre. The Texas "Amateur Radio Operator" plates DO have a nice lightning bolt in the middle, though.

Attachments

Last edited:

I thought they sounded pretty good - a lot like a 6DQ6B in a short fat bottle. The Shuguang tubes have a bit more Pd than the U.S. tubes, and they have a visible heater, so a better choice for audio. The pins have a squared off end, rather than tapered, so I would not put them in a valuable radio for fear of wrecking an old socket.

The 2E26 should have the same type of sensitive screen grid that the 6146 and other sweep tubes have, but I found in practice that this is not true. They work quite well as a triode at voltages about like a 6V6 work at. 2E26 has a very low grid resistor spec that can likely be ignored in most cases, but I did find one that would run away when the spec was exceeded. Seemed like I used 100K as the grid resistor for 6146.

About the SMD thing - for the longest I felt like it was too difficult, too small, I'm too darn old, too stupid, need to retool, etc., but an RF project presented the opportunity / need to make the switch to SMD, and with some gentle coercion, I made the switch and I have to say, I have not really looked back. I started with 1206 ( 1/4 watt equiv. ) and when I first received them, I thought they were just impossibly small, but after a month or two, decided they were too BIG.

0805 ( 1/8 watt equiv. ) is conveniently small and really easy to work with. About the only "new" tools one would need to switch to SMD is a hot air gun for rework and appropriate proto boards for building on. I use the same adjustable temp soldering iron / tip that I use for everything else. It's just faster and easier with SMD. I travel between two houses, and stay mostly at the second house these days, so I have to carry stuff with me in 16" toolcases. A staggering amount of SMD stuff can be carried in my solid state RF toolkit, compared to what I can fit in my audio / tube toolkit of the same size. I haven't purged my through hole parts because at some point my eyes will go and I will need them, but other than refreshing my capacitor stock to take advantage of the smaller sizes of modern parts, and some resistor assortments to equip my travel tool kits, I've quit buying through hole parts.

The 2E26 should have the same type of sensitive screen grid that the 6146 and other sweep tubes have, but I found in practice that this is not true. They work quite well as a triode at voltages about like a 6V6 work at. 2E26 has a very low grid resistor spec that can likely be ignored in most cases, but I did find one that would run away when the spec was exceeded. Seemed like I used 100K as the grid resistor for 6146.

About the SMD thing - for the longest I felt like it was too difficult, too small, I'm too darn old, too stupid, need to retool, etc., but an RF project presented the opportunity / need to make the switch to SMD, and with some gentle coercion, I made the switch and I have to say, I have not really looked back. I started with 1206 ( 1/4 watt equiv. ) and when I first received them, I thought they were just impossibly small, but after a month or two, decided they were too BIG.

0805 ( 1/8 watt equiv. ) is conveniently small and really easy to work with. About the only "new" tools one would need to switch to SMD is a hot air gun for rework and appropriate proto boards for building on. I use the same adjustable temp soldering iron / tip that I use for everything else. It's just faster and easier with SMD. I travel between two houses, and stay mostly at the second house these days, so I have to carry stuff with me in 16" toolcases. A staggering amount of SMD stuff can be carried in my solid state RF toolkit, compared to what I can fit in my audio / tube toolkit of the same size. I haven't purged my through hole parts because at some point my eyes will go and I will need them, but other than refreshing my capacitor stock to take advantage of the smaller sizes of modern parts, and some resistor assortments to equip my travel tool kits, I've quit buying through hole parts.

I've got a BaoFeng here somewhere...

I bought a BaoFeng and a Radioddity when at the insistence of a large US public safety radio manufacturing company that I might have worked for, the "assault radio ban of 2018" as I called it was pushed through the FCC. This made the importation and sale of radios usable on public safety frequencies illegal in the US. The cheap radios didn't go away as predicted, but TX on the public safety bands might have been blocked, I don't know. Mine will TX on any frequency.

Anyone remember the "do not cut the yellow jumper wire in the USA" sticker on a popular 10 meter AM/SSB "ham radio." Or the existence of the Siltronix 1011C, which was basically a 60 watt CB set that also covered 10 meters.

About the SMD thing - for the longest I felt like it was too difficult, too small, I'm too darn old, too stupid, need to retool, etc., but an RF project presented the opportunity / need to make the switch to SMD, and with some gentle coercion, I made the switch and I have to say, I have not really looked back. I started with 1206 ( 1/4 watt equiv. ) and when I first received them, I thought they were just impossibly small, but after a month or two, decided they were too BIG.

