It’s easy, it’s cheap, it’s got lots of quarter path shape options and it’s my ‘day job’. except we are a swing shift from 4 pm-3am... and we listen to streamed WiFi or ancient PA overhead in the gigantic multi area open floor plan space and it’s a bit large to use a conventional ‘boombox’, so we might ‘grow’ and it’s a structural steel shop, so it can be built and heavy... forklift and steel is everywhere...

it’s a go if I can get the owner to okay it. she, only needs to see a drawing or anything and it’s most a sure thing as anyone above me is on board and have approved.

no $$ on her end. Only materials to make it are the deal. And with that I suspect it’ll fly. but is the idea stupid, or a waste of ‘novelty’? Steel in a steel shop is the fun factor and why it’s even considered or approved I’m betting.

The fabrication complexities are a welcome addition and even exposing any is fun as nobody really does’ speakers ’ Diy, but some musicians and Music hobbyists are coworkers..

Plain Jane TL with offset driver and single or pair of 12, 15” Dayton ultimax, RSS or DSC or similar are easy to convince people are okay to invest in. Anyone, just give them the link to parts Express and it seems to be fine and I don’t have to pick and choose why Wal-Mart drivers and Amps or car audio crazy boom Boom from Best Buy Might not be right for ‘everyone’ to listen to all night... and there’s all the car audio ideas in power and amplifier the midrange and tweeters and everything in this already... if it’s a ‘go’. it’s a collection of parts and pieces if it pans out as everyone chips in ‘stuff’..

however, that is not in question to you guys.. I will certainly listen to speaker people and suggestions . Hecxecrge question if it’s validity?

. Hecxecrge question if it’s validity?

Most likely , 10-14 gage pressbroke and thus rigid with internal bracing and minimal volume losses and CSA in the path of a TL? Then, shot with a deadening ruberizrd compound like under coating for chassis? mayvevlined with pink Home Depot foam insulating boards, I don’t think I can use concrete brisk, lol. or id ask... and while I can use plywood in areas I really need to sell it by ‘steel’ to the owner or it’s Back to the boom box on overhead PA system 25 feet high thru the phone line to ... junk!And cannot hear much of it over the noise of production. It’s no good...it’s 45 years or older to and part of an old drive in theatre with part of some other stuff including back to 1954 when this shop started by ‘to the owners father.

Mild steel is possible? Weight doesn’t mater, nothing does, technically, except that I can create a proper ‘steel’ TL...?

it’s a go if I can get the owner to okay it. she, only needs to see a drawing or anything and it’s most a sure thing as anyone above me is on board and have approved.

no $$ on her end. Only materials to make it are the deal. And with that I suspect it’ll fly. but is the idea stupid, or a waste of ‘novelty’? Steel in a steel shop is the fun factor and why it’s even considered or approved I’m betting.

The fabrication complexities are a welcome addition and even exposing any is fun as nobody really does’ speakers ’ Diy, but some musicians and Music hobbyists are coworkers..

Plain Jane TL with offset driver and single or pair of 12, 15” Dayton ultimax, RSS or DSC or similar are easy to convince people are okay to invest in. Anyone, just give them the link to parts Express and it seems to be fine and I don’t have to pick and choose why Wal-Mart drivers and Amps or car audio crazy boom Boom from Best Buy Might not be right for ‘everyone’ to listen to all night... and there’s all the car audio ideas in power and amplifier the midrange and tweeters and everything in this already... if it’s a ‘go’. it’s a collection of parts and pieces if it pans out as everyone chips in ‘stuff’..

however, that is not in question to you guys.. I will certainly listen to speaker people and suggestions

Most likely , 10-14 gage pressbroke and thus rigid with internal bracing and minimal volume losses and CSA in the path of a TL? Then, shot with a deadening ruberizrd compound like under coating for chassis? mayvevlined with pink Home Depot foam insulating boards, I don’t think I can use concrete brisk, lol. or id ask... and while I can use plywood in areas I really need to sell it by ‘steel’ to the owner or it’s Back to the boom box on overhead PA system 25 feet high thru the phone line to ... junk!And cannot hear much of it over the noise of production. It’s no good...it’s 45 years or older to and part of an old drive in theatre with part of some other stuff including back to 1954 when this shop started by ‘to the owners father.

Mild steel is possible? Weight doesn’t mater, nothing does, technically, except that I can create a proper ‘steel’ TL...?

