i use cool edit.Thanks for running those scans. As we can see, 30Hz reproduction would be valuable in my case.

Also, I further see the value in high efficiency designs, even if a single cab doesn't grab the low end - your Xoc1.m sample above proves it's flat to 30Hz w/4 cabs

What program are you using to scan the files?

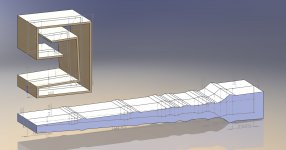

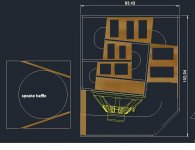

here is a good compromise.

ruff sketch stil need some work ~510 ltrs

if u later decide to ad a 3rd sub it wil go straigt to 30

Last edited:

no ,its just easy'er to use in csa stacks if they are symetrical.

Hi, I have a question regarding CSAs. Jbell often talks about the directivity of tapped horns, is it necessary to use THs in a CSA? Is their inherent directivity not enough? How many dB rear wave reduction can you expect with a CSA, compared to that of a TH?

In general, nice thread crescendo, always good to see designs capable of reproducing dubstep basslines.

I'm impressed by some of the CAD horn foldings in this thread. What are you guys using (Xoc1 in particular)?

I Jason

I use Dessault Systemes Solidworks - 3D parametric CAD

Attachments

u can use csa for bas steering and/or rear wave reductionHi, I have a question regarding CSAs. Jbell often talks about the directivity of tapped horns, is it necessary to use THs in a CSA? Is their inherent directivity not enough? How many dB rear wave reduction can you expect with a CSA, compared to that of a TH?

In general, nice thread crescendo, always good to see designs capable of reproducing dubstep basslines.

but usually only necessary in medium to large array's (> 6 cabs per side)

there are multyple ways to get there.

here are some intresting links.

bass guide.pdf (application/pdf-object)

Bass Here, Not There: Directional Low Frequency

TI330_1.2E.PDF (application/pdf-object)

i use autocad 2011I'm impressed by some of the CAD horn foldings in this thread. What are you guys using (Xoc1 in particular)?

Last edited:

im gona have surgery tomorow,if al go's wel ill be back in a few days.

justin check out post 21 ,i think its a good compromise.model it and see.

the lows

and this oneHi, I have a question regarding CSAs. Jbell often talks about the directivity of tapped horns, is it necessary to use THs in a CSA? Is their inherent directivity not enough? How many dB rear wave reduction can you expect with a CSA, compared to that of a TH?

In general, nice thread crescendo, always good to see designs capable of reproducing dubstep basslines.

wp - Subwoofer Arrays v04 .pdf (application/pdf-object)

Just a tiny reminder, that the models we use (hornresp and akabak) are only so accurate and reality often differs from the model... it could be lost time to argue about minimal differences between designs. Building a "beta" box and seeing how far reality correlates with the simulation should be more rewarding.

From experience (listening and looking at alot of spectral data), i can tell that a 30hz cutoff is great for dubstep. Nothing of interest in the 20s at all (some rare exceptions do exist, but in those cases the lowest note usually has at least a first harmonic, which makes its fundamental hard to hear anyway since our hearing is pretty bad that low) and even the low 30s are less important than the area between 40 and 50, spoken from a statistical perspective.

Of course, i dont want to spoil the fun. And besides, i love those folding schemes. It makes me want to build a sub

From experience (listening and looking at alot of spectral data), i can tell that a 30hz cutoff is great for dubstep. Nothing of interest in the 20s at all (some rare exceptions do exist, but in those cases the lowest note usually has at least a first harmonic, which makes its fundamental hard to hear anyway since our hearing is pretty bad that low) and even the low 30s are less important than the area between 40 and 50, spoken from a statistical perspective.

Of course, i dont want to spoil the fun. And besides, i love those folding schemes. It makes me want to build a sub

Last edited:

im gona have surgery tomorow,if al go's wel ill be back in a few days.

justin check out post 21 ,i think its a good compromise.model it and see.

I'm really liking that compromise!

Hope the surgery isn't anything tooo major. We all here wish you a safe surgery and a speedy recovery!!

Crescendo

I see that you would like a width of 24" external. I assume that you would be using 18mm (3/4") birch ply for a PA cabinet so this would give an internal width of 572mm (22.5 in). Also I see that the you have a preference for the 550 litre cabinet. Please note that in practical terms the real cabinet might have a lower response and efficiency due to the volume of the driver in the horn mouth, which is something that is probably not completely taken account of in the sims.

I,m not completely convinced about using an inductor to flatten the passband response. I think we will struggle to find an inductor that will be satisfactory at the sort of power levels your looking at.

BTW would you be using the QSC PLX RMX amplifiers in 4 ohm bridge for a pair of 8 ohm drivers? This gives 1700W per driver for the PLX3402 and 1200W per driver for the RMX2450.

I assuming that this is the way that you want to go forward with this and that you are probably looking at a pair of cabinets to start with.

I think we need to nail your requirements before setting out a final folding scheme. Once that is complete a physical prototype might be in order

I see that you would like a width of 24" external. I assume that you would be using 18mm (3/4") birch ply for a PA cabinet so this would give an internal width of 572mm (22.5 in). Also I see that the you have a preference for the 550 litre cabinet. Please note that in practical terms the real cabinet might have a lower response and efficiency due to the volume of the driver in the horn mouth, which is something that is probably not completely taken account of in the sims.

I,m not completely convinced about using an inductor to flatten the passband response. I think we will struggle to find an inductor that will be satisfactory at the sort of power levels your looking at.

BTW would you be using the QSC PLX RMX amplifiers in 4 ohm bridge for a pair of 8 ohm drivers? This gives 1700W per driver for the PLX3402 and 1200W per driver for the RMX2450.

I assuming that this is the way that you want to go forward with this and that you are probably looking at a pair of cabinets to start with.

I think we need to nail your requirements before setting out a final folding scheme. Once that is complete a physical prototype might be in order

he back again.as expected infection was spread severly and they had to remove my hearbones,meaning my hearing is not getting better(one side)

it wasn't good anway,but stil a dissapointment.

stil a lot of pain and groggyness.but i wil be ok again.

i agree wth xco1 bilding a test moddel.

looking at the ss15 th of jbel id say use 15 mm birch ply for the actual moddel,just use bracing in the mout bit and the flappy ends.

u can always put a coil in series later if u want but you must use an aircoil(no ferrit coil)1.2 mm minnimum.

time for sawdust

it wasn't good anway,but stil a dissapointment.

stil a lot of pain and groggyness.but i wil be ok again.

i agree wth xco1 bilding a test moddel.

looking at the ss15 th of jbel id say use 15 mm birch ply for the actual moddel,just use bracing in the mout bit and the flappy ends.

u can always put a coil in series later if u want but you must use an aircoil(no ferrit coil)1.2 mm minnimum.

time for sawdust

"I see that you would like a width of 24" external"

24" width external or less (two cabs side by side equaling 48") or 48" tall external or less (loading the cabs sideways in the truck) are just optimal dimensions as they will be less hassle to take in an SUV.

"I assume that you would be using 18mm (3/4") birch ply for a PA cabinet"

Xoc1, what do you think about using 15mm birch w/bracing?

"Please note that in practical terms the real cabinet might have a lower response and efficiency due to the volume of the driver in the horn mouth, which is something that is probably not completely taken account of in the sims."

What would you recommend - or is this just a heads-up?

"BTW would you be using the QSC PLX RMX amplifiers in 4 ohm bridge for a pair of 8 ohm drivers?"

I will be using whatever amp is suitable for the cabs; but, yes - the plan was to wire the cabs parallel and run the amp(s) 4 ohm bridged.

"I think we need to nail your requirements before setting out a final folding scheme."

Let me know if there's any more info you need

"he back again"

Glad to have you back - safely. Too bad to find out they had to be removed. Hope the pain reduces quickly.

"i agree wth xco1 bilding a test moddel."

I'm all for building a test model. Would I be building the enclosure like normal (with poly adhesive), just minus the braces?

"looking at the ss15 th of jbel"

What ss15??

"u can always put a coil in series later if u want but you must use an aircoil(no ferrit coil)1.2 mm minnimum."

I'll start the coil research

24" width external or less (two cabs side by side equaling 48") or 48" tall external or less (loading the cabs sideways in the truck) are just optimal dimensions as they will be less hassle to take in an SUV.

"I assume that you would be using 18mm (3/4") birch ply for a PA cabinet"

Xoc1, what do you think about using 15mm birch w/bracing?

"Please note that in practical terms the real cabinet might have a lower response and efficiency due to the volume of the driver in the horn mouth, which is something that is probably not completely taken account of in the sims."

What would you recommend - or is this just a heads-up?

"BTW would you be using the QSC PLX RMX amplifiers in 4 ohm bridge for a pair of 8 ohm drivers?"

I will be using whatever amp is suitable for the cabs; but, yes - the plan was to wire the cabs parallel and run the amp(s) 4 ohm bridged.

"I think we need to nail your requirements before setting out a final folding scheme."

Let me know if there's any more info you need

"he back again"

Glad to have you back - safely. Too bad to find out they had to be removed. Hope the pain reduces quickly.

"i agree wth xco1 bilding a test moddel."

I'm all for building a test model. Would I be building the enclosure like normal (with poly adhesive), just minus the braces?

"looking at the ss15 th of jbel"

What ss15??

"u can always put a coil in series later if u want but you must use an aircoil(no ferrit coil)1.2 mm minnimum."

