Hi Everyone

I am kind of new here and after having built few vented enclosures for bass / midbass drivers, I decided to go forward and build Tapped Horn types in order to get the best of my RCF LF15N401 with this plan :

Apache H15 .

But before-hand, I have few questions in mind :

I am also open to any other "simpler" design that would give close results to this design, the idea here is to have an enclosure that give the most powerful SPL / DB for the minimum power needed.

Ex : https://www.gearclubdirect.com/rcf-passive-ip55-800w-15-neo-subwoofer/ ?

Here is the spec sheet of the driver : https://www.rcf.it/c/document_libra...2ce-9d1e-4cf4-b611-d85de1526836&groupId=20195

Here is a picture of the ported enclosures I have built for the record

Thank you in advance for your lights. BLESS

I am kind of new here and after having built few vented enclosures for bass / midbass drivers, I decided to go forward and build Tapped Horn types in order to get the best of my RCF LF15N401 with this plan :

Apache H15 .

But before-hand, I have few questions in mind :

- Vibrations : I need to have my setup (turntables + mixer) diretly on the top of the enclosure : How will it goes with the bass vibrations ? Will I be able to operate everything smoothly or will it be unpracticable ? If too shaky, what would be a solution to have my setup on the enclosure or as close as possible ? I need to be ultra compact

- Plan Optimization : On the plan, it's written that many drivers are fittable, but I know that each driver has it's own characteristics, so on it's on enclosure size. How could I optimize this plan for the RCF LF15N401 and be sure I'm getting the best of the driver ?

- Wood type : Is it ok if I use MDF or I strictly need to use plywood ?

I am also open to any other "simpler" design that would give close results to this design, the idea here is to have an enclosure that give the most powerful SPL / DB for the minimum power needed.

Ex : https://www.gearclubdirect.com/rcf-passive-ip55-800w-15-neo-subwoofer/ ?

Here is the spec sheet of the driver : https://www.rcf.it/c/document_libra...2ce-9d1e-4cf4-b611-d85de1526836&groupId=20195

Here is a picture of the ported enclosures I have built for the record

Thank you in advance for your lights. BLESS

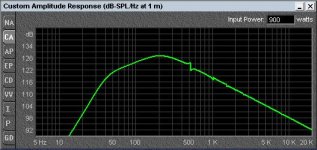

I couldn't find a hornresp model for H15 but your woofer would work in Jim Bell's Single Sheet tapped horn. - - (don't know how the vertical movement of the cone would muck with turntable use vs lateral)

power handling within the 9mm xmax is around 72 volts - that's a nice woofer

I think SS15, when properly braced, can use "half-inch" Baltic birch plywood which would be infinitely

better than MDF for portability and other reasons.

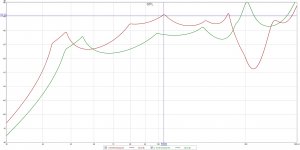

Here's how that tapped horn should look vs an 85 liter reflex tuned to 36Hz

power handling within the 9mm xmax is around 72 volts - that's a nice woofer

I think SS15, when properly braced, can use "half-inch" Baltic birch plywood which would be infinitely

better than MDF for portability and other reasons.

Here's how that tapped horn should look vs an 85 liter reflex tuned to 36Hz

Last edited:

If you build tapped horns you will not want to put your equipment directly on top of them.

A pair of SS15 cabinets might give you 130db and hearing damage shortly afterwards.

The biggest compromise with the SS15 size tapped horn is the lowest notes are slightly lacking, but that said they deliver astounding levels compared to the same driver in a reflex cabinet. Note in the sim above they beat the reflex from 40hz up.

A pair of SS15 cabinets might give you 130db and hearing damage shortly afterwards.

The biggest compromise with the SS15 size tapped horn is the lowest notes are slightly lacking, but that said they deliver astounding levels compared to the same driver in a reflex cabinet. Note in the sim above they beat the reflex from 40hz up.

that RCF is one of the recommended drivers for the Apache H15. I do like the idea of Jim Bell's cabinet having a lot of power (and low excursion) in the kick drum region. Even the old 1951 Karlson box with appropriate driver can trash a reflex - but SS15 will have more gain in the low end.

