Hello DIYers, as I've mentioned a year back in THIS thread, I just decided and pulled the trigger on the 2x B&C 21SW152-4 subs for my 2ch music setup.

The project consist on 2x 21" subs with down-firing ports tuned between 18~20Hz to replace the current sealed Ultimax UM18-22 ~5FT3 sub, in hopes to target the best of both worlds or at least to be close, to get some deep lows and high impact upper bass with low distortion.

I have to admit this is the first time I work with this kind of large subwoofers, and I want to post here my current design options and get some advice of the owners with success on this kind of subs before deploy the project.

Also like previously mentioned, this is a 99% music setup and I listen to a very broad variety of music genres but mainly rock, oldies and electronic when I'm in the "Moar BASS" mod.

I currently have two own designs which are very similar to the "PSA TV3612" in regards to the port location which is down-firing, unfortunately I can't get them work with single 6" ports without having a lot of air velocity/lots of chuffing when the subs are drived at maximum capacity(regarding WinISD), then my only options here are between 2x 6" ports, one 8" port or a straight slot port embedded in the rear side of the box, so my bias for now is the single 8" down-firing port.

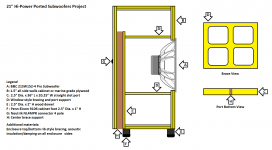

I will post some images of the cartoonish paint draws(sorry I'm not good at drawings ) of the two boxes design, one resembles the one with the 8" port and the other with the slot port, while the one with the 2x 6" ports being discarded; the planned box material is to use between BCX, cabinet grade ply or marine grade ply, however since the cost of the marine plywood here in P.R. is way expensive, I guess that I can try and find average quality on probably BCX or cabinet grade plywood and double up 3/4" to form a 1.5" sandwich on all sides.

) of the two boxes design, one resembles the one with the 8" port and the other with the slot port, while the one with the 2x 6" ports being discarded; the planned box material is to use between BCX, cabinet grade ply or marine grade ply, however since the cost of the marine plywood here in P.R. is way expensive, I guess that I can try and find average quality on probably BCX or cabinet grade plywood and double up 3/4" to form a 1.5" sandwich on all sides.

Also here is a material that I'm looking to know if it may be useful for this large sub boxes project, it is called: EB1S White High-Pressure Laminate Plywood Melamine Board, I can also double up those material as well and they look very flat stable and seems to have little to none voids, well at least looks like so at naked eye.

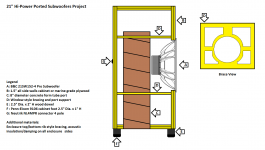

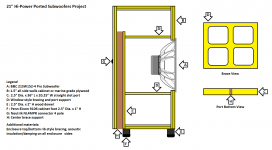

Well to conclude, here are the draws of the enclosure design in question, so what design is more appealing for this 21" drivers:

Measures: 48" H x 24" W x 24" D.

Walls: all 1.5" thick walls with braces.

Finish: Black-mate laminate.

Volume: 11.5FT3 gross, around 9.2 FT3 Net. after port/driver/bracing.

--------------------------------------------------------

Alternative measures using 5/8" sheets:

Measures: 42" H x 24" W x 26.5" D.

Walls: all 1.25" thick walls with braces.

Finish: Black-mate laminate.

Volume: 11.8FT3 gross, around 9.5 FT3 Net. after port/driver/bracing.

--------------------------------------------------------

Design with an 8" down-firing port:

Design with an back straight slot port:

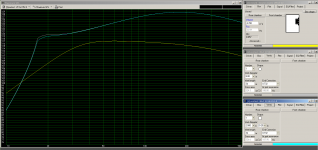

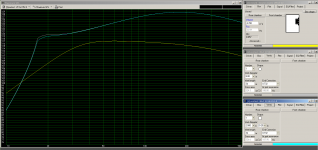

WinISD Maximum SPL and current UM18-22 for compare:

Regards, sorry for my English.

The project consist on 2x 21" subs with down-firing ports tuned between 18~20Hz to replace the current sealed Ultimax UM18-22 ~5FT3 sub, in hopes to target the best of both worlds or at least to be close, to get some deep lows and high impact upper bass with low distortion.

I have to admit this is the first time I work with this kind of large subwoofers, and I want to post here my current design options and get some advice of the owners with success on this kind of subs before deploy the project.

Also like previously mentioned, this is a 99% music setup and I listen to a very broad variety of music genres but mainly rock, oldies and electronic when I'm in the "Moar BASS" mod.

I currently have two own designs which are very similar to the "PSA TV3612" in regards to the port location which is down-firing, unfortunately I can't get them work with single 6" ports without having a lot of air velocity/lots of chuffing when the subs are drived at maximum capacity(regarding WinISD), then my only options here are between 2x 6" ports, one 8" port or a straight slot port embedded in the rear side of the box, so my bias for now is the single 8" down-firing port.

