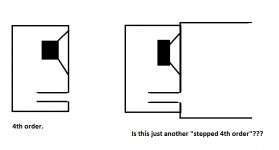

Because you add a third chamber. The large front resonator is a third tuned chamber.

View attachment 765377

How is the last section not a tuned extra chamber?

The last section LOOKS like a stepped positive expansion from S3 to S4.

If there was a port in/or after S4/S5, then the model looks like a true TH8 or TQWP8.

However, you are correct. You added a tuned 3rd chamber (which is also the port) to the TQWP that turns the enclosure into a TQWP8. My apologies!

View attachment 765389

Would you consider both to be 4th order enclosures?

View attachment 765390

View attachment 765391

A BR with a large front resonator should be called "stepped 4th order" if you call my ROAR or HROAR a "Stepped tapped horn" or "stepped 6th order".

No, but I see your point!

The large car audio HROAR10 was tested yesterday. With the two 1 ohm voice-coils in parallel and the 3500 watt amp pushed until the 200 Ampere fuse blew he got 143,88 dB @ 33 Hz. This after playing very very loud for several hours while demoing this HROAR10 for people. The magnet was so hot that it burnt your fingers if you touched it. I guess 150 dB is not far of with a cool driver and a larger amp. The driver never did more then +- 10 mm cone excursion even with his 3500 watt amp driven to clipping.

Attachments

The last section LOOKS like a stepped positive expansion from S3 to S4

I agree the lines get a bit blurred and fuzzy when designing quarter wave based high order boxes. I am more used to the more distinct ported chambers very well defined by the pronounced constriction of the ports between the chambers. I use the frequency response to determine the nature of a section. A large straight section like the frontresonator of a ROAR has a quarter wave resonance that is clearly seen in the spl graph as a peak at its fundamental. And if the steps are small and incremental in cross section area then lines get even more blurred and fuzzy.

The large car audio HROAR10 was tested yesterday. With the two 1 ohm voice-coils in parallel and the 3500 watt amp pushed until the 200 Ampere fuse blew he got 143,88 dB @ 33 Hz. This after playing very very loud for several hours while demoing this HROAR10 for people. The magnet was so hot that it burnt your fingers if you touched it. I guess 150 dB is not far of with a cool driver and a larger amp. The driver never did more then +- 10 mm cone excursion even with his 3500 watt amp driven to clipping.

Very impressive!

Attachments

View attachment 761287

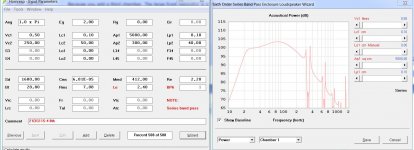

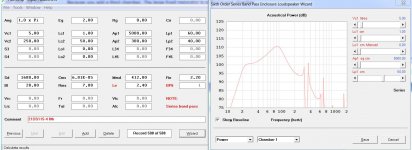

I have been playing around with this new series tuned 8th order BP function in Hornresp and I am impressed by the simulated response that is possible to get.

Here is a single B&C 15TBX100 in a 8th order BP. 26 - 152 Hz is almost 3 octaves of usable bandwidth!!!

Only 13 m/s port velocity at xmax for the driver. Much less from the large quarter wave front resonator.

How big would this enclosure be? i don't understand exactly how to calculate it.

right now, I have two THAM15 equipped with B&C 15TBX100. I was planning to build a ROAR15 to compare them. Now, this simulation looks very promising, especially because of the extended low end. but the corresponding enclosure surely would be a lot bigger than the roar15, isn't it?

For those living in Sweden/Norway:

The GAS Alpha 10D2 which Circlomannen recommends is now at sale at BRL

GAS ALPHA 10D2 | GAS | Billjud | Brl.se

Lets gets some HROAR out there in the wild!

The GAS Alpha 10D2 which Circlomannen recommends is now at sale at BRL

GAS ALPHA 10D2 | GAS | Billjud | Brl.se

Lets gets some HROAR out there in the wild!

Another HROAR build

Another car audio bass driver HROAR build. It is very suitable for home theater and Hifi use as well - if the rather tactile, physical and powerful reproduction of bass is not a problem for neighbors, family or pets.

GAS has a new series of bass drivers, and the 12 inch drivers seams to be suitable for the HROAR design. GPX 300D1 – GAS Car Audio

The Qts might be a little to high for my liking and I would prefer a little more Bl, but my hands on experience indicates that it is a very nice and powerful driver.

We have a few hours of work left before we can measure and test it.

Our first impressions from just pushing the lid/top as tight as we could with our hands and body weight and powering this beast from a 10 watt 6 Dollar Ebay amp - is most promising. The radiator below the living room widows was rattling quite loudly and the bass was felt all throughout our house.

Another car audio bass driver HROAR build. It is very suitable for home theater and Hifi use as well - if the rather tactile, physical and powerful reproduction of bass is not a problem for neighbors, family or pets.

GAS has a new series of bass drivers, and the 12 inch drivers seams to be suitable for the HROAR design. GPX 300D1 – GAS Car Audio

The Qts might be a little to high for my liking and I would prefer a little more Bl, but my hands on experience indicates that it is a very nice and powerful driver.

We have a few hours of work left before we can measure and test it.

Our first impressions from just pushing the lid/top as tight as we could with our hands and body weight and powering this beast from a 10 watt 6 Dollar Ebay amp - is most promising. The radiator below the living room widows was rattling quite loudly and the bass was felt all throughout our house.

The port is large enough to mount the driver through. It is large enough for my arm as well. It might not be fun to change the driver through the port, but I hope it is manageable even though it might be a bit awkward.

This box is meant to be as simple to build as reasonable possible, and I want to avoid removable panels in the pipe section as this increases the risk of leaks substantially.

This box is meant to be as simple to build as reasonable possible, and I want to avoid removable panels in the pipe section as this increases the risk of leaks substantially.

I suspect that those screws that are nearest to the side panel will be very difficult, if not impossible, to reach through the vent.

Having a removeable panel in a high compression area can result in some issues, yes. Leaks and higher losses due to panel flex. But these can be planned for, and are likely a more preferable option to having to break apart the box if the driver has to be checked or replaced.

Having a removeable panel in a high compression area can result in some issues, yes. Leaks and higher losses due to panel flex. But these can be planned for, and are likely a more preferable option to having to break apart the box if the driver has to be checked or replaced.

It is easy to access the driver through the port for service or driver replacement. The port is large enough to lift the driver through if needed.

I suspect that those screws that are nearest to the side panel will be very difficult, if not impossible

Not impossible, but somewhat awkward.

I hope we don´t need to service or replace the driver to often though... It is not very fun fighting with a heavy driver and hard to reach bolts way back in the dark corners of the front resonator of an HROAR.

But it is doable if we need to.

But it is doable if we need to.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- ROAR with Helmholtz front resonator