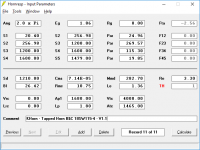

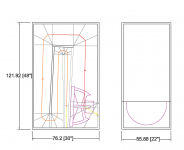

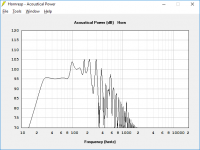

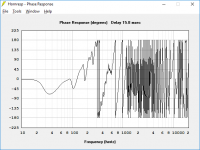

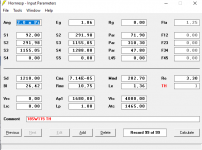

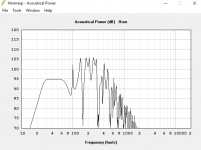

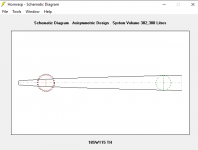

Here is a tapped horn I am designing for PA applications.

I wanted response down to 30Hz and the ability to fit it into my Kia, and looked at the Othorn and Keystone for inspiration (and reference since I am new to hornresp).

This is a preliminary design not accounting for volume from bracing, hardware, or driver. It also uses all 18mm wood, which may be overkill - maybe I should reduce the interior panels to 12mm?

I'm not sure if I measured L45 correctly, but otherwise I think my measurements are accurate. Please correct me if I am wrong!

Any advice, suggestions, or criticisms are welcome!

EDIT: B&C 18SW115-4 shown

I wanted response down to 30Hz and the ability to fit it into my Kia, and looked at the Othorn and Keystone for inspiration (and reference since I am new to hornresp).

This is a preliminary design not accounting for volume from bracing, hardware, or driver. It also uses all 18mm wood, which may be overkill - maybe I should reduce the interior panels to 12mm?

I'm not sure if I measured L45 correctly, but otherwise I think my measurements are accurate. Please correct me if I am wrong!

Any advice, suggestions, or criticisms are welcome!

EDIT: B&C 18SW115-4 shown

Attachments

Last edited:

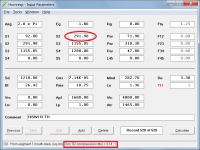

What GM is saying is to make S2 larger.

At a high compression ratio the cone "sees" a lot of pressure, and at high power levels the cone will need to be strong to be reliable. At this time you can choose to reduce the compression ratio (increase s2) and avoid well reduce at least - issues.

At a high compression ratio the cone "sees" a lot of pressure, and at high power levels the cone will need to be strong to be reliable. At this time you can choose to reduce the compression ratio (increase s2) and avoid well reduce at least - issues.

What GM is saying is to make S2 larger.

At a high compression ratio the cone "sees" a lot of pressure, and at high power levels the cone will need to be strong to be reliable. At this time you can choose to reduce the compression ratio (increase s2) and avoid well reduce at least - issues.

Thanks for explaining that. Sometimes saying fix this or that is not so helpful if you don't fully understand the problem. With what you said, what GM said now makes sense.

Last edited:

hardware, or driver. It also uses all 18mm wood, which may be overkill - maybe I should reduce the interior panels to 12mm?

When it comes to cabinets I don't think it is possible to overkill... Too heavy to lift, most definitely, overkill hmm don't think so.

Thanks for explaining that. Sometimes saying fix this or that is not so helpful if you don't fully understand the problem. With what you said, what GM said now makes sense.

I mistakenly thought my pointing out how I arrived at it was sufficient rather than just saying make it bigger.

GM

I mistakenly thought my pointing out how I arrived at it was sufficient rather than just saying make it bigger.

GM

I have noticed the more we know about something, the harder it can be to explain. We progress slowly to the point we know infinitely more than we knew coming into it, and when we explain it in a way we think is a dead simple and so easy a moron could understand it, it can still be way over the head of someone starting out.

The biggest trap is using acronyms and industry terms. We use them because we assume everyone knows what we mean, but often this is the point that can either make or break someones understanding. When I was at Microsoft we had TLAs (Three Letter Acronyms) for everything including acronyms.

In my hay day if you heard me talking in full on licensing speak with another licensing specialist, you would be flat out telling I was speaking English.

Then as we get really knowable we can fall into the trap of stating the problem, not the fix, like the answer is obvious.