I'd do something like a bunch of THAM15 or THAM18 tapped horn subwoofers. They have very good output for their size. In steel you'll need more top, back and bottom bracing. All structural resonances need to be an octave or more above the passband. Get a feel for what 300Hz sounds like, compare that with a knuckle wrap test on a steel span of the sort of dimensions you will find in the build. It shouldn't be too hard getting your structural resonances suitably high in frequency.

Hang the speakers facing down from the roof.

BTW, cool idea!

Hang the speakers facing down from the roof.

BTW, cool idea!

Thank you! Actually read your website and builds a number of times and lots of tops and tricks along the way because of that in all kinds of things past and future . The tham is also a solid opportunity. sure thing too.! and I’d even put that into ROar which I can say I’m Familiar quite well, if it’s more of the same thought your having?

A few random ideas, but limited to wondering where to attack resonating junk and panel flex in steel sheet plate. Guesses on my end..

if I kiss the panels with a diagnol twice(X) in abrake, they quickly gain a rigid version of themselves by minimal plastic deformation. huge doors in hospital basements or heat/AC doors do this and a few concrete mold bent plate forms at rooflines.

the welding is actually a lot of internal stresses as it cools it will trap that which might have warped otherwise or can be an intentional part of creating even more stored and bound up energy, which can help(?)? Easier to avoid but if useful Is even easier too allow it?

Im

definitely putting THam in the Rolodex. and 300 hz is already playing as I type

A few random ideas, but limited to wondering where to attack resonating junk and panel flex in steel sheet plate. Guesses on my end..

if I kiss the panels with a diagnol twice(X) in abrake, they quickly gain a rigid version of themselves by minimal plastic deformation. huge doors in hospital basements or heat/AC doors do this and a few concrete mold bent plate forms at rooflines.

the welding is actually a lot of internal stresses as it cools it will trap that which might have warped otherwise or can be an intentional part of creating even more stored and bound up energy, which can help(?)? Easier to avoid but if useful Is even easier too allow it?

Im

definitely putting THam in the Rolodex. and 300 hz is already playing as I type

What about double wall ( stayed like a loco fire box ), filled with sand. Your fabrication shop is just a bit bigger than ours, ha!, you're lucky you like the same music, we have several different " radios " playing at once, along with the din of hammers angle grinders 'n such.

Member

Joined 2009

Paid Member

cracked case, there is cultural and ethnic backgrounds and that's in music. you touched on a real thing... we have to leave the ability for all to vote yes, but anyone to privately say no and be respected. so far so good, and anything goes, ill tolerate if anyone will, and i eat anyones 'no' as if it was mine so its anonomously on me, not anyone trying to feed a family without country westerm or rap or rock or in there ear if not okay. classic rock is pretty neutral it seems... but spanish or mexican music is not neglected and clean language in rap might sneak in for a bit... thats a stretch, but im not denying anyone and itll vote, itll play! productivity is in this too. im sure you now anything helps, this is blue collar and served unfriendly to the seasons and weather

id love to sneak sand in between walls but it might be abusing the materials and cut list?maybe layer of internal butyl roofing funk or mass loaded rubbery ? drywall, but it gets a bit messy..? but its a big silly metal box or two and a TL shape or tapped pipe or horn... it might need help inside beyond rigid and under a tension? polyfil, or synthetic is fine for that, wool obviously might be an insect or 100... but otherwise anything can be hidden or even ugly for sound in an ugly place, lol oi dont think anyone will care, because if it sounds good its all good?\!!

id love to sneak sand in between walls but it might be abusing the materials and cut list?maybe layer of internal butyl roofing funk or mass loaded rubbery ? drywall, but it gets a bit messy..? but its a big silly metal box or two and a TL shape or tapped pipe or horn... it might need help inside beyond rigid and under a tension? polyfil, or synthetic is fine for that, wool obviously might be an insect or 100... but otherwise anything can be hidden or even ugly for sound in an ugly place, lol oi dont think anyone will care, because if it sounds good its all good?\!!

Last edited:

Our fabrication shop may be TINY compared to yours, but we do have a foundry so old sand could be disposed of in a creative way. I wonder ( considering the size the speakers will be ) if someone will be asked to climb inside to change the stuffing, I know a skinny bloke who used to work in fabrication, aircraft wings I think and he was always the one climbing through a tight hole, although he coolest job was programming a computer - by punching holes in cardboard ! If you play Rodrigo and Gabriela you'll have Spanish and metal in one. What about substituting iron filings for sand ?

rodrigo likes dubstep and trance, he already wants the THAMs!!

