Yes, try listening to some silver cable and you may 'discover' something for yourself.

I now have loopback recordings that illustrate this 'brightness', who cares what 'theory' says when the facts are clear.

Dan.

I've got some silver plated wires, does that count?

Try Specialist in craft wire, knitted craft wire, silver wire, enamelled copper, resistance wires, stainless steel, plated wires and many more!, they have the pure 99.99% soft and sterling 925. Use 2-3 feet length for listening tests.I've got some silver plated wires, does that count?

So a couple of files were bunky but not fatally, so what ?.

So what? Just that we are evaluating the flaws of your system and not the supposed wire material sonic influence. That is the tragedy of most audiophiles, because of their incompetence they have serious flaws in their systems which they attribute to some magic unknown material properties or phenomena. Just because of their incompetence and ignorance. That is the real case, together with psychoacoustic effects.

Time to repeat these questions as there have been only very vague answers so far from the few here that did bother to respond.

I would like to pose a few questions to the cable specialists:

1 - Any known very directional wires/cables one can buy or easily build from scratch?

3 - Would directionality (the direction A vs B difference) typically be an error closely correlated to the signal, that is, not random enough to be reduced considerably by precise time-domain averaging which is used as a method to dig down deep in the uncorrelated noise?

Note that correlated noise signatures (like excess current noise from mediocre resistors) still appear in spite of the heavy averaging (on the order of 10,000 blocks of sample data, typically).

2 - Would directionality appear in cable loopback with an integrated single DAC/ADC device, that is, when freed from many typical other noise/error sources like RF ingress and balancing currents?

I'm asking because I'm in a process of constantly refining my measurement strategies and time-domain averaging techniques enabling a view down at least some 40dB below the analog noise floor in the signal and especially in diff test residuals, having a virtual analog resolution of around 30bits. With a fully arbitrary test signal, actually.

So if (at least some) cable directionality effect is real and fulfils the above criteria (and maybe others?) it should be possible to measure and quantify under very real working conditions with "real" signals (to avoid any potential pitfalls of steady-state type of measurements), should't it?

Point is, it's an almost ideal candidate to exploit the power of differential testing because "standard" linear/nonlinear phenomena should remain unchanged. No trimming or post-processing needed to empirically match gross changes (like from different cables) which greatly increases robustness of the method. Some special care is needed though, for the automatic switching matrix that is required to implement this (still under construction).

2 - Would directionality appear in cable loopback with an integrated single DAC/ADC device, that is, when freed from many typical other noise/error sources like RF ingress and balancing currents?

Klaus, let me be not very serious and pick just one of your questions

No, in the loopback arrangement and ABX test there will be no effect, because the subject does not know which recording is which

-or-

yes, because the system used is so poor that it is unable to yield same signal data for the two runs of the same file

Wow, don't let Dan see this site, he'll be like a kid in a candy store.Try Specialist in craft wire, knitted craft wire, silver wire, enamelled copper, resistance wires, stainless steel, plated wires and many more!, they have the pure 99.99% soft and sterling 925. Use 2-3 feet length for listening tests.

This is not the right way to measure noise. Not that it matters, because your theory is crazy and you said it could be heard with a Samsung phone, but I don't have a Bose system. I have Sennheiser HD800s and Dynaudio monitors.You have no real clue about audio or the results that I am achieving. So a couple of files were bunky but not fatally, so what ?. You have not indicated that you have auditioned any of the other loopback recordings, suggest a track you know and like and I will process it for you. My next round of loopback recordings should capture directional effects and stand as proofs. Then we can debate the causes, in the meantime you could try reversing one interconnect and try the experiment for yourself, that is if you have a stereo worth listening to (IIRC you have a little Bose satellite system, is that right ?).

Dan.

Maybe Mr. Colburn or Mr. Hoyt can help a bit more?... 1 - Any known very directional wires/cables one can buy or easily build from scratch?...

I have had cable directionality demonstrated to me as a measurement. It was due to poor cable design and construction. I don't know if it was audible or not but it could be measured and was also position dependent.

... Connector contact resistance is very highly variable, especially with poor connectors like RCA plugs and represents a swamping variable in the test. In our many audio systems in the cassette and optical disc plants we had to constantly clean and maintain both BNC and XLR connectors which could variously show a level drop, rectification artifacts or intermittent noises.

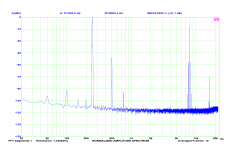

I always love how these valve amps have mains IM on every input signal at 30dB over the noise floor.

However, I do not think that it is a necessary behavior of the tube amp design.

Attachments

I have not followed all of this semantic debate, but, in my language, we use the word "directivity" rather to speak of the distribution of the sonorous power of a speaker in space, and the word dispersion to speak of the way the surfaces that obstruct sound waves ... reflect them in space.Since it is such a non-issue for audio, the use of the word 'dispersion' in acoustics is generally (and thus, correctly) used to describe the 3D characteristics of a loudspeaker. These, as we all know, are heavily impacted by frequency.

In optics, a perfect mirror has 0 dispersion, if I do not mistake, a matte wall reflect and disperses a ray of light in all directions. Likewise, a flat rigid wall has 0 dispersion, an irregular surface wall in relation to the considered wavelength acts like the dull wall.

