Hi all,

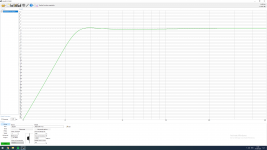

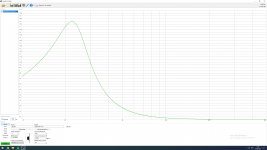

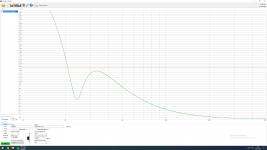

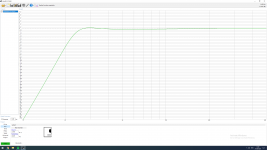

So am in (hopefully) the final stages of designing my first enclosure, I decided to go for the Dayton Audio RSS315HF-4 12" driver. Using WiniSD I have worked out that the internal volume will be 3.7ft^3 tuned to 24Hz.

I just wanted to post the plans on here before sending them off to get the wood cut to make sure that it all looks ok, I also have a few questions.

Firstly, does the bracing look strong enough? was just going to have that one central panel but could add in a second one if needed.

Secondly, is a crossover needed if it will just be on its own amplifier channel (which has DSP) and if so will this need to be a band pass filter? I have struggled to find information on what values of capacitors/inductors I would need to use. If anyone could point me in the right direction that would be amazing.

Sorry for the hand drawings do not have access to design software. are there any free softwares that are good for 2D design? would be helpful to draw out the individual parts on there for accuracy.

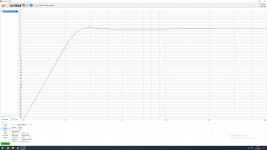

I think I've attached all relevant graphs.

Any other tips are very welcome, thanks in advance

P.S. am aware that this driver is better in a sealed enclosure but ported suits me better for what ill be using it for.

So am in (hopefully) the final stages of designing my first enclosure, I decided to go for the Dayton Audio RSS315HF-4 12" driver. Using WiniSD I have worked out that the internal volume will be 3.7ft^3 tuned to 24Hz.

I just wanted to post the plans on here before sending them off to get the wood cut to make sure that it all looks ok, I also have a few questions.

Firstly, does the bracing look strong enough? was just going to have that one central panel but could add in a second one if needed.

Secondly, is a crossover needed if it will just be on its own amplifier channel (which has DSP) and if so will this need to be a band pass filter? I have struggled to find information on what values of capacitors/inductors I would need to use. If anyone could point me in the right direction that would be amazing.

Sorry for the hand drawings do not have access to design software. are there any free softwares that are good for 2D design? would be helpful to draw out the individual parts on there for accuracy.

I think I've attached all relevant graphs.

Any other tips are very welcome, thanks in advance

P.S. am aware that this driver is better in a sealed enclosure but ported suits me better for what ill be using it for.

Attachments

Personally I prefer to use dowel (rod) strategically placed, by ear, it can be moved around if tight fitting, and when the good places are found PVA'd into place. It is easier than cutting your obolid shapes, and multiple pieces can be used with a minimal loss of volume. You could consider corner bracing with Scotia, but that is labour intensive.

Personally I prefer to use dowel (rod) strategically placed, by ear, it can be moved around if tight fitting, and when the good places are found PVA'd into place. It is easier than cutting your obolid shapes, and multiple pieces can be used with a minimal loss of volume. You could consider corner bracing with Scotia, but that is labour intensive.

Thanks, what thickness rod do you prefer to use?

I cannot work out what that horizontal in your second picture is, or is meant to do.

Front to back dowels are effective where the cabinet is most likely to flex, ie in the middle near the woofer cut-out.

Just 'suck it and see' using knuckle rap and the ear to determine deadness.

Front to back dowels are effective where the cabinet is most likely to flex, ie in the middle near the woofer cut-out.

Just 'suck it and see' using knuckle rap and the ear to determine deadness.

Also how does it work with having a speaker terminal? surely cutting out wood and replacing with thin plastic will cause issues on the back panel?

Use SpeakOn.

Chris

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Help finalising enclosure design (Dayton RSS315HF-4)