I will post some images of the cartoonish paint draws(sorry I'm not good at drawings

Also here is a material that I'm looking to know if it may be useful for this large sub boxes project, it is called: EB1S White High-Pressure Laminate Plywood Melamine Board, I can also double up those material as well and they look very flat stable and seems to have little to none voids, well at least looks like so at naked eye.

Well to conclude, here are the draws of the enclosure design in question, so what design is more appealing for this 21" drivers:

Measures: 48" H x 24" W x 24" D.

Walls: all 1.5" thick walls with braces.

Finish: Black-mate laminate.

Volume: 11.5FT3 gross, around 9.2 FT3 Net. after port/driver/bracing.

--------------------------------------------------------

Alternative measures using 5/8" sheets:

Measures: 42" H x 24" W x 26.5" D.

Walls: all 1.25" thick walls with braces.

Finish: Black-mate laminate.

Volume: 11.8FT3 gross, around 9.5 FT3 Net. after port/driver/bracing.

--------------------------------------------------------

Design with an 8" down-firing port:

Design with an back straight slot port:

WinISD Maximum SPL and current UM18-22 for compare:

Regards, sorry for my English.

Last edited:

Some inspiration:

21" B&C DS115-8 Subwoofer - Respiro Del Diavolo - Bass Projects - Data-Bass Forums

Its a common issue with these large high excursion drivers that the port is the limiting factor.

21" B&C DS115-8 Subwoofer - Respiro Del Diavolo - Bass Projects - Data-Bass Forums

Its a common issue with these large high excursion drivers that the port is the limiting factor.

I'm following this thread! This looks insane! What amp are using?

Hi, currently have 2x Samson S2000 old-school heavy-iron Class A/B amplifiers but one is being used for the 10" midbasses and the other is bridged driving the current UM18-22 @ 4ohms, haven't clipped it yet.

Given that this new subs will be placed in a small 10W x 9D x 8H room, my options are that one Samson S2000 may be enough hopefully, otherwise use both of them bridged one for each sub, ultimately have been interested on an RMX5050a or a Class D.

Some inspiration:

21" B&C DS115-8 Subwoofer - Respiro Del Diavolo - Bass Projects - Data-Bass Forums

Its a common issue with these large high excursion drivers that the port is the limiting factor.

Hi, thank you for pointing on that thread, really helpful, been reading about this pro subs for home for a while indeed, definitely some terrific work there on those huge boxes and port bend.

I would go for a push-push with hard mechanical bonding (carbon tube?) of the two magnets to eliminate vibration. Closed cabinet and Linkwitz transform tuned to Q=0,5. But you have to get 4 for stereo. Maybe "settle" for 18"...

//

Hi, thanks for the suggestion on the dual opposing style, I was also reading on a build with passive radiators using this driver, however I'm leaning towards a relatively compact ported design and a maximum of 24"W x 24"D since they will be placed in the corners close to the walls.

@TNT, yeah I've read exceptional results on the Ricci's dual possessed 21SW152, but as you've mentioned early, at the expense of getting two more 21SW152 and more power for a dual subs setup, between instead of chasing for extreme SPL, I'm also looking for a balance between efficiency and moderate SPL hopefully.

Its a common issue with these large high excursion drivers that the port is the limiting factor.

Xmax seems to be only 15mm, so it's not very high.

Save space, save wood, smaller more rigid box & better sound?

How about using the Rod Elliot / Bag End sub woofer method...Sub-Woofer Controller

I have attached a sim with your drivers and calculated real world out put and box dimensions allowing for 35mm thick birch play walls.

Hope it helps?

Cheers

A.

How about using the Rod Elliot / Bag End sub woofer method...Sub-Woofer Controller

I have attached a sim with your drivers and calculated real world out put and box dimensions allowing for 35mm thick birch play walls.

Hope it helps?

Cheers

A.

Attachments

Hello, thanks a lot for the really useful info and the plots on this drivers, also looking now on the ajdesigner as well to play a bit with it too.

And indeed +1 for the DBX DriveRack PA2, been using it for few years and is the tool of choice I would recommend in the $400 range.

And indeed +1 for the DBX DriveRack PA2, been using it for few years and is the tool of choice I would recommend in the $400 range.

Small update!

So I headed up to my local Home Depot to grab the Quickrete concrete form tube and look for the plywood, the tube where in good shape and feel sturdy.

Unfortunately all the Plywood there was a complete disappointment, very sad to the eyes looking at all those Plywood sheets(Pine, Virola, Okume and Melamine) in an erratic bad/abused shape , deformed and/or bent and a lot of deep blemishes

, deformed and/or bent and a lot of deep blemishes , the others sheets who looked a little nice in the veneer faces where full of voids all around the edges, definitely a no go.

, the others sheets who looked a little nice in the veneer faces where full of voids all around the edges, definitely a no go.

