...

I was with the Research Instruments division. So our customers were research labs throughout the world. And standards labs, accelerator facilities etc. A more difficult customer base is difficult to think of!

...

Difficult but, IMO, the fun/interesting work to do.

There’s an audio publication in the UK (HiFi News?) run by Pete Miller that looks at the bit depth and bandwidth on recordings as a matter of course. When I looked a few years ago, many claimed ‘hi res’ or ‘hi def’ and were absolutely nothing of the sort. A lot are bog standard 16/44 and some were up-sampled. Ditto many SACD - just resampled original recordings.

At least with vinyl there’s a few less layers of bs to contend with and the expectations are more realistic.

I have a "dirty idea" to artificially increase bandwidth but I don't even wanna mention it. It's probably easy enough to guess, anyway.

You bet on the Aphex Aural Exciter?I have a method guaranteed to win the lottery. Of course it is the obvious method.

I wasn't planning on explaining this further, but in looking for something else I stumbled across this. Relevant quote:

A Harmonic RestorerNow here is the problem: many of us own hundreds, if not thousands of CDs, which we are not willing (or unable) to replace with high-resolution downloads. What can we do? One thought that comes to mind is a harmonic restoring circuit that would add some of the missing ultra-sonic information to CD playback.

Many years ago I read about the Aphex device or similar distortion-creating circuits used for restoring upper harmonics in recordings bandlimited to something well below 20kHz, so it's logical that the idea that could be used for "restoring" ultrasonic harmonics as this article says. Regrettably, the writer goes through this longish article, comes up with a couple of circuits, analyzes harmonic distortion, but then doesn't say anything about how it sounds. Did he do any listening? Did he build the circuit? Did he succeed in making a CD sound like an LP as he hears it?

But yes, for anyone selling "high-res" content online, this could be used to make recording that LOOK LIKE they're made from masters containing ultrasonic material.

AES E-Library >> Triode Emulatorsimilar distortion-creating circuit

We ran Cryopumps in our vacuum chambers and and I thought hitting <10K was cold!! 5 mK? WOW!

Howie

Weird things, dilution fridges. They use regular helium4, and the lighter isotope helium3, which is missing a neutron.

At the bottom end is a chamber in which the heavier helium4 is a superfluid, and the helium3 floats on top and has the viscosity of corn oil. The fortunate accident is that in equilibrium He3 diffuses downwards into the superfluid He4. The concentration of He3 in the He4 is ~6%. So you use a monster pump to reduce the 6%. "hot" He3 then diffuses down to try to get back to 6%.

And that is the cooling mechanism.

There are all sorts of counterflow heat exchangers upstream to precool incoming gases which use sintered silver to get the surface area up. And all sorts of other gubbins to make it work.

There is even a Wiki page about the technology, which covers the main points Dilution refrigerator - Wikipedia

But a few millikelvin is warm! If you bolt onto a dilution fridge a nuclear demagntization stage, you can get down to a very few tens of microkelvin.

Difficult but, IMO, the fun/interesting work to do.

As one of the "difficult" customers, I can attest to the challenges of acquiring the hardware needed for what we do.

When the machine you tend to has a down time cost of 127 thousand dollars per hour, you tend to be a bit picky when it comes to buying critical hardware. Especially when a failure of one component requires 24/7 work for 19 days for ten to 15 people to get back online..

It is what it is...I never try to make a vendor do something they are not used to, that never ends well.

But I also have to walk the picket fence w/r to what I can teach a vendor...there are many legal issues w/r to giving one vendor an advantage over other.. As a non-lawyer, I stay away from that stuff..

jn

ps..my worst case cold thing was programming the PLC for a pump skid with 2 100 HP motors to pull a dewar down to 1.88K for testing of some LHC magnets. All I had to do was make the PID control the pressure at (I think) 11 millitorr. Difficult as the skid was 100 feet of 10 inch pipe away from the dewar, so I had to really dumb down the time constants..Honestly, childs play compared to milli and micro kelvin stuff..

Last edited:

You're right - things have to work, and work well. Customer difficulty came from the grant of money from the University or Research Institute. Typically, a customer would need a quotation yesterday in order to apply for the overall project money.

But the difficulty was that the time from applying from the money to getting it to spend might be 18 months to 3 years, sometimes even more. By that time, technology requirements moved on - so they needed something different (a larger bore or higher field magnet, a different sample space etc), which inevitably was more expensive. But the customer only had the money for the original spec we quoted for. So we took the hit on our margins.

Then on top, the customer contracts people often slapped a penalty clause on delivery date. The practical effect of which, on a complex delivery there were delays, once the profit had been eroded to zero, the project was "Cinderella-ed", and just parked in a corner of the shop floor, because other machines were profitable.

There were some fun and games too. Our installation people arrived at one institute with a big magnet. The customer had measured the facility doors to determine that the magnet would fit. It didn't (customer measured the doors wrong). So they had to hang around while a team arrived to demolish a wall to admit the magnet.

