I think I want to try my hands at building a blown driver - this one being a 10" driver that I have on hand at the moment that has a blown coil and destroyed former. Have any of you done something similar, and if so, what sites do you use to source the relevant components? Of the top of my head, it looks like I'd need a new coil (and former), cone, dustcap, surround, spider and of course the glue to hold it all together. I may also need a "ring" to raise the spider a bit as the original driver had an issue with the coil bottoming too easily.

It seems to be a dying art Brian, I can’t find much on it.

I did however blow a much loved speaker and so bought a winding machine from aliexpress to have a go with.

It’s a bit gritty and bit sloppy but I intend to have a go anyway.

Finding the right wire to replace the existing stuff seems to be the difficult bit.

I did however blow a much loved speaker and so bought a winding machine from aliexpress to have a go with.

It’s a bit gritty and bit sloppy but I intend to have a go anyway.

Finding the right wire to replace the existing stuff seems to be the difficult bit.

Attachments

What an amazing opportunity to wind a VC for motional feedback.

The drive winding is routine. But the feedback winding would be fine wire and much longer - in order to generate a large voltage to feed back.

(Ordinary dual voice coils can't be used because they don't make much voltage unless maybe for 16 Ohms, which I've never seen. Sony had a driver like I described above.)

B.

The drive winding is routine. But the feedback winding would be fine wire and much longer - in order to generate a large voltage to feed back.

(Ordinary dual voice coils can't be used because they don't make much voltage unless maybe for 16 Ohms, which I've never seen. Sony had a driver like I described above.)

B.

Search (in USA?) for aftermarket voice coil and speaker reconing suppliers.I think I want to try my hands at building a blown driver - this one being a 10" driver that I have on hand at the moment that has a blown coil and destroyed former. Have any of you done something similar, and if so, what sites do you use to source the relevant components? Of the top of my head, it looks like I'd need a new coil (and former), cone, dustcap, surround, spider and of course the glue to hold it all together. I may also need a "ring" to raise the spider a bit as the original driver had an issue with the coil bottoming too easily.

post a couple pictures to have an idea of what are we talking about: front (cone) , side, back, and one through frame window showing spider joining cone and voicecoil.

Spiders are made in different heights.

If you get all fresh moving parts then you may cut cone and spider edge to remove whole moving assembly from frame and magnet but don´t do that yet, you *might* try to reuse some of original parts , although that´s way more difficult than plain replacing everything and sometimes impossible.

EDIT: Colombian site "Construya su Videorockola" has a couple videos on speaker reconing and homemade voice coils, (in Spanish), watch them as a basic guide.

Last edited:

Search....

In light of your good experience, I'd appreciate your reaction to post #3 and making a motional feedback winding.

BTW, to avoid inductive interaction, is it possible for a person wind the two coils on opposite sides (interior and exterior) of the coil tube? Or otherwise separated?

B.

Last edited:

I use these suppliers for parts

https://qsr.net.au/catalogues/

Spare parts to repair your loudspeakers

MISC Speaker Repair Parts Archives - Speaker Exchange

https://www.springfieldspeakerrepair.com/Default.asp

and there are probably a few more if you do a web search.

cheers, Arthur.

https://qsr.net.au/catalogues/

Spare parts to repair your loudspeakers

MISC Speaker Repair Parts Archives - Speaker Exchange

https://www.springfieldspeakerrepair.com/Default.asp

and there are probably a few more if you do a web search.

cheers, Arthur.

I found this guy on eBay: Epo-Tek 353ND Professional High Temperature Two Part Epoxy | eBay

He is selling a single use 3gr blister pack of high temperature epoxy, I’m going to order some tomorrow when I get into the office but for tonight I stripped, cleaned, adjusted and oiled the winding machine.

Its’s not very good, pretty accurate on counts but sloppily and cheaply made. If I end up doing much more of this I shall invest in a better machine rather than bore out and re-bush this one...

It did however enable me to strip the wire from the voice coil and count the number of turns at the same time.

My coil had 50 turns of a wire 0.12mm across. I think this is 0.125mm metric and I have ordered some of that size magnet wire to compare.

The voice coil was loose at the top of the winding and this made it difficult to measure the winding height. I made it to be 6mm by eyeball guesstimate.

50 turns at 0.125mm gives 6.25mm, so I will be using that.

The next step is to clean the Kapton and roughen it for the glue, do I need to have former turned to a precise diameter for this or can I get away with doing it between centres?

He is selling a single use 3gr blister pack of high temperature epoxy, I’m going to order some tomorrow when I get into the office but for tonight I stripped, cleaned, adjusted and oiled the winding machine.

Its’s not very good, pretty accurate on counts but sloppily and cheaply made. If I end up doing much more of this I shall invest in a better machine rather than bore out and re-bush this one...

It did however enable me to strip the wire from the voice coil and count the number of turns at the same time.

My coil had 50 turns of a wire 0.12mm across. I think this is 0.125mm metric and I have ordered some of that size magnet wire to compare.