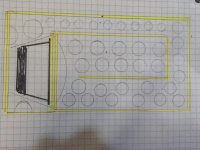

stuffing is a bitch inside a TL or similar unless you plan ahead to have decent access in most of the upper section. if offset it makes it potentially easier. kinda like this and in the driver hole you get a lot of access inside? if its is THA of HORN folding its probably even trickier and access panels are likely a hgeavier material thickness and legit bolt on with drilled and tapped fastener mountin flange over gasket material.. ups the issue potential, but anything can be sealed with enough caul, goop, pudding, mud or booger weldz

stuffing is a bitch inside a TL or similar unless you plan ahead to have decent access in most of the upper section. if offset it makes it potentially easier. kinda like this and in the driver hole you get a lot of access inside? if its is THA of HORN folding its probably even trickier and access panels are likely a hgeavier material thickness and legit bolt on with drilled and tapped fastener mountin flange over gasket material.. ups the issue potential, but anything can be sealed with enough caul, goop, pudding, mud or booger weldz

Do you do bead blasting? Bead blasting media might work. I can remember someone shoveling some old iron filings and he said they started to get a bit " warm ", I'm not sure if this would be a problem with steel.

Sand blasted to paint rarely, but shipped out and returned to finish galvanized. There’s solid steel drop and random a dead weight that might be available to tie into (sorta)? It’s not gonna be very likely if it gets too crazy or horribly ugly, though?

Pretty sure I can get the main panels front and behind the driver a space to fill with sand or similar? I’ll jyst make a note of that now, and consider it a plan.

Last edited:

Do you do bead blasting? Bead blasting media might work. I can remember someone shoveling some old iron filings and he said they started to get a bit " warm ", I'm not sure if this would be a problem with steel.

Sand blasted to paint rarely, but shipped out and returned to finish galvanized

https://www.diyaudio.com/forums/sub...rns-pipes-concepts-builds-21.html#post5806687

Check out the type c. All right angles and easy driver access. I’ve done them in plywood and they do the job. The only downside is that for any of the designs to work well you need strong drivers that cost some money

Check out the type c. All right angles and easy driver access. I’ve done them in plywood and they do the job. The only downside is that for any of the designs to work well you need strong drivers that cost some money

https://www.diyaudio.com/forums/sub...rns-pipes-concepts-builds-21.html#post5806687

Check out the type c. All right angles and easy driver access. I’ve done them in plywood and they do the job. The only downside is that for any of the designs to work well you need strong drivers that cost some money

How do you like these compared to another type of subwoofer? those are really unique in a couple distinct ways as far as the approach to a 6/8th order qwpipe/horn, right?. I really can’t tell what’s NOT to like, other than the power requirements (efficient needs electrical and the driver to transfer it into the air piston pump for a lot of air and at the highest pressure areas of a qw pipe path(closed ends of two pipes here)? kind of how I envision it? probably tuned a bit tall like mid 30s not much lower(long qw paths are lots of air to push)? Pretty badass, very interesting. always liked that guys (MAtthew)creative ideas and unique ways to simulate tricky things in horn response. Must admit a lot of influence in a few things come straight off of his ‘canvas’ and slapped into my own often. Maybe more than I even realize.

Made about 30 feet of this in a channel shape ~1x3 and tighter 1.5” holes spacing. 14 gage, kinda takes the structural into cosmetic more than otherwise, but the material was rusty (but free) so hard to complain. the 1” and 3” dimensions being opposite the ideal to be a rigid brace, but I’m probably being picky?

This as an exterior ‘cage’ or similar is kinda where I went with the ‘industrial’ theme suggestion. Kinda feels like it might work as an intentionally weathered look to wood plywood underneath that mimicked with a roughed up paint job with worn edges and corners? kinda makes me wanna use this in a ‘practice’ on my own personal subwoofer initially? I have an excuse to make new versions of current cabinets with a unique look and even tweak them in rebuilding the replacement. The rabbit hole of DIY is deep. I’m slipping again, lol!

This as an exterior ‘cage’ or similar is kinda where I went with the ‘industrial’ theme suggestion. Kinda feels like it might work as an intentionally weathered look to wood plywood underneath that mimicked with a roughed up paint job with worn edges and corners? kinda makes me wanna use this in a ‘practice’ on my own personal subwoofer initially? I have an excuse to make new versions of current cabinets with a unique look and even tweak them in rebuilding the replacement. The rabbit hole of DIY is deep. I’m slipping again, lol!

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Mild steel welded and pressbroke enclosures