Last edited:

WOW that was a fast one, amazing activity here ^^

- @freddi, thank you so much for your advanced technical analysis already ! I'm warping my head around it and I'm now telling myself that it may be simpler and lighter to just build a bigger vented box with a proper volume / wood port (instead of the PVC I'm using and that is rattling at high volume).

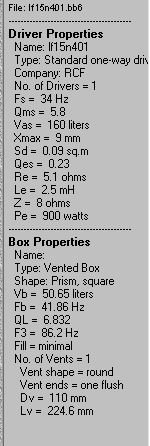

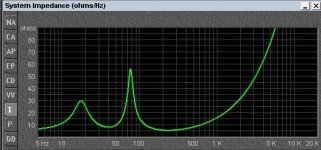

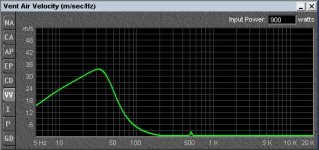

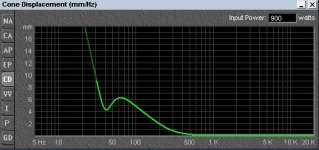

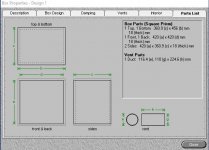

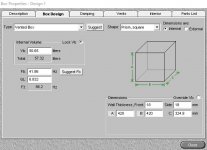

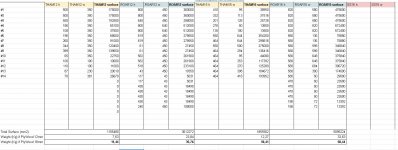

I'm attaching here the design of this enclosure I have built thanks to BassBox pro. Even if a DB difference would be noticeable with the TH type, do you think it would be worst-it to improve this vented one to really get the best of the RCF driver ? Any tips for that ?

Also, I have a limitation of weight and size so I need to find a good balance between enclosure efficiency, enclosure size and enclosure weight.

- @chris661, I didnt knew that I could cancel the vibrations by stacking 2 enclosures together, good news ! According to your experience, do you think I would be able to succeed having very little to no vibrations if stacking them well ? I sadly don't have the choice to put my setup on these cabinets.

- @Xoc1, got you, safety first ^^ but I need to find a solution for this, maybe I'll experiment with chris662 approach. A friend also told me about reinforcing the cabinets with fiberglass. I was thinking building a metal structure with another wood board on the top in order to not get the direct vibrations.

- @freddi, thank you so much for your advanced technical analysis already ! I'm warping my head around it and I'm now telling myself that it may be simpler and lighter to just build a bigger vented box with a proper volume / wood port (instead of the PVC I'm using and that is rattling at high volume).

I'm attaching here the design of this enclosure I have built thanks to BassBox pro. Even if a DB difference would be noticeable with the TH type, do you think it would be worst-it to improve this vented one to really get the best of the RCF driver ? Any tips for that ?

Also, I have a limitation of weight and size so I need to find a good balance between enclosure efficiency, enclosure size and enclosure weight.

- @chris661, I didnt knew that I could cancel the vibrations by stacking 2 enclosures together, good news ! According to your experience, do you think I would be able to succeed having very little to no vibrations if stacking them well ? I sadly don't have the choice to put my setup on these cabinets.

- @Xoc1, got you, safety first ^^ but I need to find a solution for this, maybe I'll experiment with chris662 approach. A friend also told me about reinforcing the cabinets with fiberglass. I was thinking building a metal structure with another wood board on the top in order to not get the direct vibrations.

Last edited:

Attached in this post the screenshots of the vented enclosure.

Wow so long time I haven't used Vbulletin, good memories XD

Wow so long time I haven't used Vbulletin, good memories XD

Attachments

@freddi, I am now looking at Jim Bell's SS15 tapped horn. Great design ^^ seems easy to build, compact and powerful. This guy deserves a medal.

To be sure, is this the most latest version ? SS15

Also, In your opinion, would it be worst it for me to take the time trying to optimizing the enclosure for the specific RCF driver I am using or not worst the hustle ?