The voice coil was loose at the top of the winding and this made it difficult to measure the winding height. I made it to be 6mm by eyeball guesstimate.

50 turns at 0.125mm gives 6.25mm, so I will be using that.

The next step is to clean the Kapton and roughen it for the glue, do I need to have former turned to a precise diameter for this or can I get away with doing it between centres?

Attachments

Ok, thanks everyone for your responses so far. I'll try to get to answer all the questions and queries below.

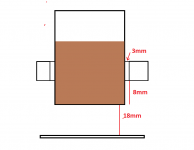

For some physical dimension info, here goes: The distance from the top of the gap to the bottom plate is 33 mm, the coil length is 23 mm and the rated Xmax is 8 mm, which puts the gap at 7mm (23-2*8). As the coil is wound all the way to be bottom of the former, that puts about 18 mm (33-(7+8)) between the bottom of the former and the bottom plate. The distance from the spider to the top of the gap is the same 18 mm or slightly more. This means that while there's a lot of space between the former. the former's going to bottom out before the triple joint hits the top plate, which is what I think led to the demise of this particular driver.

The coil is a 2" coil, and the gap width is about 3mm (it might be slightly under as the edges are slightly bevelled). The former is 42mm (1.65") high. The spider is 14mm (5.5") in diameter. The cone is 50mm (2" high).

Cone + Surround : 28g

Spider: 2g

Coil/Former: 35g

The driver was rated at 100 Watts, 8 ohms.

I'd really like to reuse the cone (which I've managed to successfully separate from the former), but I need a good way to remove the foam surround from it. Seeing that it's a plastic cone, bathing the joint in acetone is probably not the best approach, and then there's the challenge of removing the plastic inverted dustcap if that's actually required for properly aligning the voice coil in the gap.

So far I think I've found a replacement spider that might work (size-wise), but I've been told that it's pretty stiff - 5.58" x 2" Flat Linear Roll Spider | The Lord of Bass

And if I manage to reuse the original cone, there are surround kits available for it (based on a Google search on its part number - 902-5861), e.g. Amazon.com: Springfield Speaker 10" Foam Surround Edge Repair Kit - Compatible with Infinity 902-0032, 902-2673, 902-2864, 902-3061, 902-3067: Home Audio & Theater

Alternatively, I can go with a rubber surround like the one at the following link which should fit - Amazon.com: 10inch Perforated Rubber Speaker Foam Edge Subwoofer Surround Rings Replacement Parts for Speaker Repair or DIY (Black)(2pcs): Home Audio & Theater

The challenge though is how to remove the original surround from the plastic cone without damaging it?

And the biggest challenge at the moment is finding a replacement voice coil. Quite a few 2" coils available, but there's always one thing (former height, winding depth, the number of turns in the gap, etc.) that stops each one I've come across so far from being the best fit for this driver.

Of course all of this is going to cost way more than the original driver did, but I'm doing it for the experience, not to save costs

For some physical dimension info, here goes: The distance from the top of the gap to the bottom plate is 33 mm, the coil length is 23 mm and the rated Xmax is 8 mm, which puts the gap at 7mm (23-2*8). As the coil is wound all the way to be bottom of the former, that puts about 18 mm (33-(7+8)) between the bottom of the former and the bottom plate. The distance from the spider to the top of the gap is the same 18 mm or slightly more. This means that while there's a lot of space between the former. the former's going to bottom out before the triple joint hits the top plate, which is what I think led to the demise of this particular driver.

The coil is a 2" coil, and the gap width is about 3mm (it might be slightly under as the edges are slightly bevelled). The former is 42mm (1.65") high. The spider is 14mm (5.5") in diameter. The cone is 50mm (2" high).

Cone + Surround : 28g

Spider: 2g

Coil/Former: 35g

The driver was rated at 100 Watts, 8 ohms.

I'd really like to reuse the cone (which I've managed to successfully separate from the former), but I need a good way to remove the foam surround from it. Seeing that it's a plastic cone, bathing the joint in acetone is probably not the best approach, and then there's the challenge of removing the plastic inverted dustcap if that's actually required for properly aligning the voice coil in the gap.

So far I think I've found a replacement spider that might work (size-wise), but I've been told that it's pretty stiff - 5.58" x 2" Flat Linear Roll Spider | The Lord of Bass

And if I manage to reuse the original cone, there are surround kits available for it (based on a Google search on its part number - 902-5861), e.g. Amazon.com: Springfield Speaker 10" Foam Surround Edge Repair Kit - Compatible with Infinity 902-0032, 902-2673, 902-2864, 902-3061, 902-3067: Home Audio & Theater

Alternatively, I can go with a rubber surround like the one at the following link which should fit - Amazon.com: 10inch Perforated Rubber Speaker Foam Edge Subwoofer Surround Rings Replacement Parts for Speaker Repair or DIY (Black)(2pcs): Home Audio & Theater

The challenge though is how to remove the original surround from the plastic cone without damaging it?