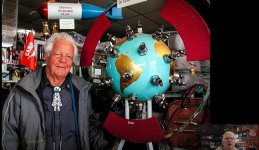

We built massive 4 Tesla, 0.5 metre bore magnets for mineral separation (this became a standard product). This thing had a 10 ton iron shield to manage the stray field of this huge industrial magnet. Image attached, on our shop floor prior to shipment.

The first shipment of this went up a tributary of the Amazon to a kaolin clay processing site. That went out on an Antonov, then a seriously big air ride truck, then on a barge.

The water to back-flush the clay impurities out came from the Amazon. We'd put massive filters in place to prevent plants, sludge etc getting in. The mine operators got pissed off that the filters kept getting plugged up - so they just took them out. So next the machine itself got plugged up with frogs "the size of small dogs".

May, many similar stories.

But the difficulty was that the time from applying from the money to getting it to spend might be 18 months to 3 years, sometimes even more. By that time, technology requirements moved on - so they needed something different (a larger bore or higher field magnet, a different sample space etc), which inevitably was more expensive. But the customer only had the money for the original spec we quoted for. So we took the hit on our margins.

Then on top, the customer contracts people often slapped a penalty clause on delivery date. The practical effect of which, on a complex delivery there were delays, once the profit had been eroded to zero, the project was "Cinderella-ed", and just parked in a corner of the shop floor, because other machines were profitable.

There were some fun and games too. Our installation people arrived at one institute with a big magnet. The customer had measured the facility doors to determine that the magnet would fit. It didn't (customer measured the doors wrong). So they had to hang around while a team arrived to demolish a wall to admit the magnet.

We built massive 4 Tesla, 0.5 metre bore magnets for mineral separation (this became a standard product). This thing had a 10 ton iron shield to manage the stray field of this huge industrial magnet. Image attached, on our shop floor prior to shipment.

The first shipment of this went up a tributary of the Amazon to a kaolin clay processing site. That went out on an Antonov, then a seriously big air ride truck, then on a barge.

The water to back-flush the clay impurities out came from the Amazon. We'd put massive filters in place to prevent plants, sludge etc getting in. The mine operators got pissed off that the filters kept getting plugged up - so they just took them out. So next the machine itself got plugged up with frogs "the size of small dogs".

May, many similar stories.

Attachments

Last edited:

With respect to quote.. to pay, you are totally correct. The money is torturous.

I will be honest. Nowadays, the fights to get money from above to do what is needed is really making me think retirement is better. I've been holding on because I believe what I do is important, but I find that I am far less excited to continue.

Tomorrow I may feel different. Who knows.

Jn

I will be honest. Nowadays, the fights to get money from above to do what is needed is really making me think retirement is better. I've been holding on because I believe what I do is important, but I find that I am far less excited to continue.

Tomorrow I may feel different. Who knows.

Jn

There was something about frogs and magnets - floating frogs.

Nobel Prize in physics: Andre Geim went from levitating frogs to science’s highest honor.

Nobel Prize in physics: Andre Geim went from levitating frogs to science’s highest honor.

Frogs the size of small dogs... That's gotta be worth a few million right there.

Ha ha! I suppose it is better than dogs the same size as small frogs

Speaking of "The Black Hole", Craig Hollabaugh on his youtube livestream talks about the salvage lots at Los Alamos in the 1970's. One old coot owned 7 houses around town in which he'd store surplus electronics. Eventually, he bought the "Piggly Wiggly" grocery when it went bankrupt and sold surplus from Los Alamos == calling it "The Black Hole".

TTwG #08 - I Have A Problem - THE Estate Sale of a Lifetime - YouTube

TTwG #08 - I Have A Problem - THE Estate Sale of a Lifetime - YouTube

Attachments

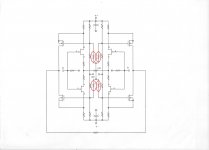

Are you shure this is the complete circuit diagram ?

The text tells that the junction of the four questiined resistors is the CM output versus the DM mode output directly below.

But I don’t see how this could ever be an output.

Just DC voltage dividers between V+ and V- with only four high impedance gates connected.

But when this is not meant as output, I agree that the function of these 4 resistors is superfluous.

And why aren’t the outer mosfets not marked as outputs ?

Hans

The text tells that the junction of the four questiined resistors is the CM output versus the DM mode output directly below.

But I don’t see how this could ever be an output.

Just DC voltage dividers between V+ and V- with only four high impedance gates connected.

But when this is not meant as output, I agree that the function of these 4 resistors is superfluous.

And why aren’t the outer mosfets not marked as outputs ?

Hans

Last edited:

It should be the common mode point where the common mode servo connects to correct the common mode offset. It is not the complete schematic.

Nice to see you around John! I hope you are fully jabbed and healthy!

Cheers!

Howie

- Home

- Member Areas

- The Lounge

- The Black Hole......