Just took your car for a drive around the block and I could hear a metallic noise, it's about 8-10,000 Hz, it there for a duration of about four seconds, then it goes away, it starts off soft then increase in volume. (ok kind of informative, but at the same time completely useless information without some kind of context). While it's all useful information in diagnosing a problem, it's a lot of superfluous information for a beginner.

Just took your car for a drive around the block and I could hear a metallic noise coming from the right rear of the car, it's probably the brakes. You might want to look at how much material is left on the pads, as they may be worn to the point they are scraping on the disc and damaging the disc.

You may feel what you said was the second thing, but often it is the first one (we are all guilty of it).

googlyone telling us the "what" needs to be looked at is the key. From what little I understand of Hornresp I know S2 is an area, and by saying the area of something I can actually see on the screen (I am very visual), I had an aha moment, ok so increasing the area "there" is what is going to cause the reduction in pressure. That now makes sense.

The information given wasn't wrong, far from it, it just wasn't usable without that last clue.

It's kind of the what's broken, and here how you fix it...

Last edited:

That is why I would love to see Hornresp help changed to a graphical interface, with a proper search function. Just seeing that highlighted box can often make all the difference in the world. You can describe the box, tell me it's dimensions, tell me it's color, and it's texture, but until I can actual see it, I can't move on to knowing if Schrodinger's cat is alive or dead.

In retrospect this is what I was trying to say to David about the help. It was written in a way I just couldn't understand the meaning of. I know what the words mean, but it is structured in a similar way to here is the problem, or the technical specs... Now you go off and work out where to apply it.

In retrospect this is what I was trying to say to David about the help. It was written in a way I just couldn't understand the meaning of. I know what the words mean, but it is structured in a similar way to here is the problem, or the technical specs... Now you go off and work out where to apply it.

Last edited:

GM,...now that HR has become so complex even I sometimes can't use it without using its HELP Files, FIND feature, I'm thinking I should follow David's example and just point to it.

GM

HR (Human Resources) can be difficult ;^).

Been a long time since I've opened Hornresp, but I'd be surprised if "Compression Ratio" is mentioned as CR in it's Help files.

As a point of reference for KhrisKhad (and akvaro), S2 is around 485 in the Keystone (about a 2.5/1 compression ratio) and VTC (volume of throat chamber) is estimated to be 7800 (a larger volume than akvaro entered), also using the BC18SW115-4.

Hornresp assumes a flat cone (no VTC), while an 18" and the 18mm baffle cut out creates quite a bit of VTC, The large VTC somewhat reduces the actual compression ratio.

That said, even with a strong driver like the BC18SW115 I'd still agree 3/1 compression ratio is about as high as one should go if using the full Xmax/Xvar excursion if low distortion and long cone life are desired.

Art

Last edited:

Been a long time since I've opened Hornresp, but I'd be surprised if "Compression Ratio" is mentioned as CR in it's Help files.

It is not even mentioned as "compression ratio", let alone "CR"

The value can however be read from the main Input Parameters window by moving the mouse pointer over S2 (for a tapped horn).

Attachments

The value can however be read from the main Input Parameters window by moving the mouse pointer over S2 (for a tapped horn).

Or moving the mouse pointer over Sd, for that matter...

HR (Human Resources) can be difficult ;^).

Been a long time since I've opened Hornresp, but I'd be surprised if "Compression Ratio" is mentioned as CR in it's Help files.

Got that right, spent a goodly portion of my career as an engineering specialty project team manager, which included being the 'liaison' with the unionized manufacturing shop [ugh!], so 'double trouble'.

Worse, I couldn't find it searching for it using individual words or phrases, so wonder if it's there at all in any form.

GM

Or moving the mouse pointer over Sd, for that matter....

This I didn't know, though after checking various 'oddball' sims where S2 doesn't work, Sd does, so maybe add it to the HELP file and delete the S2 option?

GM

I always figured you had to calc CR...

FWIW, I calc the 3:1/S2 CR first to design with heavy duty drivers and go lower as Vas and/or Qt rises an/or the need for max efficiency [> 1:1] regardless of size.

GM

Last edited:

FWIW, I calc the 3:1/S2 CR first to design with heavy duty drivers and go lower as Vas and/or Qt rises an/or the need for max efficiency [> 1:1] regardless of size.

GM

So if you use a 3:1 for a best case scenario (heavy duty driver, low VAS etc), what do you use on low end for a worse case scenario?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 30Hz 18" Tapped Horn Design