Just tried the v1.16 and v1.18 in Parallel Mono mode.

Does not play as loud as compared to just using one of the amps in stereo. Volume turned up all the way.

Plus it does not sound as good.

Tried swapping the output wires to the speakers. Same result.

Will now try the Balanced Mono configuration again.

Other suggested measures?

Thanks,

Michael

Does not play as loud as compared to just using one of the amps in stereo. Volume turned up all the way.

Plus it does not sound as good.

Tried swapping the output wires to the speakers. Same result.

Will now try the Balanced Mono configuration again.

Other suggested measures?

Thanks,

Michael

Its not always easy figuring out all the different modes.Just tried the v1.16 and v1.18 in Parallel Mono mode.

Parallel mono. Each channel in the amp should the same input. The speaker outputs are wired in parallel.

Sounds like either/or one amp is not receiving an input signal, the input signals are somehow 'different' or the output connections are out of phase with respect to each other.Does not play as loud as compared to just using one of the amps in stereo. Volume turned up all the way.

Plus it does not sound as good.

Each channel in isolation should play at the same volume as the other. When the outputs are placed in parallel there should be no real subjective increase in level and theoretically none at normal or low levels.

Appears now to be working fine in Bridge Monoblock mode.

Monitoring the amps temperature.

Must have hooked the up the speakers wires incorrectly the first time I ran it in this mode.

