Create it in segments which themselves originate off one of the pressure nulls? And ensure the driver outputs are in this format as well. any deviation from that is a clear detriment in offsets outside of one of those units of length as well.

If each one of those is considered a 90 degree phase change and start as polarity opposites you can arrive at an end result. Example: a straight horn area in a length ratio to the horn off the other side (compound). Start the long side at zero and the short side as 180. And create 3:1 in length(segments/time) Now its 300 and 100cm and in phase porportionally. (Path and folding aside). Do that as an offset driver and its 1:1+1 nearly. (104, 97,97 offset driver to be exact) but your driver must be optomised for that or any Fb, Fs. Thats where our math cones in...

Using that method and skewing it to actually fit the driver entry is tricky and requires a s2 sized up typically, but putting it at a fold is certainly a solution.

the out puts ate both in the same location. theres nothing to guess.

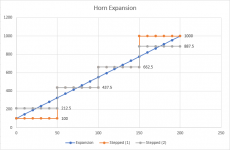

The stepped expansion is a bit more complicated. But not if you start at the csa prescribed in that math. Look at a roar vs a paraflex and theres a gap in the middle you must fill with a step in the parallel but not in the series.

Yet results can be near exact the same in response spl. Use the same ideas and its the same in a dayton rss, a skar ddx, and from there i dunno. Fancy low Q drivers put a twist in resoonse shape that gets confusing to those who think its suppose to be flat. i think it night become clear soon that some if tge things Circlomen used to say about his design with thams designer were far more real that ‘just for a guy’ was allowing him to suggest. It unfortunate, because as it turns out much of what he was saying is absolute in sciences in turbines, vane pumps and circular exit shapes. Parabolic rectangle shapes and circles are a 2d thought in a 4d action. The sound is the 4th?

A roar at 2:1 length is perfectly wonderful if we look at the expansion ratio. In order to make a paraflex emulate that it needs a step in the long path.

What is the freq at 0,-90,180,360,90,180,-90 of phase response and impedance response in each of those? And off each side of the cone? Thats the special secret sauce. And the answer to your question i have totally avoided because that is the answer.

The paraflex and roar ideas hold the answer to a lot of things if placed side by side. Ask anyone who has both and used both and for an expert opinion try Jose Ramos @ FB griup paraflex or TS parameters. He has a trophy ot two for credentials and a thriving audio business with his father. he has what you seem to be asking i think? Ts clear nobody else is satisfying that curiousity you've been poking at and helping others do as well. Many thanks btw. Please try Jose. I hope hecan shed some light or get you some clues to solve it )

If each one of those is considered a 90 degree phase change and start as polarity opposites you can arrive at an end result. Example: a straight horn area in a length ratio to the horn off the other side (compound). Start the long side at zero and the short side as 180. And create 3:1 in length(segments/time) Now its 300 and 100cm and in phase porportionally. (Path and folding aside). Do that as an offset driver and its 1:1+1 nearly. (104, 97,97 offset driver to be exact) but your driver must be optomised for that or any Fb, Fs. Thats where our math cones in...

Using that method and skewing it to actually fit the driver entry is tricky and requires a s2 sized up typically, but putting it at a fold is certainly a solution.

the out puts ate both in the same location. theres nothing to guess.

The stepped expansion is a bit more complicated. But not if you start at the csa prescribed in that math. Look at a roar vs a paraflex and theres a gap in the middle you must fill with a step in the parallel but not in the series.

Yet results can be near exact the same in response spl. Use the same ideas and its the same in a dayton rss, a skar ddx, and from there i dunno. Fancy low Q drivers put a twist in resoonse shape that gets confusing to those who think its suppose to be flat. i think it night become clear soon that some if tge things Circlomen used to say about his design with thams designer were far more real that ‘just for a guy’ was allowing him to suggest. It unfortunate, because as it turns out much of what he was saying is absolute in sciences in turbines, vane pumps and circular exit shapes. Parabolic rectangle shapes and circles are a 2d thought in a 4d action. The sound is the 4th?

A roar at 2:1 length is perfectly wonderful if we look at the expansion ratio. In order to make a paraflex emulate that it needs a step in the long path.

What is the freq at 0,-90,180,360,90,180,-90 of phase response and impedance response in each of those? And off each side of the cone? Thats the special secret sauce. And the answer to your question i have totally avoided because that is the answer.

The paraflex and roar ideas hold the answer to a lot of things if placed side by side. Ask anyone who has both and used both and for an expert opinion try Jose Ramos @ FB griup paraflex or TS parameters. He has a trophy ot two for credentials and a thriving audio business with his father. he has what you seem to be asking i think? Ts clear nobody else is satisfying that curiousity you've been poking at and helping others do as well. Many thanks btw. Please try Jose. I hope hecan shed some light or get you some clues to solve it )

Put an rss265 ho4 in an offset driver perfect in length and folded to return to path’ zero.or TH as 0.01cm in the last segment.

Straight pipe, constant CSA. (Use your bass cannon math but in OD entry?)

Then put that in a paraflex with no offset (L45 is 0.01cm...)

what was required to do that(even if its fake) is an ideal stepped expansion. but that same length is then divisible in many ways and breaking it up further is up to whoever assumes they need to for some reason? but a corkscrew shape sure seems functional to me. And so does a dog food duct. and L12? Did you leave it as it was in OD? or is it 0.01cm too?

I think this is important to note. I think its also ironic youve already done much of this i mentioned i hope this helps, i hope it helps you find what youre looking for too. Im tripping on my own feet on a similar search i think. but ive abandoned the ‘flare’ and its all hypotenueses of right triangles stacked in various ‘run’, not ‘rise’. Ten years of building multistory stairwells and stuck QCi g these very akward things before welding, and straightening them after warping to drop in fit up via crane at ‘apple, ebay, amazon, kaiser permante.... i hope i at least know a stepped and increasing or decreasing radius.. its a pain in the butt, but they never shipped them back to be fixed because they didnt fit?

i hope this helps, i hope it helps you find what youre looking for too. Im tripping on my own feet on a similar search i think. but ive abandoned the ‘flare’ and its all hypotenueses of right triangles stacked in various ‘run’, not ‘rise’. Ten years of building multistory stairwells and stuck QCi g these very akward things before welding, and straightening them after warping to drop in fit up via crane at ‘apple, ebay, amazon, kaiser permante.... i hope i at least know a stepped and increasing or decreasing radius.. its a pain in the butt, but they never shipped them back to be fixed because they didnt fit?

I sure wish i could make a real bass horn. Out of 14 gage, pressbroke and long landings over a stepped expansion. It would be EASY, even if huge. In the shop with the overhead cranes.

If i ever get rich suddenly i promise to use a box plan if youll create it

maybe? This is handy for so many things : far more than just steps, arc, cord, polygons, prisms truncated...? Trying to think of more, but its all just a rise /run set as hypotenuse then a nosing line is referenced as each point if the stair is laid down as horizontal. not sure what your shape is but a stair uses common 7.5” on 12” +/- over 12-13” treads with 1” of ‘kick back at that nosing line to accomodate humans ‘steppping’’. Draw that as you have and its centered on hpotenuses.

Printable Polygon Templates

Straight pipe, constant CSA. (Use your bass cannon math but in OD entry?)

Then put that in a paraflex with no offset (L45 is 0.01cm...)

what was required to do that(even if its fake) is an ideal stepped expansion. but that same length is then divisible in many ways and breaking it up further is up to whoever assumes they need to for some reason? but a corkscrew shape sure seems functional to me. And so does a dog food duct. and L12? Did you leave it as it was in OD? or is it 0.01cm too?

I think this is important to note. I think its also ironic youve already done much of this i mentioned

I sure wish i could make a real bass horn. Out of 14 gage, pressbroke and long landings over a stepped expansion. It would be EASY, even if huge. In the shop with the overhead cranes.

If i ever get rich suddenly i promise to use a box plan if youll create it

maybe? This is handy for so many things : far more than just steps, arc, cord, polygons, prisms truncated...? Trying to think of more, but its all just a rise /run set as hypotenuse then a nosing line is referenced as each point if the stair is laid down as horizontal. not sure what your shape is but a stair uses common 7.5” on 12” +/- over 12-13” treads with 1” of ‘kick back at that nosing line to accomodate humans ‘steppping’’. Draw that as you have and its centered on hpotenuses.

Printable Polygon Templates

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.