THANKS

To be sure, is this the most latest version ? SS15

Also, In your opinion, would it be worst it for me to take the time trying to optimizing the enclosure for the specific RCF driver I am using or not worst the hustle ?

THANKS

I am also open to any other "simpler" design that would give close results to this design

Martinsson's Blog - ROAR15

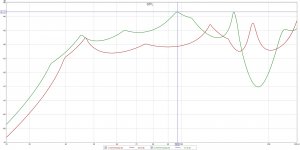

Only straight cuts and 90 degree angles. Very easy build. Much more output from a given driver and power, especially in the midbass where most of the energy in modern music is.

It has a very nice duality of character in that i has a very physical and tactile low end and a very nice punch and attack at the same time. Something I very seldom hear from normal tapped horns.

Attachments

Hi Circlomanen, very interesting design ! The only downside is that it would add more weight but no pain no gain  Does it fits any drivers ? I would think about adapting it to my other 12" midbass drivers with Neodyum magnet : MB12N351 ( https://service.rcf.it/c/document_l...22-200b-48e3-8fde-ccba0805410f&groupId=216492 )

Does it fits any drivers ? I would think about adapting it to my other 12" midbass drivers with Neodyum magnet : MB12N351 ( https://service.rcf.it/c/document_l...22-200b-48e3-8fde-ccba0805410f&groupId=216492 )

Does it fits any drivers ? I would think about adapting it to my other 12" midbass drivers with Neodyum magnet : MB12N351

It is best suited to high Bl, Low Qts drivers like the RCF 15N401 or B&C 15DS115.

I would guess that your MB12N351 is very suitable for the ROAR12 design:

Martinsson's Blog - ROAR12

Since the ROAR series is a split path design with a plane loading of the driver into the front resonator chamber it is very nice to the driver at high power levels. No warping or uneven loading that can lead to the voice coil scraping against the pole piece or similar.

A single ROAR12 could hold its own against two B&C 18TBX100 in bass reflex boxes in a direct comparison, in every aspect except the last 10 - 15 Hz below 40 Hz. It had much more punch and a higher definition and sounded overall much better.

that SS15 sim looks pretty good - you could ask at the SS15 thread. I think TB46 who made that plan, probalby passed away a few years back.

For a resonator hybrid, there's also the activity of MMJ and associates - maybe MMJ has some hornresp models pubhished at Facebook for comparison

High Order Quarterwave Society (DIY Bass A-Z) Public Group | Facebook

For a resonator hybrid, there's also the activity of MMJ and associates - maybe MMJ has some hornresp models pubhished at Facebook for comparison

High Order Quarterwave Society (DIY Bass A-Z) Public Group | Facebook

The SS15 is tuned higher than 40 Hz, compared to the vented design, so it's not really a true comparison. The vented alignment will reach lower with less distortion, and may be a better fit if you play music that goes down that low. And also, no, SS15-type folds typically don't really make good tables, particularly for turntables  .

.

Roger that, thank again dear community. I'm exploring now the different design and will compare the wood weight vs enclosure efficiency.

To come back about the vibrations, I realized that if I'm starting sending signals from 40Hz with the crossover, I may not have them ? By experience From which frequency an enclosure stops to "shake" ? In any cases the driver will start working properly from 35Hz so not a big deal for me. I prefer clear and "not so deep" bass than a shaky sub.

To come back about the vibrations, I realized that if I'm starting sending signals from 40Hz with the crossover, I may not have them ? By experience From which frequency an enclosure stops to "shake" ? In any cases the driver will start working properly from 35Hz so not a big deal for me. I prefer clear and "not so deep" bass than a shaky sub.

Greatness ! Circlomanen, in a similar fashion, how could I quickly compare the 2 designs for the midbass MB12N351 drivers on a THAM12 vs ROAR12 ? I have WinISD and just got Hornresp if it can help.

I can't believe that in 2 days I almost find the perfect designs for my sound system. You guys are magical

I can't believe that in 2 days I almost find the perfect designs for my sound system. You guys are magical

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Ported Sub to Tapped Horn. Few questions before starting