Lol

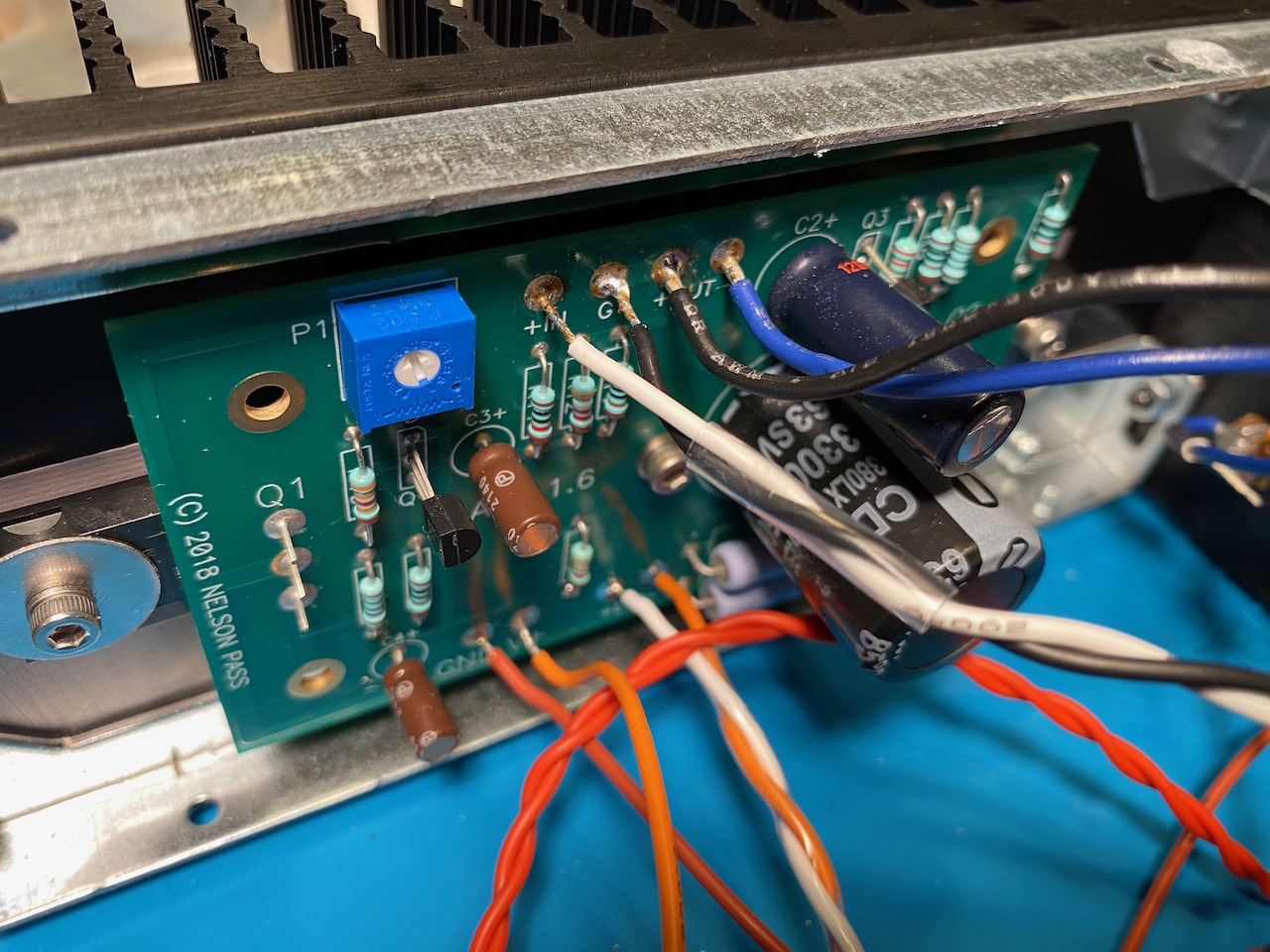

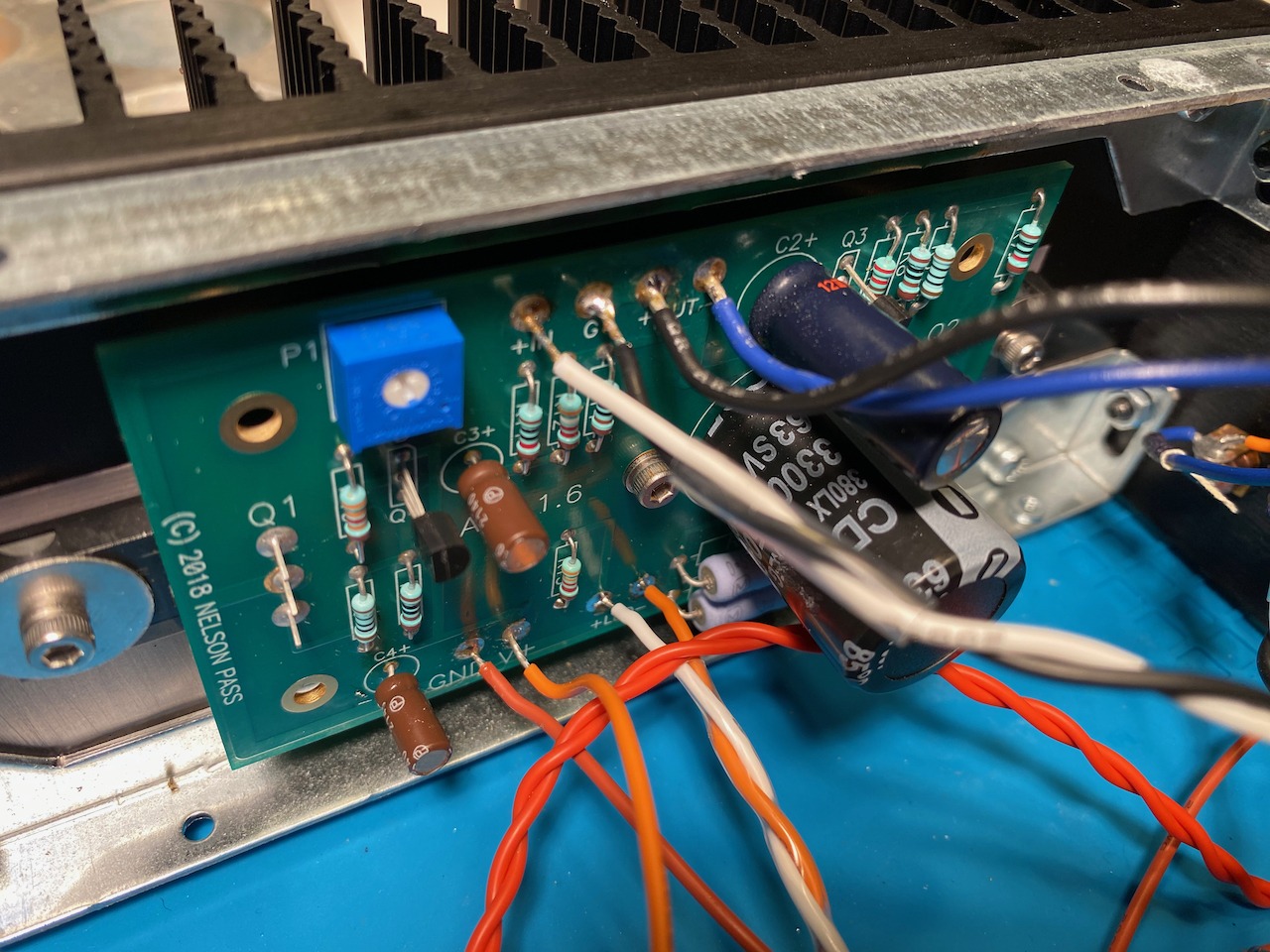

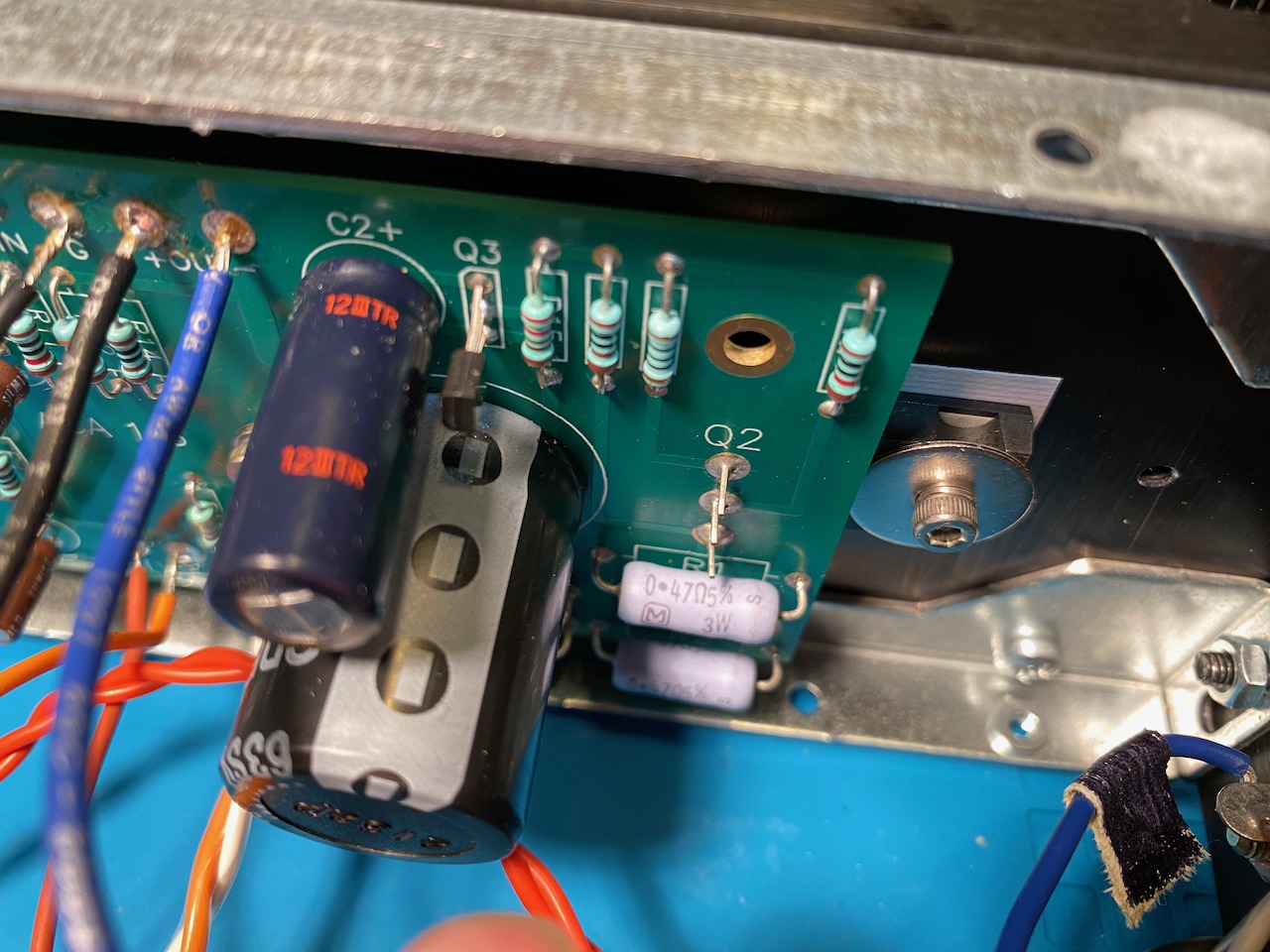

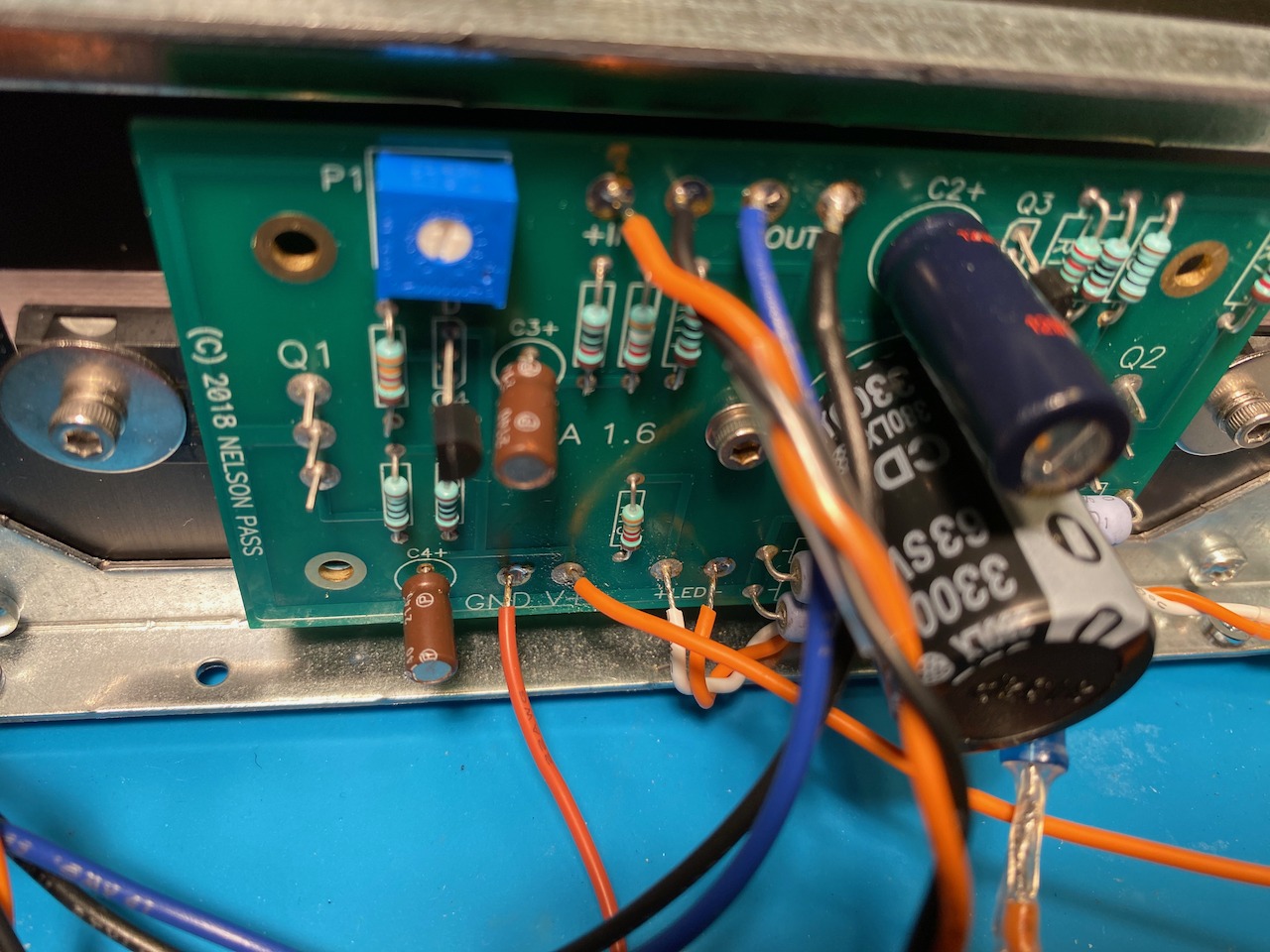

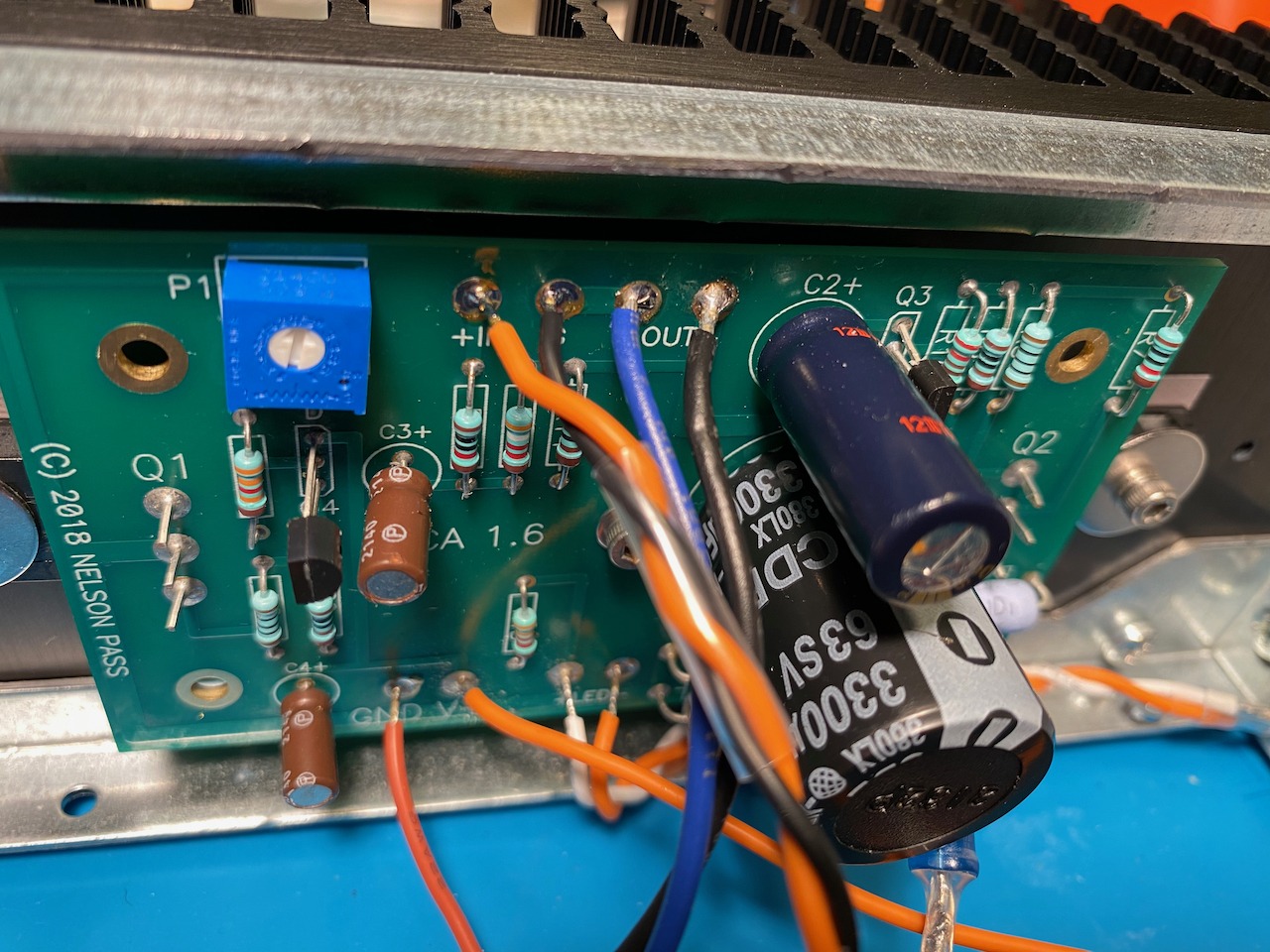

In addition to what @6L6 suggested, please post close up, high-res images of your board so we can help.Hey all,

I got the 1.6 version of the amp that I first assembled in a wooden case in 2020. So far it got super nice but since I didn't have time to finish properly the enclosure I decided to get the aluminium one a few days ago.

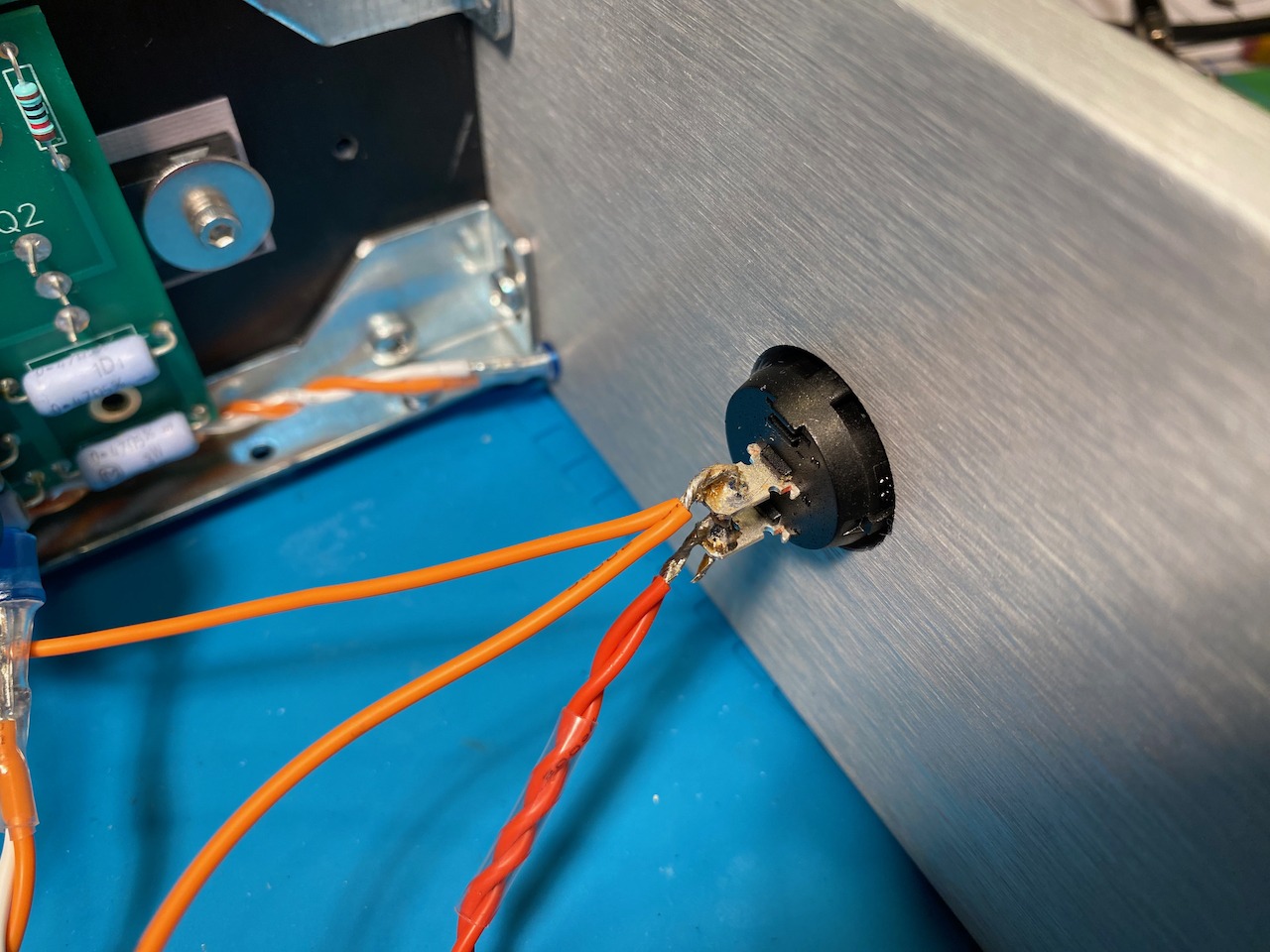

So I decided to transfer the whole set up into the aluminium case, and realizing that the DC power input jack wires were too short compared to my wooden setup to reach the rear panel, I just soldered it the wires witout attaching the barrel connector to the panel, you know, just for the test. And then it got wrong... While the amp being turned on, I observed a little crack on the little tab of the barrel connector. What I suppose is that the red twisted pair of wires touched the ground bus.

And now, only one PCB delivers the sound. I guess the other one burnt somewhere but I dunno where to start checking ? Could you guys please orientate me in the diagnosis ?

Thanks in advance, best regards. Baptiste.

Ps: sorry for my english, I'm doing my best though.

--Tom

I know I said it is working fine now, but...

On further listening whichever channel is being driven by the v1.16 ACA is louder than the channel driven by the v1.18.

I've compensated by using the balance control, turning down the v1.16 and turning up the v.18.

This sounds pretty good, but the v1.16 now runs hotter.

So what are the alternate fixes?

Update the v1.16 to a v1.18 by replacing the two-way switch with a three-way switch and all the resistors in the v1.16. in accordance with the v1.18 layout.

All the above plus the rest of the circuit board components.

Suggestions on where to buy these components with equivalent quality? Please be specific.

Perhaps its best to not even try. Just sell or give away the v1.16 and build another v1.18.

Or more extreme...

Rebuild both kits trying as best as possible to use matching components.

Suggestions and recommendations?

Suggested sources for components?

Thank You!!!

On further listening whichever channel is being driven by the v1.16 ACA is louder than the channel driven by the v1.18.

I've compensated by using the balance control, turning down the v1.16 and turning up the v.18.

This sounds pretty good, but the v1.16 now runs hotter.

So what are the alternate fixes?

Update the v1.16 to a v1.18 by replacing the two-way switch with a three-way switch and all the resistors in the v1.16. in accordance with the v1.18 layout.

All the above plus the rest of the circuit board components.

Suggestions on where to buy these components with equivalent quality? Please be specific.

Perhaps its best to not even try. Just sell or give away the v1.16 and build another v1.18.

Or more extreme...

Rebuild both kits trying as best as possible to use matching components.

Suggestions and recommendations?

Suggested sources for components?

Thank You!!!

The heat generated depends 100% on the power supply voltage and the quiescent current draw and can be very subjective. This also has no bearing on differences in 'loudness'.

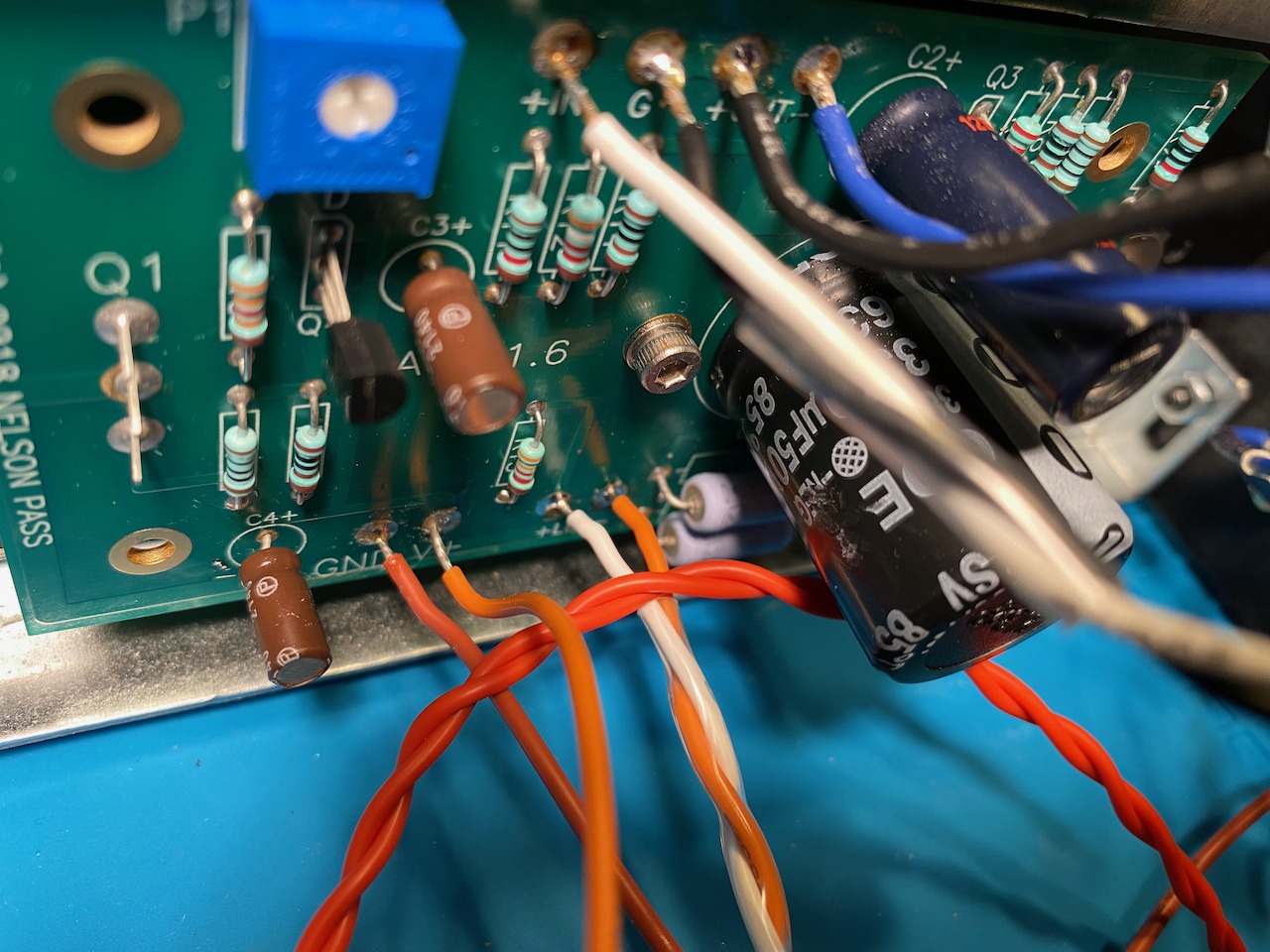

Measure the supply voltage for each amp and measure the volt drop across the low value 0.47 and 0.68 ohm resistors. Make 100% certain you have the correct values fitted here.

The original ACA I believe used a 19 volt supply and the later ones a 24 volt supply. So measure and see what each is running on.

Lets say you measure 24 volts supply and 0.37 volts across either of the 0.47 ohm resistors. The resistors are in parallel and so equate to a single 0.235 ohm.

The current is 0.37/0.235 which is 1.57 amps. The power dissipation is 1.57*24 which is 37 watts (for that channel). That is conclusive proof all is OK.

You do not need 'matched' components for anything in this amp.

The actual 'gain' which determines how 'loud' it is for a given input level is determined only by R11 and R12 and equals numerically R12/R11. Make sure these values are correct (you don't need measure them which you can not do in circuit anyway, just look at the code on them). I think the original version might have used a different value for R12 compared to the later ones so check you have the same fitted to both amps.

The switch always seems to confuse. All it does is route the input signal to one channel according to what mode you want the amp to run in. Replacing it will achieve nothing. If you have any doubt then just measure the continuity from the amp inputs (R11) and make sure it connects to where it is supposed to.

Measure the supply voltage for each amp and measure the volt drop across the low value 0.47 and 0.68 ohm resistors. Make 100% certain you have the correct values fitted here.

The original ACA I believe used a 19 volt supply and the later ones a 24 volt supply. So measure and see what each is running on.

Lets say you measure 24 volts supply and 0.37 volts across either of the 0.47 ohm resistors. The resistors are in parallel and so equate to a single 0.235 ohm.

The current is 0.37/0.235 which is 1.57 amps. The power dissipation is 1.57*24 which is 37 watts (for that channel). That is conclusive proof all is OK.

You do not need 'matched' components for anything in this amp.

The actual 'gain' which determines how 'loud' it is for a given input level is determined only by R11 and R12 and equals numerically R12/R11. Make sure these values are correct (you don't need measure them which you can not do in circuit anyway, just look at the code on them). I think the original version might have used a different value for R12 compared to the later ones so check you have the same fitted to both amps.

The switch always seems to confuse. All it does is route the input signal to one channel according to what mode you want the amp to run in. Replacing it will achieve nothing. If you have any doubt then just measure the continuity from the amp inputs (R11) and make sure it connects to where it is supposed to.

Well... I finished assembly of my ACA 1.8 kit just a few moments ago, which was my first real attempt at any electronics build. I thought I had checked all my wiring, but upon connecting power I only found one LED lit.

After the power had been connected for just a minute or two as I was preparing to adjust the DC balance, I noticed a tiny puff of smoke from the inside of the power connector and immediately disconnected the 24V DC in. I rechecked all my wiring and indeed I had reversed the left channel LED +/- to the circuit board.

I'm a total novice here and honestly a bit unsure how to proceed without causing damage to myself or the amp. Can anyone offer some advice on how I might proceed? I've already fixed the LED connection, but I'm unsure whether I should reconnect power before any other steps.

I've been really amazed by all the help offered here, and so just want to say a big thanks to the community in advance if anyone's able to help.

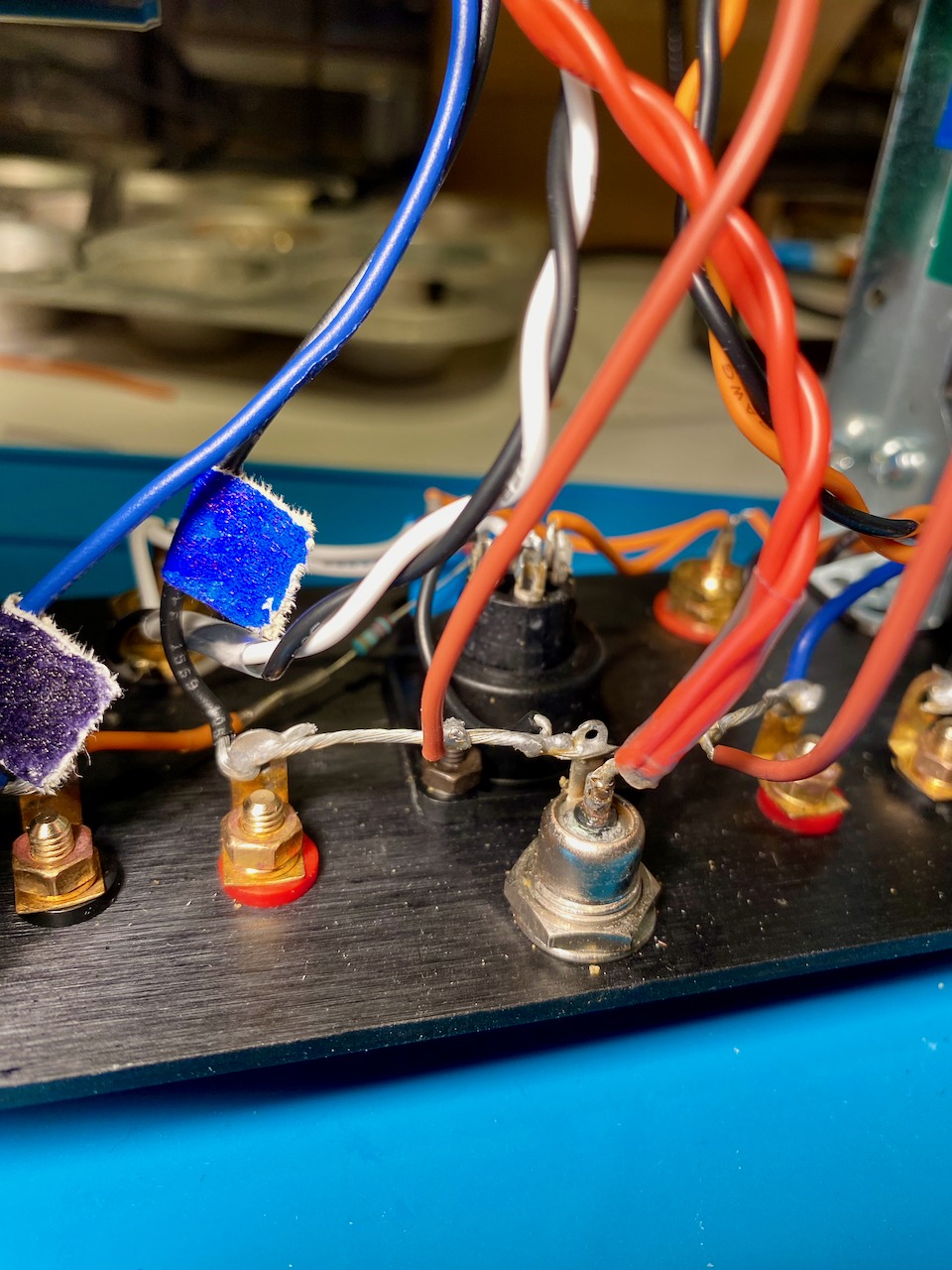

I've taken the best photos I could with my phone, so I hope they're helpful. I'd be very happy to take additional pictures if it might assist in diagnosis.

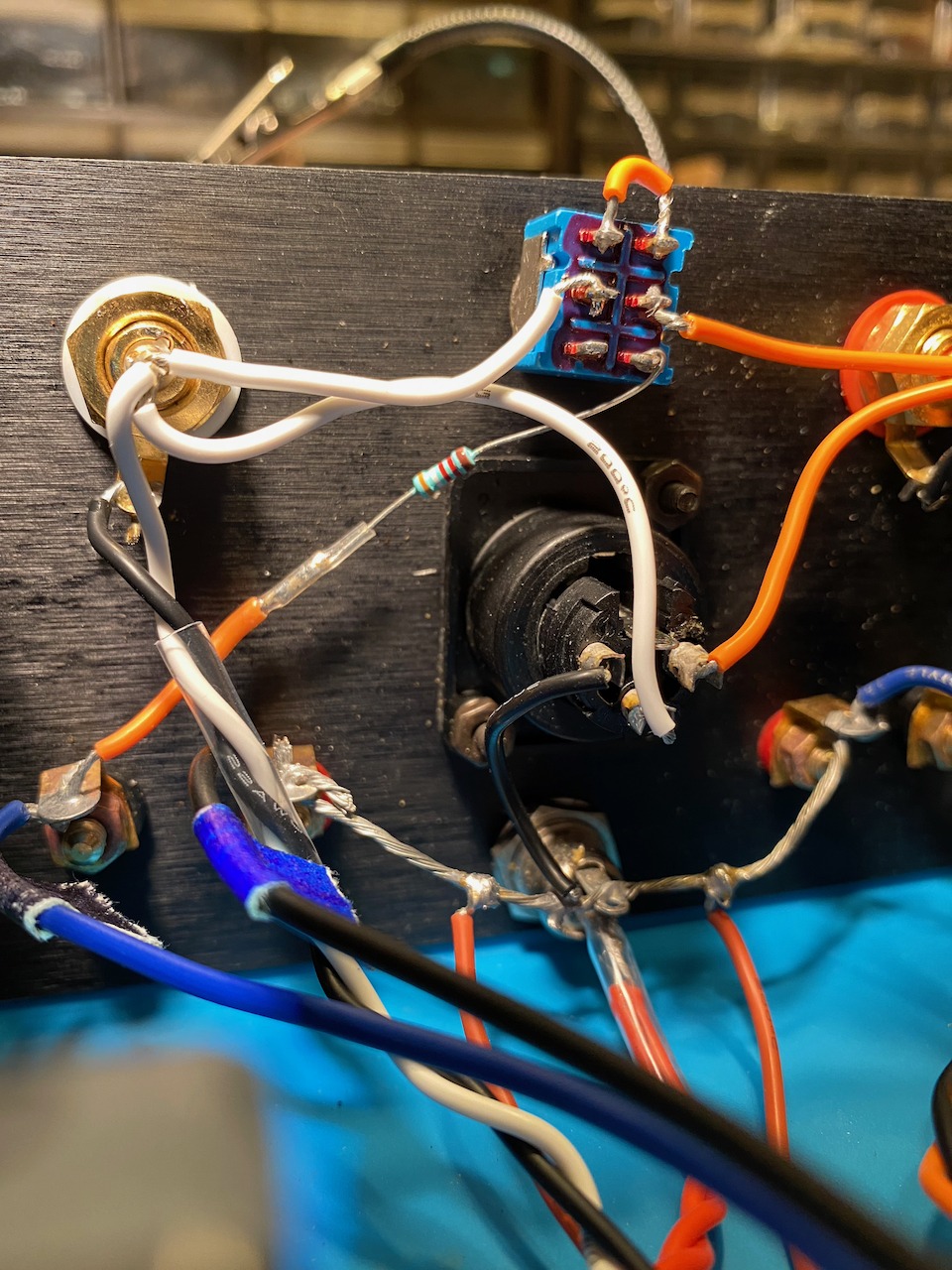

Please note that after noticing some complaints about the supplied wire, I swapped in some other wire (https://www.amazon.com/dp/B01M0O1NXM?psc=1&ref=ppx_yo2ov_dt_b_product_details) in my favorite color, orange, in place of the red 22ga and used brown for the power grounds, as well as replacing the black LED . I also mistakenly swapped the blue & black 18ga colors (blue/black) on the left channel speaker posts, but they were correctly wired to the PCB and tagged with some colored tape as a reminder. Hope it doesn't cause too much confusion.

After the power had been connected for just a minute or two as I was preparing to adjust the DC balance, I noticed a tiny puff of smoke from the inside of the power connector and immediately disconnected the 24V DC in. I rechecked all my wiring and indeed I had reversed the left channel LED +/- to the circuit board.

I'm a total novice here and honestly a bit unsure how to proceed without causing damage to myself or the amp. Can anyone offer some advice on how I might proceed? I've already fixed the LED connection, but I'm unsure whether I should reconnect power before any other steps.

I've been really amazed by all the help offered here, and so just want to say a big thanks to the community in advance if anyone's able to help.

I've taken the best photos I could with my phone, so I hope they're helpful. I'd be very happy to take additional pictures if it might assist in diagnosis.

Please note that after noticing some complaints about the supplied wire, I swapped in some other wire (https://www.amazon.com/dp/B01M0O1NXM?psc=1&ref=ppx_yo2ov_dt_b_product_details) in my favorite color, orange, in place of the red 22ga and used brown for the power grounds, as well as replacing the black LED . I also mistakenly swapped the blue & black 18ga colors (blue/black) on the left channel speaker posts, but they were correctly wired to the PCB and tagged with some colored tape as a reminder. Hope it doesn't cause too much confusion.

measure if the PS still works.

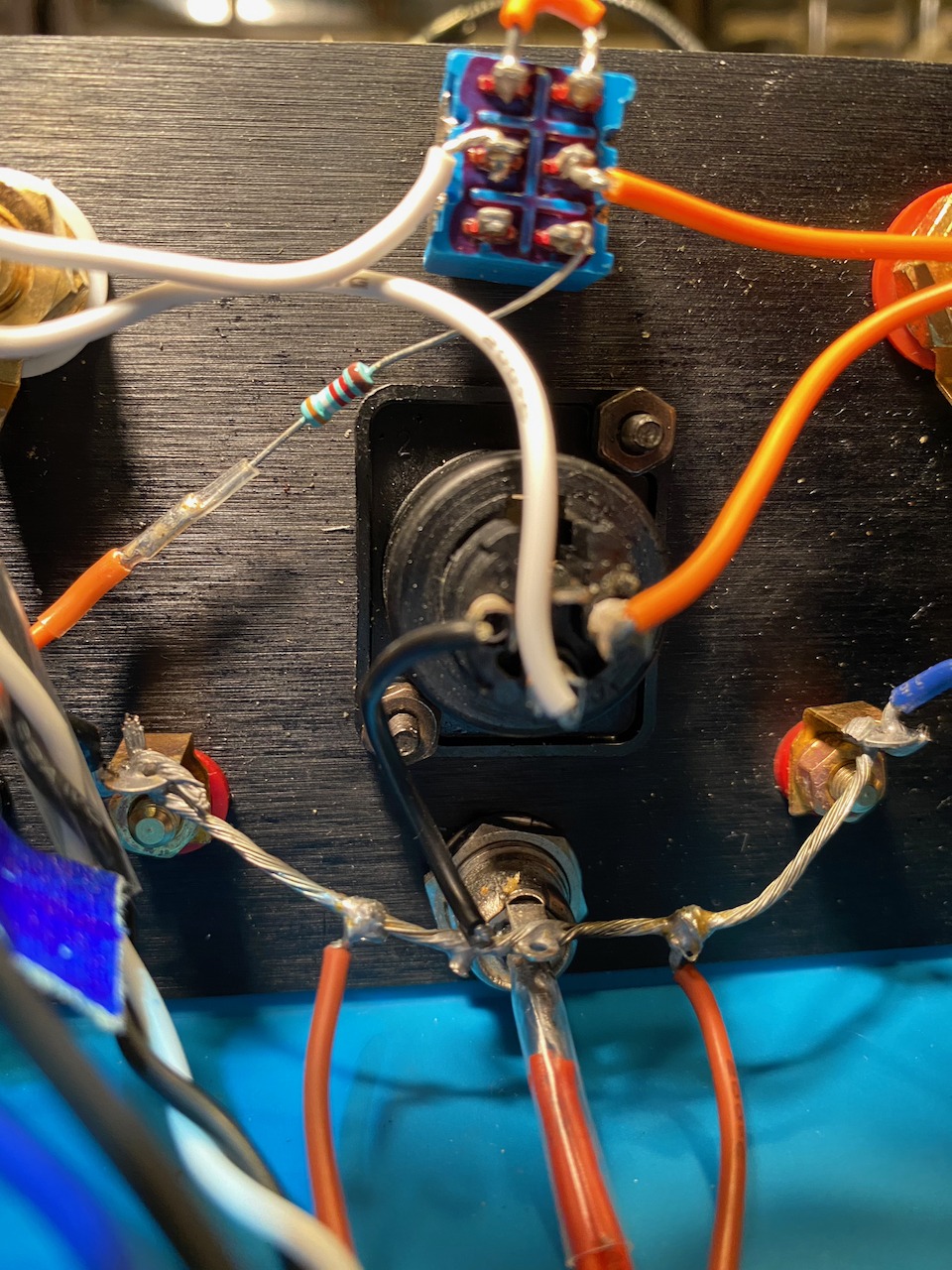

measure if you have continuity between the hot and ground of the PS jack on the chassis. If you do, time to replace.

edit:

the jack looks ugly, like it has corrosion on it. Suggested to take a close look at it and test connections.

Some of your solder joints could use revisiting. Want a good shiny finish to them.

If the PS is working correctly and getting correct voltage into the chassis, try one board at a time to reduce pull on the PS until you know both channels are working correctly.

measure if you have continuity between the hot and ground of the PS jack on the chassis. If you do, time to replace.

edit:

the jack looks ugly, like it has corrosion on it. Suggested to take a close look at it and test connections.

Some of your solder joints could use revisiting. Want a good shiny finish to them.

If the PS is working correctly and getting correct voltage into the chassis, try one board at a time to reduce pull on the PS until you know both channels are working correctly.

Last edited:

Thanks so much for the suggestions.

I do still see a light on the PSU brick. Is that all I'm looking for? Please forgive my ignorance. And is there something I can do to clean up the power jack or will I need a replacement?

Not sure if it's relevant, but I was using the Fire Metall Eutectic solder and some old flux that I found in my dad's workshop. Does flux have a shelf life or anything like that?

I do still see a light on the PSU brick. Is that all I'm looking for? Please forgive my ignorance. And is there something I can do to clean up the power jack or will I need a replacement?

Not sure if it's relevant, but I was using the Fire Metall Eutectic solder and some old flux that I found in my dad's workshop. Does flux have a shelf life or anything like that?

