When I read JC post where he asked suggestions for good hook-up wire, I thought to reply that if the gauge is adequate, he would be OK with individual wires from the bundles of CAT 5 wire. (based not on directionality concerns but on the thought that telecommunication industry has far more demanding requirements than audio for the connecting cables and that long runs of not proper wiring would have unacceptable consequences for them. So if CAT 5 wire is the proper wire for them how it can not be good for hook up wire inside audio equipment )

But I said to myself, you will make another public exposure of how cheap you are and I didn't post it.

But here we are again.

George

There aren't that many plants making CAT 5 style wire. The volume is huge BUT the margins are tiny. You need to start with a big investment. The machine was something like $300M 20 years ago. Its around 100M long so you need a large operation just to move the material through. And move a lot of stuff to make it pay off at all. The quality is good and consistent. Its almost 100% tested on a network analyzer. The insulation is an RF grade material to meet the 500 MHz loss testing and lack of impedance variations. The copper is not 7N or even necessarily 5N. I had some made up with silver plated copper. It distinctly outperformed the straight copper as a CAT5E cable BUT we could not make the numbers work. The production commitment was way too high and the cost increase was over 50%.

CAT 5(etc) is usually single conductor (except certain patch cables) and not a large gauge so it can be useful. I would use it in a pinch but I prefer stranded wire, which is usually more reliable over time.

Hi all,

Some relevant information to the wire issue:

I spent some time at Clinton Wire & Cable Co. in Clinton MA in the 1970s, and the way they drew wire was to pass it at fairly high speed through a drawing die with grease and re-reel it, then unreel it through another smaller die, and repeat back and forth until they got the gauge they needed. The point being the finished wire had been drawn both ways many times to get to the final diameter.

Howie

Some relevant information to the wire issue:

I spent some time at Clinton Wire & Cable Co. in Clinton MA in the 1970s, and the way they drew wire was to pass it at fairly high speed through a drawing die with grease and re-reel it, then unreel it through another smaller die, and repeat back and forth until they got the gauge they needed. The point being the finished wire had been drawn both ways many times to get to the final diameter.

Howie

Electromigration - Wikipedia

Not much at all, John. We simply don't hit these kinds of current densities in bulk wires. The bottom end of this range (1E4) would be the equivalent of putting 13 amps through a cat5 wire (26 gauge).

The typical current density at which electromigration occurs in Cu or Al interconnects is 1E6 to 1E7 A/cm2. For solder joints (SnPb or SnAgCu lead-free) used in IC chips, however, electromigration occurs at much lower current densities, e.g. 1E4 A/cm2.

Not much at all, John. We simply don't hit these kinds of current densities in bulk wires. The bottom end of this range (1E4) would be the equivalent of putting 13 amps through a cat5 wire (26 gauge).

Electromigration - Wikipedia...Not much at all, John. We simply don't hit these kinds of current densities in bulk wires. The bottom end of this range (1E4) would be the equivalent of putting 13 amps through a cat5 wire (26 gauge).

???Electromigration due to poor fabrication processes was a significant cause of IC failures on Commodore's home computers during the 1980s. During 1983, the Commodore 64 computer for a time had a nearly 50% customer return rate.

Failure of interconnects inside an IC, yes. They aren't quite 26 gauge

https://www.cerc.utexas.edu/vlsi-seminar/Syed_uttalk.pdf

Anyone (Scott? Mark?) remember the ‘tin whiskers’ thing in the semiconductor world a few years ago when the industry went lead free?

I remember seeing before and after photos of these (conductive) whiskers growing across IC pins. It was solved but there were a lot of comncerns about it at the time.

I remember seeing before and after photos of these (conductive) whiskers growing across IC pins. It was solved but there were a lot of comncerns about it at the time.

Pavel, understood, I'm using cheapest RCA connectors with cable braid soldered evenly around connector shell. It looks that the RCA-shielded twisted pair with the shield connected on the source side-RCA is the worst case for ground loop current according to your setup

Yes, I agree.

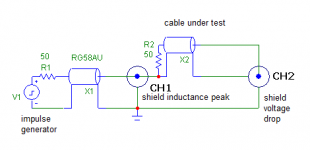

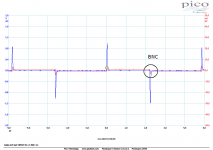

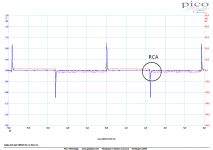

The attached images show a good coax cable, 1m, once terminated with BNC and second terminated with "good" RCA. The biggest difference is in the inductive peak (red trace), that shows discontinuity introduced by the RCA connectors.

Attachments

Sure, and there are also these gold embrittlement, precipitation hardening, phase transformation and perhaps a few others I am not even aware of to add to the complication.... remember the ‘tin whiskers’ thing in the semiconductor world a few years ago when the industry went lead free?

....

Of course, gpapag, this scholarly article is NOT about AUDIO BREAK-IN OF WIRES. It does show however, that pure copper, at room temperature can actually migrate at a mesoscopic level on its own. Just think what an electric current applied could do!

Mr. Curl. I had asked you to provide a source to confirm your writing that “Break-in of metals actually has been noted” and you kindly responded by providing the book, page numbers and finally a scan of the pages where the evidence was supposed to be.