The last 30 years of my career involved only SMD stuff since I designed two way radios and cell phones. I always wondered why big trunk mounted police radios used 0204 SMD stuff, so I asked......it's all about the money. At that time the high volume of cell phone production put the 0204 passives at the low spot on the cost curve. The pin density of most modern SMD IC's REQUIRE their use. You can't get the bypass caps close enough to the chip with any bigger parts. The CPU in a cell phone has up to 256 pins on it. The CPU in the last two way radio I did (2010) had 144 pins and the board had 10 layers to connect them all.

At the point of my departure from Motorola (2014) the 0201 was taking over the sweet spot in the cost curve. I had probably $1000 worth of soldering equipment on my desk, and a $2000 microscope, but for the last several years I had to get a lab tech who was actually older than me to solder some of the small stuff for me. All the fancy tools in the world won't help if the peak to peak vibration at the end of the tweezers due to hand shake is greater than the size of the parts.

This has only gotten worse with age, so I'm rapidly trying to build all of my SMD stuff (0603 an larger) while I still can. It's now to the point where I solder my fingers while building things like UNSET boards.

Back in the 1980's I spent some time shaking mobile radio equipment apart on a giant custom built shaker table. The original machine must have been built in the 60's, used a bunch of vacuum tubes and offered a selection of typical waveforms (sine, triangle, square, etc, and amplitudes calibrated in peak to peak excursion in millimeters. That's where I got that term.

Some time in the late 80's that machine got replaced with a fancy solid state unit that had profiles that were digitized from actual test scenarios. My favorite was "Military Jeep dash" with the excursion set on about 13 mm. Nothing could survive that!

My younger brother has the tremors real bad. They were visible when he was young and have grown to tens of millimeters at the hand today. I just drop things all the time and can't keep a tiny part in the tweezers, or bump all those around it when trying to place it.

There are two ways to do SMD assembly. The "safe" way involves soldering each part one at a time with tweezers and a soldering iron. Bumping a part or two won't move anything since each part is soldered before going to the next one.

The "fast" way was what I called the frying pan method at Motorola because that's what I actually used the first time I did it. Each part is sitting in a sticky goo until the entire board is "reflowed." It is possible to make a total mess requiring a complete do-over with a misplaced tweezer strike.

You put solder paste on each SMD pad, either with a tiny syringe, or a solder stencil made by the board house and a squeegee. They you place each part in the paste with tweezers, place the board in the frying pan, and place the frying pan on a hot plate turned up to about 280C. Once the solder has reflowed, move the frying pan to a large heat sink. Heating up a Teflon pan may not be so good for the person doing it, so the pan was replaced with a piece of 0.100'' aluminum held with a pair of Vise Grips.

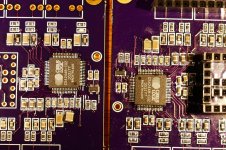

The fast way makes for a better looking board. The board on the left was done "fast." The board on the right was done "safe."

Some time in the late 80's that machine got replaced with a fancy solid state unit that had profiles that were digitized from actual test scenarios. My favorite was "Military Jeep dash" with the excursion set on about 13 mm. Nothing could survive that!

My younger brother has the tremors real bad. They were visible when he was young and have grown to tens of millimeters at the hand today. I just drop things all the time and can't keep a tiny part in the tweezers, or bump all those around it when trying to place it.

There are two ways to do SMD assembly. The "safe" way involves soldering each part one at a time with tweezers and a soldering iron. Bumping a part or two won't move anything since each part is soldered before going to the next one.

The "fast" way was what I called the frying pan method at Motorola because that's what I actually used the first time I did it. Each part is sitting in a sticky goo until the entire board is "reflowed." It is possible to make a total mess requiring a complete do-over with a misplaced tweezer strike.

You put solder paste on each SMD pad, either with a tiny syringe, or a solder stencil made by the board house and a squeegee. They you place each part in the paste with tweezers, place the board in the frying pan, and place the frying pan on a hot plate turned up to about 280C. Once the solder has reflowed, move the frying pan to a large heat sink. Heating up a Teflon pan may not be so good for the person doing it, so the pan was replaced with a piece of 0.100'' aluminum held with a pair of Vise Grips.

The fast way makes for a better looking board. The board on the left was done "fast." The board on the right was done "safe."

Attachments

Has anybody ever HEARD a 6146B audio amp? On paper, it SHOULD sound great...and I seem to remember seeing current production advertised somewhere.

Ampeg SVT300 used 6 of them on bass amp ... Big sound

UNSET Update Request

Is it soup yet?

(for the whippersnappers, that was a tagline from Lipton's dehydrated soup commercials in the 1970s)

PS The shock troops (or maybe Special Forces) in The TubeLab Army will gladly take the wonky bad silkscreen/small holed version. Just sayin'.

Is it soup yet?

(for the whippersnappers, that was a tagline from Lipton's dehydrated soup commercials in the 1970s)

PS The shock troops (or maybe Special Forces) in The TubeLab Army will gladly take the wonky bad silkscreen/small holed version. Just sayin'.

I had the first of the new boards up an running without issue. Then I started messing with it and let the smoke out. A slip of the screwdriver scattered the screen regulator mosfet. Good outdoor working weather has kept me away from the bench since I blew it up. I might get back to it later tonight.....unless Sherri finds something else that needs my immediate attention.

The dead board is working again. I have discovered a few minor issues that can be minimized with component value tweaks. There will need to be a board to fix a possible power up issue and fix up all the other little issues.

These boards can be used for amp builds, and I will make them available to early adopters at a reduced price once I have done some more testing and created a preliminary parts list.

This board is quite flexible and can be used with everything from 6V6's and 6W6's to big A$$ sweep tubes and both SE and P-P configurations, and possible PSE mono on a single board. All the possibilities make it like the Universal Driver board, one parts list does not fit all, but I'll try to make it fit most.

Those who want a PC board, with a complete parts list that you can just build and use may want to wait a bit. I plan on building a few of these things in both SE and high powered P-P configurations to make sure that there are no hidden problems.

Here is the schematic of the current UNSET board. All the funny stuff around the output tube is a jumper matrix allowing the use of any octal tube, or any tube with the use of off board sockets.

These boards can be used for amp builds, and I will make them available to early adopters at a reduced price once I have done some more testing and created a preliminary parts list.

This board is quite flexible and can be used with everything from 6V6's and 6W6's to big A$$ sweep tubes and both SE and P-P configurations, and possible PSE mono on a single board. All the possibilities make it like the Universal Driver board, one parts list does not fit all, but I'll try to make it fit most.

Those who want a PC board, with a complete parts list that you can just build and use may want to wait a bit. I plan on building a few of these things in both SE and high powered P-P configurations to make sure that there are no hidden problems.

Here is the schematic of the current UNSET board. All the funny stuff around the output tube is a jumper matrix allowing the use of any octal tube, or any tube with the use of off board sockets.

Attachments

I'm in.

edit: I didn't realize there were paralleled pFET's at the output tube. I'm not sure I have enough, hope they are not part of the semiconductor shortage going on right now ...

hold the phone

I only have four ( 4 ) FQPF9P25 in stock. Dang.

Can QRP UNSET's get by with only one pFET in the output stage?

edit: I didn't realize there were paralleled pFET's at the output tube. I'm not sure I have enough, hope they are not part of the semiconductor shortage going on right now ...

hold the phone

I only have four ( 4 ) FQPF9P25 in stock. Dang.

Can QRP UNSET's get by with only one pFET in the output stage?

Last edited:

I'm in.

edit: I didn't realize there were paralleled pFET's at the output tube. I'm not sure I have enough, hope they are not part of the semiconductor shortage going on right now ...

I posted a PDF of the Eagle 5.11 schematic used to generate the PC board. It must accommodate EVERYTHING that goes into the board, including all the holes (lower right).

There is only one fet per output tube, but two possible ways to install it, top of board, or bottom of board. This was handled on the TSE-II by having two sets of holes for the heat sinks. Here the heat sink doesn't move (it's too big), the mosfet does. The schematic must show both possibilities in order to get them into the PCB design. There are two big P-fets, two little P-fets, and one N-fet per build. There is some lead manipulation needed on the small fets, but two different footprints for each large fet. Only one gets placed.

So far I haven't seen to many shortages on discrete through hole semiconductors. The problem with big CPU's is the fab time, 3 to 6 months from start to finish, and the consolidation of major wafer fabs. There are only a few production ready fabs in the world capable of the small geometry (less than 30 nm) stuff needed for modern CPU chips. I'm sure that the situation is worse now than when I was still working, but even IBM sold or shut down their production fabs as I was leaving Motorola (they were building our chips). The biggies now are TSMC, Samsung, Intel, Global Foundaries, NXP, AMD, and a few others. The guys making big mosfets and other discretes are still using old fabs and are pretty much unaffected.

- Home

- More Vendors...

- Tubelab

- UNSET is coming?