In any case, by striking an obstacle, and depending on the rigidity of the wall, part of the sound waves are absorbed, and transformed into heat.

There is also a dispersion due to the transmission media itself, the air in our case, which varies with the humidity, just as the mist attenuates and disperses the light rays.

A solid media transmits sound waves like a waveguide.

Last edited:

Goop™ makes directional effects of standard cables more obvious, and also makes more obvious that the TS/GC cable is indeed essentially non directional.

Careful Goop is already a registered trademark.

Thanks I use it in fun, in honour of whichever smart alec it was here that named it so. Goop is actually a good name for cosmetics, an Aus colloquial name is Spakfilla.

In that case I take it backThanks I use it in fun, in honour of whichever smart alec it was here that named it so.

Goop is actually a good name for cosmetics, an Aus colloquial name is Spakfilla.

Dan, I take it all back, congratulations on your partnership with Gwyneth Paltrow

You are mistaken. Most of us do not deny that you are convinced to had heard a difference. You have to accept as an hypothesis it can be an auto suggestion as well. The question is not on the effects, but the cause. If you can hear a difference, you HAVE to explain yourself and others why. Ensure the problem exists before to propose a solution. And this solution HAS to be based on phenomena and laws that has been demonstrated as physical laws, verified as correct (working) in each and every case. Not by some mystical smoky theories that is the product of your imagination.I can and have made technically correct recordings and they are in the folders/files posted, you have just seized on a couple of recordings that were not 'perfect' in order to bolster your 'argument' which is based on coarse 'theory'.

Almost everyone agrees (apart you and J.C.?) that a copper cable is not directional. If something goes, in your particular case (your set-up) in the opposite direction, you must first look elsewhere, if something resembling a zener diode in parallel with some capacitor is not in your circuit. Probably hidden in the interconnections and layers of impurities that cover your contacts.

Hence:

My determination of directional characteristic is by swapping cable directions and listening....the sound changes follow cable changes, and both channel cables exhibit the same effects, ie there is nothing wrong with the interconnects.

The fact that you have published files with drops makes bad interconnect highly likely. You have the same result with different cables ? Look around in the part of YOUR circuit that do not change between the two tries.

When so many contributors from so many different backgrounds are telling you the same thing: why are you stubborn?

You will not sell your magic cables here. And, if you want to sell them elsewhere, look more on your "story telling" than on your copies of files.

For the moment neither one is convincing.

Just my two cents

Last edited:

Thanks cool, great source of wires, a few alloys I didn't know about.Try Specialist in craft wire, knitted craft wire, silver wire, enamelled copper, resistance wires, stainless steel, plated wires and many more!, they have the pure 99.99% soft and sterling 925. Use 2-3 feet length for listening tests.

Dan.

Because the price of Copper has increased a lot, many network cables are now made of aluminium, like during the second world war. Notice they don't add any bit error when a file is transmitted across them. Even if you reverse head to tail the cable direction.Thanks cool, great source of wires, a few alloys I didn't know about.

Because Aluminium is not such a good conductor, the wire is covered with a thin slice of copper, that transmit the HF (skin effect) and protect the aluminium from oxygen and the instant formation of isolating alumina.

As I use network cables for my line interconnects at home, I tried to compare them with pure copper ones by careful listenings, to figure out if I was able to feel any difference in the reproduction of music. 0, NADA, nothing.

Because copper resists better to repeated bending, I continue with copper. But I know WHY.

I could perhaps re-sell them by telling a nice story that aluminum makes the sound lighter? ;-)

Last edited:

IME silver plated copper can sound overly/wrongly bright, tin plated copper can sound overly dull/damped.I've got some silver plated wires, does that count?

IME clean silver can sound good and add a subtle/fine lift in highs and subjective dynamics and clarity.

Dan.

I suspect the copper clad is there to make electrical connections properly. Aluminum oxidizes and ruins the connection integrity. While copper will assist at the very high frequencies, I would say it is to allow using the standard connectors.Because the price of Copper has increased a lot, many network cables are now made of aluminium, like during the second world war. Notice they don't add any bit error when a file is transmitted across them. Even if you reverse head to tail the cable direction.

Because Aluminium is not such a good conductor, the wire is covered with a thin slice of copper, that transmit the HF (skin effect) and protect the aluminium from oxygen and the instant formation of isolating alumina.

Jn

When a word is used in a particular meaning by experts such as Neumann, JBL, and any other googleable quantity, except by you, to mean the horizontal and vertical coverage of a sound source, whom to trust?

I remember how long it took to realize the "definition" of non-linear in an R/C circuit was the fact that an exponential is never a straight line. That definition with respect to the concept of linear time invariant conditions for circuit analysis you won't find in any reference.

I thought to this, of course. But the way RJ plugs cut both the isolator and enter IN the wire, when crimped with the pliers, leaves me to think that the contact is made with aluminum. Once the two parts in close contact with high pressure, they must be safe from the air ?

I suspect the copper clad is there to make electrical connections properly. Aluminum oxidizes and ruins the connection integrity. While copper will assist at the very high frequencies, I would say it is to allow using the standard connectors.

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III