Now you turn back to unsupported assumptions. Not good.

George

John Curl's Blowtorch preamplifier part III

John Curl's Blowtorch preamplifier part III

John Curl's Blowtorch preamplifier part III

Not good enough test scenario for audio cable (lacking drama and suspense )The quality is good and consistent. Its almost 100% tested on a network analyzer. The insulation is an RF grade material to meet the 500 MHz loss testing and lack of impedance variations.

The copper is not 7N or even necessarily 5N. I had some made up with silver plated copper. It distinctly outperformed the straight copper as a CAT5E cable BUT we could not make the numbers work. The production commitment was way too high and the cost increase was over 50%.

Now we are talking. Now this is the kind of story that has to be sold together with an overpriced product.

And I think you missed your chance Demian to get rich and famous. You could have bought the test run wire for pennies.

Look where you are now. Behind your pc screen, typing posts that risk placing you in Ed’s peanut gallery

I have noted the peanut gallery has now changed from "cable" to "wire."

George

Only if they have a need to work on extreme "critical applications"....maybe the lead researchers on this planet need to learn reality as it applies to high end audio??

So many world class researchers need to learn this stuff...

Lockheed Martin finally was able to convince the RAAF that wire direction only mattered in critical applications, such as audio, and was irrelevant to the otherwise mundane systems in the F-35A.

Yes, I agree.

The attached images show a good coax cable, 1m, once terminated with BNC and second terminated with "good" RCA. The biggest difference is in the inductive peak (red trace), that shows discontinuity introduced by the RCA connectors.

Especially the so-called 75Z RCA from manufacturers that produce mainly BNC (similar connetors) usually share the same construction details beside the dimensional differences. Shield connection will be same as in the BNCs as 360 degree crimp or press connection. This kind of RCA was already available in the 1980s but obviously did not fit to most of the more exotic cable constructions.

<snip>

Incidently, Indra mentioned annealing.

Dan, this process should draw your attention and sooth this neurotic assumption that dislocations within the metal are the cause of the mythical directionality in conducting (AC mind you) electrical signals in a wire .

Have you tried reading what annealing does to metals in general and to copper in particular? How is it performed? Have you heard of loop annealing?

Dan how well are you informed on the wire drawing processes used in factories before drawing conclusions? Processes, engineering, metallurgical details?

Cold drawing at these high speeds that modern equipment is working today, isn’t exactly “cold”.

600d Celsius is readily achieved during drawing wire through the formers (friction) and this is above the ½ melting temperature of copper. You know what effect has this on copper?

This is a whole new world. Be willing to study before safely assuming such assumptions

PS. Just knowing how easily new dislocations are induced in a copper wire by simply bending the wire during normal handling, makes the whole scenario of dislocations-generated wire electrical directionality a good joke.

George

A couple of years ago i was wondering why i couldn´t find any pics from cable manufacturers, featuring the Ohno casting process, showing the internal crystal structure of the processed cable ready for use.

For some of the reasons you mentioned above - sharing these as probably everybody who was ever involved in cable construction and manufacturing - i suspected too that during the draw process the nice single crystal structure existing in the rods due to the Ohno process would not survive.

So i tried to find some studies about the effects, first with no success, but eventually some publications from chinese experimenters showed up in the according metallurgy journals.

Iirc they used something like 8mm as starting diameter and monitored the resulting alterations of the crystal structure during the process.

As expected the single crystal structure did not survive, but it wasn´t a chaotic structure either, as the variations occured along only a few preferred crystal directions forming something more like a paralled orientated structure in the wires.

Again iirc, they did not repeat it until really small gauges were reached.

If it is of interest i´ve to search for it in my archives.

Now someone else is trying to bring numbers into this discussion.DPH said:Not much at all, John. We simply don't hit these kinds of current densities in bulk wires. The bottom end of this range (1E4) would be the equivalent of putting 13 amps through a cat5 wire (26 gauge).

I don't quite get the flow of logic from "copper crystals can migrate" to 'audio cables need burn-in'. What is the change in conductance and linearity during this migration? Does LIGO or CERN do cable burn-in?john curl said:Copper crystals can migrate at room temperature just finding their lowest energy state. It can be seen with an electron microscope over time. Any electric current would just help it along, perhaps even find a better state for conducting electricity at low levels.

That is one of the difficulties in understanding wires and cables, there is simply not enough studies. This Conductivity_Copper.pdf document shows C15100 exhibiting a 5% difference between annealed and rolled. Perhaps break in would have discernible effect on improperly annealed (and crap grade) wires?...I don't quite get the flow of logic from "copper crystals can migrate" to 'audio cables need burn-in'. What is the change in conductance and linearity during this migration?...

Electromigration - Wikipedia

Not much at all, John. We simply don't hit these kinds of current densities in bulk wires. The bottom end of this range (1E4) would be the equivalent of putting 13 amps through a cat5 wire (26 gauge).

I've only dealt with electromigration twice in my career. One was on aluminum trace on an IC, second was a bad solder joint design done by CERN.

On an IC, the silicon heat sinks the trace allowing high density currents. At CERN they were running 13 kilo amps, and the poor solder joint design pushed all the current through an area of tin/silver about 1mm by 5mm.

John

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III