Has or would anyone run this design in HornResp with a Lab12C? Specs here: https://www.parts-express.com/pedocs/specs/290-668-eminence-speaker-lab-12c-specifications.pdf I built a pair of $325 Lab 12 based PA tapped horn. ~35hz extension, but they are way too big, don't pack well, and look horrible at weddings and 'upscale' events. This design is much more visually appealing and hides well, and would pack much better.

Has or would anyone run this design in HornResp with a Lab12C? Specs here: https://www.parts-express.com/pedocs/specs/290-668-eminence-speaker-lab-12c-specifications.pdf I built a pair of $325 Lab 12 based PA tapped horn. ~35hz extension, but they are way too big, don't pack well, and look horrible at weddings and 'upscale' events. This design is much more visually appealing and hides well, and would pack much better.

I don't think that the SS15 is a good match for the Lab 12 driver. Resonance frequency is too high.

It should be possible to do a simple TH design for the Lab12 that's a lot smaller, but it will be lower in efficiency as well. I suggest opening a new thread and asking for assistance in that regard.

I'm curious as to how those Kappalites hold up as well. I'm looking very closely at the 12" version for another project that I may start this summer.

The Kappalite 15's held up fine through 3 years of high power rock shows with name acts in 6 fury subs. Mine are still floating around colorado as 3 pairs in use by dj's. I think that as long as you use a compression plate and pay attention, they are quite robust. Only failure I has was ONE lead popped off the spadelug and I simply resoldered it and kept running it for 2 years+.

They do fade a slight bit as the heat builds but not enough that average people notice. I did use a 24db 35hz cut.

Compression drivers use phase plugs, but this is bass where wave length is large compared to the driver and horn dimensions, plus the path is out to the left, very asymmetrical. Something might improve things, but I doubt optimal would be a reflection of the cone shape.

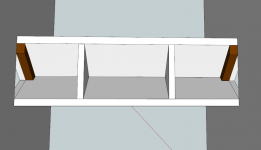

Hi all, I am looking the best version of the SS15. The one without the single sheet limitation.

Is there a version that performs better than this one:

Is there a version that performs better than this one:

An externally hosted image should be here but it was not working when we last tested it.

Compression drivers use phase plugs, but this is bass where wave length is large compared to the driver and horn dimensions, plus the path is out to the left, very asymmetrical. Something might improve things, but I doubt optimal would be a reflection of the cone shape.

The cone correction is added to compensate the cone volume and make build more accurate with the simulation.

To check the effect you just need to run the hornresp simulation with and without Vtc and make your conclusions.

It slightly improve upper limit frequencies and reduce cone displacement once it correct the compression ratio.

Hi all, I am looking the best version of the SS15. The one without the single sheet limitation.

The one you are looking for needs to be designed for your targets and for a while it doesn't exist, people may help you if you ask.

Perhaps I'm blind, but I've been up and down this thread without finding it. Does anyone have a link to the most up to date hornresp input for this box?

Left is the model I have and I think it's the must updated one.

Right is the custom version I build for my needs and to match the driver I was planning to use.

Where are most people placing handles on these cabs? Would using parts express' pocket handle underneath the 8" panel cause any problems? They are pretty deep handles and it seems like they'd cause a disturbance being so far into the path.

Parts Express Plastic Pocket Speaker Cabinet Handle 4-Sided

Thanks!

Parts Express Plastic Pocket Speaker Cabinet Handle 4-Sided

Thanks!

Hey Klampy, what's your long term opinion on the JB1500s? Having now owned them for a few years in these boxes are they holding up well?

In this box, do you think they'd make a good general purpose PA bass bin in place of say double 15 or 18" boxes?

Any failed drivers/surrounds etc and how hard to you push them?

Cheers for any input

sorry for the super delayed response.

i love these subs. as far as in place of a double 18... it would depend on location, (indoor/outdoor) as these dont go super dooper low ~40hz but they go to 40 with proper grunt.

i came in looking for the Hornresp data as im getting ready to build two more for a total of 8. so yes i love them enough to build more after these years of owning them.

the FS Audio drivers i use are NLA which is massively disappointing. so now im chasing a driver that matches the JB1500 ive been using closely enough that i can use them together.

going to be costly to replace the 6 i have now if i have to.

NOT HAPPY JAN....

15mm birch ply is strong.

The weak links are the joints.

Design your joints to be robust and airtight.

15mm has half the stiffness of 18mm (stiffness varies with the fourth power of thickness ratio - or is it the third power?).

Thus you need to design in sufficient bracing to reduce flexure.

Pocket hole jig if you inventive. Every 35 mm or so in the high pressure areas and every 60 to 75 mm in other areas.

Makes for a lot of drilling and screwing of the cabinet. But a strong cabinet you will achieve without to much fancy joinery.

The best trick to understand is to back off the position of the pocket until it is at leas 30mm away from the edge of your panel so that there is a good amount of plies to bear the holding pressure of your screws.

Another tip is to get particle board screws, or deep root screws. These have an aggressive thread profile, as in much fewer threads per linear length than normal wood screws such as a standard sheet metal screw or drywall screw. Again talking screw type if you can all of the above with a partially thread free shank you are in the best shape as this will allow proper tightening of the boards together without thread binding in the piece where the screw is started.

Hope this is clearer than mud!

handle

that might be a little harder to carry the sub since its not straight,

I placed mine "unusual handles" in the cab side, taking advantage of the space lost in the folding.

that might be a little harder to carry the sub since its not straight,

Yes, just not very well without you ;^).This thread is still going?

Good to see you are still alive!

Art

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge