G'day chaps.

Hailing from New Zealand here. We're on day 4 of what is presumed to be a 4 week lockdown.

So what have you all built so far during lockdown?

So far I've built a glassware audio 12vac aikido board wired for 18vac with 12au7 tubes.

New Aikido 12Vac PCB and part kits

Doesn't it look lovely in the testing rig?

Its currently running an old use set of new production Tung Sol 12au7s for burn in duties. The sound is as expected from Aikido preamp - darn nice.

I've also made a very crude and yet serviceable attempt at beating a U-shaped piece of mild steel i salvaged from an old Sony midi system into the front panel of another salvaged chassis that never had metal at the front.

]

I beat it flat over an old BMW straight 6 engine block that came with my rented accommodation as an anvil.

I hacked out a section of the 'flat sheet'

Hailing from New Zealand here. We're on day 4 of what is presumed to be a 4 week lockdown.

So what have you all built so far during lockdown?

So far I've built a glassware audio 12vac aikido board wired for 18vac with 12au7 tubes.

New Aikido 12Vac PCB and part kits

Doesn't it look lovely in the testing rig?

Its currently running an old use set of new production Tung Sol 12au7s for burn in duties. The sound is as expected from Aikido preamp - darn nice.

I've also made a very crude and yet serviceable attempt at beating a U-shaped piece of mild steel i salvaged from an old Sony midi system into the front panel of another salvaged chassis that never had metal at the front.

]

I beat it flat over an old BMW straight 6 engine block that came with my rented accommodation as an anvil.

I hacked out a section of the 'flat sheet'

Attachments

Last edited:

Hi, since I caught the virus (not sure as no test was spent) I stayed in selfquarantaine for over 2.5 weeks. Tools and parts in abundance so I had to spend my time well.

I made this small TDA7297 based amplifier and called it the Corona amp. It has an ideal rectifier, 22,000 µF filter cap, Rcore transformer. It has 2 inputs that are switched with a relais.

It sounds very good. I also made a few audiophile LDO power supplies.

I made this small TDA7297 based amplifier and called it the Corona amp. It has an ideal rectifier, 22,000 µF filter cap, Rcore transformer. It has 2 inputs that are switched with a relais.

It sounds very good. I also made a few audiophile LDO power supplies.

Attachments

Last edited:

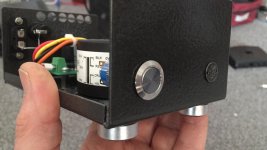

It is built with left over parts that were mostly new/unused and some surplus stuff I had. Board is a Chinese TDA board but heavily modified. The LT4320 ideal rectifier is from a group buy here and it is more expensive than any other part in the amp. It is my thought that the ideal rectifier is responsible for the excellent result. Because I wanted it to look good and be sturdy so it took me 4 whole days to do the metal work and building. The casing is impossible to use as it is too small but it is what I had on hand so I made it all fit. I had to use an extension axle and a bearing for this.

Chassis is NOS/NIB from a german company that simple rebadged them and bought them from HiFi 2000. It is called Galaxy. I paid 25 for 2 of them.

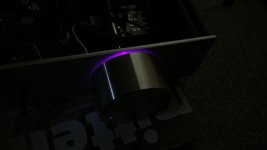

The volume knob is seventies Akai and modified for the current use but I found it to be too large. It has been replaced by a slightly smaller and less deep Akai knob also from the seventies. I simply drill a small hole in them and fill these with 2 component glue to function as a lit indicator. These were tuner knobs. It was meant to see the input switching by 2 different LEDs but since I had flulike feeling I accidentally used 2 of the same purple color LEDs.....Still it looks nice and one can see input switching clearly as the lower LED starts to glow. The upper one is the power on indicator and also serves to show that input one is chosen. Very simple logic: on means there is light. Switching to input 2 means more light at the lower side of the knob

I used a left over input relay board for input switching. Output terminals are silver plated sixties military material. So contrary to my normal building style this really is a mix of various left over things. I had to overcome my dislike for this and it turned out to be sounding excellent with its tiny 2 x 3W. It has since been in use every day although the power switch is not connected yet. I am waiting for a fused terminal block to finish this.

Chassis is NOS/NIB from a german company that simple rebadged them and bought them from HiFi 2000. It is called Galaxy. I paid 25 for 2 of them.

The volume knob is seventies Akai and modified for the current use but I found it to be too large. It has been replaced by a slightly smaller and less deep Akai knob also from the seventies. I simply drill a small hole in them and fill these with 2 component glue to function as a lit indicator. These were tuner knobs. It was meant to see the input switching by 2 different LEDs but since I had flulike feeling I accidentally used 2 of the same purple color LEDs.....Still it looks nice and one can see input switching clearly as the lower LED starts to glow. The upper one is the power on indicator and also serves to show that input one is chosen. Very simple logic: on means there is light. Switching to input 2 means more light at the lower side of the knob

I used a left over input relay board for input switching. Output terminals are silver plated sixties military material. So contrary to my normal building style this really is a mix of various left over things. I had to overcome my dislike for this and it turned out to be sounding excellent with its tiny 2 x 3W. It has since been in use every day although the power switch is not connected yet. I am waiting for a fused terminal block to finish this.

Last edited:

Nice,

That is quite a hilariously overbuilt power supply for 3w. One can never have too much power supply imo.

I was wondering about the size of that chassis. Do you have any internal shots? It must be a very tight fit

Very tight. Apart from the self promoting aspect the fact that it is a nice but rather various build makes me reluctant to show the innards.

The PSU is made around a too low specced Rcore (6V 3.4A) transformer. All other transformers that I have are too large for the casing. So enough current but rather low voltage. The ideal rectifier manages to make it 10.6V together with the 22,000 µf cap. It is very loud though!

Since this is my first real world application with an ideal rectifier I think this is why it sounds so good. It has taken the place of my "official" amplifiers and right now I am thinking to rebuild it with a larger casing and higher voltage transformer (I have 12V 4A Rcore transformers in stock) ...

Last edited:

Well if it helps you. It sounds way too good to be neglected  Meanwhile I found shielded cabling for the inputs which could be a nice upgrade. The heatsink is a custom made one from an old inverter. I cut it and sanded it to fit exactly. Then I made the mistake by screwing/glueing the chip to the heatsink not realising the tab is -/GND. This meant the chassis which should be connected to PE to be in direct connection with audio GND which is a big Nono in the non anglosaxon electrical world. This is why PE is lifted with a 10 Ohm 5W resistor.

Meanwhile I found shielded cabling for the inputs which could be a nice upgrade. The heatsink is a custom made one from an old inverter. I cut it and sanded it to fit exactly. Then I made the mistake by screwing/glueing the chip to the heatsink not realising the tab is -/GND. This meant the chassis which should be connected to PE to be in direct connection with audio GND which is a big Nono in the non anglosaxon electrical world. This is why PE is lifted with a 10 Ohm 5W resistor.

Attachments

Last edited:

Covid-19 seems to enhance productivity. Here some pictures of a non-safe (I am certified etc. so I know) ultra low noise LDO PSU partly made with recycled parts (like the casing which was of a ring system for hearing disabled people). Bummer, the new stainless steel switch measures 30 to 50 ohm when switched so very unsafe so it will be replaced. Strangely it is 0 Ohm in NC mode. PE is not used despite being required. Since it is my personal device I leave it like it is, it is safe enough for my lab where floating 230V mains is used. The logo which covers an existing hole was pulled from an old sweater

Attachments

Last edited:

Glad to hear some feedback from both someone who endured the illness, as well as that fantastic power supply! What are you using as a source?

My efforts have been limited to some tweaking on consumer equipment that had been headed to the thrift store anyways. Will be gifted to a friend shortly.

It must be a reliability thing to use so many coupling capacitors in consumer tuner/amplifiers.

They are all gone now except for a pair in front of the amplifier that were replaced with some Wima mks2 4.7uf.

My efforts have been limited to some tweaking on consumer equipment that had been headed to the thrift store anyways. Will be gifted to a friend shortly.

It must be a reliability thing to use so many coupling capacitors in consumer tuner/amplifiers.

They are all gone now except for a pair in front of the amplifier that were replaced with some Wima mks2 4.7uf.

PASS A40 with Sanken outputs using alexcp boards. I have almost everything here at home to finish the build. Running nice and warm yet very stable. Both left and right channels have 5mV offset. I will assemble the case and try it out with the desk top power supply. If it does not fail, I will install the actual power supplies, fuses etc. I have some other 'virus lock down' projects/upgrades so I will try to stay busy.

Attachments

It must be a reliability thing to use so many coupling capacitors in consumer tuner/amplifiers.

They are all gone now except for a pair in front of the amplifier that were replaced with some Wima mks2 4.7uf.

I have a Marantz SR4200 AVR that from DAC to output has 5 DC blocking caps. I declared it a lost cause, but it comes apart pretty easily....

I have a Marantz SR4200 AVR that from DAC to output has 5 DC blocking caps. I declared it a lost cause, but it comes apart pretty easily....

Sounds like you got yourself a cheap chassis and power transformer.

As those other threads were closed, here is a non-audio project

MIT Will Post Free Plans Online for an Emergency Ventilator That Can Be Built for $100

DIY Audio Editors note: We are allowing this one post because of the warnings therein such as:

"The team is particularly concerned about the potential for well-meaning but inexperienced do-it-yourselfers to try to reproduce such a system without the necessary clinical knowledge or expertise with hardware that can operate for days; around 1 million cycles would be required to support a ventilated patient over a two-week period. Furthermore, it requires code that is fault-tolerant, since ventilators are precision devices that perform a life-critical function. To help curtail the spread of misinformation or poorly-thought-out advice, the team has added to their website verified information resources on the clinical use of ventilators and the requirements for training and monitoring in using such systems"

MIT Will Post Free Plans Online for an Emergency Ventilator That Can Be Built for $100

DIY Audio Editors note: We are allowing this one post because of the warnings therein such as:

"The team is particularly concerned about the potential for well-meaning but inexperienced do-it-yourselfers to try to reproduce such a system without the necessary clinical knowledge or expertise with hardware that can operate for days; around 1 million cycles would be required to support a ventilated patient over a two-week period. Furthermore, it requires code that is fault-tolerant, since ventilators are precision devices that perform a life-critical function. To help curtail the spread of misinformation or poorly-thought-out advice, the team has added to their website verified information resources on the clinical use of ventilators and the requirements for training and monitoring in using such systems"

Last edited by a moderator:

Well I'm not in quarantine, and still able to work, but I started a new project anyway - mainly because I start more things than I finish, but also because I might need something to do in a few weeks.

So I have almost built up 2 output stages, one with 6P6S and another with 6P1P-EV, for sake of comparison.

So I have almost built up 2 output stages, one with 6P6S and another with 6P1P-EV, for sake of comparison.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Member Areas

- The Lounge

- Audio Builds during the Covid-19 Lockdown