And the biggest challenge at the moment is finding a replacement voice coil. Quite a few 2" coils available, but there's always one thing (former height, winding depth, the number of turns in the gap, etc.) that stops each one I've come across so far from being the best fit for this driver.

Of course all of this is going to cost way more than the original driver did, but I'm doing it for the experience, not to save costs

Attachments

What an amazing opportunity to wind a VC for motional feedback.

This being my first attempt at rebuild, that's likely to make the process a lot more complex than it needs to be

The challenge though is how to remove the original surround from the plastic cone without damaging it?

Well, I managed to find a way. On a lark I just sprayed the where the surround was joined to the cone with WD-40 and left it to sit overnight. The next day, the surround pealed off very easily, and any glue residue that was left was easily wiped off with a napkin soaked in WD-40. Washing the cone with detergent afterwards got rid of all of the WD-40. You can barely see where the surround was joined to the cone, which works for me as I when I rebuild this driver, I want to join the surround behind the cone, not in front of it.

The "glue" that was used to bond the surround to the cone doesn't appear to be a cyanoacrylate type, like what was apparently used to bond the cone to the former. It looks more like a silicone-based glue. And it looks like the same type of glue was used to bond the dust cover to the cone, so I'm going to try the same "trick" tonight to see if I can get the dust cover off, which I think will make it easier to align the coil in the gap.

I'm still facing the challenge of finding a replacement voice coil for this rebuild. Not too surprising - I'm guessing speaker rebuilds only make sense for higher-value drivers...

Attachments

Success - the WD-40 soak worked.

To finish the cleanup job, I'll have to remove the leftover cyanoacrylate glue at the base of the cone, but that's less critical and I'll probably just sand it off by hand or with a Dremel or something. That joint is going to be hidden behind the dustcap when I rebuild the driver (if I find a suitable voice coil, of course).

To finish the cleanup job, I'll have to remove the leftover cyanoacrylate glue at the base of the cone, but that's less critical and I'll probably just sand it off by hand or with a Dremel or something. That joint is going to be hidden behind the dustcap when I rebuild the driver (if I find a suitable voice coil, of course).

Attachments

I'm leaving some links of interest for parts and repairs.

DIY Voice Coil with Cone

https://www.audiofriends.nl/speakerfoam/en/

DIY Voice Coil with Cone

https://www.audiofriends.nl/speakerfoam/en/

Attachments

I thought so. I have Kappa 9s with woofers of similar construction. It'll be tough to round those parts up if at all possible. Unless you find someone involved in their manufacture.The driver is an Infinity 902-5861 10" subwoofer driver that was used in at least two of their commercial home audio subwoofer offerings. A search online brings up quite a few sites that supply replacement foam surrounds for this driver, but not much else.

What an amazing opportunity to wind a VC for motional feedback.

The drive winding is routine. But the feedback winding would be fine wire and much longer - in order to generate a large voltage to feed back.

(Ordinary dual voice coils can't be used because they don't make much voltage unless maybe for 16 Ohms, which I've never seen. Sony had a driver like I described above.)

B.

So don't use a voltage amp, use a current amp to amplify I to V.

Mike

I thought so. I have Kappa 9s with woofers of similar construction. It'll be tough to round those parts up if at all possible. Unless you find someone involved in their manufacture.

Biggest trouble I'm running into at the moment is that the sellers are not publishing enough information about their voice coils.

Things that are typically missing:

1. Weight - this will impact Fs (but this can be counteracted by a stiffer spider). One supplier quoted weight, and it turned out that it's likely shipping weight.

2. Winding density, e.g. turns per cm. This directly impacts BL (being the "L" part in that parameter). I think that If I want to replace a coil without significantly impacting BL, I need to make sure that the winding density of the replacement coil is similar to the original one.

3. External diameter - lots of suppliers quote the internal diameter, not the external one. It would be a shame if a bought a coil that fits over the pole but can't fit into the gap

Example: The original coil for my driver weighs 35g and has about 55x4 turns (manually counted, 4 layer coil) over a winding width of 23mm, which works out to about 95 windings per cm. I found the following coil online that looked like it would be a suitable replacement, but the devil turned out to be in the details: the weight is 43g and winding width is 25.4mm and the number of turns appears to be around 44x4, which works out to be 70 windings per cm, a significant drop from the original. This is enough to shift the driver's Qts from 0.32 to 0.58, assuming that I use a stiffer suspension with the heavier coil to bring Fs back to its original value. Erk... So my search continues...

2" Speaker Voice Coil 2.016" / Speaker Part / 4 Ohm / 4 Layer | eBay

I have had good luck with thelordofbass.com. They have black rubber glue for the surround and dust cap, CA glue for the spider and triple joint, tinsel lead, spiders, voice coils, frames, dust caps, cones, and motors. I reconed a 10” subwoofer awhile back and used it in my work truck under heavy use and it’s still going strong. I have 4 more to recone just haven’t had anytime. You can find pictures of the subwoofer in the car audio system pictures section on this site.

Regards,

Matt

Regards,

Matt

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Rebuilding a driver...