Greets!

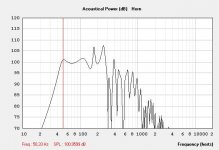

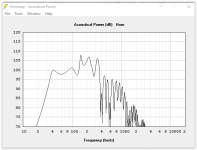

'Best'? Don't know, but here's a very simple ~153 L [net] one using published specs that if all [12] were tightly stacked with only 500 W ea. will in theory put out around 145 dB/m setting on the ground or massive stage:

GM

What i must do with the .txt file*

Hi USRFobiwan,

Post #7: "...40Hz is hard to get with the Tham design.

When you add the bottom segment as Forsman did you can get there:

http://www.diyaudio.com/forums/subwoofers/224160-thorn-f1-learning-experiance-tapped-horn.html

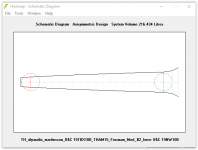

I drew one up W=23-7/8" D=23-7/8" H=31-7/8", and it looks fine w/ the B&C 15NW100. I can post the drawing if there is interest, it is larger than the original THAM15.

Regards,

Post #7: "...40Hz is hard to get with the Tham design.

When you add the bottom segment as Forsman did you can get there:

http://www.diyaudio.com/forums/subwoofers/224160-thorn-f1-learning-experiance-tapped-horn.html

I drew one up W=23-7/8" D=23-7/8" H=31-7/8", and it looks fine w/ the B&C 15NW100. I can post the drawing if there is interest, it is larger than the original THAM15.

Regards,

Attachments

Martinsson's Blog

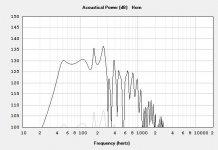

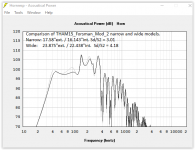

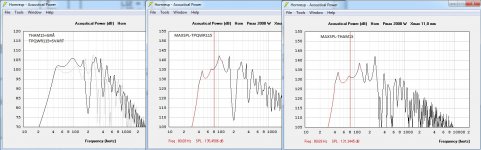

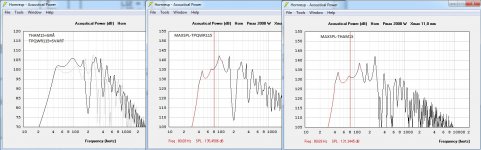

We are updating the THAM-series with the front-resonator enhanced tapped pipe design I have been exploring for some time now.

You get a very high efficiency and a great midbass-attack from this design.

Here is some comparison between the normal THAM15 and the TPQWR-115, both with the same B&C 15TBX100.

The B&C 15NW100 should work like a charm in this horn.

We are updating the THAM-series with the front-resonator enhanced tapped pipe design I have been exploring for some time now.

You get a very high efficiency and a great midbass-attack from this design.

Here is some comparison between the normal THAM15 and the TPQWR-115, both with the same B&C 15TBX100.

The B&C 15NW100 should work like a charm in this horn.

To cut or not to cut...

Hi martina,

Post #13: "...internal size of: 670mm High 800mm deep and 410mm wide...Is it possible, design a FLH or TH into this enclosure..."

That's a bit of a loaded question. What is the material of the existing boxes, and are you a master woodworm? Tapped horns w/ high throat compression require solid construction and air tightness of the horn path. Also, it's hard to give an opinion w/o seeing the enclosure details.

Tapped horns w/ high throat compression require solid construction and air tightness of the horn path. Also, it's hard to give an opinion w/o seeing the enclosure details.

You have never defined/posted the low corner for your project, assuming around a solid 40Hz you end up w/ a path length as in Posts #9 and #10. Luckily, two of your dimensions are already close to the side view, so you have to evaluate what happens when you narrow the enclosure while maintaining approximately the same horn fold. All areas (S1-S5 in Hornresp) become smaller, the path length gets to be a little longer, the compression ratio increases from 3 to 4. It should work, if the driver can handle the high compression ratio, something I do not know, and I cannot evaluate. Obviously, other folds can be made to fit, maybe better?

I'll attach an SPL comparison, and a quick sketch.

Regards,

Hi martina,

Post #13: "...internal size of: 670mm High 800mm deep and 410mm wide...Is it possible, design a FLH or TH into this enclosure..."

That's a bit of a loaded question. What is the material of the existing boxes, and are you a master woodworm?

You have never defined/posted the low corner for your project, assuming around a solid 40Hz you end up w/ a path length as in Posts #9 and #10. Luckily, two of your dimensions are already close to the side view, so you have to evaluate what happens when you narrow the enclosure while maintaining approximately the same horn fold. All areas (S1-S5 in Hornresp) become smaller, the path length gets to be a little longer, the compression ratio increases from 3 to 4. It should work, if the driver can handle the high compression ratio, something I do not know, and I cannot evaluate. Obviously, other folds can be made to fit, maybe better?

I'll attach an SPL comparison, and a quick sketch.

Regards,

Attachments

Last edited:

Martinsson's Blog

We are updating the THAM-series with the front-resonator enhanced tapped pipe design I have been exploring for some time now.

You get a very high efficiency and a great midbass-attack from this design.

View attachment 590436

Here is some comparison between the normal THAM15 and the TPQWR-115, both with the same B&C 15TBX100.

The B&C 15NW100 should work like a charm in this horn.

That is really interesting simulation. I know you guys where busy with the resonator concept. So can we call this THAMMB?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Tapped Horn for B&C 15NW100