So I will keep looking for others plywood suppliers in P.R. and comparing they quality before buy, otherwise my last resort would be to use double sheets of .75" of MDF but I will try my best to avoid the MDF in favor for some durability and less heavy boxes.

Regards

So I headed up to my local Home Depot to grab the Quickrete concrete form tube and look for the plywood, the tube where in good shape and feel sturdy.

Unfortunately all the Plywood there was a complete disappointment, very sad to the eyes looking at all those Plywood sheets(Pine, Virola, Okume and Melamine) in an erratic bad/abused shape

, the others sheets who looked a little nice in the veneer faces where full of voids all around the edges, definitely a no go.

, the others sheets who looked a little nice in the veneer faces where full of voids all around the edges, definitely a no go.So I will keep looking for others plywood suppliers in P.R. and comparing they quality before buy, otherwise my last resort would be to use double sheets of .75" of MDF but I will try my best to avoid the MDF in favor for some durability and less heavy boxes.

Regards

Xmax seems to be only 15mm, so it's not very high.

higher than you used to be able to get with decent motor force from a 21" driver. There are drivers with more xmax but they are more expensive:

NSW6021-6 - Loudspeakers | Eminence Speaker

21IPAL LF Drivers - B&C Speakers

and in the case of the 21IPAL xvar is listed as less than xmax which implies its compliance limited for excursion. I'm ignoring car audio drivers here I'm sure there is some obscenely expensive thing with an enormously heavy cone/motor in that field.

So you are looking for design suggestions?

Looking at your SPL the box lacks a little volume, but I understand there has to be a limit.

Well, these drivers seem to suck on closed boxes (and so 4th orders also), but vented is way to go. So why not 2 vents?

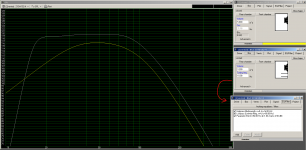

Look at this 6th order. You could gain some SPL between 20 and 45 Hz. OK, you miss the SPL above 50 Hz, but it's a sub right?

Looking at your SPL the box lacks a little volume, but I understand there has to be a limit.

Well, these drivers seem to suck on closed boxes (and so 4th orders also), but vented is way to go. So why not 2 vents?

Look at this 6th order. You could gain some SPL between 20 and 45 Hz. OK, you miss the SPL above 50 Hz, but it's a sub right?

Attachments

So you are looking for design suggestions?

Looking at your SPL the box lacks a little volume, but I understand there has to be a limit.

Well, these drivers seem to suck on closed boxes (and so 4th orders also), but vented is way to go. So why not 2 vents?

Look at this 6th order. You could gain some SPL between 20 and 45 Hz. OK, you miss the SPL above 50 Hz, but it's a sub right?

Hi PCSoldaat, yeah the box could definitely gain a lil more volume by halving the wall thickness, however the material at HD is notoriously inferior hence doubling up on the material and asked some suggestions on the materials I've mentioned like the BCX, Melamine but I was not very specific about on the tittle, nevertheless the material was very underspec/poor when I checked

Also the box should remain at a maximum 24"Wx24"D and a maximum of 48"H since the box may be close a windows with an air conditioner installed in it and is already at those limits.

I initially wanted them to be 42" tall but since the doubling up on wall thickness plus the straight down-firing port I was forced to make them 48" tall to gain extra volume and leave clearance on the port from the top so definitely there's always trade-offs.

Between here's some sim from WinISD(I set QL 20) about the possible FR/SPL after adding small peq with 80Hz xover point, so IIRC with both subs engaged there is an extra 6dB gain.

A 6th order BP is not any harder to build. Biggest difference is that the driver is inside. You will have 2 vents, both could be downfiring. But since volume is very limited: stay with your vented box.

Reducing wall thickness will a gain a little room, but raises the need for bracing!

I think the baffle should still be double to be strong enough to hold the driver.

Reducing wall thickness will a gain a little room, but raises the need for bracing!

I think the baffle should still be double to be strong enough to hold the driver.

You are right about the bracing needs on tin walls, since I'm not so creative when it comes to bracing, I will stay doubling up all walls so can use lesser bracing.

Also unlike the 6th BP, since this subs are for music I want them to be also strong and clean in the upper bass as well.

Also unlike the 6th BP, since this subs are for music I want them to be also strong and clean in the upper bass as well.

Circular shapes are naturally more stiff than rectangular. In that case the tube ports will cost less material than straight slots, in favor for more internal volume of the box.

Bracing btw is not a difficult thing, you just need more on thin walls. You could add one at the centre of the driver and add some bracing on top and bottom.

Bracing btw is not a difficult thing, you just need more on thin walls. You could add one at the centre of the driver and add some bracing on top and bottom.

- Home

- Loudspeakers

- Subwoofers

- 21" Subwoofers design suggestion