I'll start the coil research

Last edited:

JBells Large TH used 18mm (3/4") Ply.

As was Wood1y,s RCF 15" TH....

Dare I say that a Danley TH118 is 18mm Birch Ply

I think that ScreamerUSA Furybox is also 18mm (But failed to find a specific reference)

As this project is about reaching 30Hz and high power levels, I would say that 18mm might be prudent. 15mm might be possible dependent on your cabinetry skills, and how much time you are prepared to dedicate to bracing the cabinet without causing any adverse effects.

I know of a double 15" FLH design that works well in 15mm birch ply, but it is far more complicated than this TH, and the double horn construction avoids having an unbraced side to the horn mouth.

epa

wishing you a speedy recovery from your operation.

My partner had a similar procedure on one of her ears a couple of years ago, and despite the hearing loss still appreciates good music, and the differences when I improve our home soundsystem using the fantastic amount of knowlege available here on Diyaudio

As was Wood1y,s RCF 15" TH....

Dare I say that a Danley TH118 is 18mm Birch Ply

I think that ScreamerUSA Furybox is also 18mm (But failed to find a specific reference)

As this project is about reaching 30Hz and high power levels, I would say that 18mm might be prudent. 15mm might be possible dependent on your cabinetry skills, and how much time you are prepared to dedicate to bracing the cabinet without causing any adverse effects.

I know of a double 15" FLH design that works well in 15mm birch ply, but it is far more complicated than this TH, and the double horn construction avoids having an unbraced side to the horn mouth.

epa

wishing you a speedy recovery from your operation.

My partner had a similar procedure on one of her ears a couple of years ago, and despite the hearing loss still appreciates good music, and the differences when I improve our home soundsystem using the fantastic amount of knowlege available here on Diyaudio

fast healing epa.

The ss15 isn't a 30hz box, it's a 45hz box. It is loud and a great PA performer, and makes 40hz with authority in pairs. A few mods could get it to about 35hz, but I think solid 28hz, and 32hz d&b notes are non starters for this design. With a grill, the ss15 really doesn't need any additional bracing, even though it is built with 1/2" ply. My personal rule of thumb is that any panel over 12" -- needs some kind of bracing. In the ss15, that only applies to the top, back, and bottom panels. My limited bracing accomplishes everything needed except for the mouth.

The 'compromise' plan from earlier in this thread looks good. Basically an extra fold for the stadiumhorn. I find that the TH's I build play just a bit lower than I expect, so the compromise design that doesn't quite get to the desired low end cut -- is usually right on target.

The ss15 isn't a 30hz box, it's a 45hz box. It is loud and a great PA performer, and makes 40hz with authority in pairs. A few mods could get it to about 35hz, but I think solid 28hz, and 32hz d&b notes are non starters for this design. With a grill, the ss15 really doesn't need any additional bracing, even though it is built with 1/2" ply. My personal rule of thumb is that any panel over 12" -- needs some kind of bracing. In the ss15, that only applies to the top, back, and bottom panels. My limited bracing accomplishes everything needed except for the mouth.

The 'compromise' plan from earlier in this thread looks good. Basically an extra fold for the stadiumhorn. I find that the TH's I build play just a bit lower than I expect, so the compromise design that doesn't quite get to the desired low end cut -- is usually right on target.

thnx all

i have no ideer what 2 expect from a hearing aid,but if your partner hears improvements,thats a bit comforting i gues tnx.

for thicknes one could use 15mm and use more bracing,or use 18 mm with less bracing.i think its up to the constructor.

i think jbells argument of max 12"spacing makes sence .

in our "compromise" moddel that means top, back and bottem

its up to justin now to choose a design and thicknes,knowing that the actual design wil be a few hz lower and less efficient then predicted in hr.

i have no ideer what 2 expect from a hearing aid,but if your partner hears improvements,thats a bit comforting i gues tnx.

for thicknes one could use 15mm and use more bracing,or use 18 mm with less bracing.i think its up to the constructor.

i think jbells argument of max 12"spacing makes sence .

in our "compromise" moddel that means top, back and bottem

its up to justin now to choose a design and thicknes,knowing that the actual design wil be a few hz lower and less efficient then predicted in hr.

hollow out your bracing. (big holes) Solid bracing reduces low end output (in cabinets I've built) I don't think your 'bottom' brace will accomplish much, better to grill or put a couple of vertical braces and a horizontal brace right at the mouth opening

Attachments

Last edited:

donehollow out your bracing. (big holes) Solid bracing reduces low end output (in cabinets I've built) I don't think your 'bottom' brace will accomplish much, better to grill or put a couple of vertical braces and a horizontal brace right at the mouth opening

a strong gril like your ss15 is a good ideer

Last edited:

- Home

- Loudspeakers

- Subwoofers

- C/E/X PA Flat to 30 (FT30) PA TH Awesomeness