Last edited:

the Fire Metall solder doesn't require a flux. There's some links down the page for soldering videos. They'll show how the joints should look when done: https://diyaudiostore.com/collections/consumables/products/fire-metall-solder?variant=31518430396489

Do you have a DMM? If you don't, highly recommended to get one. Very handy for troubleshooting. If you do or once you get one, check the output voltage of the SMPS. The v1.8 should be spitting out 24V if I remember correctly.

Also, the power jack needs checking to ensure it hasn't shorted the hot side to the ground shield. You indicated that a puff of smoke came from it so very curious as to what happened to it. Once the functioning of the SMPS and the power jack are deteremined to be working correctly, time to try powering up again.

iso-alcohol can be used ot clean the excess flux off.

Do you have a DMM? If you don't, highly recommended to get one. Very handy for troubleshooting. If you do or once you get one, check the output voltage of the SMPS. The v1.8 should be spitting out 24V if I remember correctly.

Also, the power jack needs checking to ensure it hasn't shorted the hot side to the ground shield. You indicated that a puff of smoke came from it so very curious as to what happened to it. Once the functioning of the SMPS and the power jack are deteremined to be working correctly, time to try powering up again.

iso-alcohol can be used ot clean the excess flux off.

Good to know… I’m sure my soldering technique has some room for improvement. I’ve probably overdone the flux so I’ll retry some of the dull spots without.

I do have a basic DMM and have watched a few videos about the various modes but I’m still a bit lost without step by step guides to be honest.

Would you mind explaining the process to check the PS & jack voltage safely? Really appreciate the help!

I do have a basic DMM and have watched a few videos about the various modes but I’m still a bit lost without step by step guides to be honest.

Would you mind explaining the process to check the PS & jack voltage safely? Really appreciate the help!

For the SMPS, set the DMM to VDC, put the red probe inside the output ferrule and the black on shiny bit of the outer barrel of the output ferrule. This should read 24VDC.

For the power jack on the chassis, a couple ways to do it:

1. Set the DMM for Ohms (Omega symbol) and measure the resistance between the jack center pin and the outer barrel. Place one probe on the center pin and the other probe on the ground bus/wire. This should be very large, 1M or higher.

2. If the DMM has a continuity checker (marked by the radiatiing sounds waves symbol that is a bit like "(((", set it to that. Touch the two probes together and there should be a steady beep for as long as the probes are touching. Now do like number 1 (touch a probe to the center pin and the other probe to the ground bus/wire) and listen for a beep.

If resistance is 1M ohm or higher OR the beep doesn't sound, the jack should be good. If the resistance is low (anything under 1M) or there is a beep, need to replace the jack or figure out what is causing the short.

For the power jack on the chassis, a couple ways to do it:

1. Set the DMM for Ohms (Omega symbol) and measure the resistance between the jack center pin and the outer barrel. Place one probe on the center pin and the other probe on the ground bus/wire. This should be very large, 1M or higher.

2. If the DMM has a continuity checker (marked by the radiatiing sounds waves symbol that is a bit like "(((", set it to that. Touch the two probes together and there should be a steady beep for as long as the probes are touching. Now do like number 1 (touch a probe to the center pin and the other probe to the ground bus/wire) and listen for a beep.

If resistance is 1M ohm or higher OR the beep doesn't sound, the jack should be good. If the resistance is low (anything under 1M) or there is a beep, need to replace the jack or figure out what is causing the short.

Last edited:

23.98V DC on the power supply! That's a relief, at least!

Thanks for helping me realize I needed to set the function to the o))) symbol! They were all marked on the dial but I needed to also press a "function" button to get into continuity mode.

1. I get a reading of ~370 Ohms which slowly climbs towards 390ish the longer I keep the black lead on the busbar or outer barrel and the red probe on the power center pin.

2. Check beeps, but I get about the same reading as above with red on center pin and black to the bus.

FWIW, I also get a solid ground check from the busbar to the chassis and the GND pins on both PCBs.

Seems like I'll need a new power jack? I looked on the DIYAudio site but didn't see that single part anywhere.

Are there any obvious things I should start looking for to identify a short? I don't see any touching wires/leads that aren't connected in the 1.8 wiring diagram. Again, really can't thank you enough for the detailed troubleshooting! It's giving me hope

Thanks for helping me realize I needed to set the function to the o))) symbol! They were all marked on the dial but I needed to also press a "function" button to get into continuity mode.

1. I get a reading of ~370 Ohms which slowly climbs towards 390ish the longer I keep the black lead on the busbar or outer barrel and the red probe on the power center pin.

2. Check beeps, but I get about the same reading as above with red on center pin and black to the bus.

FWIW, I also get a solid ground check from the busbar to the chassis and the GND pins on both PCBs.

Seems like I'll need a new power jack? I looked on the DIYAudio site but didn't see that single part anywhere.

Are there any obvious things I should start looking for to identify a short? I don't see any touching wires/leads that aren't connected in the 1.8 wiring diagram. Again, really can't thank you enough for the detailed troubleshooting! It's giving me hope

If you have the correct 24 volts getting to the PCB then you can carry on fault finding. Measure on the PCB itself and confirm you have 24 volts between ground and the centre pin of Q2.

The reversed LED will not cause any damage to the ACA itself although it will have caused the reverse voltage rating of the LED to be exceeded. That may or may not have impaired the LED. If it lights its fine.

The reversed LED will not cause any damage to the ACA itself although it will have caused the reverse voltage rating of the LED to be exceeded. That may or may not have impaired the LED. If it lights its fine.

Well, as soon as I reconnected the power to the amp I got more popping/smoke on the inner (amp interior) side of the power connector. I assume this means I'll need a new one and to rewire that part. Is this the right replacement? Anything else I should try while I wait for a new jack?

Well it does appear like you need a new one  Very strange. When you solder to the centre pin (in particular) make sure you use a hot iron and be as quick as you reasonably can so as not to overheat/melt anything in the jack.

Very strange. When you solder to the centre pin (in particular) make sure you use a hot iron and be as quick as you reasonably can so as not to overheat/melt anything in the jack.

It looks about right but I've never seen one for real and so perhaps others can weigh in on that.

It looks about right but I've never seen one for real and so perhaps others can weigh in on that.

One bitten, twice shy, and all... would a pre-wired jack plug like this do the job? Could I just desolder the busbar & power from the fried jack, replace with the prewired one, and then reconnect the black wire to the busbar and red to power? Does the wire (18ga) vs. tab make a difference?

If the above works, I think it'd be faster than a) waiting for shipping on a couple kit-matched jacks and b) save me from a potentially annoying extra step given DIYAudio support mentioned these jacks from DigiKey might require drilling and thus chassis disassembly, especially since I don't have a hand drill here.

If the above works, I think it'd be faster than a) waiting for shipping on a couple kit-matched jacks and b) save me from a potentially annoying extra step given DIYAudio support mentioned these jacks from DigiKey might require drilling and thus chassis disassembly, especially since I don't have a hand drill here.

- Home

- The diyAudio Store

- Amp Camp Amp Kit 1.6/1.8